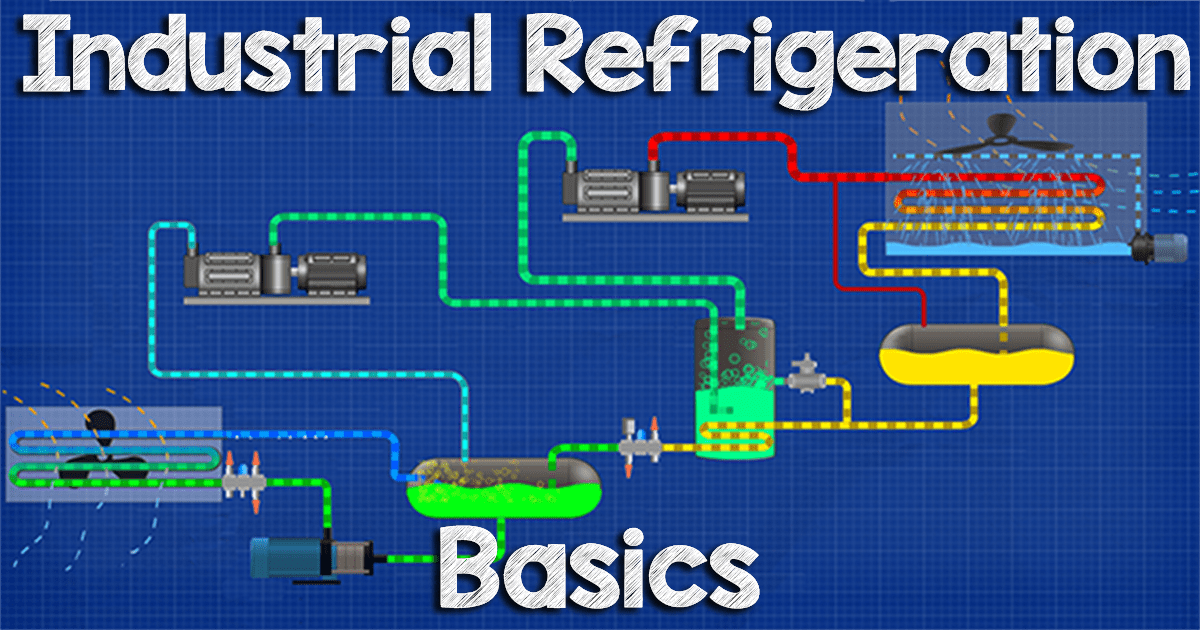

The global refrigerant market is undergoing significant transformation, driven by increasing demand for energy-efficient cooling solutions and tightening environmental regulations. According to Mordor Intelligence, the global refrigerant market was valued at USD 19.8 billion in 2023 and is projected to grow at a CAGR of 4.7% from 2024 to 2029. A key contributor to this growth is the continued use of R134a—a hydrofluorocarbon (HFC) refrigerant widely adopted in household refrigerators due to its favorable thermodynamic properties and compatibility with existing compressor technologies. Despite regulatory pressures to transition toward lower-global-warming-potential (GWP) alternatives, R134a remains a dominant player, particularly in emerging markets where cost-effectiveness and system reliability are prioritized. As demand for refrigeration rises alongside urbanization and cold chain development, manufacturers specializing in R134a-based solutions are strategically positioning themselves to meet performance and compliance standards. The following list highlights the top seven R134a refrigerator manufacturers leveraging market trends, technological innovation, and scale to maintain leadership in a competitive and evolving landscape.

Top 7 R134A For Refrigerator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Refrigerants

Domain Est. 2018

Website: daikinchemicals.com

Key Highlights: Daikin Chemicals has developed advanced range of fluorine refrigerants, lower GWP HFC and HFC blends for the domestic, industrial and commercial segment….

#2 R134a Refrigerant

Domain Est. 1995

Website: agas.com

Key Highlights: R134a is an HFC refrigerant, which requires polyolester (POE) lubricant to be used in the compressor. WARNING: This product can expose you to chemicals ……

#3 R134a

Domain Est. 1998

Website: nationalref.com

Key Highlights: R134a is a widely used refrigerant for automotive and HVAC systems, offering reliable cooling performance and easy replacement compatibility….

#4 Freon™ 134a

Domain Est. 1998

Website: freon.com

Key Highlights: Learn how Freon™ 134a, a hydrofluorocarbon (HFC) retrofit refrigerant for R-12, can be used in commercial refrigeration, chillers, and home appliances….

#5 Opteon™ XP10 (R-513A) Refrigerant

Domain Est. 2000

Website: opteon.com

Key Highlights: Opteon™ XP10 (R-513A) refrigerant is a low global warming potential (GWP) hydrofluoroolefin (HFO) based replacement for R-134a. Learn more here….

