The global quartz composition market has experienced robust growth, driven by rising demand for durable, low-maintenance materials in construction, architecture, and interior design. According to Grand View Research, the global engineered quartz market size was valued at USD 5.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This expansion is fueled by increasing residential and commercial infrastructure development, particularly in emerging economies, as well as the material’s superior performance characteristics—such as stain resistance, non-porosity, and design versatility—compared to natural stone alternatives. As sustainability and aesthetic consistency become key purchasing criteria, leading manufacturers are investing heavily in R&D and production capacity to meet rising global demand. In this evolving landscape, a select group of companies have emerged as dominant players, combining innovation, scale, and product diversification to capture significant market share. Here, we present the top 10 quartz composition manufacturers shaping the industry’s future.

Top 10 Quartz Composition Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quantra quartz. The toughest, most beautiful quartz surfaces in the …

Domain Est. 2009

Website: quantra.in

Key Highlights: Quantra® is a leading manufacturer of quartz surfaces. Buy Quartz stone countertops, sinks, basins, shower trays. Contact us now!…

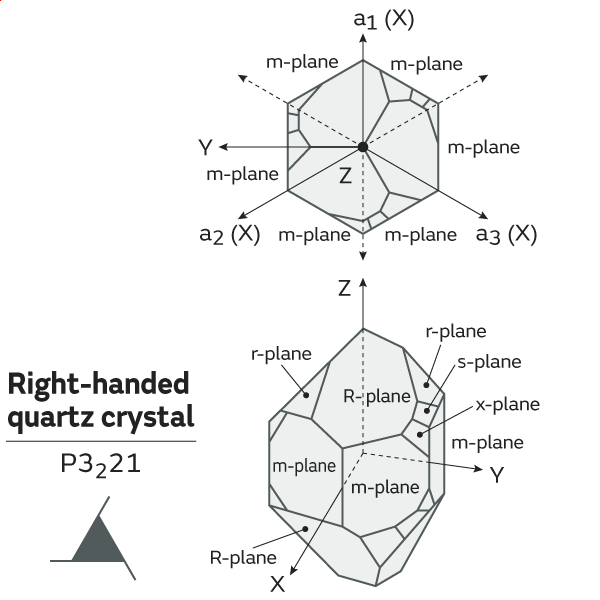

#2 Basic knowledge of optical devices

Domain Est. 1994

Website: murata.com

Key Highlights: The chemical formula for quartz crystals is SiO2. Quartz crystals are trigonal system crystals. Incidentally, quartz glass, which is also SiO2, is amorphous ……

#3 SM Quartz: quartz surfaces

Domain Est. 1998

Website: santamargherita.net

Key Highlights: SM Quartz products offer a large choice of colors, textures and exclusive finishes. Nuances, composition and sizes can be fully customized. Waterjet cutting and ……

#4 Production of Quartzforms® quartz composite

Domain Est. 2002

Website: quartzforms.com

Key Highlights: Quartzforms® is a quartz composite produced by the exclusive Bretonstone ® process. Discover its composition, warranties, qualities and certifications….

#5 Belenco Quartz Surfaces. Breton factories Turkey

Domain Est. 2010

Website: belenco.com

Key Highlights: We combine the quartz durability and elegance with unique designs, converting them into high quality surfaces at our factories equipped by the state-of-the-art ……

#6 High Purity Quartz

Domain Est. 2011

Website: thequartzcorp.com

Key Highlights: A material ideally suited for high-tech manufacturing. High purity quartz sand has the distinct physical properties to become a successful crucible. Quartz ……

#7 PentalQuartz® Countertop Collections Online

Domain Est. 2019

Website: arcsurfaces.com

Key Highlights: What is the composition of PentalQuartz? Depending on the color, PentalQuarz is made from approximately 90–93% natural quartz crystals, along with resins ……

#8 Fused Quartz

Domain Est. 2020

Website: momentivetech.com

Key Highlights: Momentive Technologies offers a comprehensive range of high-purity fused quartz products designed to meet the rigorous demands of today’s industries….

#9 What is Quartz? Discover premium quartz from Phenikaa Hue

Website: phenikaahue.com

Key Highlights: Paint products containing quartz offer superior color durability and excellent resistance to harsh weather conditions, making them ideal for exterior paints, ……

#10 Best Quartz Stone Manufacturers in India

Domain Est. 2022

Website: miraaksurfaces.com

Key Highlights: Explore Miraak Surfaces, the best quartz stone manufacturers in India. Discover premium engineered stone, quartz countertops, and quartz marble surfaces….

