The global greenhouse market is experiencing robust growth, driven by increasing demand for sustainable agriculture, rising food security concerns, and advancements in controlled environment farming technologies. According to a report by Mordor Intelligence, the global greenhouse market was valued at approximately USD 28.6 billion in 2023 and is projected to grow at a CAGR of over 13.5% from 2024 to 2029. A key enabler of this expansion is the widespread adoption of cost-effective and durable materials such as PVC tubing, which offers flexibility, corrosion resistance, and ease of assembly—making it a preferred choice for small to mid-scale greenhouse construction, particularly in emerging markets.

PVC tube greenhouses are gaining popularity among hobbyists, commercial growers, and agri-tech startups due to their affordability and quick deployment. With the Asia Pacific region leading in greenhouse adoption—fueled by government support and rising urban farming initiatives—manufacturers specializing in PVC greenhouse systems are scaling production and innovating design for better thermal efficiency and structural resilience. As the agricultural sector continues its shift toward resource-efficient practices, the demand for reliable, high-performance PVC greenhouse solutions is poised for sustained growth. This list highlights the top nine PVC tube greenhouse manufacturers that are shaping the future of accessible and sustainable controlled-environment agriculture.

Top 9 Pvc Tube Greenhouse Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Picarro, Inc.

Domain Est. 2002

Website: picarro.com

Key Highlights: At Picarro, we provide complete solutions for monitoring greenhouse gas (GHG) and volatile organic compounds (VOC) with trusted data analytics, expert guidance, ……

#2 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle · Delivering life’s essentials through the most eco-friendly plastic pipe products on the market. · Express Service Trucks (ESTs) Deliver within 24 hours ……

#3 Griffin Greenhouse Supplies

Domain Est. 1996

Website: griffins.com

Key Highlights: Griffin Greenhouse Supplies is one of the finest companies in horticultural services and is dedicated to providing the best all-around service to its customers….

