The global Powersports Original Equipment Manufacturer (OEM) parts market, which includes critical components for youth and entry-level motorcycles like the Yamaha PW80, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. This steady expansion is driven by rising demand for performance upgrades, increased participation in youth motorsports, and a growing focus on maintenance and customization among riders. As the market expands, identifying reliable manufacturers of high-quality PW80 components—ranging from pistons and carburetors to suspension systems and drive chains—has become essential for distributors, repair shops, and enthusiasts alike. Based on market presence, product range, customer reviews, and OEM partnerships, the following nine manufacturers have emerged as leaders in delivering durable, performance-oriented parts for the PW80 platform.

Top 9 Pw80 Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 2000 Yamaha PW80 OEM Dirt Bike Parts

Domain Est. 2000

Website: motosport.com

Key Highlights: Enjoy our everyday low prices on 2000 Yamaha PW80 OEM Dirt Bike parts. Buy with MotoSport and save up to 40% and get free shipping on orders over $79!…

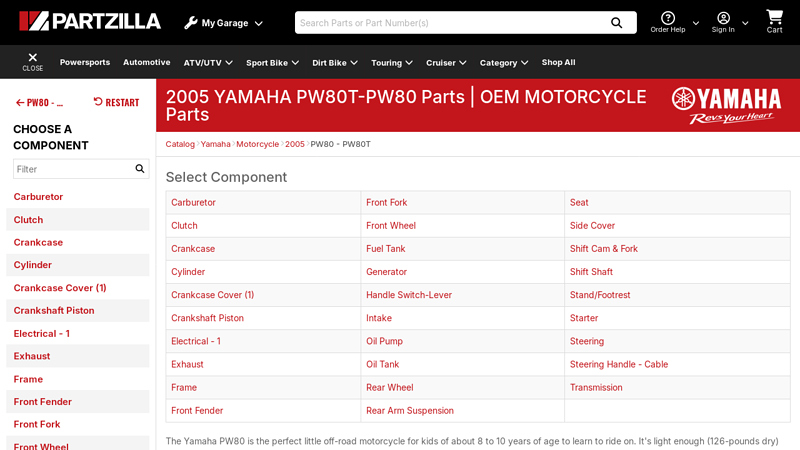

#2 Yamaha PW80 OEM Parts – PW80T

Domain Est. 2003

Website: partzilla.com

Key Highlights: Broken PW80 parts? No problem! Partzilla.com stocks hundreds of OEM Yamaha PW80 at deeply discounted prices and they are all ready to ship directly to your door ……

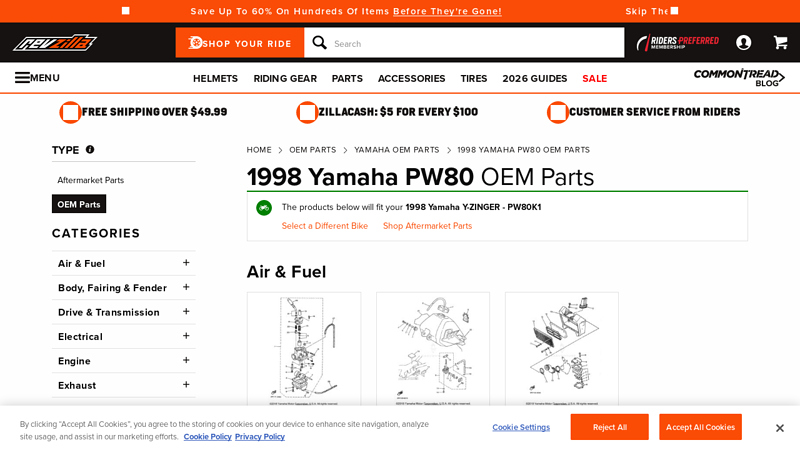

#3 1998 Yamaha PW80 OEM Parts Finder & Fiche Lookup

Domain Est. 2006

Website: revzilla.com

Key Highlights: 1998 Yamaha PW80 OEM parts diagrams. Look up genuine Yamaha part numbers in the industry’s most up-to-date online catalog & user-friendly parts finder….

