The global radiant barrier market is experiencing robust growth, driven by increasing demand for energy-efficient building solutions and rising awareness of sustainable construction practices. According to a 2023 report by Mordor Intelligence, the market is projected to grow at a CAGR of 5.8% from 2023 to 2028, fueled by stringent energy conservation regulations and the expansion of residential and commercial infrastructure in emerging economies. Similarly, Grand View Research valued the global reflective insulation market — a key segment encompassing radiant barriers — at USD 3.2 billion in 2022, with expectations for continued expansion due to advancements in material technology and growing adoption in HVAC and roofing applications. As energy costs rise and green building standards become more prevalent, radiant barriers have emerged as a critical component in reducing heat transfer and improving thermal performance. This growing momentum has elevated the prominence of leading manufacturers who combine innovation, scalability, and compliance with international energy codes. The following list highlights the top six radiant barrier manufacturers shaping the industry through product excellence, R&D investment, and global market reach.

Top 6 Radient Barrier Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 FI-FOIL® Reflective Insulation Manufacturer

Domain Est. 1998

Website: fifoil.com

Key Highlights: FI-FOIL® premium multi-layer attic radiant barrier is the highest performing product available in the market, reducing temperatures in the attic by up to 30°….

#2 Radiant Barrier USA

Domain Est. 2021

Website: radiantbarrierusa.com

Key Highlights: Radiant Barrier USA insulation provides an easy and efficient way to save energy and money while creating a consistent, safer living and work environment….

#3 Innovative Insulations

Domain Est. 1997

Website: radiantbarrier.com

Key Highlights: Our radiant barriers are crafted from high-performance reflective material, primarily aluminum foil, designed to maximize energy efficiency by reflecting up to ……

#4 Radiant Barriers

Domain Est. 1999

Website: energy.gov

Key Highlights: Radiant barriers are installed in homes — usually in attics — primarily to reduce summer heat gain and reduce cooling costs….

#5 rFOIL Reflective Insulation and Radiant Barriers

Domain Est. 2000

Website: rfoil.com

Key Highlights: Quality reflective insulation and radiant barrier products and quick order fulfillment. Worldwide. Safe, Clean, Easy, and Effective to Use….