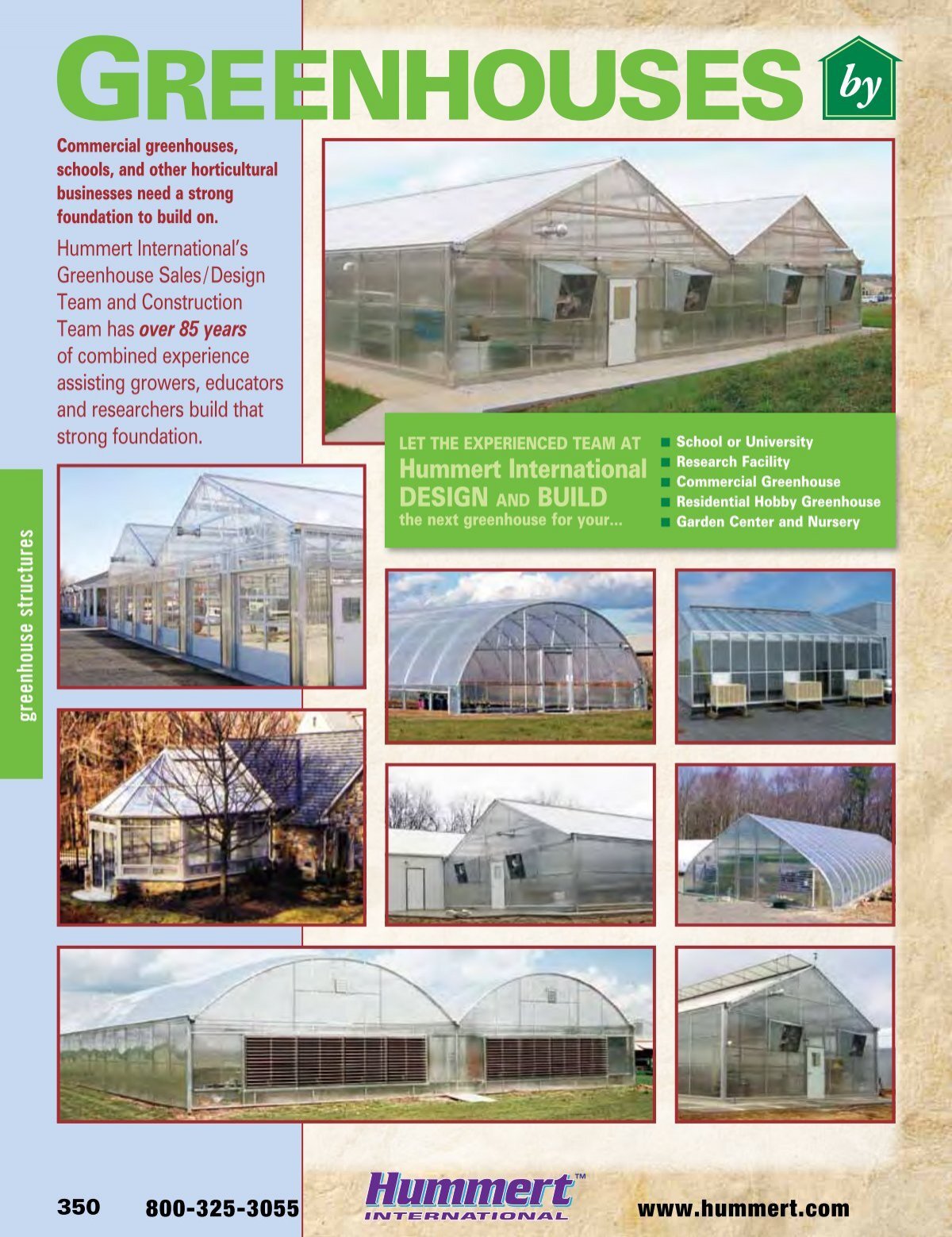

#4 Hummert International

Domain Est. 1996

Website: hummert.com

Key Highlights: Hummert International is a family owned and oriented distributor of horticultural products and services….

#5 Rimol Greenhouses

Domain Est. 1999

Website: rimol.com

Key Highlights: Rimol Greenhouses are the most dependable greenhouse structures around. Let us design and build the perfect greenhouse or high tunnel for your growing ……

#6 Oval tube

Domain Est. 2001

Website: jhuete.com

Key Highlights: The oval tube represents a major advance in greenhouse construction, as it offers two main benefits: greater strength and light output….

#7 PVC Greenhouse Kit (Fittings and Snap Clamps Only)

Domain Est. 2002

#8 Growers Solution

Domain Est. 2003

Website: growerssolution.com

Key Highlights: Growers Solution offers premium greenhouses and supplies, gardening accessories, and expert growing solutions for hobbyists and professionals….

#9 Prospiant

Domain Est. 2020

Website: prospiant.com

Key Highlights: Discover Prospiant, a leading commercial greenhouse company, where quality blends with manufacturing expertise to provide solutions tailored to your needs.Missing: pvc tube…

Expert Sourcing Insights for Pvc Tube Greenhouse

H2: 2026 Market Trends for PVC Tube Greenhouses

The global market for PVC tube greenhouses is poised for notable transformation by 2026, driven by advancements in agricultural technology, rising demand for sustainable farming solutions, and the increasing adoption of cost-effective greenhouse structures in emerging economies. Several key trends are expected to shape the trajectory of this niche sector:

1. Rising Demand in Developing Regions

PVC tube greenhouses are gaining popularity in regions such as Southeast Asia, Africa, and Latin America due to their low cost, ease of assembly, and suitability for small-scale farming. As food security becomes a priority and governments promote controlled environment agriculture, the affordability and simplicity of PVC structures make them an ideal choice for subsistence and commercial farmers alike.

