The global radial arm saw market is experiencing steady growth, driven by increasing demand in woodworking, metal fabrication, and construction industries. According to Mordor Intelligence, the power tools market—under which radial arm saws fall—is projected to grow at a CAGR of over 5.8% from 2024 to 2029, fueled by rising industrial automation and infrastructure development. Similarly, Grand View Research valued the global power tools market at USD 37.6 billion in 2023, with a forecasted CAGR of 5.3% through 2030, underpinned by technological advancements and expanded DIY applications. As demand for precision cutting equipment rises, radial saw arm manufacturers are innovating with enhanced durability, accuracy, and automation. This growth trajectory has intensified competition, leading to a concentrated landscape of leading manufacturers shaping the future of industrial and commercial cutting solutions. Below are the top six radial saw arm manufacturers leading this expansion.

Top 6 Radial Saw Arm Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Radial arm saws

Domain Est. 1997

Website: omgainc.com

Key Highlights: These precision radial arm saws are very versatile, multi-purpose and extremely heavy duty machines….

#2 Southern Tool Page

Domain Est. 1997

Website: southern-tool.com

Key Highlights: Welcome to Southern Tool! We carry the top Brands and best Variety of Automotive, Construction, HVAC, Industrial, Material Handling, Metalworking, ……

#3 Woodworking Radial Saws Minimax

Domain Est. 1997

Website: scmgroup.com

Key Highlights: Scm’s radial saws in the “formula” series with the heavy cast iron structure are available with a 650, 750 and 900 mm trimming capacity….

#4 Original Saw Company

Domain Est. 1998

Website: originalsaw.com

Key Highlights: Original Saw Company is the only Radial Arm and Beam Saw manufactured in the USA, learn more about our quality crosscut power saws….

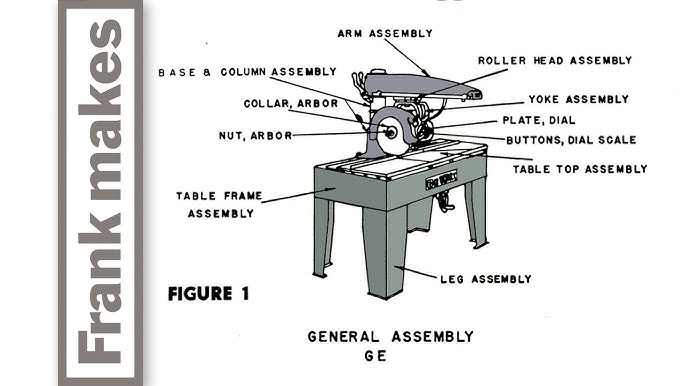

#5 Item Category: PARTS, RADIAL

Domain Est. 2000

Website: circlesaw.com

Key Highlights: 1-day deliveryOriginal Saw Company manufactures wood cutting radial arm saws, metal cutting radial arms, horizontal beam saws, cross cut saws, flat extension tables, roller ……

#6 MAGGI

Domain Est. 2011

Website: maggi-technology.com

Key Highlights: Our radial arm saws are essential machines in artisan carpenter’s workshops for cutting and trimming solid wood, chipboard, and MDF, and for cutting it at a 45° ……

Expert Sourcing Insights for Radial Saw Arm

H2: Projected Market Trends for Radial Saw Arms in 2026

The radial saw arm market is poised for notable evolution by 2026, driven by technological advancements, shifting industrial demands, and growing emphasis on precision and automation in manufacturing and construction sectors. Key trends shaping the market include:

-

Increased Adoption of Automation and Smart Technology

By 2026, radial saw arms are expected to integrate more advanced automation features, such as programmable logic controllers (PLCs), digital readouts, and IoT connectivity. These enhancements allow for improved accuracy, remote monitoring, and predictive maintenance, particularly in high-throughput industrial environments. -

Growth in Metal Fabrication and Construction Industries

The continued expansion of infrastructure development and metalworking industries—especially in emerging economies—will drive demand for high-performance radial saw arms. These tools are essential for cutting metal pipes, bars, and structural sections with precision, supporting their widespread use in fabrication shops and construction sites. -

