The global pyrography and engraving tools market has seen steady growth, driven by rising interest in artisanal crafts and the increasing adoption of precision tools in small-scale manufacturing and hobbyist communities. According to a report by Grand View Research, the global soldering equipment market was valued at USD 1.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. While this broader category includes industrial applications, the niche segment for creative tools—such as pyrography soldering irons—has also expanded alongside growing consumer engagement in woodworking, DIY crafts, and personalized gift-making.

This surge in demand has catalyzed innovation among manufacturers focusing on temperature control, ergonomic design, and versatility in tip configurations. As the market becomes more competitive, a select group of companies are emerging as leaders—combining technical precision with user-centric design. Based on product quality, market presence, and customer reviews, here are the top 8 pyrography soldering iron manufacturers shaping the industry today.

Top 8 Pyrography Soldering Iron Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Yihua Factory

Domain Est. 2011

Website: yihua-gz.com

Key Highlights: Yihua as a company with over twenty-three years of experience in manufacturing soldering station ,rework station ,soldering iron ,wood burning tools ,car ……

#2 YiHua Company

Domain Est. 2013

Website: yihua-soldering.com

Key Highlights: Our company is a Chinese soldering rework station supplier. It manufactures hot air rework station, lead free soldering station, DC power supply, soldering ……

#3 Top Pyrography Tool Supplier & Manufacturer in China

Domain Est. 2023

Website: zhongdisolder.com

Key Highlights: With our durable and easy-to-use pyrography pens, you can easily create intricate designs, patterns, and text onto various surfaces with precision and accuracy….

#4 Woodburning

Domain Est. 1997

Website: treelineusa.com

Key Highlights: 30-day returnsTreeline carries complete woodburning kits, individual wood burning pens, and all kinds of pyrography accessories….

#5 Woodburning project kit

Domain Est. 2010

Website: weller-tools.com

Key Highlights: The Weller WLPROWB128A 28-piece Create Your Own Woodburning Project Kit inspires creativity with everything you need to begin your journey as a woodburning ……

#6 SOLDERING IRON, PYROGRAPHY FOR WOOD AND LEATHER …

Domain Est. 2011

Website: ewimax.pl

Key Highlights: In stockWood soldering iron so-called. dEDRA DED7544 pyrograph is a device with which we can not only connect wires, cables or solder integrated elements in ……

#7 Leather Pyrography Pen Battery Operated sold by A

Domain Est. 2014

Website: gas-tool.com

Key Highlights: Leather Pyrography Pen is a good soldering iron to field service repair on small parts and components. Also great working at light duty jobs….

