The global rack and gear set market is experiencing steady growth, driven by rising demand across industrial automation, material handling, and renewable energy sectors. According to a report by Mordor Intelligence, the global rack and pinion systems market was valued at USD 3.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by increasing adoption in wind turbines, construction machinery, and precision motion control applications. As industries prioritize efficiency, reliability, and high-load capacity in linear motion systems, rack and gear sets have become critical components in modern mechanical design. With technological advancements and growing automation in manufacturing, the need for high-performance rack and gear solutions continues to rise—making the selection of reliable manufacturers more important than ever. Below, we highlight the top 10 rack and gear set manufacturers leading innovation, quality, and market share in this evolving landscape.

Top 10 Rack And Gear Set Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

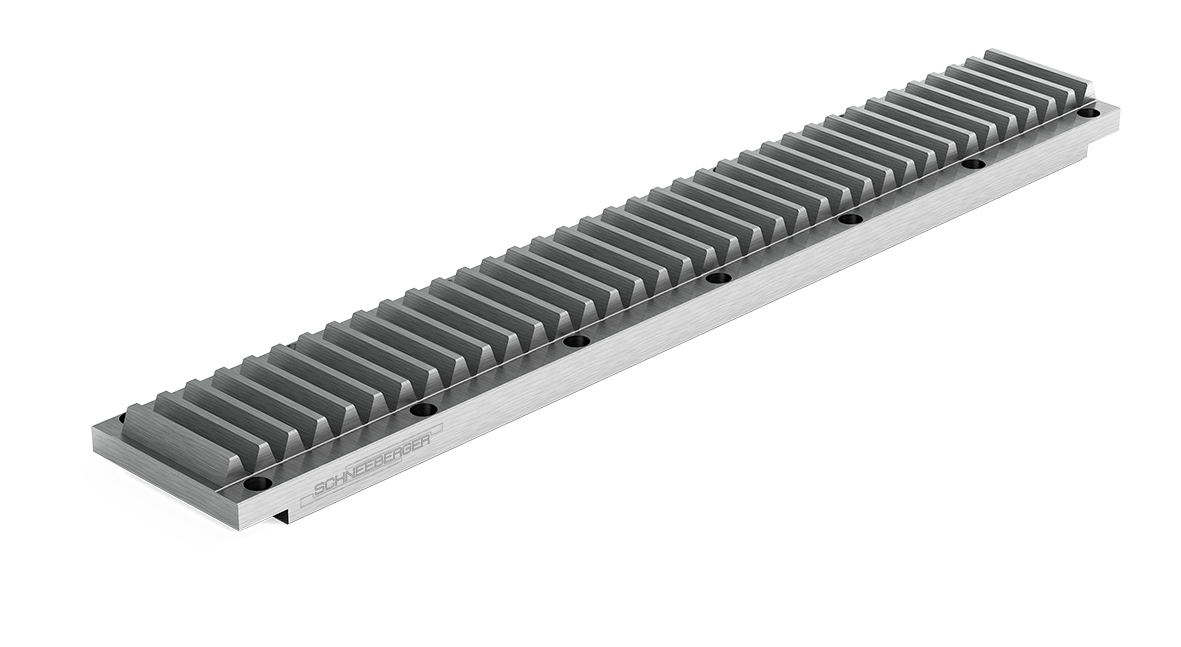

#1 Custom Gear Rack Manufacturer

Domain Est. 1995

Website: pic-design.com

Key Highlights: PIC Design manufactures precision gear racks in a variety of sizes, pitches & materials to meet your needs. We offer both standard & custom gear racks….

#2 Gear Rack Manufacturers

Domain Est. 2002

Website: industrial-gears.com

Key Highlights: See leading gear rack manufacturers and suppliers who produce reliable, high quality products that are made right here in the USA for competitive prices….

#3 Gears, Racks, Pinions & Differentials

Domain Est. 1995 | Founded: 1950

Website: sdp-si.com

Key Highlights: Made in New York since 1950. We specialize in the design and manufacture of high-quality precision gears and custom gear assemblies for OEMs worldwide. Our ……

#4 Moore Gear & Manufacturing

Domain Est. 1999

Website: mooregear.com

Key Highlights: We are a leading manufacturer of custom and standard gear racks and gears with over 80 years of commitment to our customers….