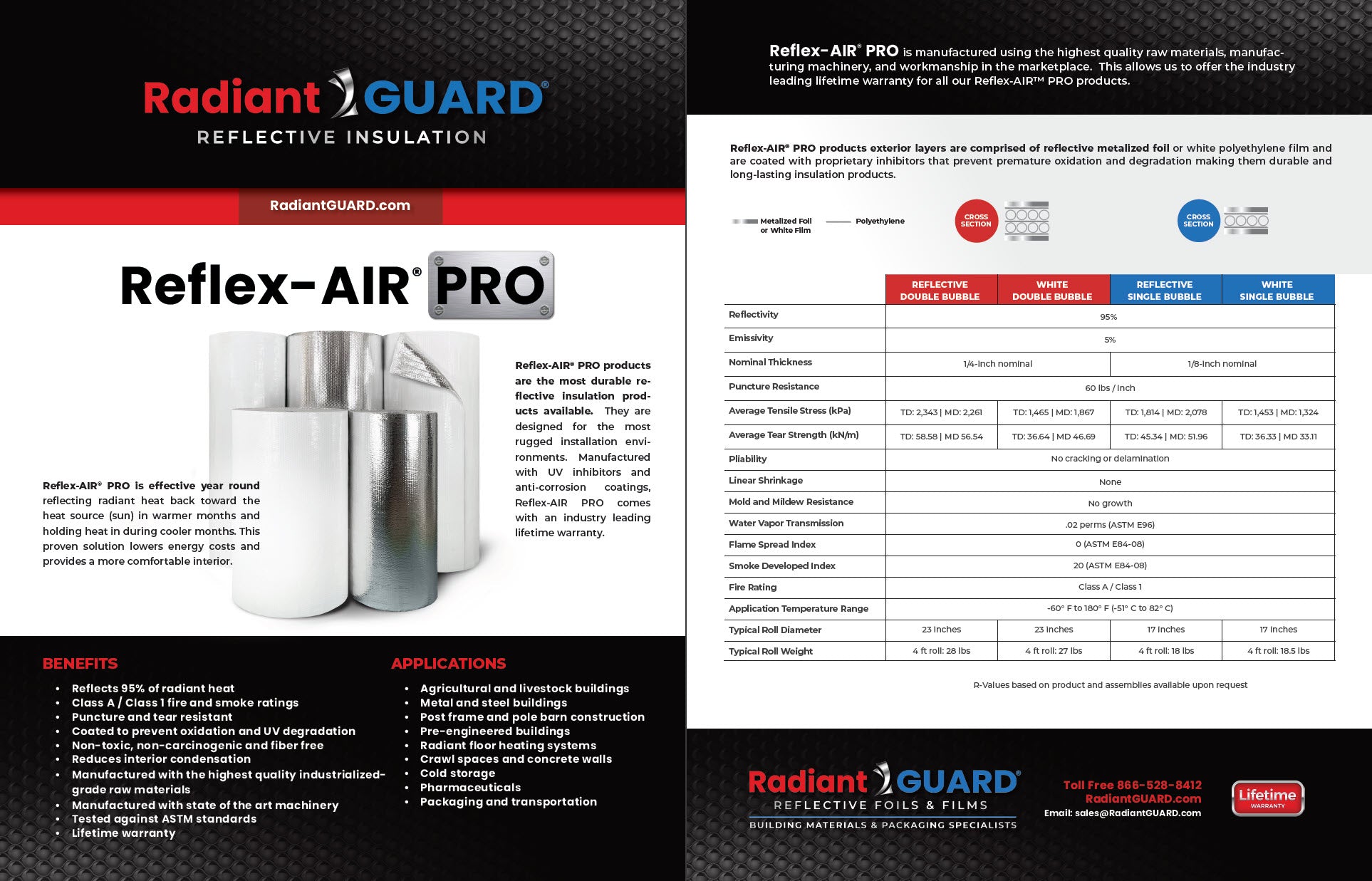

#6 Radiant Barrier Product Selection Guide

Domain Est. 2006

Website: radiantguard.com

Key Highlights: This Product Selection Guide is intended for potential consumers trying to decide which product to choose for their intended installation application….

Expert Sourcing Insights for Radient Barrier

H2: 2026 Market Trends for Radiant Barriers

The radiant barrier market is poised for significant evolution by 2026, driven by rising energy efficiency demands, advancements in building codes, and growing consumer awareness of sustainable construction practices. Radiant barriers—reflective materials that reduce radiant heat transfer—are increasingly integrated into residential, commercial, and industrial buildings, especially in warm and mixed climates. Below is an analysis of key market trends expected to shape the radiant barrier industry by 2026.

-

Increased Adoption in Residential Construction

With homeowners prioritizing energy savings and comfort, radiant barriers are becoming a standard feature in new home builds and retrofits. The U.S. Department of Energy and ENERGY STAR programs continue to promote radiant barriers in attic installations, particularly in southern states. By 2026, growing DIY renovation trends and online availability of radiant barrier products are expected to further accelerate residential uptake. -

Stringent Building Energy Codes

Governments worldwide are tightening energy efficiency regulations. In the U.S., the International Energy Conservation Code (IECC) updates and state-level mandates (e.g., California’s Title 24) increasingly favor high-performance insulation systems. Radiant barriers are gaining recognition as cost-effective solutions to meet compliance, especially in roofing and attic applications. This regulatory tailwind is expected to boost demand significantly by 2026. -

Growth in Commercial and Industrial Applications

Beyond residential use, radiant barriers are being adopted in warehouses, data centers, and cold storage facilities where temperature control is critical. The expansion of e-commerce and logistics infrastructure in warm climates is driving demand for energy-efficient building envelopes. By 2026, integration with metal roofing systems in industrial buildings is projected to be a major growth segment. -