#8 ZONEPACK Pyrography Soldering Iron Set for Wood Burning & Foil …

Domain Est. 2018

Expert Sourcing Insights for Pyrography Soldering Iron

H2: 2026 Market Trends for Pyrography Soldering Irons

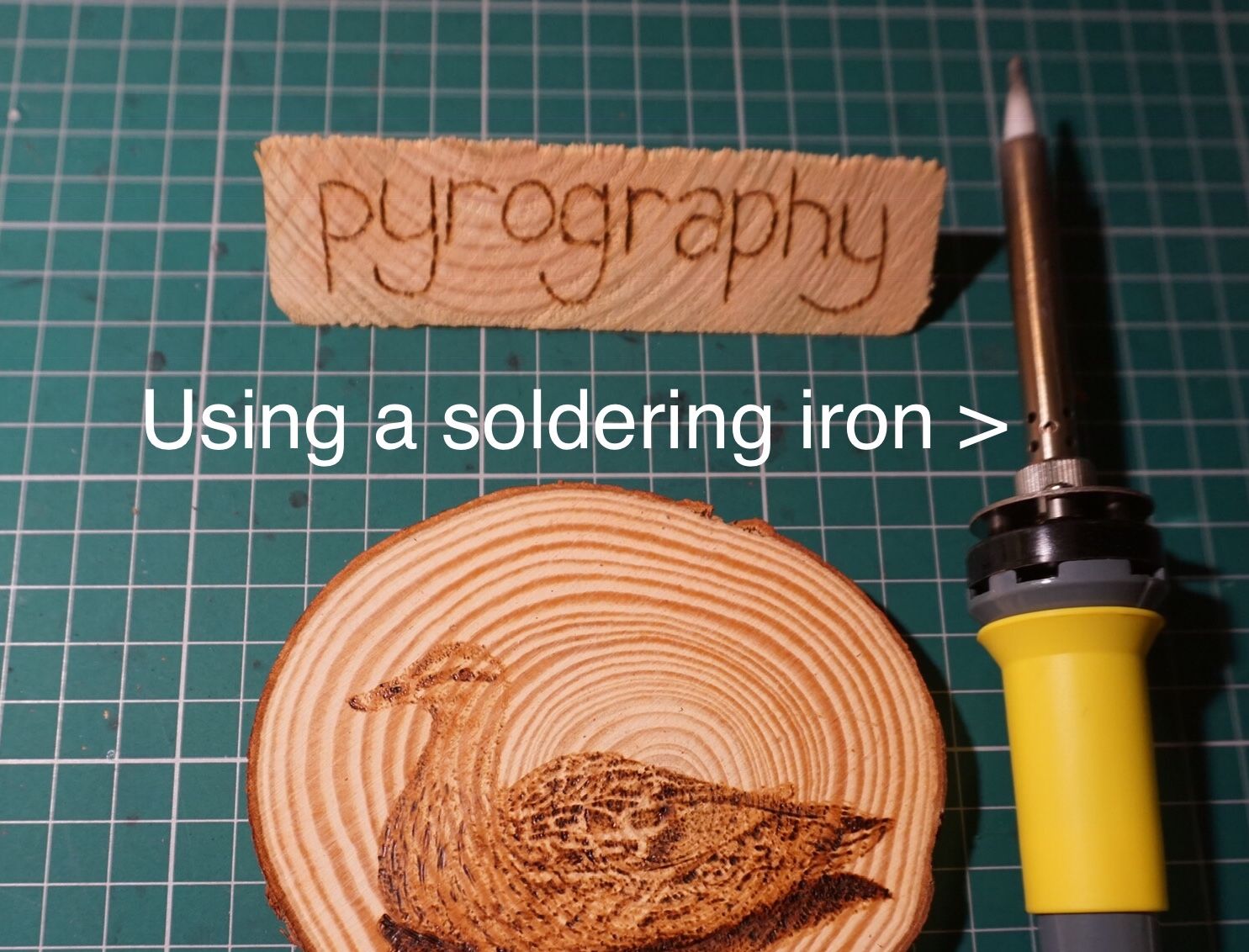

The global market for pyrography soldering irons is poised for notable evolution by 2026, driven by technological innovation, shifting consumer preferences, and expanding applications beyond traditional craft circles. These specialized tools, used for woodburning art and fine detailing, are increasingly intersecting with broader trends in DIY culture, digital fabrication, and sustainable craftsmanship.

One of the most significant trends shaping the 2026 landscape is the integration of smart technology into pyrography tools. Manufacturers are developing soldering irons with digital temperature controls, Bluetooth connectivity, and app-based customization, allowing artists greater precision and repeatability in their work. These advanced models appeal to both hobbyists and professional artisans seeking consistency and enhanced creative control.

Another key factor is the surge in demand from the maker movement and home-based creatives. Online platforms such as Etsy, YouTube, and Instagram have amplified interest in handcrafted goods, fueling a growing market for accessible, high-quality pyrography tools. As a result, brands are expanding their product lines to include beginner-friendly kits, ergonomic designs, and interchangeable tips to cater to a wider audience.

Sustainability is also influencing design and material choices. By 2026, eco-conscious consumers are prioritizing energy-efficient devices and tools made with recyclable or responsibly sourced materials. In response, manufacturers are emphasizing low power consumption, longer product lifespans, and environmentally friendly packaging.