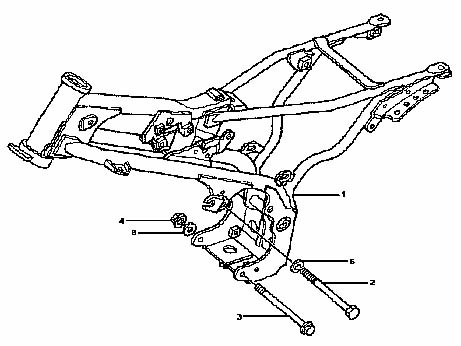

#4 yamaha pw 80 pw80 (4bc7) 1997 frame

Domain Est. 2021

Website: oem-bike-parts.com

Key Highlights: You can find here the Yamaha PW80 (4BC7) 1997 FRAME exploded view and spare parts list….

#5 Genuine Yamaha Chain and Sprocket Kit

Domain Est. 2000

Website: yamaha-motor.ca

Key Highlights: … Parts · Yamalube · Lifestyle · Riding Gear · Snowmobile · Trail · Off-Trail · Utility · Youth · Snowblowers · Shop Now · Accessories · Service Parts · Yamalube ……

#6 pwonly page

Domain Est. 2001

Website: vps99246.inmotionhosting.com

Key Highlights: Shop for Yamaha Pw50 and Pw80 parts online and order direct from the largest PW Yamaha Spare Parts supplier! Check out our huge online inventory exclusivity….

#7 Yamaha PW80 parts

Domain Est. 2001

Website: cmsnl.com

Key Highlights: Yamaha spare parts for PW80 Motorcycle. ✓ Swift delivery ✓ Original Yamaha PW80 parts….

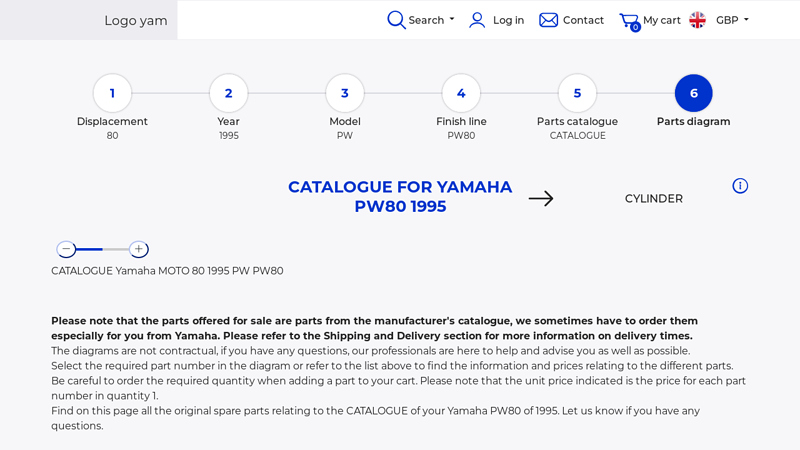

#8 Catalogue for Yamaha PW80 1995

Domain Est. 2010

Website: bike-parts-yam.com

Key Highlights: Find on this page all the original spare parts relating to the CATALOGUE of your Yamaha PW80 of 1995. Let us know if you have any questions….

#9 PW Parts

Domain Est. 2014

Website: pwparts.co.za

Key Highlights: IMPORTERS AND SUPPLIERS OF HIGH QUALITY AFTERMARKET SPARE PARTS Shop Now PW50 | PW80 | YFS200 Blaster | KTM50. Wishing all our valued customers Merry ……

Expert Sourcing Insights for Pw80 Parts

H2: 2026 Market Trends for PW80 Parts

The market for PW80 engine parts—used primarily in business aviation and regional aircraft platforms such as the Cessna Citation Mustang and other light jets—is expected to undergo notable shifts by 2026. Driven by fleet age, sustainability initiatives, and advancements in supply chain dynamics, several key trends are shaping the demand, availability, and technological evolution of PW80 components.