#5 ATLANTA Drive Systems, Inc. Gear Racks

Domain Est. 2004

Website: atlantadrives.com

Key Highlights: Welcome to the widest range of standard racks & pinions in the World! Consisting of both helical & straight (spur) tooth versions, in an assortment of sizes, ……

#6 Types of Gears

Domain Est. 2015

Website: khkgears.net

Key Highlights: There are many types of gears. This page explains the various types of gears, including spur gears, bevel gears, worm gears and helical gears….

#7 Linear Rack Supplier & Manufacturer

Domain Est. 2023

Website: cskmotions.com

Key Highlights: Linear racks efficiently convert rotary motion into linear motion. Racks can be customized to suit specific applications based on length, tooth profile ……

#8 MAVAL Industries

Domain Est. 1998

Website: mavalgear.com

Key Highlights: Our premium line of NEW aftermarket steering components are proven to deliver high performance and endurance, from the company that has set the standard for ……

#9 Helical Rack & Pinion Products

Domain Est. 1998

Website: gamweb.com

Key Highlights: GAM Rack & Pinion Products Include: Helical Gear Rack, Helical Pinions, Helical Rack and Pinion Systems, Rack and Pinion Accessories, Lubrication Systems….

#10 Standard & Custom Spur Gear Racks

Domain Est. 2007

Website: ondrivesus.com

Key Highlights: Ondrives.US manufactures stainless steel gear racks in a wide range of standard sizes and offers customization for non-standard applications….

Expert Sourcing Insights for Rack And Gear Set

H2: 2026 Market Trends for Rack and Pinion Systems (Rack and Gear Set)

The global rack and pinion systems (commonly referred to as rack and gear sets) market is poised for significant transformation by 2026, driven by advancements in automation, electric mobility, and industrial digitalization. These precision mechanical components, essential for converting rotational motion into linear movement, are witnessing renewed demand across multiple high-growth sectors. Below is an analysis of key market trends expected to shape the rack and gear set industry in 2026.

1. Surge in Industrial Automation and Robotics

Manufacturing facilities worldwide are increasingly adopting automation to enhance efficiency and reduce labor costs. By 2026, rack and pinion systems are expected to play a pivotal role in automated guided vehicles (AGVs), robotic arms, and high-speed gantry systems. Their durability, precision, and ability to handle heavy loads make them ideal for use in smart factories and Industry 4.0 environments.

2. Growth in Electric and Autonomous Vehicles

The automotive sector’s shift toward electric and autonomous vehicles is driving innovation in steering systems. Rack and pinion steering, particularly electric power-assisted steering (EPAS), continues to dominate due to its energy efficiency and compact design. As autonomous driving technologies mature, demand for highly reliable and responsive rack and gear systems will increase, especially in self-steering mechanisms and adaptive suspension systems.

3. Expansion in Renewable Energy Applications

Solar tracking systems and wind turbine pitch control are emerging as key growth areas. Rack and pinion mechanisms are being utilized for precise angular adjustments in solar panel arrays to maximize energy capture. By 2026, increasing investments in renewable infrastructure, especially in Asia-Pacific and North America, are expected to boost demand for corrosion-resistant and high-load-capacity gear sets.

4. Advancements in Material Science and Manufacturing

Manufacturers are adopting advanced materials such as case-hardened steels, stainless alloys, and composite coatings to improve wear resistance and longevity. Precision grinding and additive manufacturing techniques are enhancing gear accuracy and reducing production lead times. These innovations are expected to lower lifecycle costs and expand application potential in aerospace, medical equipment, and defense.

5. Regional Shifts and Supply Chain Reconfiguration

Asia-Pacific, led by China, India, and South Korea, is projected to be the fastest-growing market due to rapid industrialization and government support for automation. Meanwhile, North America and Europe are focusing on high-precision, customized solutions for niche applications. Companies are also reshoring or nearshoring production to mitigate supply chain disruptions, influencing localization strategies in rack and gear manufacturing.