Expert Sourcing Insights for Quartz Composition

H2: Market Trends for Quartz Composition in 2026

As we approach 2026, the global market for quartz composition—particularly engineered quartz used in construction, interior design, and industrial applications—is poised for significant evolution driven by technological innovation, sustainability demands, and shifting consumer preferences. Below are the key trends shaping the quartz composition market in 2026:

1. Surge in Sustainable and Recycled Materials

Environmental consciousness continues to influence material selection across industries. By 2026, manufacturers are increasingly incorporating recycled quartz, post-industrial waste, and bio-based resins into engineered quartz slabs. Leading companies are highlighting low-carbon production processes and achieving environmental certifications (e.g., NSF, Greenguard), responding to green building standards like LEED and BREEAM. This trend is especially strong in North America and Western Europe.

2. Expansion of Ultra-Premium and Customizable Designs

Homeowners and designers are demanding more personalized, high-end aesthetics. In 2026, the market sees a rise in quartz products with advanced digital printing, textured surfaces, matte finishes, and hyper-realistic patterns mimicking natural stone, concrete, or even wood. Brands are leveraging AI-driven design tools to offer made-to-order color and pattern options, enhancing appeal in luxury residential and hospitality sectors.

3. Growth in Asian and Middle Eastern Markets

While North America and Europe remain dominant, Asia-Pacific—especially China, India, and Southeast Asia—is experiencing rapid urbanization and rising disposable incomes, fueling demand for durable, low-maintenance surfacing solutions. The Middle East also shows strong growth due to large-scale infrastructure and real estate developments. Local production hubs are emerging to reduce import dependency and logistics costs.

4. Technological Advancements in Manufacturing

By 2026, automation, AI-driven quality control, and IoT-enabled production lines are standard in major quartz manufacturing facilities. These technologies improve consistency, reduce waste, and enable faster turnaround. Additionally, innovations in resin formulations enhance heat and scratch resistance, broadening quartz’s application beyond countertops into flooring, wall cladding, and even furniture.

5. Competitive Pressure and Consolidation

The quartz market is becoming increasingly competitive, with both multinational giants (e.g., Caesarstone, Silestone, Cambria) and regional players vying for market share. Price pressures and the need for R&D investment are driving mergers and acquisitions, particularly among mid-sized manufacturers aiming to scale sustainably and expand distribution networks.

6. Shift Toward Health and Hygiene-Centric Features

Post-pandemic consumer behavior continues to emphasize cleanliness and hygiene. Quartz brands are launching antimicrobial surface treatments and non-porous finishes that resist mold, bacteria, and stains—features particularly valued in kitchens, healthcare facilities, and commercial spaces.

7. Regulatory and Raw Material Challenges

Supply chain volatility, especially concerning resin (derived from petrochemicals) and high-purity silica, remains a concern. Geopolitical factors and fluctuating energy prices may impact production costs. In response, companies are investing in alternative binding agents and localized sourcing strategies to mitigate disruptions.

Conclusion

By 2026, the quartz composition market is characterized by innovation, sustainability, and globalization. As consumer expectations rise and environmental regulations tighten, the industry is adapting through technological advancement and strategic diversification. Companies that prioritize eco-friendly production, design flexibility, and emerging market penetration are likely to lead the next phase of growth in the engineered quartz sector.

Common Pitfalls in Sourcing Quartz Compositions (Quality, IP)

Sourcing Quartz Compositions—especially for use in macOS applications—can introduce several challenges related to both quality and intellectual property (IP). Being aware of these pitfalls can help developers and organizations avoid technical issues, legal risks, and project delays.

Poor Quality or Outdated Compositions

Many Quartz Compositions available online are created by hobbyists or shared without thorough testing. These may suffer from performance issues, visual glitches, or compatibility problems with newer macOS versions. Relying on low-quality compositions can degrade user experience and require significant debugging or rework.

Lack of Documentation and Support

Sourced compositions often come with minimal or no documentation. Without clear instructions on inputs, parameters, or usage, integrating them into a project becomes time-consuming. Additionally, absent support channels make troubleshooting difficult when issues arise.

Compatibility Issues

Quartz Compositions may be built for specific versions of Quartz Composer (now deprecated) or certain hardware configurations. They might not function correctly in modern development environments or with current rendering frameworks like Metal, leading to unexpected crashes or rendering artifacts.

Intellectual Property (IP) Risks

Many compositions are shared without clear licensing terms. Using such assets without proper rights can lead to IP infringement, especially if the composition contains copyrighted visual elements, audio, or code derived from proprietary sources. Always verify the license—preferably using permissively licensed (e.g., MIT, BSD) or public domain resources.

Hidden Dependencies or External Resources

Some compositions rely on external image files, movie clips, or plugins that are not included in the distribution. Missing these dependencies can break functionality, and tracking them down may be difficult or violate usage rights.

Security Vulnerabilities

Quartz Compositions can execute JavaScript or interact with system resources. Sourcing untrusted compositions may introduce security risks, such as code injection or unauthorized access to user data, particularly if used in sandboxed applications.

