The global quick release mechanism market is experiencing robust growth, driven by rising demand across aerospace, automotive, industrial automation, and outdoor equipment sectors. According to Mordor Intelligence, the global couplings market—of which quick release mechanisms are a critical component—is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by increasing automation, the need for rapid equipment maintenance, and the adoption of modular systems in manufacturing. Additionally, Grand View Research estimates that the global pneumatic components market, a key application area for quick release fittings, will expand at a CAGR of 5.2% from 2023 to 2030, underpinned by advancements in factory automation and compressed air systems. As industries prioritize efficiency and safety, quick release mechanisms have evolved into mission-critical components. This growing demand has propelled innovation and competition among manufacturers, resulting in highly reliable, durable, and application-specific solutions. The following list identifies the top 9 quick release mechanism manufacturers leading this transformation through technological advancement, global reach, and strong performance metrics.

Top 9 Quick Release Mechanism Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Hammar H20

Domain Est. 1996

Website: cmhammar.com

Key Highlights: Hammar produces the release mechanism for many of the world’s EPIRB manufacturers. The EPIRB manufacturers, in many cases, produce their own bolts, and the ……

#2 Quick Release Coupling Manufacturers Suppliers

Domain Est. 2002

Website: quickdisconnectcouplings.com

Key Highlights: Explore a comprehensive selection of quick release coupling manufacturers and suppliers renowned for their reliable products….

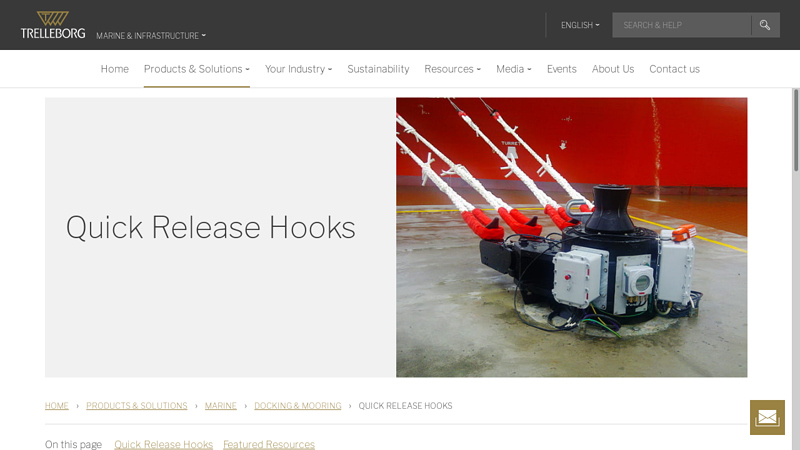

#3 Quick Release Hooks

Domain Est. 1996

Website: trelleborg.com

Key Highlights: Trelleborg’s QRHs enable mooring lines to be safely secured, quickly and easily released even when loaded to their safe working load limit….

#4 Quick Release Clamp

Domain Est. 1996

Website: dwk.com

Key Highlights: The quick release clamp allows the quick and secure fastening of flat flange vessels and lids. Slipping or accidental opening of the joint is not possible. The ……

#5 Custom actuators and release mechanisms

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton’s release mechanisms utilize non-explosive actuators to provide rapid releases with low-power consumption across a wide range of operating temperatures….

