The global quicklatch market is experiencing steady expansion, driven by increasing demand across aerospace, automotive, and industrial equipment sectors. According to Mordor Intelligence, the global aircraft latch market—of which quicklatches are a critical component—is projected to grow at a CAGR of over 4.5% from 2024 to 2029, fueled by rising aircraft production and the need for lightweight, reliable fastening solutions. Similarly, Grand View Research reports that the broader mechanical fasteners market was valued at USD 75.6 billion in 2022 and is expected to grow at a CAGR of 6.3% through 2030, reflecting heightened adoption in manufacturing and transportation industries. As operational efficiency and component durability become key priorities, quicklatch manufacturers are innovating to meet stringent performance standards. In this evolving landscape, seven leading companies have emerged for their engineering excellence, product reliability, and global footprint—shaping the future of quick-connect fastening technology.

Top 7 Quicklatch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 3M™ Rugged Comfort Quick Latch Half Facepiece Reusable …

Domain Est. 1988

Website: 3m.com

Key Highlights: Highlights. Quick latch drop-down mechanism allows for easy on and off for moving in and out of contaminated areas without needing to remove a hard hat or ……

#2 Subsea Quick Latch

Domain Est. 1995

Website: nov.com

Key Highlights: The quick latch is hydraulically operated and uses a set of locking dogs to lock the two pieces of equipment together. The locking dogs work independently and ……

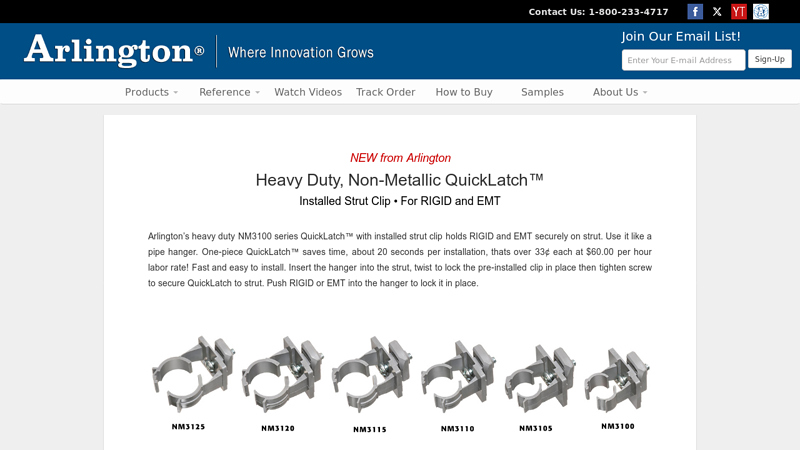

#3 Installed Strut QuickLatch

Domain Est. 1998

Website: aifittings.com

Key Highlights: Use it like a pipe hanger. One-piece QuickLatch™ saves time, about 20 seconds per installation, thats over 33¢ each at $60.00 per hour labor rate! Fast and easy ……

#4 Nm3125 1″ RMC IMC & PVC Quicklatch Hanger

Domain Est. 1998

Website: granitecityelectric.com

Key Highlights: Heavy duty QuickLatch™ with installed strut clip holds 1″ RIGID, IMC, or PVC securely on strut. Use it like a pipe hanger….

#5 Quik Latch

Domain Est. 2009

Website: q-latch.com

Key Highlights: The button stays in the down position until re-latched, and then the button pops back up. No more pins to keep up with! Simple installation with basic tools….

#6 Quik

Domain Est. 2010

Website: quik-latch.com

Key Highlights: The Quik-Latch mini latches are highly effective removable fasteners for body panels, hoods, trunks, and interior compartments….

#7 Arlington Heavy Duty, Non

Domain Est. 2010

Website: electricalindustry.ca

Key Highlights: Arlington’s heavy duty NM3100 series QuickLatch with installed strut clip holds RIGID and EMT securely on strut. Use as you would a pipe hanger….

Expert Sourcing Insights for Quicklatch

H2: 2026 Market Trends for Quicklatch

Based on current technological, economic, and consumer behavior trajectories, the 2026 market landscape for Quicklatch—a manufacturer of innovative fastening and locking solutions—will be shaped by several key trends. These trends present both significant opportunities and competitive challenges, particularly as industries prioritize efficiency, security, and sustainability.

1. Accelerated Adoption of Smart and IoT-Enabled Hardware

By 2026, the integration of IoT (Internet of Things) into physical hardware is expected to be mainstream across sectors like construction, logistics, automotive, and smart homes. Quicklatch is well-positioned to capitalize on this trend by expanding its portfolio of smart latching systems—products equipped with sensors, wireless connectivity (e.g., Bluetooth LE, Zigbee), and remote monitoring capabilities. Demand will grow for latches that offer real-time status updates, access control logging, and integration with broader building or vehicle management systems. Partnerships with IoT platform providers will become essential to ensure compatibility and scalability.