-

Increasing Demand Due to Aging Fleets

As the global fleet of aircraft powered by Pratt & Whitney Canada’s PW600 series (the PW80 is part of this family) matures, the need for maintenance, repair, and overhaul (MRO) services and replacement parts is expected to rise steadily through 2026. Many early-model Citation Mustangs are approaching or exceeding their mid-life cycle, leading to higher part replacement rates. This lifecycle trend is driving consistent aftermarket demand for hot-section components, fuel nozzles, turbine blades, and engine control units. -

Growth in the Used Serviceable Material (USM) Market

With rising new part costs and supply chain constraints, the market for used, serviceable PW80 parts is expanding. By 2026, the USM segment is projected to account for over 30% of total PW80 part transactions, particularly for high-value components like axial compressors and gearbox assemblies. Third-party vendors and MRO providers are capitalizing on this trend by offering certified, traceable used parts, reducing downtime and total cost of ownership for operators. -

Supply Chain Resilience and Localization

Global disruptions have prompted OEMs and distributors to reevaluate supply chain strategies. Pratt & Whitney Canada and its partners are investing in regional distribution hubs and digital inventory platforms to enhance part availability. By 2026, predictive analytics and blockchain-based part tracking are expected to improve transparency and reduce counterfeit risks in the PW80 parts ecosystem. -

Sustainability and Circular Economy Initiatives

Environmental regulations and ESG (Environmental, Social, and Governance) goals are influencing the PW80 parts market. There is growing emphasis on component refurbishment, life extension, and sustainable manufacturing. Pratt & Whitney’s “EcoParts” initiative, which includes remanufactured and overhauled components, is gaining traction. By 2026, remanufactured parts could represent up to 25% of the total PW80 aftermarket, supported by FAA and EASA approvals for extended life cycles. -

Digitalization and Predictive Maintenance

Advancements in engine health monitoring (EHM) systems are enabling operators to predict part failures before they occur. Integration of IoT sensors and AI-driven analytics allows for condition-based maintenance, reducing unplanned downtime and optimizing part replacement schedules. As more PW80-powered aircraft adopt these technologies, demand will shift toward smart components and data-enabled service packages. -

Competitive Pressure from Independent MROs

Independent maintenance providers are expanding their capabilities to offer OEM-equivalent PW80 parts at lower costs. These companies are gaining market share by obtaining PMA (Parts Manufacturer Approval) for critical components. By 2026, PMA parts could capture 15–20% of the market, especially in North America and Europe, where regulatory acceptance is strongest.

Conclusion

The 2026 market for PW80 parts reflects a mature yet evolving aftermarket landscape. Operators and service providers can expect increased competition, greater availability of sustainable and digital solutions, and a more resilient supply chain. Strategic investments in data analytics, part certification, and circular economy models will be key to capturing value in this dynamic environment.

Common Pitfalls Sourcing PW80 Parts (Quality, IP)

Sourcing parts for the Pratt & Whitney PW800 series engines—used in business and regional aviation—requires careful attention to avoid critical risks related to part quality and intellectual property (IP) rights. Falling into these pitfalls can lead to safety issues, regulatory violations, financial losses, and legal consequences.

Poor Quality Control and Non-Certified Parts

One of the most significant risks when sourcing PW80 parts is receiving substandard or counterfeit components. The aviation industry demands strict adherence to safety and performance standards, and using non-OEM or uncertified parts can jeopardize airworthiness.

- Counterfeit or Fake Parts: Illegitimate suppliers may offer parts that appear authentic but lack proper material certifications, heat treatment records, or traceability. These parts may fail prematurely under operational stress.

- Lack of Regulatory Compliance: Parts must meet FAA, EASA, or other relevant aviation authority standards. Sourcing from vendors without proper Repair Station (e.g., FAA Part 145) or Production Approval (e.g., PMA, DER) can result in non-compliance during audits.

- Inadequate Traceability: Aviation-grade parts require full traceability (mill certs, overhaul history, service records). Parts without documented history increase regulatory risk and reduce resale value of the engine.

Intellectual Property (IP) and Licensing Violations

Pratt & Whitney holds strict intellectual property rights over PW80 engine designs, components, and technical data. Unauthorized reproduction or reverse engineering of parts infringes on these rights and can lead to legal action.

- Unlicensed Reverse Engineering: Some third-party manufacturers produce “look-alike” parts by reverse engineering PW80 components without licensing. These violate P&W’s IP and may not meet original performance or durability standards.