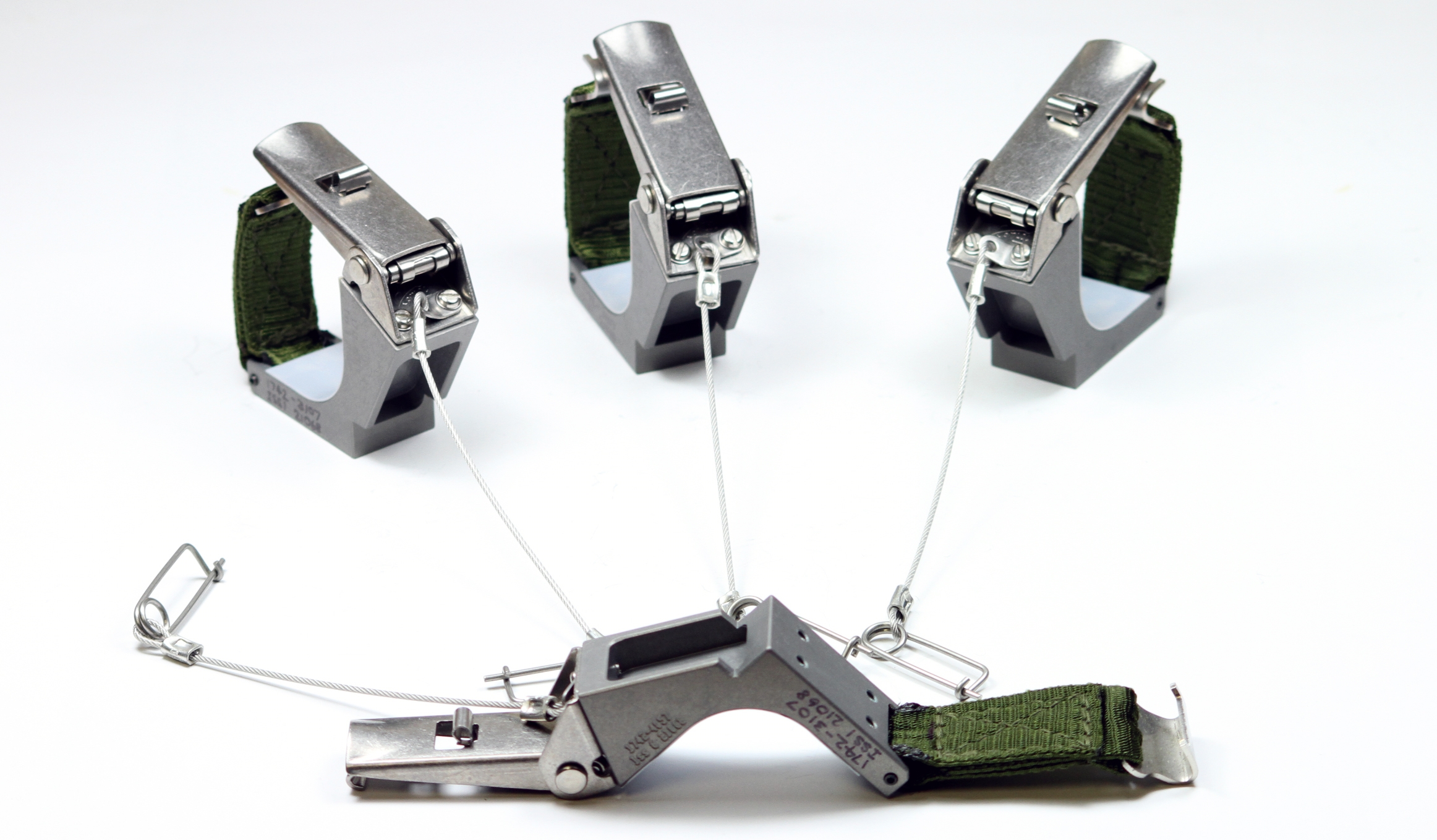

#6 Sea Catch Toggle Release

Domain Est. 1998

Website: seacatch.com

Key Highlights: The Sea Catch toggle release is a mechanical quick release designed exclusively for releasing an object or line under load. (253) 858-1985….

#7 Faster

Domain Est. 2015 | Founded: 1951

Website: fastercouplings.com

Key Highlights: Faster is a worldwide leader in couplings since 1951. Our production of couplings, hydraulic components is completely Made in Italy….