2. Emphasis on Cost-Effective and Portable Solutions

With inflationary pressures on agricultural inputs and growing interest in urban and backyard farming, consumers are gravitating toward modular and portable greenhouse systems. PVC tube greenhouses offer a lightweight, customizable, and reusable alternative to traditional metal-framed greenhouses, appealing to hobbyists and smallholders seeking flexibility and minimal installation costs.

3. Integration with Sustainable Practices

Although PVC is a petroleum-based product, manufacturers are responding to environmental concerns by developing recyclable PVC blends and promoting longer product lifespans through UV-stabilized coatings. Additionally, the energy efficiency of small-scale PVC greenhouses—when paired with passive solar design and rainwater harvesting systems—enhances their appeal in eco-conscious markets.

4. Technological Enhancements and Hybrid Designs

By 2026, integration with smart farming tools such as IoT sensors, automated ventilation, and mobile monitoring systems is expected to grow even in low-cost greenhouse setups. While PVC tube structures may not support heavy tech infrastructure natively, hybrid models combining PVC frames with polycarbonate or reinforced covers are emerging to accommodate digital agriculture tools.

5. Competition from Alternative Materials

Despite their advantages, PVC tube greenhouses face growing competition from alternatives such as HDPE (high-density polyethylene) frames and bamboo-composite structures, particularly in eco-sensitive markets. Innovations in bioplastics and corrosion-resistant alloys may limit the long-term scalability of pure PVC systems unless manufacturers invest in material upgrades.

6. Regulatory and Environmental Scrutiny

Environmental regulations targeting single-use plastics and non-recyclable construction materials may impact the PVC greenhouse market. By 2026, producers may need to comply with stricter standards on material sourcing, recyclability, and end-of-life disposal, potentially increasing production costs but also fostering innovation in circular economy models.

Conclusion

The PVC tube greenhouse market in 2026 will be defined by its role as an accessible entry point into protected cultivation. While constrained by material limitations and environmental concerns, its future growth hinges on innovation in sustainability, smart integration, and continued relevance in resource-limited agricultural settings. Strategic adaptation to evolving consumer and regulatory demands will determine the long-term viability of PVC-based greenhouse solutions.

Common Pitfalls When Sourcing PVC Tube Greenhouses (Quality & IP)

Sourcing PVC tube greenhouses can be cost-effective, but buyers often encounter significant challenges related to product quality and intellectual property (IP) concerns. Being aware of these pitfalls helps avoid substandard products and potential legal issues.

Poor Material Quality and Durability

One of the most frequent issues is receiving PVC tubes made from low-grade or recycled materials. These tubes often lack UV stabilizers, making them brittle and prone to cracking under sunlight exposure. Thin-walled or inconsistently extruded PVC compromises structural integrity, leading to greenhouse collapse during wind or snow loads. Additionally, poor-quality connectors and fasteners can fail prematurely, reducing the overall lifespan of the structure.

Lack of Compliance with Safety and Environmental Standards

Many low-cost PVC greenhouse kits—especially those sourced from unverified suppliers—do not comply with regional safety or environmental regulations. Some PVC formulations may contain harmful additives like lead or phthalates, which can leach into soil or degrade into toxic byproducts. Buyers risk importing non-compliant products that could be rejected at customs or banned in environmentally sensitive markets.

Inadequate Structural Design and Engineering

Generic PVC greenhouse designs often lack proper engineering for local climate conditions. Without adequate wind or snow load calculations, these structures are vulnerable to damage. Some suppliers provide misleading specifications or omit critical design details, leading to unstable installations. Buyers may also face challenges with unclear or poorly translated assembly instructions, increasing the risk of incorrect construction.

Intellectual Property Infringement Risks

Sourcing from manufacturers in regions with weak IP enforcement increases the risk of purchasing counterfeit or pirated greenhouse designs. Some suppliers replicate patented greenhouse systems—such as unique connector mechanisms or ventilation features—without authorization. Buyers importing such products could face legal liability, shipment seizures, or reputational damage, especially in markets with strong IP protections like the EU or U.S.

