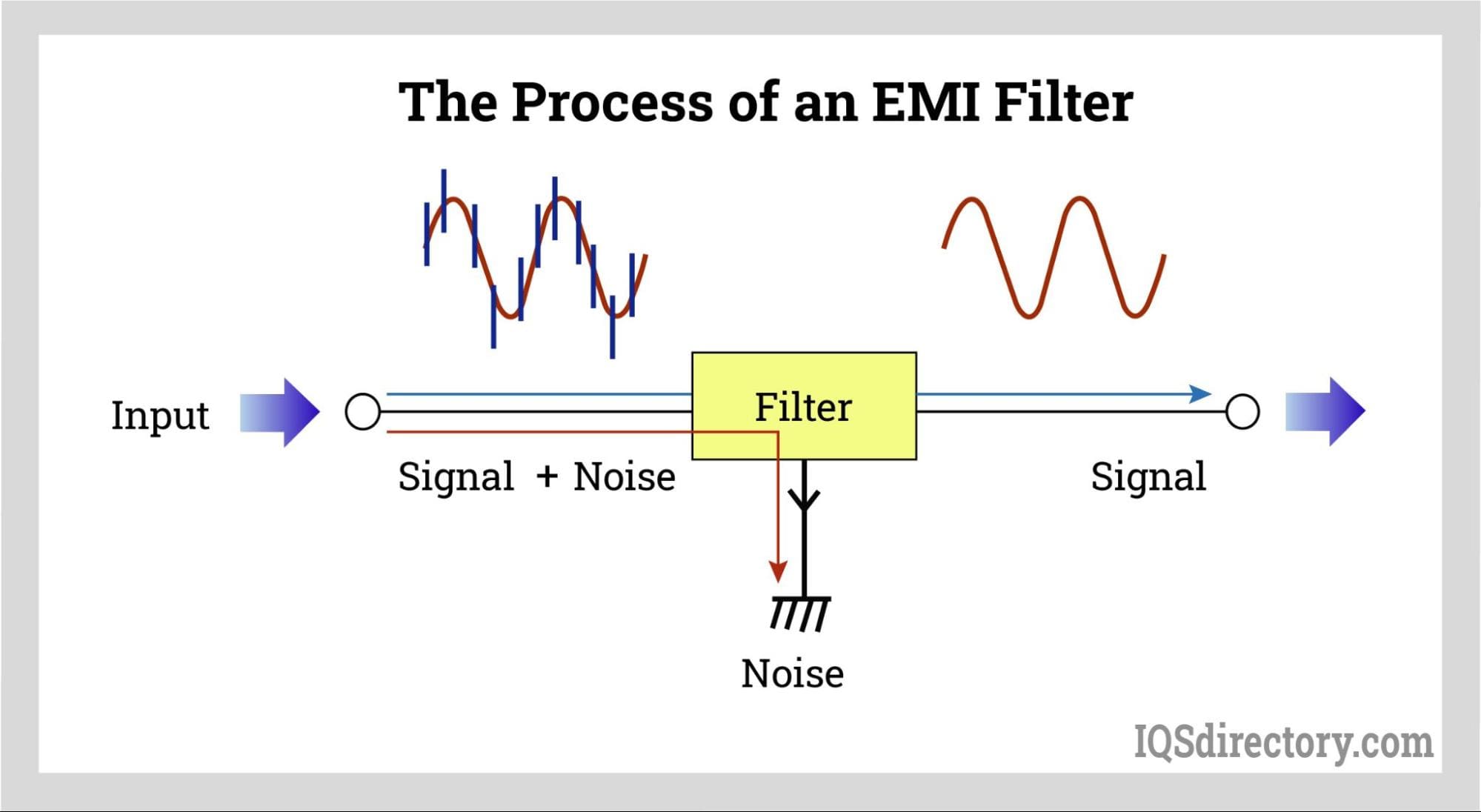

The global demand for radio frequency interference (RFI) filters is on a steady rise, driven by increasing electromagnetic pollution from consumer electronics, industrial equipment, and telecommunications infrastructure. According to a 2023 report by Mordor Intelligence, the global EMI/RFI filter market is projected to grow at a CAGR of over 6.5% from 2023 to 2028, reaching an estimated valuation of USD 3.8 billion by the end of the forecast period. This growth is fueled by the proliferation of 5G networks, expansion in aerospace and defense applications, and stricter regulatory standards for electromagnetic compatibility (EMC) across regions. As electronic systems become more compact and interconnected, the need for high-performance RFI filtering solutions has become critical to ensure signal integrity and device reliability. In this competitive and rapidly evolving landscape, a select group of manufacturers have emerged as leaders, combining innovation, precision engineering, and global reach to address the rising challenges of electromagnetic interference. The following list highlights the top nine RFI filter manufacturers shaping the industry’s future.

Top 9 Radio Frequency Interference Filter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Microwave Filter Company

Domain Est. 1997 | Founded: 1967

Website: microwavefilter.com

Key Highlights: Microwave Filter Company, Inc. (MFC) is a leader in the design, development and manufacture of high quality filter products since 1967….

#2 Corcom EMI & RFI Filters

Domain Est. 1992

Website: te.com

Key Highlights: TE offers a catalog of over 70 Corcom filter series that provide solutions to your EMI or RFI signal issues….

#3 EMC & EMI Filters

Domain Est. 1993

Website: ctscorp.com

Key Highlights: CTS is the leader in EMI/RFI filters and offers a diverse product line of standard as well as custom filters to suppress electromagnetic interference (EMI)…