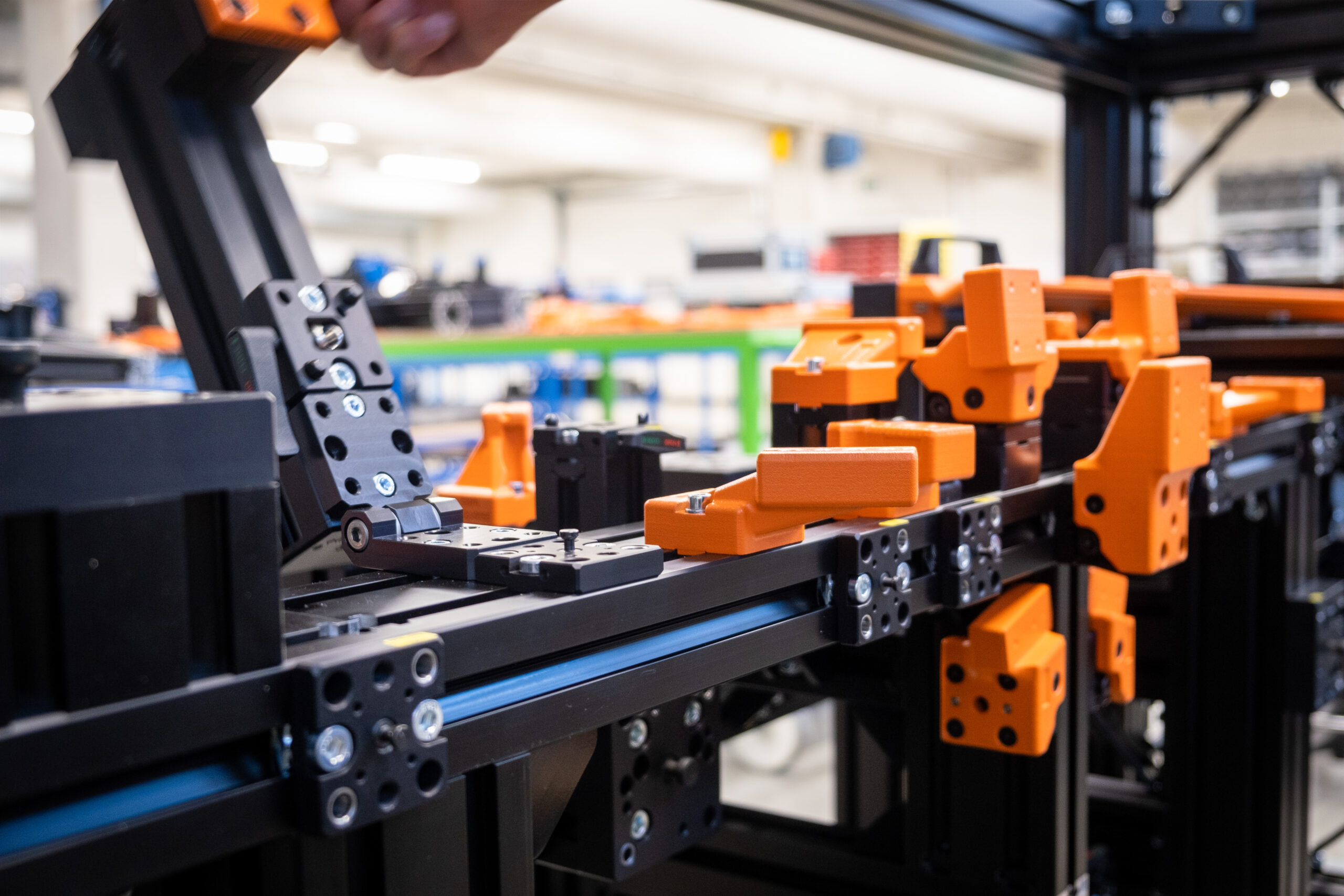

#8 Bespoke Quick Release Mechanisms

Domain Est. 2016

Website: clarendonsf.com

Key Highlights: Clarendon Specialty Fasteners manufacture bespoke Quick Release Mechanisms for a variety of non-standard applications. Designed and engineering from our ……

#9 OTH Pioneer Rigging

Domain Est. 2021

Website: othrigging.com

Key Highlights: These remote controlled hooks eliminate safety incidents and reduce your overall costs. More money in your pocket. This system pays for itself….

Expert Sourcing Insights for Quick Release Mechanism

H2: 2026 Market Trends for Quick Release Mechanisms

The global market for quick release mechanisms is poised for significant evolution by 2026, driven by technological innovation, expanding applications, and shifting industrial demands. These mechanical components—designed to allow rapid attachment and detachment of parts without tools—are becoming increasingly vital across multiple sectors, including automotive, aerospace, industrial automation, outdoor equipment, and medical devices. The following trends are expected to shape the quick release mechanism market in 2026:

-

Growth in Automation and Robotics

The rising adoption of automation in manufacturing and logistics is fueling demand for reliable and efficient quick release systems. In robotic arms and end-effectors, quick release mechanisms enable rapid tool changes, improving operational flexibility and reducing downtime. By 2026, advancements in modular robotics and collaborative robots (cobots) will further integrate smart quick release solutions with sensors and IoT connectivity for real-time performance monitoring. -

Lightweight and High-Strength Materials

As industries prioritize weight reduction without compromising strength, manufacturers are turning to advanced materials such as high-grade aluminum alloys, titanium, and composite polymers. These materials enhance the durability and performance of quick release mechanisms, particularly in aerospace and automotive applications where performance and safety are critical. -