#6 R

Domain Est. 2018

Website: igasusa.com

Key Highlights: R-134a (1,1,1,2-Tetrafluoroethane) is a widely used hydrofluorocarbon (HFC) refrigerant, designed primarily for medium-temperature refrigeration and air ……

#7 Dewgas R

Domain Est. 2021

Website: dewgas.com

Key Highlights: R-134a used primarily as a “high – temperature” refrigerant for domestic refrigeration and automobile air conditioners. It is safe for normal handling….

Expert Sourcing Insights for R134A For Refrigerator

H2: Market Trends for R134a in Refrigerators (2026 Outlook)

As the global refrigeration industry evolves in response to environmental regulations, technological advancements, and shifting consumer demands, the market for R134a—a hydrofluorocarbon (HFC) refrigerant widely used in domestic refrigerators—faces significant transformation by 2026. While R134a has been a staple in refrigerator manufacturing due to its non-flammability, stability, and efficiency, its future is increasingly constrained by environmental concerns and international policy shifts.

Regulatory Pressure and Phase-Down Initiatives

A key trend shaping the 2026 landscape is the ongoing global phase-down of high-GWP (Global Warming Potential) refrigerants under the Kigali Amendment to the Montreal Protocol. R134a, with a GWP of 1,430, is specifically targeted in many regions. By 2026, countries in the European Union, North America, and parts of Asia are expected to enforce stricter quotas on HFC production and import, directly impacting R134a availability and cost. The EU’s F-Gas Regulation, for example, mandates a cumulative HFC reduction of 67% by 2024 and continues to tighten through 2030, pushing manufacturers toward lower-GWP alternatives.

Shift Toward Natural Refrigerants

The refrigerator industry is accelerating the adoption of natural refrigerants such as R600a (isobutane), which has a GWP of just 3 and superior thermodynamic performance. By 2026, most new refrigerator models in Europe and increasingly in North America and emerging markets are expected to use R600a instead of R134a. This transition is driven not only by regulation but also by cost efficiency and consumer demand for sustainable appliances. As a result, R134a’s market share in new refrigerator production is projected to decline significantly, particularly in premium and energy-efficient product lines.

Legacy Systems and Aftermarket Demand

Despite the decline in new installations, R134a will retain relevance in the service and repair market. Millions of refrigerators manufactured between the early 2000s and early 2020s still use R134a, creating sustained demand for retrofitting, recycling, and recharging. By 2026, the aftermarket segment is expected to become the primary source of R134a consumption, supported by the growth of refrigerant reclamation services and closed-loop recovery systems. However, the rising cost of virgin R134a due to production caps may incentivize faster retirement of R134a-based units.

Technological and Competitive Landscape

Innovation in compressor design and system optimization has reduced the performance gap between R134a and newer refrigerants, diminishing one of R134a’s key advantages. Meanwhile, advancements in flammability mitigation technologies have eased safety concerns around hydrocarbons like R600a, further eroding R134a’s competitive position. Major appliance manufacturers—including Whirlpool, LG, and Haier—are aligning their product roadmaps with sustainability goals, favoring hydrocarbon refrigerants for new models.

Regional Variations

Market trends for R134a in 2026 will vary by region. In mature markets such as the EU and U.S., R134a use in new refrigerators will be minimal. In contrast, some developing economies may continue using R134a due to existing infrastructure, lower upfront costs, and slower regulatory implementation. However, international funding mechanisms like the Multilateral Fund for the Montreal Protocol are supporting technology transfer, which may accelerate the transition even in these regions.

Conclusion

By 2026, the R134a market for refrigerators will be in structural decline, driven by stringent environmental regulations, the rise of natural refrigerants, and shifting industry standards. While demand will persist in the service sector, particularly for legacy units, R134a is expected to be largely phased out of new refrigerator production in most major markets. Stakeholders—including manufacturers, service providers, and policymakers—must adapt to this changing landscape by investing in sustainable alternatives and supporting a responsible transition.

Common Pitfalls When Sourcing R134a for Refrigerators (Quality & Intellectual Property)

Sourcing R134a refrigerant for refrigerator applications requires careful attention to both quality and intellectual property (IP) concerns. Overlooking these factors can lead to system failures, safety hazards, legal exposure, and reputational damage. Below are the key pitfalls to avoid:

1. Quality-Related Pitfalls

a. Contaminated or Impure Product

One of the most common and damaging issues is receiving R134a that contains impurities such as moisture, air, hydrocarbons (e.g., butane), or other refrigerants (e.g., R12, R22).

– Impact: Moisture leads to acid formation and compressor failure. Hydrocarbons increase flammability risk. Air reduces cooling efficiency.

– Pitfall: Sourcing from non-certified or low-cost suppliers who lack rigorous quality control.