2. Growth in Modular and Lightweight Design Across Industries

Industries such as electric vehicles (EVs), renewable energy installations, and prefabricated construction are increasingly adopting modular and lightweight designs to improve efficiency and reduce costs. Quicklatch can leverage its engineering expertise to develop high-strength, lightweight fastening solutions using advanced materials like aerospace-grade aluminum, composites, or recycled alloys. These products will need to balance durability with ease of installation and reconfiguration—key requirements in modular applications.

3. Emphasis on Sustainability and Circular Economy

Sustainability will be a non-negotiable factor in procurement decisions by 2026. Customers across B2B and B2C segments will demand products with lower carbon footprints, recyclable materials, and longer lifecycles. Quicklatch can differentiate itself by adopting eco-design principles—minimizing material waste in production, using recycled content, and designing for disassembly and reuse. Transparency in supply chain sustainability (e.g., verified low-impact sourcing) will also strengthen brand trust and market access, especially in EU and North American markets with tightening environmental regulations.

4. Rise in Automation and Robotics in Manufacturing and Logistics

As automation expands in warehouses, distribution centers, and production lines, there will be increased demand for fastening systems that support robotic handling, quick-change tooling, and automated assembly processes. Quicklatch can develop latching mechanisms optimized for machine readability (e.g., standardized interfaces, QR-coded components) and high-cycle durability. These innovations will be critical in sectors like e-commerce fulfillment and automated guided vehicles (AGVs), where reliability and speed are paramount.

5. Geopolitical and Supply Chain Resilience

Ongoing supply chain volatility—driven by geopolitical tensions, trade policies, and climate-related disruptions—will push companies toward regionalization and nearshoring. Quicklatch may need to diversify its manufacturing footprint or establish regional production hubs by 2026 to reduce lead times and mitigate risks. Resilient supply chains will also involve digital twin technologies for inventory forecasting and blockchain for traceability, enhancing operational agility.

6. Heightened Cybersecurity Concerns in Connected Devices

As Quicklatch expands into smart locking solutions, cybersecurity will become a critical differentiator. By 2026, customers will expect robust data encryption, secure firmware updates, and compliance with global cybersecurity standards (e.g., ISO/IEC 27001, NIST). Proactive investment in secure-by-design principles and third-party security certifications will be essential to gain market trust and avoid reputational damage from potential breaches.

Strategic Implications for Quicklatch

To thrive in the 2026 market, Quicklatch should focus on:

– Prioritizing R&D in smart, connected fastening systems.

– Building strategic partnerships with IoT platforms and automation providers.

– Strengthening sustainability credentials through transparent reporting and eco-innovation.

– Investing in agile, resilient supply chains with regional flexibility.

– Enhancing cybersecurity infrastructure for digital products.

In conclusion, the 2026 market will reward innovation, adaptability, and sustainability. Quicklatch’s ability to align its product development and business model with these macro-trends will determine its competitive edge and long-term growth potential.

Common Pitfalls Sourcing Quicklatch (Quality, IP)

When sourcing Quicklatch components—whether for integration into larger systems or as standalone products—organizations often encounter significant challenges related to quality assurance and intellectual property (IP) risks. Being aware of these pitfalls is crucial to avoiding costly disruptions, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Manufacturing Standards

Quicklatch mechanisms often require precision engineering to ensure reliable performance and safety. Sourcing from suppliers with inconsistent quality control processes can result in variations in material strength, dimensional accuracy, or durability. This inconsistency may lead to premature failure, especially in high-cycle or safety-critical applications.

Lack of Certification and Testing

Many Quicklatch applications—particularly in aerospace, automotive, or medical industries—require compliance with strict industry standards (e.g., ISO, AS9100, or MIL-SPEC). Suppliers may claim compliance without proper certification, exposing buyers to regulatory and safety risks. Always verify test reports and audit supplier quality management systems.

Use of Substandard Materials

To reduce costs, some suppliers may substitute specified materials (e.g., using inferior-grade stainless steel or plastics). This compromises corrosion resistance, load capacity, and long-term reliability. Ensure material certifications (e.g., mill test reports) are provided and validated.

Intellectual Property (IP) Risks

Unauthorized Replication or Counterfeiting

Quicklatch designs may be protected under patents, trademarks, or design rights. Sourcing from unauthorized manufacturers or regions with weak IP enforcement increases the risk of purchasing counterfeit or infringing products. This can lead to legal liability, product recalls, or import bans.