Integration with Smart Technologies

The trend toward Industry 4.0 and smart manufacturing is leading to the development of intelligent quick release systems. By 2026, expect increased integration with electronic locking indicators, RFID tagging, and wireless diagnostics. These features improve traceability, maintenance scheduling, and operational safety, especially in complex industrial environments. -

Expansion in Consumer and Recreational Markets

Quick release mechanisms are gaining popularity in consumer-driven sectors such as outdoor gear (e.g., hiking backpacks, camera mounts, bicycles), sports equipment, and modular furniture. The demand for user-friendly, tool-free solutions continues to grow, pushing manufacturers to design intuitive and aesthetically pleasing mechanisms. -

Sustainability and Design for Recyclability

Environmental regulations and corporate sustainability goals are influencing product design. By 2026, manufacturers will increasingly prioritize recyclable materials and designs that facilitate disassembly for end-of-life recycling, aligning with circular economy principles. -

Regional Market Shifts

Asia-Pacific, led by China, India, and Southeast Asia, is expected to dominate market growth due to expanding manufacturing bases and rising investments in automation. Meanwhile, North America and Europe will maintain strong demand driven by high-tech industries and stringent safety standards. -

Customization and Modular Solutions

End-users are demanding more customized and modular quick release systems tailored to specific applications. This trend is pushing suppliers to offer configurable platforms that support rapid prototyping and scalable production.

In conclusion, the 2026 market for quick release mechanisms will be defined by innovation, intelligence, and adaptability. Companies that invest in R&D, embrace digital integration, and respond to sustainability demands will be best positioned to capitalize on emerging opportunities across diverse industries.

Common Pitfalls When Sourcing a Quick Release Mechanism (Quality and IP)

Poor Quality Due to Inadequate Material Selection

One frequent issue when sourcing quick release mechanisms is the use of substandard materials that compromise durability and safety. Suppliers may opt for lower-grade metals or plastics to cut costs, leading to premature wear, failure under load, or susceptibility to environmental factors like corrosion or temperature fluctuations. Without clear material specifications and rigorous quality checks, buyers risk receiving components that do not meet performance requirements.

Insufficient Testing and Certification

Many sourced quick release mechanisms lack proper functional testing or third-party certification, especially when procured from low-cost manufacturers. Without verification of load capacity, cycle life, or safety standards compliance (e.g., ISO, ANSI, or CE), the mechanism may fail in critical applications. Relying solely on supplier claims without independent validation increases the risk of field failures.

Lack of Design Standardization and Interchangeability

Sourcing from multiple or non-specialized suppliers can result in inconsistent designs, making replacement or integration difficult. Non-standard dimensions, thread types, or actuation forces can lead to incompatibility with existing systems. This undermines the reliability and serviceability of equipment that depends on quick release functionality.

Infringement of Intellectual Property (IP) Rights

A significant legal risk arises when sourcing mechanisms that replicate patented designs without authorization. Some suppliers, particularly in regions with lax IP enforcement, may produce near-identical copies of proprietary quick release systems. Purchasing such components can expose the buyer to infringement claims, supply chain disruptions, or reputational damage.

Inadequate Documentation and Traceability

Missing or incomplete technical documentation—such as engineering drawings, material certifications, or test reports—hinders quality assurance and traceability. Without these, it becomes difficult to verify compliance, replicate the part, or conduct root cause analysis in case of failure. This also complicates efforts to protect or defend against IP challenges.

Hidden Tooling and Reverse Engineering Risks

When working with contract manufacturers, there’s a risk that molds, jigs, or design data could be retained or duplicated without permission. This enables unauthorized production and creates potential IP leakage. Buyers may unknowingly lose control over their proprietary designs, especially when non-disclosure agreements (NDAs) or IP assignment clauses are weak or absent.

Overlooking Regulatory and Industry-Specific Requirements

Certain industries (e.g., aerospace, medical, or automotive) have strict regulatory standards for mechanical components. Sourcing a generic quick release mechanism without ensuring compliance with these sector-specific requirements can lead to product recalls, certification delays, or safety incidents.

Logistics & Compliance Guide for Quick Release Mechanism

This guide outlines the essential logistics and compliance considerations for the handling, transportation, and regulatory adherence of Quick Release Mechanisms (QRMs). QRMs are critical safety devices used in marine, aerospace, industrial, and emergency applications, requiring strict control throughout the supply chain.

Regulatory Compliance

Quick Release Mechanisms are subject to various national and international regulations due to their safety-critical nature. Compliance ensures reliability and legal operation.