No Long-Term Maintenance

Since Apple deprecated Quartz Composer, community support and updates are limited. Sourced compositions may not be maintained, making them unsuitable for long-term projects that require scalability or future macOS compatibility.

Best Practices to Avoid Pitfalls

- Always verify the source and license of any Quartz Composition.

- Prefer compositions from reputable repositories or creators with clear documentation.

- Test thoroughly in your target environment before integration.

- When possible, create or commission custom compositions to ensure quality and IP safety.

Logistics & Compliance Guide for Quartz Composition

Material Overview

Quartz composition refers to engineered stone products made primarily from ground natural quartz crystals (typically 90–95%) bound with resins, pigments, and other additives. These materials are widely used in countertops, flooring, and wall cladding due to their durability, aesthetic appeal, and resistance to stains and scratches. Proper logistics and compliance protocols are essential to ensure safe handling, environmental responsibility, and adherence to regulatory standards throughout the supply chain.

Regulatory Compliance

Engineered quartz products must comply with regional and international regulations governing material safety, emissions, and workplace health. Key compliance requirements include:

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals – ensures safe use of chemical components, especially resins and binders.

– LEED Certification (U.S.): Compliance with low-VOC (volatile organic compound) emissions standards may contribute to sustainable building credits.

– OSHA & GHS (Global): Employers must provide Safety Data Sheets (SDS) and ensure worker protection during fabrication, especially regarding silica dust exposure.

– California Proposition 65: Requires warnings if products contain chemicals known to cause cancer or reproductive harm, such as crystalline silica.

Transportation & Handling

Proper handling minimizes damage and ensures worker safety during transit and storage:

– Packaging: Quartz slabs must be vertically stored and secured with edge protectors and wooden crating to prevent chipping or cracking.

– Loading/Unloading: Use forklifts or slab vacuum lifters; never drag or lay slabs flat unless specifically designed for horizontal storage.

– Environmental Conditions: Store in dry, temperature-controlled environments to prevent resin degradation or warping. Avoid exposure to prolonged UV light.

Dust & Silica Exposure Management

Cutting, grinding, or polishing quartz generates respirable crystalline silica, a known carcinogen:

– Engineering Controls: Use water suppression systems and local exhaust ventilation (LEV) during fabrication.

– Personal Protective Equipment (PPE): Workers must wear NIOSH-approved respirators (N95 or higher), safety goggles, and protective clothing.

– Air Monitoring: Conduct regular air quality testing to ensure silica levels remain below OSHA’s Permissible Exposure Limit (PEL) of 50 µg/m³ (8-hour TWA).

– Training: Provide mandatory training on silica hazards and safe work practices per OSHA 29 CFR 1910.1053.

Environmental & Disposal Compliance

Waste generated during quartz processing must be managed responsibly:

– Slurry Waste: Collected slurry from wet cutting contains silica and resin residues; dispose of as non-hazardous solid waste per local regulations, or recycle through approved reprocessing facilities.

– Unused Materials: Leftover slabs or offcuts may be repurposed or donated; avoid landfill disposal where possible.

– Chemical Waste: Spent resins or contaminated cleaning agents must be handled as hazardous waste if classified as such under RCRA (U.S.) or equivalent frameworks.

Certification & Documentation

Maintain comprehensive records to demonstrate compliance:

– Safety Data Sheets (SDS) for all resins, adhesives, and additives used.

– Product test reports for VOC emissions (e.g., Greenguard Gold certification).

– Worker training logs and exposure monitoring records.

– Proof of proper waste disposal, including manifests and facility certifications.

Import/Export Considerations

Global trade of quartz products may require adherence to additional standards:

– Customs Documentation: Accurate HS codes (e.g., 6810.19 for artificial stone) and commercial invoices.

– Tariff & Duties: Monitor trade agreements and anti-dumping regulations, especially for products originating from regions like China or India.

– Phytosanitary & Packaging Rules: Wooden crates must comply with ISPM 15 for international shipments.

Adhering to this guide ensures safe, legal, and sustainable movement and use of quartz composition materials across the supply chain.

Conclusion for Sourcing Quartz Composition:

Sourcing quartz composition is a critical step in ensuring the quality, performance, and consistency of materials used across various industries, including construction, electronics, and renewable energy. High-purity quartz with consistent compositional properties is essential for applications requiring thermal stability, chemical resistance, and electrical insulation. A thorough evaluation of the geological origin, mineral impurities, trace elements, and processing methods allows manufacturers to select the most suitable quartz sources tailored to their specific needs. Additionally, reliable supply chains and sustainable sourcing practices are increasingly important to support long-term project viability and environmental responsibility. Ultimately, strategic sourcing of quartz composition not only enhances end-product reliability but also contributes to operational efficiency and competitive advantage in the global market.