Geographically, North America and Europe continue to dominate the market due to strong craft traditions and high disposable incomes. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth, particularly as e-commerce platforms improve access to niche tools and educational content.

Finally, the convergence of pyrography with STEM and educational initiatives is expanding its relevance. Schools and workshops are adopting pyrography soldering irons as tools for teaching design, patience, and fine motor skills, contributing to long-term market sustainability.

In summary, the 2026 pyrography soldering iron market reflects a blend of tradition and innovation—where age-old artistry meets modern technology and global connectivity. With increasing product differentiation, digital integration, and educational adoption, the sector is on track for steady growth and broader cultural relevance.

Common Pitfalls When Sourcing a Pyrography Soldering Iron (Quality & IP Risks)

Sourcing a pyrography soldering iron—especially for commercial use or resale—can present several challenges related to product quality and intellectual property (IP). Avoiding these pitfalls is essential to ensure safety, performance, and legal compliance.

Poor Build Quality and Inconsistent Performance

Many low-cost pyrography irons, particularly those sourced from generic manufacturers, suffer from subpar materials and inconsistent heating control. Common issues include:

- Unreliable temperature regulation: Units may lack precise thermostats, leading to overheating or fluctuating tips, which can burn wood or fail to create clean burns.

- Fragile heating elements: Low-quality nichrome wires or ceramic components degrade quickly, shortening the tool’s lifespan.

- Poor ergonomic design: Handles may become uncomfortably hot or lack grip, increasing user fatigue and safety risks.

- Inadequate insulation: Cheap construction can expose live wires or create electrical hazards.

These flaws not only diminish the user experience but may also pose fire or electric shock risks, potentially leading to product liability issues.

Counterfeit or IP-Infringing Designs

A significant risk when sourcing pyrography irons is unintentionally acquiring or distributing counterfeit products that violate intellectual property rights. Key concerns include:

- Design patent infringement: Many reputable brands (e.g., Razertip, Colwood) hold patents on unique pen body shapes, tip retention systems, or control units. Copycat models often mimic these designs closely.

- Trademark violations: Unauthorized use of brand names, logos, or packaging can lead to legal action, shipment seizures, or marketplace takedowns.

- Stolen technical specifications: Some suppliers replicate proprietary circuitry or firmware without permission, infringing on trade secrets or utility patents.

Procuring such products—even unknowingly—can expose your business to lawsuits, customs penalties, or reputational damage.

Lack of Safety Certifications

Reputable pyrography tools should comply with regional safety standards (e.g., CE, UL, RoHS). Many budget models lack proper certification, indicating:

- Failure to meet electrical safety requirements

- Use of hazardous materials (e.g., lead, phthalates)

- Non-compliance with electromagnetic compatibility (EMC) norms

Selling uncertified products can result in regulatory fines, import bans, or consumer recalls.

Misleading Specifications and Opaque Supply Chains

Suppliers may exaggerate features such as:

- Wattage or temperature range

- Number of included tips (often low-quality or incompatible)

- Compatibility with branded accessories

Additionally, unclear manufacturing origins make it difficult to verify ethical labor practices or material sourcing, increasing reputational and compliance risks.

Conclusion

To mitigate these pitfalls, conduct thorough due diligence: verify supplier credentials, request safety certifications, inspect samples for quality and IP compliance, and consult legal experts when scaling production or distribution. Investing in authentic, high-quality tools protects both users and your business.

Logistics & Compliance Guide for Pyrography Soldering Iron

Product Classification and Identification

Pyrography soldering irons are specialized tools used for wood burning art. They typically operate on low-voltage electrical power and feature heated tips to create designs on wood and other organic materials. For logistics and compliance purposes, these tools are classified under electrical hand tools and may fall under broader categories such as “soldering equipment” or “artistic instruments” depending on the jurisdiction. The Harmonized System (HS) code commonly used is 8515.31 (Electrodes, nozzles and other non-consumable parts for arc-welding or arc-cutting machines; parts of electric soldering irons), though local customs authorities may require additional classification verification.