6. Integration with Smart Technologies and IoT

By 2026, intelligent rack and pinion systems integrated with sensors, predictive maintenance algorithms, and IoT platforms will gain traction. Real-time monitoring of gear wear, temperature, and alignment enables preemptive servicing, reducing downtime in critical operations. This trend is particularly relevant in CNC machinery, semiconductor manufacturing, and logistics automation.

7. Sustainability and Energy Efficiency Regulations

Stricter environmental regulations are pushing industries to adopt energy-efficient motion control solutions. Rack and gear systems with optimized tooth profiles and reduced friction are being developed to meet these standards. OEMs are increasingly prioritizing greener manufacturing processes and recyclable materials in product design.

Conclusion

The 2026 outlook for the rack and gear set market is one of steady growth and technological evolution. Key drivers include automation, electrification, renewable energy adoption, and digital integration. Companies that invest in R&D, adopt sustainable practices, and align with Industry 4.0 standards are likely to capture significant market share. As demand diversifies across industries, the rack and pinion system will remain a cornerstone of modern mechanical engineering.

Common Pitfalls When Sourcing Rack and Pinion (Rack and Gear Set)

Sourcing rack and pinion systems (often referred to as rack and gear sets) involves navigating several critical challenges, particularly concerning quality and intellectual property (IP). Overlooking these can lead to performance issues, legal risks, and increased costs.

Quality-Related Pitfalls

Insufficient Material and Hardness Specifications

Failing to clearly define material grades (e.g., induction-hardened 1045 steel, alloy steels) and surface hardness requirements (e.g., HRC 58–62 on the tooth surface) can result in premature wear, pitting, or tooth breakage under load. Offshore suppliers may use substandard materials to cut costs.

Poor Tooth Profile and Precision Tolerances

Rack and pinion systems demand high precision. Inadequate attention to DIN or AGMA standards for tooth profile accuracy, pitch error, and runout can cause backlash, noise, vibration, and reduced system life. Sourcing from manufacturers without proper gear inspection equipment increases this risk.

Inadequate Surface Finish and Case Depth

Improper case depth in hardened racks or a rough surface finish leads to accelerated wear and fatigue failure. Buyers must specify minimum case depth (e.g., 0.8–1.2 mm) and surface roughness (e.g., Ra ≤ 0.8 µm) to ensure longevity.

Lack of Traceability and Certification

Reputable suppliers provide material test reports (MTRs), heat treatment certifications, and inspection reports. Sourcing without these documents increases the risk of receiving non-compliant or counterfeit components.

Intellectual Property (IP) Pitfalls

Unintentional Infringement of Patented Designs

Many rack and pinion systems—especially those used in steering or automation—incorporate patented geometries, mounting configurations, or anti-backlash mechanisms. Sourcing generic copies without IP clearance can expose the buyer to infringement lawsuits.

Use of Counterfeit or Reverse-Engineered Components

Some suppliers offer “compatible” or “OEM-equivalent” racks that are reverse-engineered without licensing. These may mimic form and fit but infringe on protected designs, potentially leading to legal liability and supply chain disruption.

Inadequate Supplier IP Warranty and Indemnification

Failing to secure contractual assurances from suppliers that components do not infringe on third-party IP leaves the buyer legally exposed. Ensure supply agreements include IP indemnification clauses.

Ambiguous Design Ownership in Custom Solutions

When co-developing custom rack systems, unclear agreements on design ownership and usage rights can lead to disputes. Define IP rights upfront in development contracts to avoid future conflicts.

Logistics & Compliance Guide for Rack And Gear Set

Product Overview and Classification

The Rack And Gear Set is a mechanical assembly used in industrial, automotive, or automation applications. It typically consists of a linear rack and a mating pinion gear, often made from hardened steel or engineered polymers. For logistics and compliance purposes, this product is classified under HS Code 8483.40 (Transmission shafts, cranks, gear boxes, and other transmission components). Confirm the exact HS code with local customs authorities based on material composition and intended use.