#4 EMI Protection

Domain Est. 1996 | Founded: 1968

Website: spectrumcontrol.com

Key Highlights: Spectrum Control has been delivering reliable filter products to mitigate EMI and radio frequency interference (RFI) since 1968 in the most challenging…

#5 EMI Filters

Domain Est. 1998

Website: curtisind.com

Key Highlights: We offer standard and custom line filters. Our team of engineers can design and manufacture any style of EMI filter or RFI filter to your specifications….

#6 EMI Filter Fabrication Project

Domain Est. 1998

Website: captorcorp.com

Key Highlights: Captor Corp. provides full in-house EMI/RFI filter design, engineering, manufacturing, and testing capabilities. We can manufacture single and multi-circuit EMI ……

#7 Custom EMI Filters

Domain Est. 1998

Website: electrocube.com

Key Highlights: Electrocube designs, manufactures custom EMI & RFI Filters. Find out what they are, how they work and what Electrocube custom EMI Filters can offer….

#8 EMI Filter Solutions

Domain Est. 2015

Website: astrodynetdi.com

Key Highlights: Explore Astrodyne TDI’s 60+ years of expertise in EMI/EMC filters for various applications. Contact us for top-quality solutions for your needs….

#9 EMI Filters

Domain Est. 2019

Website: premieremc.com

Key Highlights: We offer an extensive line of standard EMI Power Line Filters for all AC and DC applications, including military, tempest and facility/SCIF….

Expert Sourcing Insights for Radio Frequency Interference Filter

H2: 2026 Market Trends for Radio Frequency Interference (RFI) Filters

The global market for Radio Frequency Interference (RFI) filters is expected to experience substantial growth and transformation by 2026, driven by increasing electromagnetic pollution, rising demand for electronic device reliability, and the rapid expansion of connected technologies. Key trends shaping the RFI filter market in 2026 include:

-

Proliferation of 5G and IoT Networks

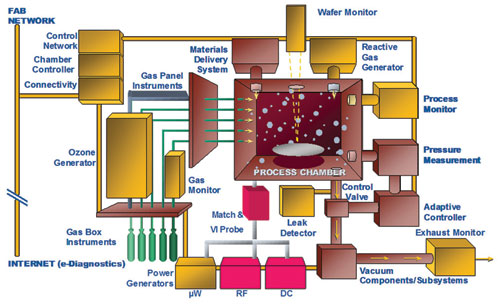

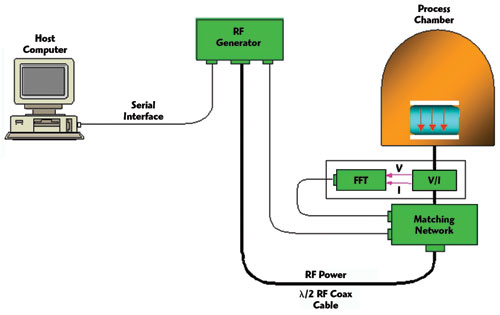

The widespread rollout of 5G infrastructure and the exponential growth of Internet of Things (IoT) devices are major catalysts for RFI filter demand. With higher-frequency bands and denser network architectures, 5G systems are more susceptible to interference. RFI filters are critical in ensuring signal integrity and minimizing noise in base stations, small cells, and user equipment. Similarly, in IoT ecosystems—spanning smart homes, industrial automation, and healthcare—compact and efficient RFI filters are essential to prevent cross-device interference. -

Stringent Electromagnetic Compatibility (EMC) Regulations

Governments and regulatory bodies worldwide are tightening EMC standards to reduce electromagnetic interference in consumer electronics, automotive systems, and medical devices. By 2026, compliance with standards such as IEC, FCC, and CISPR will drive manufacturers to integrate advanced RFI filtering solutions early in product design, boosting market demand. -

Growth in Electric Vehicles (EVs) and Automotive Electronics

The automotive sector is a key growth area for RFI filters. Electric and hybrid vehicles generate significant electromagnetic noise from high-power inverters, motors, and charging systems. As EV adoption accelerates, so does the need for robust RFI suppression to protect sensitive onboard electronics and ensure safety and performance. By 2026, automotive-grade RFI filters are expected to dominate segment growth. -

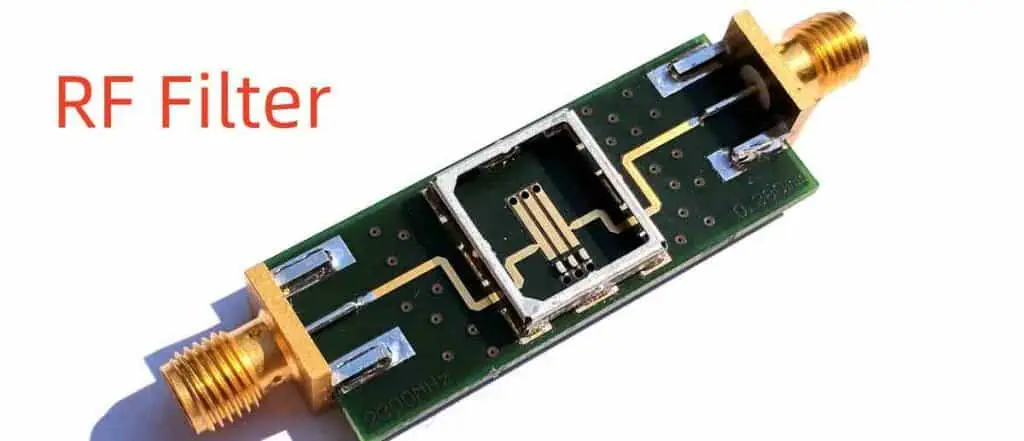

Miniaturization and Integration in Consumer Electronics

With the trend toward smaller, thinner, and more powerful devices—such as smartphones, wearables, and AR/VR headsets—there is increasing demand for miniature, high-performance RFI filters. Manufacturers are focusing on developing compact, surface-mount, and multilayer ceramic filters that offer high attenuation in limited board space without compromising efficiency. -

Advancements in Filter Materials and Design

Innovations in materials such as ferrites, piezoelectric ceramics, and metamaterials are enabling more efficient and broadband RFI filtering. By 2026, smart filters with tunable frequencies and adaptive filtering capabilities—leveraging AI and real-time monitoring—are expected to enter high-end applications in aerospace, defense, and telecommunications. -

Expansion in Industrial and Renewable Energy Applications

Industrial automation and renewable energy systems (e.g., solar inverters, wind turbines) generate high levels of electrical noise. RFI filters are critical for protecting control systems and ensuring grid compliance. As global investments in smart grids and green energy grow, demand for industrial-grade RFI filters will rise steadily through 2026. -

Regional Market Shifts

Asia-Pacific, particularly China, Japan, and South Korea, will remain the largest market for RFI filters due to concentrated electronics manufacturing and aggressive 5G deployment. However, North America and Europe are expected to see strong growth due to advancements in automotive electronics, defense systems, and regulatory compliance requirements.