Demand for Energy Efficiency and Compact Designs

Manufacturers are focusing on developing radial saw arms that consume less energy and occupy smaller footprints without sacrificing cutting capacity. This trend responds to the growing need for sustainable manufacturing practices and space optimization in modern workshops. -

Rise in CNC-Integrated Radial Saw Systems

Computer Numerical Control (CNC) integration is becoming a standard in higher-end radial saw arms, enabling automated, repeatable cuts with minimal human intervention. The 2026 market will likely see increased adoption of hybrid systems combining radial arm functionality with CNC precision, particularly in aerospace and automotive sectors. -

Regional Market Expansion in Asia-Pacific

Countries such as China, India, and Vietnam are expected to lead market growth due to rapid industrialization and investments in manufacturing infrastructure. Local production of radial saw arms is also on the rise, reducing costs and increasing accessibility. -

Emphasis on Safety and Operator Ergonomics

New models by 2026 will likely feature enhanced safety mechanisms such as automatic blade guards, emergency stop systems, and vibration-dampening technologies. Regulatory standards and workplace safety requirements are pushing manufacturers to prioritize operator well-being. -

Material Innovation in Saw Arm Components

To improve durability and reduce weight, manufacturers are incorporating high-strength alloys and composite materials into radial saw arm construction. This supports longer service life and better performance under heavy-duty conditions.

In summary, the 2026 radial saw arm market will be characterized by smarter, safer, and more efficient machines tailored to meet the demands of modern industrial applications. Companies that invest in innovation, sustainability, and regional market development are likely to gain a competitive edge.

Common Pitfalls When Sourcing a Radial Saw Arm (Quality and Intellectual Property)

Sourcing a radial saw arm—whether for original equipment manufacturing (OEM), replacement parts, or integration into a larger system—presents several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls can help mitigate costly mistakes.

Poor Material and Manufacturing Quality

One of the most frequent issues when sourcing radial saw arms, especially from low-cost suppliers, is subpar material selection and manufacturing processes. Inferior steel alloys or inadequate heat treatment can lead to premature fatigue, warping, or catastrophic failure under operational stress. Poor machining tolerances affect alignment, resulting in inaccurate cuts and increased wear on bearings and blades.

Lack of Quality Control and Certification

Many suppliers, particularly in emerging markets, may lack robust quality control systems or fail to provide necessary certifications (e.g., ISO 9001, material test reports). Without documented quality assurance, buyers risk receiving inconsistent batches, increasing downtime and safety hazards. Absence of traceability also complicates root-cause analysis during field failures.

Design Infringement and IP Violations

Sourcing from unverified suppliers raises the risk of inadvertently acquiring a radial saw arm that infringes on existing patents or design rights. Some manufacturers produce clones or reverse-engineered versions of branded components. Purchasing such parts can expose your company to legal liability, including infringement claims, import seizures, or reputational damage.

Inadequate Documentation and Technical Support

Low-cost suppliers may provide incomplete technical documentation—missing dimensional drawings, load specifications, or installation guidelines. This lack of support complicates integration, maintenance, and compliance efforts. In the event of a failure, the absence of detailed specs also hinders troubleshooting and liability determination.

Hidden Costs from Rework and Downtime

While initial pricing may appear attractive, poor-quality radial saw arms often lead to higher total cost of ownership. Frequent breakdowns, alignment issues, and safety incidents result in unplanned downtime, increased maintenance labor, and potential damage to other machine components. These hidden costs can far exceed the savings from a lower purchase price.

Supply Chain and Long-Term Reliability Risks

Relying on suppliers with uncertain IP status or questionable business practices introduces supply chain vulnerability. If a supplier is forced to cease production due to IP litigation, your production line could face interruptions. Additionally, lack of long-term support or spare parts availability jeopardizes equipment longevity.

To avoid these pitfalls, conduct thorough due diligence: verify supplier credentials, request material and process certifications, perform independent quality audits, and consult legal experts to assess IP risks before finalizing procurement.