- Use of Proprietary Technical Data: Access to P&W engineering drawings, maintenance manuals, and specifications is restricted. Unauthorized use or distribution of this data by suppliers or maintenance providers constitutes IP infringement.

- Trademark and Branding Misuse: Illegitimate parts may bear P&W logos or part numbers without authorization, misleading buyers into believing they are genuine OEM components.

Supply Chain Transparency and Vendor Reliability

Opaqueness in the supply chain increases exposure to both quality and IP risks. Unverified vendors may act as middlemen without direct access to certified sources.

- Lack of Direct OEM or Authorized Distributor Relationships: Relying on brokers without verifiable links to Pratt & Whitney or licensed manufacturers increases the risk of receiving non-compliant parts.

- Inadequate Audit Trails: Buyers must ensure suppliers can provide complete documentation, including airworthiness certificates, conformity statements, and export licenses where applicable.

Mitigation Strategies

To avoid these pitfalls, operators and MROs should:

– Procure exclusively through OEM channels or authorized PMA (Parts Manufacturer Approval) providers.

– Verify supplier certifications (e.g., AS9100, FAA/EASA approvals).

– Demand full traceability and documentation for every component.

– Conduct due diligence on third-party vendors, including site audits when possible.

– Consult legal counsel when sourcing non-OEM parts to ensure no IP infringement occurs.

By recognizing and addressing these common pitfalls, organizations can ensure the safety, compliance, and longevity of PW80 engine operations.

Logistics & Compliance Guide for PW80 Parts

This guide outlines the key logistics and compliance requirements for handling, transporting, and managing Pratt & Whitney Canada PW80 engine parts. Adherence to these standards ensures operational efficiency, regulatory compliance, and product integrity throughout the supply chain.

Regulatory Compliance

All PW80 parts must comply with applicable aviation regulations set forth by the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and other relevant national aviation authorities. Parts must be accompanied by proper traceability documentation, including Form 8130-3 or EASA Form 1, certifying airworthiness and conformity to Type Design. Only approved Repair Stations or Manufacturers may release repaired or overhauled components.

Export Controls

PW80 parts are subject to export control regulations, including the International Traffic in Arms Regulations (ITAR) and Export Administration Regulations (EAR). Prior to international shipment, verify the correct export classification (e.g., USML Category VIII or ECCN 9A610). Obtain necessary licenses or authorizations from the U.S. Department of State (DDTC) or Department of Commerce (BIS) as required. Maintain accurate records of all export transactions for a minimum of five years.

Packaging & Handling

Use manufacturer-recommended or industry-standard packaging to protect PW80 parts from contamination, moisture, and physical damage. Sensitive components (e.g., fuel system parts, sensors) must be sealed in moisture barrier bags with desiccant and humidity indicator cards. Clearly label all packages with part number, serial number (if applicable), condition (new, overhauled, serviceable), and handling instructions (e.g., “Fragile,” “This Side Up”).

Storage Requirements

Store PW80 parts in a clean, dry, temperature-controlled environment with low humidity (ideally 30–50% RH). Avoid exposure to extreme temperatures, direct sunlight, or corrosive substances. Rotating parts, such as spools or bearings, must be preserved with protective coatings and stored in their original packaging or sealed containers. Implement a first-in, first-out (FIFO) inventory system to prevent shelf-life expiration.

Transportation & Shipping

Use carriers with experience in aviation materials handling and temperature-sensitive shipments. Ensure proper customs documentation, including commercial invoices, packing lists, and airway bills, are complete and accurate. For time- and temperature-critical parts, employ monitored shipping solutions with real-time tracking and environmental logging. Notify receiving parties in advance of high-value or hazardous material shipments.

Traceability & Documentation

Maintain full traceability for all PW80 parts throughout their lifecycle. Required documentation includes:

– Original manufacturer’s certificate (C of C)

– Maintenance and repair records

– Preservation and packaging logs

– Chain of custody documentation

Digital records must be securely stored and readily accessible for audits or regulatory inspections.

Hazardous Materials

Certain PW80 components (e.g., batteries, cleaning agents, preserved parts with corrosion inhibitors) may contain hazardous materials. Comply with IATA Dangerous Goods Regulations (DGR) for air transport, including proper classification, packaging, labeling, and documentation. Only trained and certified personnel may prepare and ship hazardous materials.