In conclusion, the RFI filter market in 2026 will be shaped by technological innovation, regulatory pressures, and the expanding footprint of wireless and high-power electronic systems. Companies that invest in compact, high-efficiency, and application-specific filtering solutions will be well-positioned to capitalize on these emerging opportunities.

Common Pitfalls Sourcing Radio Frequency Interference Filters (Quality, IP)

When sourcing Radio Frequency Interference (RFI) filters—critical components for ensuring electromagnetic compatibility (EMC) and system reliability—organizations often encounter challenges related to both quality and intellectual property (IP). Overlooking these aspects can lead to product failures, compliance issues, and legal risks. Below are common pitfalls to avoid:

Inadequate Quality Assurance Processes

Many suppliers, particularly lower-cost or non-specialized manufacturers, lack rigorous quality control procedures. This can result in inconsistent filter performance, including variations in insertion loss, impedance matching, and current handling. Without proper testing and traceability (e.g., lot-by-lot testing, ISO-certified facilities), buyers risk receiving substandard components that fail under real-world conditions or during EMC certification testing.

Misrepresentation of Performance Specifications

Some suppliers exaggerate filter performance data, such as insertion loss curves or rated current, based on ideal lab conditions rather than real-world operating environments. Buyers may unknowingly select filters that do not meet required attenuation levels across the target frequency range, leading to system-level EMI problems. Always verify specifications with independent test reports or third-party validation.

Use of Substandard Materials and Components

To reduce costs, certain manufacturers may use inferior core materials, capacitors, or inductors that degrade over time or under thermal stress. These materials can lead to premature filter failure, reduced filtering effectiveness, or even safety hazards (e.g., fire risks due to capacitor breakdown). Ensuring material specifications and sourcing transparency is essential for long-term reliability.

Lack of Compliance with International Standards

RFI filters must comply with standards such as IEC/EN 60939, CISPR, or military specifications (e.g., MIL-STD), depending on the application. Sourcing from suppliers who cannot provide certification or test reports to these standards increases the risk of non-compliance, regulatory rejection, or costly redesigns late in the product development cycle.

Infringement of Intellectual Property (IP)

Some manufacturers produce RFI filters that closely mimic patented designs from established brands without proper licensing. Using such components exposes the buyer to IP litigation, supply chain disruption, and reputational damage. Due diligence is required to confirm that the supplier holds appropriate IP rights or licenses, especially when sourcing from regions with weaker IP enforcement.

Insufficient Technical Support and Documentation

Low-cost suppliers often provide incomplete or inaccurate technical documentation, such as unclear schematics, missing de-rating curves, or inadequate installation guidelines. This lack of support can hinder proper integration into the system, leading to improper grounding, incorrect mounting, or performance shortfalls.

Counterfeit or Grey Market Components

The demand for high-performance RFI filters has led to an increase in counterfeit parts entering the supply chain. These components may appear authentic but fail to meet electrical or safety requirements. Purchasing through unauthorized distributors or brokers significantly increases the risk of receiving counterfeit goods.

Overlooking Long-Term Supply Chain Reliability

Some suppliers may offer competitive pricing initially but lack the capacity or commitment for long-term production. This can disrupt manufacturing if the filter becomes obsolete or the supplier discontinues the product line without notice, especially in industries with long product lifecycles like aerospace or industrial automation.

Avoiding these pitfalls requires thorough supplier qualification, technical audits, specification validation, and legal review of IP rights. Investing time upfront in due diligence ensures reliable performance, regulatory compliance, and protection against costly failures or legal exposure.

Logistics & Compliance Guide for Radio Frequency Interference (RFI) Filters

Overview

Radio Frequency Interference (RFI) filters are electromagnetic compatibility (EMC) components designed to suppress unwanted high-frequency noise in electrical systems. Due to their function in ensuring device compliance and safety, the logistics and regulatory handling of RFI filters require careful attention during import, export, storage, and installation.