– Mitigation: Demand and verify AHRI 700 certification, which sets purity standards. Require batch-specific test reports.

b. Use of “Drop-in” or “Replacement” Alternatives Misrepresented as R134a

Some suppliers market hydrocarbon blends (e.g., R600a-based) or other substitutes labeled as “eco-friendly R134a replacements” or even falsely as pure R134a.

– Impact: These are often flammable and incompatible with R134a systems, leading to safety risks and equipment damage.

– Pitfall: Ambiguous labeling or misleading marketing, especially from online or gray-market vendors.

– Mitigation: Purchase only refrigerants labeled as “R134a” with full chemical identity. Avoid any product labeled as a “replacement,” “green,” or “drop-in” unless specifically approved by the OEM.

c. Inadequate Packaging and Cylinder Integrity

Poorly sealed, reused, or non-standard cylinders can introduce contaminants or allow refrigerant leakage.

– Impact: Loss of charge, contamination, and exposure risks.

– Pitfall: Accepting cylinders without safety caps, unclear labeling, or from sources using non-hermetic packaging.

– Mitigation: Use only DOT-approved cylinders with tamper-evident seals and clear manufacturer branding. Inspect for damage before use.

d. Lack of Traceability and Documentation

No batch numbers, safety data sheets (SDS), or manufacturer information.

– Impact: Inability to verify authenticity or respond to quality issues. Regulatory non-compliance.

– Pitfall: Buying from intermediaries or unauthorized distributors with no documentation trail.

– Mitigation: Require full documentation including SDS, certificate of analysis, and purchase invoices with lot numbers.

2. Intellectual Property (IP)-Related Pitfalls

a. Counterfeit or Rebranded Refrigerant

Unauthorized manufacturers may produce and sell R134a under fake brand names or repackage genuine refrigerant without permission.

– Impact: Loss of warranty, poor performance, and potential liability if counterfeit product causes harm.

– Pitfall: Attractive pricing from unknown brands mimicking reputable ones (e.g., Chemours™, Honeywell™, Mexichem™).

– Mitigation: Source only from authorized distributors of major brands. Verify distributor credentials and use manufacturer verification tools (e.g., QR codes, holograms).

b. Trademark and Brand Infringement

Suppliers may use logos, names, or packaging similar to well-known brands to mislead buyers.

– Impact: Legal risk if your company inadvertently uses or distributes counterfeit products.

– Pitfall: Purchasing “generic” or “compatible” R134a with branding that mimics DuPont™ or Freon™.

– Mitigation: Avoid products with suspiciously similar branding. Confirm product authenticity directly with the IP holder.

c. Patent and Formulation Rights Violations

While R134a is off-patent, some branded versions may include proprietary additives or stabilization packages protected under IP law.

– Impact: Using non-compliant formulations may void equipment warranties or violate OEM service agreements.

– Pitfall: Assuming all R134a is functionally identical, regardless of brand or origin.

– Mitigation: Stick to formulations approved by refrigerator OEMs and use refrigerants from reputable, IP-compliant manufacturers.

Best Practices Summary

| Risk Area | Best Practice |

|—————-|——————————————————————————-|

| Quality | Source AHRI 700-certified R134a with full batch testing and SDS. |

| Purity | Reject any “replacements” or blends unless explicitly certified as R134a. |

| Packaging | Use only sealed, DOT-compliant cylinders from known manufacturers. |

| IP Compliance| Purchase only from authorized distributors; verify brand authenticity. |

| Traceability| Maintain full documentation and lot traceability for every purchase. |

By proactively addressing these pitfalls, businesses can ensure reliable performance, regulatory compliance, and legal safety when sourcing R134a for refrigeration systems.

H2: Logistics & Compliance Guide for R134a in Refrigerators

R134a (1,1,1,2-tetrafluoroethane) is a widely used hydrofluorocarbon (HFC) refrigerant in domestic and commercial refrigeration systems, including refrigerators. Due to its environmental impact and regulatory oversight, strict logistics and compliance protocols must be followed during handling, transportation, storage, and usage. This guide outlines key considerations for the safe and compliant management of R134a in refrigerator applications.

1. Regulatory Compliance

R134a is subject to international, national, and regional environmental and safety regulations. Key frameworks include:

-

Montreal Protocol and Kigali Amendment: While R134a is not ozone-depleting (ODP = 0), it has a high Global Warming Potential (GWP = 1430). The Kigali Amendment to the Montreal Protocol mandates phasedown of high-GWP HFCs, including R134a, in many countries.

-

U.S. EPA Regulations (SNAP Program): Under the U.S. Environmental Protection Agency’s Significant New Alternatives Policy (SNAP), the use of R134a in new household refrigerators has been phased out in favor of lower-GWP alternatives (e.g., R600a). However, it may still be used for servicing existing equipment.