Quality Assurance & Audits

All logistics providers and handling facilities must be approved under an FAA Part 145 or EASA Part 145 quality system, or equivalent. Conduct regular internal audits to verify compliance with this guide and regulatory requirements. Report any non-conformances or discrepancies immediately to the designated quality manager.

Training & Personnel

Personnel involved in the handling, storage, or shipment of PW80 parts must receive recurrent training in:

– Aviation regulatory requirements

– Export control compliance

– Proper packaging and preservation techniques

– Hazardous materials handling (if applicable)

Training records must be maintained and updated annually.

Record Retention

Retain all logistics and compliance records for a minimum of seven years, or as specified by applicable regulations. Records must be stored securely, either physically or electronically, and be available for inspection by regulatory authorities upon request.

Conclusion for Sourcing PW80 Parts:

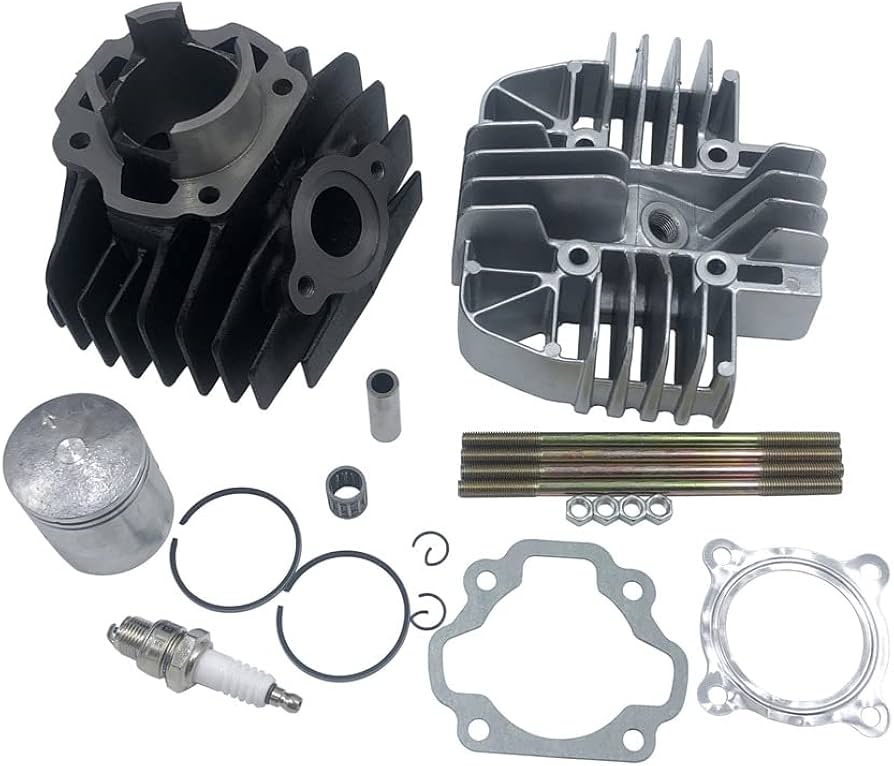

Sourcing parts for the Yamaha PW80 dirt bike requires careful consideration of availability, authenticity, cost, and reliability. Due to the model’s long-standing popularity and the fact that Yamaha continues to support it with OEM components, many essential parts remain readily available through authorized dealers and reputable online retailers. However, certain older or discontinued components may require exploration of the used or aftermarket market, where quality can vary significantly.

To ensure optimal performance and longevity, it is recommended to prioritize genuine Yamaha OEM parts for critical components such as the carburetor, ignition system, and drivetrain. For non-critical or wear items—like grips, chain, or filters—high-quality aftermarket alternatives can offer a cost-effective solution without compromising reliability.

Establishing relationships with trusted suppliers, verifying part compatibility using the bike’s VIN or model year, and comparing prices across multiple sources will help achieve a balance between quality and affordability. Ultimately, successful sourcing of PW80 parts hinges on diligent research, verification of part authenticity, and a strategic blend of OEM and aftermarket solutions tailored to budget and performance needs.