Packaging and Handling Requirements

Package the Rack And Gear Set in sturdy corrugated cardboard or wooden crates to prevent deformation or surface damage during transit. Use anti-corrosion wrapping (e.g., VCI paper) for metal components and secure parts with foam inserts or dividers to minimize movement. Label all packages with:

– Product name and part number

– Net and gross weight

– “Fragile” and “This Side Up” handling indicators

– Origin and destination details

Domestic and International Shipping

For domestic shipments within regions such as the U.S. or EU, standard freight carriers (e.g., FedEx Freight, UPS, DHL) are suitable. For international shipping:

– Use Incoterms® 2020 (e.g., FOB, EXW, or DDP) clearly defined in contracts

– Ensure compliance with IATA (air) or IMDG (sea) regulations if applicable

– Declare accurate product value, weight, and dimensions for customs clearance

– Include a commercial invoice, packing list, and bill of lading/air waybill

Customs Documentation and Duties

Prepare the following documentation for customs:

– Commercial Invoice (detailing buyer, seller, product description, unit price, total value)

– Packing List (itemizing contents per package)

– Certificate of Origin (if claiming preferential tariffs under trade agreements)

– Import Declaration (completed by importer or customs broker)

Duty rates vary by country; verify with local customs. For example, in the U.S., gear components may face duties between 2.5%–4.5%, depending on material and end use.

Regulatory Compliance

Ensure compliance with relevant standards:

– REACH & RoHS (EU): Confirm absence of restricted substances (e.g., lead, cadmium) in metal alloys and coatings

– Proposition 65 (California, USA): Provide warnings if components contain listed chemicals

– ISO Standards: Adhere to ISO 1328 (gear accuracy) and ISO 4406 (contamination levels) where applicable

Import/Export Controls

Verify if the Rack And Gear Set falls under export control regulations such as:

– EAR (U.S. Export Administration Regulations): Check ECCN (Export Control Classification Number); typically falls under EAR99 if not specifically listed

– Dual-Use Items: Confirm no military or strategic application that could trigger additional licensing

Environmental and Safety Considerations

- Lubricants (if pre-applied) must be non-hazardous and labeled per GHS standards

- Packaging should be recyclable and minimize plastic use to meet sustainability goals

- Provide Safety Data Sheets (SDS) upon request for any treated or coated components

Returns and Reverse Logistics

Establish a clear returns policy requiring:

– Pre-authorization via an RMA (Return Merchandise Authorization) number

– Original packaging for protection

– Inspection upon receipt for damage or misuse

– Compliance with local waste disposal regulations for non-reusable parts

Recordkeeping and Audit Readiness

Maintain shipping, compliance, and transaction records for a minimum of 5 years (or as required by jurisdiction). Records should include:

– Copies of all export/import documentation

– Certificates of compliance

– Internal quality and inspection reports

Ensure systems are audit-ready for customs, trade compliance, or environmental regulators.

Conclusion for Sourcing Rack and Pinion Gear Set:

After a comprehensive evaluation of technical specifications, supplier capabilities, cost considerations, quality standards, and lead times, it is concluded that sourcing the rack and pinion gear set should be strategically aligned with both immediate project requirements and long-term operational goals. The selected supplier demonstrates proven expertise in precision gear manufacturing, adherence to international quality standards (such as ISO 9001 and AGMA ratings), and the ability to provide consistent performance under expected load and environmental conditions.

Outsourcing to a reliable manufacturer offers significant advantages in terms of cost-efficiency, access to advanced machining technology, and reduced production lead times compared to in-house fabrication. Additionally, established suppliers often provide value-added services such as design support, maintenance testing, and after-sales technical assistance, contributing to improved system reliability and uptime.

In conclusion, the recommended sourcing approach—balancing cost, quality, and delivery—ensures optimal performance of the rack and pinion system within the intended application, while supporting scalability and supply chain resilience. Continuous supplier performance monitoring and periodic reassessment are advised to maintain long-term competitiveness and operational excellence.