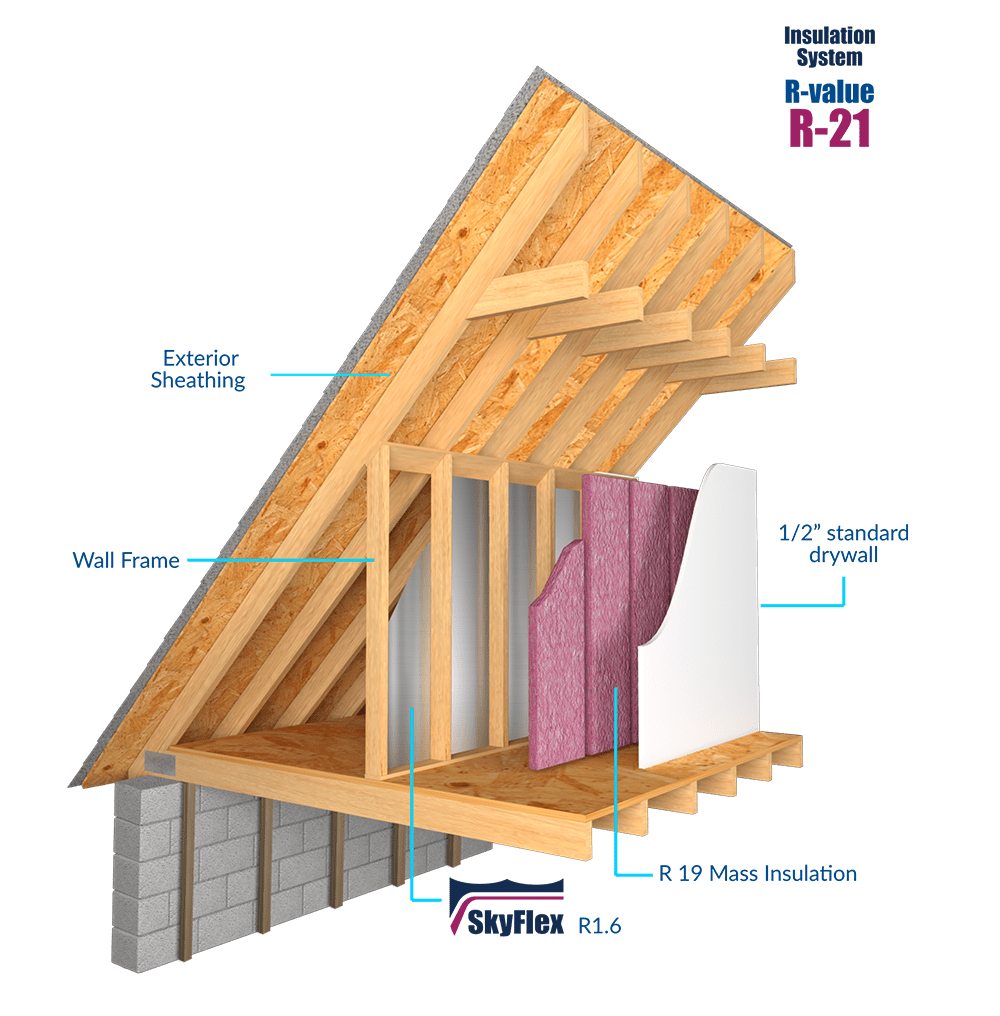

Technological Innovation and Hybrid Systems

Manufacturers are developing multi-layer radiant barriers combined with traditional insulation (e.g., foil-faced fiberglass or bubble insulation) to enhance overall thermal performance. Smart radiant barriers with reflective coatings that adapt to temperature changes are also in early development. These innovations are expected to improve efficacy and broaden application scope by 2026. -

Sustainability and Green Building Certifications

Radiant barriers contribute to LEED, Living Building Challenge, and other green certifications by reducing HVAC loads and lowering carbon emissions. As ESG (Environmental, Social, and Governance) criteria gain importance, builders and developers are more likely to specify radiant barriers in sustainable projects, further fueling market growth. -

Regional Expansion in Emerging Markets

While North America remains a dominant market, regions like Southeast Asia, the Middle East, and Latin America are witnessing increased construction activity in hot climates. Countries such as India, UAE, and Mexico are beginning to adopt radiant barriers in both public and private infrastructure, supported by government energy efficiency initiatives. This geographic diversification will expand the global market by 2026. -

Challenges and Market Barriers

Despite growth, challenges remain. Misconceptions about performance in cooler climates, inconsistent installation practices, and competition from spray foam and other insulation types may limit adoption. Education and installer certification programs are critical to overcoming these hurdles.