Regulatory Compliance

RFI filters must meet international and regional electromagnetic compatibility standards to ensure they do not emit or are not susceptible to disruptive interference. Key compliance requirements include:

- CE Marking (Europe): RFI filters used in EU markets must comply with the EMC Directive (2014/30/EU) and Low Voltage Directive (2014/35/EU), where applicable. Manufacturers must perform conformity assessments and maintain technical documentation.

- FCC Part 15 (USA): For devices incorporating RFI filters, compliance with FCC regulations is mandatory. While the filter itself may not require individual certification, it must support the end-product’s compliance with conducted and radiated emission limits.

- IEC/EN 60939 Series: This international standard covers passive filter units for electromagnetic interference suppression, including safety, performance, and test requirements.

- RoHS & REACH (EU): RFI filters must comply with restrictions on hazardous substances (RoHS) and chemical registration (REACH).

- UL/CSA (North America): Filters used in safety-critical applications may require recognition under UL 1283 (EMI Filters) or CSA C22.2 No. 8.

Ensure all RFI filters are supplied with valid compliance documentation, including Declarations of Conformity (DoC), test reports, and safety certifications.

Import and Export Considerations

- Harmonized System (HS) Code: RFI filters are typically classified under HS Code 8504.90 (Electrical transformers, inductors, and similar; parts). Confirm local tariff classifications to avoid customs delays.

- Export Controls: While most RFI filters are not controlled under dual-use regulations (e.g., EU Dual-Use Regulation or U.S. EAR), filters designed for military, aerospace, or telecommunications infrastructure may require export licenses. Verify ECCN/USML classification when applicable.

- Documentation: Include commercial invoices, packing lists, and certificates of origin. For regulated markets, provide product compliance statements and test summaries.

Packaging and Handling

- ESD Protection: RFI filters with sensitive internal components (e.g., capacitors) should be stored and shipped in static-dissipative packaging to prevent electrostatic discharge damage.

- Moisture Sensitivity: If filters contain moisture-sensitive elements, use sealed, dry packaging with desiccants and moisture indicator cards. Follow IPC/JEDEC standards for handling.

- Mechanical Protection: Use cushioning and rigid outer packaging to prevent physical damage during transit, especially for filters with solder terminals or mounting hardware.

Storage Conditions

- Environment: Store in a dry, climate-controlled environment with temperatures between 5°C and 40°C and relative humidity below 65%. Avoid condensation.

- Shelf Life: Most RFI filters have an indefinite shelf life if stored properly. However, verify capacitor longevity (especially Y-capacitors), which may degrade over long periods.

- Labeling: Clearly label packages with part number, date of receipt, compliance marks, and storage conditions.

Transportation

- Use carriers experienced in handling electronic components.

- Avoid extreme temperature exposure during transit (e.g., non-climate-controlled trucks or container holds).

- For air freight, ensure packaging meets IATA standards if transporting in bulk.

Installation and End-Use Compliance

- Ensure proper grounding and short lead lengths during installation to maintain filter effectiveness.

- Verify that the final product undergoes full EMC testing (conducted/radiated emissions and immunity) per relevant standards (e.g., IEC 61000-6 series).

- Maintain traceability of RFI filter batches for quality and recall purposes.

Summary

Proper logistics and compliance management of RFI filters ensures regulatory adherence, product reliability, and supply chain efficiency. Always verify certification status, use appropriate handling procedures, and maintain complete documentation throughout the product lifecycle.

Conclusion:

In conclusion, sourcing a radio frequency interference (RFI) filter requires a comprehensive evaluation of several key factors to ensure optimal performance and compatibility within the intended application. It is essential to define the specific electrical requirements—such as voltage, current, frequency range, and noise suppression needs—while also considering the environmental conditions and regulatory compliance standards (e.g., FCC, CE, MIL-STD). The selection process should balance factors including insertion loss, attenuation characteristics, physical size, and mounting configuration to match the system design.

Sourcing from reputable suppliers with a proven track record in electromagnetic compatibility (EMC) solutions ensures reliability and quality. Additionally, evaluating technical support, lead times, and cost-effectiveness contributes to a successful procurement strategy. By carefully aligning filter specifications with system requirements and operational demands, the correct RFI filter can effectively mitigate unwanted noise, enhance signal integrity, and ensure regulatory compliance, ultimately contributing to the overall performance and reliability of electronic systems.