Regulatory Compliance Requirements

Compliance varies by country but generally includes adherence to electrical safety, electromagnetic compatibility (EMC), and product labeling standards. Key certifications include:

– CE Marking (EU): Required under the Low Voltage Directive (2014/35/EU) and EMC Directive (2014/30/EU). The product must undergo conformity assessment and be accompanied by a Declaration of Conformity.

– UKCA Marking (UK): Mandatory for products placed on the UK market post-Brexit. Follows similar standards to CE.

– FCC Certification (USA): Required if the device emits radio frequency energy; typically applies to devices with digital controls or temperature regulation circuits.

– RoHS Compliance: Restriction of Hazardous Substances (EU and similar regulations in China, South Korea, etc.) applies to electronic components. Ensure lead, mercury, cadmium, and other restricted substances are below allowable limits.

– REACH (EU): Registration, Evaluation, Authorization and Restriction of Chemicals—applies to materials in construction (e.g., plastics, coatings).

Packaging and Labeling Standards

Packaging must ensure safe transport and include required regulatory labels:

– Clearly visible CE/UKCA/FCC marks where applicable.

– Manufacturer/importer name, address, and contact information.

– Voltage and power requirements (e.g., “Input: 110–240V AC, 50/60 Hz”).

– Warning labels for high-temperature surfaces and electrical safety (e.g., “Hot Surface – Risk of Burns”).

– Multilingual instructions and safety warnings if sold in multiple regions.

Use sturdy, recyclable packaging with adequate cushioning to prevent damage during transit.

Import/Export Documentation

International shipping requires accurate documentation:

– Commercial Invoice: Must include product description, HS code, value, country of origin, and buyer/seller information.

– Packing List: Details quantity, weight, dimensions, and packaging type.

– Certificate of Conformity: Proof of compliance with destination country standards.

– Bill of Lading/Air Waybill: Transport contract between shipper and carrier.

– Export Declaration: Required in some countries (e.g., AES filing in the USA for shipments over $2,500).

Transportation and Handling

- Mode of Transport: Suitable for air, sea, or ground freight. For air shipment, ensure compliance with IATA regulations—no hazardous materials are typically involved unless batteries are included.

- Temperature and Humidity: Store and transport in dry, temperature-controlled environments to prevent damage to electronic components.

- Handling Instructions: Mark packages as “Fragile” and “This Side Up” to avoid damage during transit.

Environmental and Disposal Considerations

- Comply with WEEE (Waste Electrical and Electronic Equipment) directives in the EU and similar e-waste regulations elsewhere. Provide information on proper disposal and recycling options.

- Include take-back or recycling program details in user manuals where required.

Post-Market Surveillance and Liability

- Maintain records of compliance testing, certifications, and customer feedback for at least 10 years.

- Establish a system to report and address product defects or safety incidents promptly.

- Product liability insurance is recommended, especially when distributing in regulated markets like the EU or North America.

Adhering to this guide ensures smooth logistics operations and regulatory acceptance across global markets for pyrography soldering irons. Always verify local requirements with legal or compliance experts before market entry.

In conclusion, sourcing a pyrography soldering iron requires careful consideration of key factors such as temperature control, tip variety, ergonomics, durability, and safety features. Whether you’re a beginner or an experienced wood burner, selecting the right tool from a reliable supplier ensures consistent performance and enhances the quality of your artwork. It is advisable to choose products with positive user reviews, solid warranties, and compatibility with interchangeable tips for greater versatility. By sourcing from reputable brands or suppliers—whether through online marketplaces, specialty craft stores, or direct manufacturer websites—you can find a pyrography soldering iron that offers both value and precision, ultimately supporting your creative expression and long-term satisfaction.