In conclusion, the radiant barrier market is on a strong growth trajectory through 2026, supported by regulatory, technological, and environmental drivers. Stakeholders who invest in innovation, education, and regional expansion will be well-positioned to capture emerging opportunities.

Common Pitfalls When Sourcing Radiant Barriers (Quality, IP)

Sourcing radiant barriers requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Performance Inconsistencies

One of the most common issues is sourcing radiant barriers made with substandard materials, such as thin aluminum coatings or low-grade substrates (e.g., kraft paper or plastic films). These materials can degrade quickly when exposed to moisture, UV light, or physical handling, reducing reflectivity and overall effectiveness. Buyers should verify emissivity ratings (should be ≤ 0.10) and ensure the product meets ASTM E1459 or C1313 standards. Lack of third-party testing or certification is a red flag.

Inadequate Durability and Long-Term Performance

Some radiant barriers lose reflectivity over time due to oxidation, delamination, or poor lamination techniques. Sourcing from suppliers who do not provide accelerated aging tests or long-term performance data may result in premature failure. Ensure the product is designed for the specific environmental conditions of the installation (e.g., high humidity, attic temperatures).

Misrepresentation of Reflectivity and R-Value Claims

Suppliers may exaggerate thermal performance, such as claiming high R-values for radiant barriers—which are not true insulators but reflect radiant heat. Misleading marketing can lead to incorrect installation expectations. Always distinguish between radiant barrier performance (measured in reflectivity/emissivity) and bulk insulation (measured in R-value).

Intellectual Property Infringement Risks

Radiant barrier technologies, especially multi-layer foils, reinforced laminates, or specialized adhesive systems, may be protected by patents. Sourcing generic versions without vetting IP status can expose buyers to infringement claims. Conduct due diligence by reviewing patent databases (e.g., USPTO) or consulting legal experts, particularly when importing from overseas manufacturers.

Lack of Compliance with Building Codes and Standards

Not all radiant barriers meet local building code requirements or qualify for energy efficiency incentives. Using non-compliant products can result in failed inspections or denied rebates. Verify that the product carries necessary listings (e.g., ICC-ES Evaluation Reports) and complies with relevant fire safety standards (e.g., ASTM E84 for flame spread).

Unverified Supply Chain and Counterfeit Products

Global sourcing increases the risk of counterfeit or rebranded products that do not match tested specifications. Relying on unverified suppliers without site audits or quality control agreements can compromise consistency. Establish clear quality assurance protocols and request batch testing reports.

Insufficient Technical Support and Warranty Coverage

Low-cost suppliers may offer limited technical guidance or weak warranty terms, leaving buyers exposed if installation issues or product failures arise. Prioritize suppliers who provide detailed installation instructions, engineering support, and comprehensive warranties backed by financial stability.

Avoiding these pitfalls requires rigorous supplier vetting, independent product verification, and proactive IP assessment—ensuring both performance reliability and legal compliance in radiant barrier procurement.

Logistics & Compliance Guide for Radiant Barrier

This guide outlines the key logistics and compliance considerations for handling, transporting, storing, and installing radiant barrier products. Adhering to these guidelines ensures product integrity, safety, and regulatory compliance throughout the supply chain.

Product Handling and Storage

Radiant barrier materials, typically composed of reflective foil laminated to substrates like plastic, kraft paper, or scrim, require careful handling to maintain performance and prevent damage.

- Storage Conditions: Store rolls or panels in a dry, well-ventilated indoor environment. Avoid exposure to moisture, direct sunlight, and extreme temperatures to prevent delamination or degradation.