- Marine Applications: QRMs used in lifeboats and davits must comply with International Maritime Organization (IMO) standards, particularly the Life-Saving Appliances (LSA) Code. Certification from classification societies (e.g., DNV, ABS, LR) is mandatory.

- Aerospace & Defense: QRMs in aircraft or military vehicles must meet FAA, EASA, or MIL-STD requirements. Documentation such as Technical Standard Orders (TSOs) or Qualified Products Lists (QPLs) may be required.

- Industrial & Rail: Compliance with ISO standards (e.g., ISO 13850 for emergency stop functions) and regional directives such as the EU Machinery Directive 2006/42/EC is essential.

- Documentation: Maintain up-to-date Certificates of Conformity (CoC), Declaration of Conformity (DoC), and test reports. Traceability records (batch/serial numbers, material certifications) must be preserved for audits.

Packaging and Handling

Proper packaging and handling prevent damage and preserve the functional integrity of QRMs during storage and transit.

- Protective Packaging: Use anti-static, moisture-resistant materials for electronic components. Mechanical QRMs should be individually boxed with cushioning to prevent shock or vibration damage.

- Environmental Protection: Store and transport QRMs in dry, temperature-controlled environments (typically 15°C to 30°C). Avoid exposure to corrosive chemicals, salt spray, or extreme humidity.

- Handling Procedures: Use clean gloves to prevent contamination. Do not disassemble or adjust mechanisms unless performed by certified personnel. Clearly label units as “Fragile” and “Do Not Drop.”

Transportation Requirements

Transport regulations vary based on the QRM’s components and destination.

- Hazardous Materials: If QRMs contain pyrotechnic or pressurized elements (e.g., in emergency release systems), they may be classified under ADR, IMDG, or IATA Dangerous Goods Regulations. Proper UN classification, labeling, and documentation are mandatory.

- Non-Hazardous Shipments: Standard commercial carriers may be used, but shock and tilt monitoring devices are recommended for high-value or sensitive units.

- Export Controls: QRMs with dual-use potential (e.g., military or aerospace) may be subject to export control regimes such as ITAR (U.S.) or EU Dual-Use Regulation. Obtain necessary export licenses before international shipment.

Inventory and Traceability

Robust inventory management ensures product authenticity and supports recalls or audits.

- Serial Number Tracking: Assign unique serial numbers to each QRM and record in a centralized database. Include manufacturing date, location, and final destination.

- Batch Control: Maintain lot traceability for raw materials and sub-components, especially for mechanisms used in regulated industries.

- Storage Conditions: Store in secure, access-controlled areas with climate monitoring. Rotate stock using FIFO (First In, First Out) to avoid obsolescence.

Installation and Field Compliance

End-user compliance is critical for operational safety and regulatory adherence.

- Certified Installation: Only trained and authorized personnel should install or maintain QRMs. Follow manufacturer’s installation manuals and torque specifications.

- Inspection and Maintenance: Adhere to scheduled inspections and functional tests as defined by OEM and regulatory bodies. Document all service activities.

- Recall Management: Establish a process to quickly communicate and act on product recalls or field safety notices. Maintain contact records for all customers and distributors.

Documentation and Record Retention

Comprehensive records support compliance, warranty claims, and incident investigations.

- Required Documents: Retain for minimum 10 years (or as per jurisdiction): manufacturing records, test results, CoC/DoC, shipping logs, calibration certificates, and customer delivery confirmations.

- Digital Archiving: Store electronic copies in secure, backed-up systems with access controls and audit trails.

By following this guide, organizations can ensure the safe, compliant, and efficient logistics management of Quick Release Mechanisms across their lifecycle.

Conclusion:

In evaluating options for sourcing a quick release mechanism, it is clear that selecting the appropriate supplier and design is critical to ensuring safety, reliability, and performance in the intended application. Key factors such as material quality, load capacity, ease of use, environmental resistance, and compliance with industry standards must be carefully considered. After assessing various suppliers, both domestic and international, a balance between cost-efficiency and product reliability must be achieved. Established manufacturers with a proven track record, certifications, and robust quality control processes offer the best assurance of long-term performance. Ultimately, investing in a high-quality quick release mechanism from a reputable source not only enhances operational efficiency but also minimizes risks associated with mechanical failure. Therefore, the recommended approach is to partner with a trusted supplier that offers technical support, customization options, and post-sale service to ensure optimal integration and sustained performance.