-

EU F-Gas Regulation (No. 517/2014): Restricts the use of HFCs with GWP > 150 in new household refrigeration equipment. R134a (GWP 1430) is banned in new domestic fridges since 2015. Its use is limited to maintenance and repair with proper certification.

-

Section 608 of the Clean Air Act (U.S.): Requires technicians to be certified to handle refrigerants. Recovery, recycling, and proper recordkeeping are mandatory to prevent emissions.

2. Transportation & Logistics

Safe and legal transport of R134a is governed by hazardous materials regulations:

-

Classification: R134a is classified as a non-flammable, compressed gas (UN 3159, Class 2.2 – Non-Flammable, Non-Toxic Gas).

-

Packaging Requirements:

- Must be transported in DOT-approved (U.S.) or ADR-compliant (EU) cylinders.

- Cylinders must be clearly labeled with UN number, hazard class, and refrigerant name.

-

Valves must be protected with caps and secured to prevent leaks.

-

Documentation:

- Shipper must provide a Safety Data Sheet (SDS).

-

Transport documents must include proper shipping name, UN number, hazard class, and quantity.

-

Storage During Transit:

- Keep cylinders upright and secured.

- Avoid exposure to heat, direct sunlight, or temperatures above 52°C (125°F).

- Segregate from oxidizers and flammable materials.

3. Storage & Handling

- Storage Conditions:

- Store in a cool, dry, well-ventilated area.

- Keep away from ignition sources (though non-flammable, decomposition at high temperatures can release toxic gases).

-

Use first-in, first-out (FIFO) inventory management.

-

Handling Precautions:

- Use appropriate PPE: safety goggles, gloves, and protective clothing.

- Avoid skin or eye contact; refrigerant can cause frostbite upon release.

- Use only approved recovery and charging equipment.

4. Leak Prevention & Emission Control

- Leak Detection: Use electronic leak detectors or UV dyes to identify leaks in refrigeration systems.

- Repair Requirements: Under EPA and F-Gas rules, leaks above certain thresholds must be repaired promptly.

- Recovery & Reclamation:

- Recover refrigerant using EPA-certified recovery equipment before servicing or disposing of refrigerators.

- Recycled or reclaimed R134a must meet AHRI Standard 700 specifications for reuse.

5. Certification & Training

- Technicians must hold valid certifications:

- EPA Section 608 Certification (Type I for small appliances) in the U.S.

- F-Gas Certification (EU) for handling fluorinated greenhouse gases.

- Companies must maintain records of technician certifications, refrigerant purchases, and recovery activities.

6. Recordkeeping & Reporting

- Maintain logs of:

- Refrigerant received and used.

- Amounts recovered, recycled, or sent for reclamation.

- Leak inspections and repairs.

- Submit annual reports where required (e.g., under EU F-Gas Regulation for large users).

7. Disposal & End-of-Life Management

- Refrigerators containing R134a must be processed in certified e-waste or refrigerant recovery facilities.

- Refrigerant must be recovered before shredding or disposal.

- Used cylinders should be returned to suppliers or disposed of via hazardous waste programs.

8. Transition to Alternatives

Due to environmental regulations, consider transitioning to lower-GWP refrigerants such as:

– R600a (isobutane) – GWP = 3, used in new domestic refrigerators.

– R1234yf or R1234ze – For certain commercial applications.

Ensure compatibility with existing systems before retrofitting.

Conclusion

Proper logistics and compliance management of R134a in refrigerators is essential to meet environmental regulations, ensure safety, and avoid penalties. As global phase-downs of HFCs continue, businesses should plan for the transition to sustainable refrigerants while maintaining strict adherence to current handling and reporting requirements.

In conclusion, sourcing R134a refrigerant for a refrigerator requires careful consideration of regulatory compliance, environmental impact, equipment compatibility, and supplier reliability. As a widely used HFC refrigerant, R134a is subject to increasing environmental regulations due to its global warming potential (GWP), prompting a gradual phase-down in many regions. It is essential to ensure that any R134a sourced is obtained legally, preferably from certified suppliers, and handled by qualified technicians to comply with EPA or local environmental standards.

Additionally, verifying that R134a is the correct refrigerant for the specific refrigerator model is crucial, as using the wrong refrigerant can lead to inefficiency, system damage, or safety hazards. With the refrigeration industry transitioning toward lower-GWP alternatives such as R1234yf or natural refrigerants, long-term planning should include evaluating the feasibility of upgrading to more sustainable systems.

Ultimately, while R134a remains available for servicing existing equipment, responsible sourcing, proper handling, and staying informed about evolving regulations are key to ensuring both operational effectiveness and environmental stewardship.