Logistics & Compliance Guide for Radial Saw Arm

This guide outlines key logistics considerations and compliance requirements for the transportation, handling, and use of Radial Saw Arms. Adherence to these guidelines ensures safe operations, regulatory compliance, and product integrity throughout the supply chain and end-user lifecycle.

Product Classification & Documentation

Radial Saw Arms are typically classified under industrial machinery components. Ensure accurate product descriptions, model numbers, and HS (Harmonized System) codes—commonly falling under 8467.30 (Parts of power-operated hand tools) or 8466.30 (Parts of machine tools). Maintain up-to-date technical specifications, user manuals, safety data sheets (if applicable), and compliance certificates for customs clearance and end-user documentation.

Packaging & Handling Requirements

Use robust, custom-fitted packaging to protect the Radial Saw Arm during transit. Secure all moving parts and coated surfaces with protective covers or padding to prevent damage. Clearly label packages with:

– Fragile and Heavy Item warnings

– Proper orientation indicators (This Side Up)

– Handling instructions (e.g., “Do Not Stack”)

Ensure lifting points or sling zones are accessible and clearly marked for safe material handling.

Transportation & Storage Conditions

Transport Radial Saw Arms via ground or sea freight, depending on shipment size and destination. Avoid exposure to moisture, extreme temperatures, and corrosive environments. Store in a dry, temperature-controlled warehouse with adequate ventilation. Keep units off the floor on pallets and shielded from dust and contaminants. Inventory should be rotated using a First-In, First-Out (FIFO) method.

Regulatory Compliance

Ensure compliance with relevant international and regional standards, including:

– CE Marking (EU): Conformity with Machinery Directive 2006/42/EC and relevant EN standards (e.g., EN 60204-1 for electrical safety)

– OSHA & ANSI Standards (USA): Compliance with OSHA 29 CFR 1910.213 and ANSI B175.1 for portable power tools

– UKCA Marking (UK): Post-Brexit equivalent to CE marking

– RoHS & REACH (EU): Restrictions on hazardous substances in electrical components and materials

Documentation such as Declarations of Conformity (DoC) must accompany shipments where required.

Import/Export Controls

Verify export licensing requirements, especially if components include controlled materials or dual-use technology. Comply with ITAR (International Traffic in Arms Regulations) if applicable, though Radial Saw Arms generally fall outside its scope. Use accurate commercial invoices, packing lists, and bills of lading. Perform due diligence on end-users to prevent diversion to unauthorized entities or regions.

End-User Safety & Installation Compliance

Provide comprehensive installation and safety instructions with each unit. Emphasize compliance with local workplace safety regulations. Require qualified personnel for installation and alignment. Confirm that end-users ground the equipment properly and integrate it into a fully compliant radial saw system with appropriate guarding and emergency stops.

Environmental & Disposal Considerations

Dispose of packaging materials according to local recycling regulations. At end-of-life, the Radial Saw Arm should be recycled in accordance with WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions. Avoid landfill disposal of metal and electronic components.

Audit & Recordkeeping

Maintain records of compliance documentation, shipping logs, quality inspections, and customer certifications for a minimum of five years. Conduct regular internal audits to verify adherence to logistics and compliance protocols. Update documentation promptly to reflect regulatory changes or product revisions.

Conclusion for Sourcing Radial Arm Saw Components:

Sourcing components for a radial arm saw requires a strategic approach that balances quality, cost, availability, and supplier reliability. After evaluating various suppliers and manufacturing options, it is evident that a combination of domestic and international sourcing offers the best value. Critical components such as the motor, arbor, and precision guides should be sourced from trusted suppliers with proven quality control to ensure safety, durability, and performance. Meanwhile, non-critical structural and housing parts can be cost-effectively procured from certified overseas manufacturers without compromising overall product integrity.

Additionally, aligning with suppliers who adhere to relevant industry standards (e.g., ISO, OSHA, CE) ensures compliance and reduces potential liability. Building long-term partnerships with key vendors enhances supply chain resilience, facilitates just-in-time inventory management, and supports scalability. In conclusion, a well-structured sourcing strategy that prioritizes quality, efficiency, and risk mitigation will enable the production of a reliable, high-performance radial arm saw while maintaining competitive pricing and timely delivery.