Unclear IP Ownership in Custom Designs

When working with suppliers to develop custom Quicklatch solutions, failure to clearly define IP ownership in contracts can result in disputes. Suppliers may claim rights to design improvements or reuse your specifications for other clients, undermining your competitive advantage.

Reverse Engineering by Suppliers

Some overseas manufacturers may reverse engineer provided samples or technical drawings and sell similar products to competitors. Non-disclosure agreements (NDAs) and robust contractual safeguards are essential to protect proprietary designs.

Inadequate Due Diligence on Supplier Legitimacy

Failing to vet suppliers’ legal standing and IP compliance history can expose companies to infringement claims. Conduct thorough background checks and request proof of licensing for patented technologies.

Mitigation Strategies

To avoid these pitfalls:

– Perform on-site audits or third-party inspections of supplier facilities.

– Require full documentation, including material certifications, test reports, and compliance certificates.

– Conduct IP clearance searches before sourcing.

– Use legally binding agreements that clearly define IP ownership, confidentiality, and compliance obligations.

– Partner with reputable suppliers who have a proven track record and transparent supply chains.

Proactively addressing quality and IP concerns ensures reliable performance and protects your business from legal and operational risks when sourcing Quicklatch components.

Logistics & Compliance Guide for Quicklatch

This guide outlines the logistics processes and compliance requirements for Quicklatch, ensuring efficient operations and adherence to applicable regulations.

Order Fulfillment Process

Quicklatch follows a streamlined fulfillment workflow:

1. Orders are processed within 24 hours of receipt.

2. Inventory is picked, packed, and quality-checked at our central warehouse.

3. Packages are shipped via approved carriers with tracking enabled.

4. Customers receive automated shipment notifications with tracking details.

Shipping & Delivery Standards

We maintain consistent shipping protocols:

– Standard delivery: 3–5 business days within domestic markets.

– International shipping: 7–14 business days, subject to destination and customs clearance.

– All shipments include tamper-evident packaging and handling labels where required.

– Carrier partnerships are regularly audited for reliability and compliance.

Inventory Management

Quicklatch ensures inventory accuracy and availability through:

– Real-time inventory tracking via our WMS (Warehouse Management System).

– Monthly cycle counts and annual physical audits.

– Safety stock levels established based on demand forecasting.

– Obsolete or expired stock is flagged and disposed of per environmental regulations.

Regulatory Compliance

Quicklatch complies with all relevant local, national, and international regulations:

– Product Safety: All products meet ISO 9001 and CE marking requirements.

– Export Controls: Shipments to restricted regions follow EAR and ITAR guidelines where applicable.

– Labeling & Documentation: Product labeling includes multilingual safety warnings, serial numbers, and compliance marks.

– RoHS & REACH: Materials used in manufacturing comply with EU environmental directives.

Customs & International Trade

For international logistics:

– Accurate HS codes are assigned to all products.

– Commercial invoices, packing lists, and certificates of origin are prepared for each export.

– Incoterms (typically FOB or DAP) are clearly defined in sales contracts.

– Customs brokers are utilized to facilitate smooth clearance.

Data Privacy & Security

Logistics data is protected in accordance with:

– GDPR for EU customer information.

– CCPA for California residents.

– Secure storage and transmission of order and shipment data via encrypted systems.

– Access restricted to authorized personnel only.

Returns & Reverse Logistics

Our returns policy ensures compliance and efficiency:

– Returns accepted within 30 days with prior authorization (RMA required).

– Inspected for damage, tampering, or misuse upon receipt.

– Refunds or replacements processed within 5 business days of inspection.

– Recycled or refurbished items handled per WEEE regulations.

Sustainability Practices

Quicklatch is committed to sustainable logistics:

– Packaging is 100% recyclable and sourced from certified sustainable suppliers.

– Carbon emissions from shipping are monitored and offset through verified programs.

– Route optimization reduces fuel consumption and delivery times.

Compliance Audits & Training

To maintain standards:

– Quarterly internal audits of logistics operations.

– Annual third-party compliance reviews.

– Mandatory training for logistics staff on safety, security, and regulatory updates.

For questions or reporting compliance concerns, contact [email protected].

In conclusion, sourcing Quicklatch components requires a strategic approach that balances quality, cost, reliability, and lead times. Evaluating potential suppliers based on certifications, production capabilities, and track record ensures consistent performance and adherence to industry standards. Engaging with suppliers who offer technical expertise and responsive support adds value beyond just procurement. Establishing long-term partnerships, considering total cost of ownership, and maintaining supply chain resilience are key to successfully integrating Quicklatch solutions into your operations. With careful due diligence and proactive supply chain management, sourcing Quicklatch can contribute significantly to operational efficiency and product reliability.