- Stacking and Support: Keep radiant barrier rolls upright on pallets. Do not stack excessively high to prevent crushing or deformation. Avoid placing heavy objects on stored material.

- Handling Precautions: Use appropriate lifting equipment for large rolls. Avoid dragging or dropping materials, which can cause tears or punctures in the reflective surface.

Transportation Requirements

Proper transportation practices are essential to protect radiant barrier products during transit.

- Weather Protection: Cover loads with waterproof tarps or use enclosed trailers to protect against rain, snow, and humidity. Foil-faced materials are susceptible to moisture damage.

- Securement: Secure rolls or panels to prevent shifting, rolling, or abrasion during transport. Use straps or braces as needed.

- Labeling: Clearly label shipments as “Fragile,” “This Side Up,” and “Protect from Moisture” to alert handlers to special handling requirements.

Regulatory Compliance

Radiant barriers must comply with relevant building codes, fire safety standards, and environmental regulations.

- Building Codes: Ensure radiant barrier products meet the requirements of applicable codes such as the International Building Code (IBC) and International Residential Code (IRC), particularly regarding thermal performance and installation methods.

- Fire Safety Standards: Radiant barriers must comply with ASTM E84 or UL 723 for surface burning characteristics. Verify flame spread and smoke-developed indices meet jurisdictional requirements. Some products may require a thermal barrier when used in occupied spaces.

- ICC-ES Evaluation Reports: Use products with an ICC-ES (International Code Council Evaluation Service) report to demonstrate code compliance for acceptance by authorities having jurisdiction (AHJ).

Environmental and Safety Compliance

- Indoor Air Quality (IAQ): Select low-emitting radiant barrier products that comply with IAQ standards such as California Section 01350 or GREENGUARD certification, especially in residential or occupied spaces.

- Recycling and Disposal: Follow local regulations for disposal of scrap or used radiant barrier materials. Some components (e.g., aluminum foil) may be recyclable; consult local waste management guidelines.

- Worker Safety: Provide personal protective equipment (PPE) such as gloves and long sleeves during installation to prevent skin irritation from scrim or fiberglass backing materials.

Installation Best Practices

Compliance extends to proper installation to ensure performance and safety.

- Ventilation Requirements: Maintain adequate air space (typically ≥ ¾ inch) on at least one side of the radiant barrier for optimal reflectivity. Follow manufacturer specifications.

- Seam and Edge Sealing: Use compatible tapes to seal seams and edges if required, ensuring continuity of the radiant barrier system.

- Fastening Methods: Use corrosion-resistant staples or fasteners as recommended by the manufacturer. Avoid over-tightening, which can tear the material.

Documentation and Traceability

Maintain accurate records to support compliance and warranty claims.

- Product Data Sheets: Keep manufacturer specifications, including reflectivity ratings (typically >90%), emissivity values, and installation instructions.

- Certificates of Compliance: Retain documentation showing compliance with ASTM, UL, or ICC-ES standards.

- Batch and Lot Tracking: Record product lot numbers and installation dates for traceability in case of recalls or performance issues.

Adherence to this logistics and compliance guide ensures radiant barrier systems perform effectively, meet regulatory requirements, and contribute to safe, energy-efficient building envelopes.

Conclusion: Sourcing a Radiant Barrier

Sourcing a radiant barrier requires careful consideration of material quality, installation requirements, climate suitability, and long-term performance. When properly selected and installed, radiant barriers can significantly improve energy efficiency by reducing heat transfer, particularly in hot climates where cooling costs are a major concern. Key factors in sourcing include choosing reputable suppliers, ensuring compliance with industry standards (such as ASTM and building codes), and evaluating product durability and reflectivity. Additionally, cost-effectiveness should be balanced against expected energy savings and potential incentives or rebates. Ultimately, partnering with experienced manufacturers and distributors, along with professional installation, ensures optimal performance and return on investment. As sustainability and energy conservation continue to gain importance, sourcing high-quality radiant barriers is a strategic step toward creating more efficient, comfortable, and environmentally responsible buildings.