Inconsistent Quality Control and Lack of Traceability

Mass-produced PVC greenhouse kits often suffer from inconsistent quality due to lax manufacturing oversight. Batch variations in tube diameter, connector fit, or coating quality can hinder assembly and performance. Additionally, many suppliers do not provide clear traceability or certifications, making it difficult to verify claims about material composition or durability.

Hidden Costs from Short Product Lifespan

While PVC tube greenhouses may appear inexpensive upfront, poor quality leads to frequent repairs or early replacement. The total cost of ownership can exceed that of higher-quality alternatives like galvanized steel or polycarbonate systems. Buyers often underestimate maintenance needs and replacement cycles, impacting long-term sustainability and ROI.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting material certifications, verifying IP status, and prioritizing quality over initial price.

Logistics & Compliance Guide for PVC Tube Greenhouse

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for your PVC tube greenhouse to ensure accurate customs clearance and tariff application. Common classifications may fall under Chapter 39 (Plastics and Articles Thereof) or Chapter 73 (Articles of Iron or Steel), depending on primary materials and structure. For a PVC-focused greenhouse, HS code 3926.30 (Plastic tubes and tubing) or 9406.00 (Prefabricated buildings) may apply. Consult local customs authorities or a licensed customs broker for precise classification.

Packaging and Shipping Requirements

Package PVC greenhouse components securely using moisture-resistant wrapping and sturdy cartons to prevent damage during transit. Disassemble kits into labeled sections (frames, connectors, cover film, fasteners) to optimize space and ease handling. Use pallets for bulk shipments and consider weather-resistant shrink-wrapping for outdoor storage or sea transport. Clearly mark packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include a detailed packing list.

Import/Export Documentation

Prepare essential documentation for international shipments, including: commercial invoice, packing list, bill of lading (or air waybill), certificate of origin, and import/export license if required. For shipments to certain regions, additional documentation such as a conformity assessment or product specification sheet may be needed. Ensure all documents accurately describe the product as a “PVC tube greenhouse kit” to avoid delays.

Regulatory and Safety Compliance

Verify compliance with destination country regulations. In the EU, ensure adherence to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) for PVC materials. In the U.S., confirm that materials meet FDA or CPSC standards if used in food-growing environments. Flame retardancy and UV stability of PVC components may be subject to local building or safety codes. Provide test reports or material safety data sheets (MSDS) upon request.

Environmental and Disposal Regulations

PVC products are subject to environmental regulations regarding recyclability and disposal. Inform customers of local recycling options for PVC components and greenhouse film. In some regions (e.g., EU under WEEE or packaging directives), producers may have extended producer responsibility (EPR). Consider offering take-back programs or recycling guidance to support compliance.

Labeling and Marking Requirements

Label each greenhouse kit with essential information, including product name, model number, batch/lot number, country of origin, and manufacturer/importer details. Include safety warnings (e.g., “Keep Away from Open Flame”) and assembly instructions. For export markets, provide multilingual labels if required (e.g., CE marking for EU, EAC for Eurasian Economic Union).

Transportation Mode and Lead Times

Choose transportation based on volume, urgency, and destination. Sea freight is cost-effective for bulk orders but has longer lead times (4–8 weeks). Air freight offers faster delivery (5–10 days) at higher cost. For domestic or regional distribution, road transport provides flexibility and shorter delivery windows. Plan logistics around seasonal demand peaks (e.g., spring planting season).

Customs Duties and Trade Restrictions

Research applicable import duties, taxes (e.g., VAT, GST), and potential trade restrictions in the destination country. Some nations may impose anti-dumping duties on imported plastic or construction products. Utilize free trade agreements (e.g., USMCA, RCEP) where applicable to reduce or eliminate tariffs. Work with a customs broker to ensure duty optimization and accurate declaration.

Quality Control and Inspection Protocols

Implement pre-shipment inspections to verify product quality, packaging integrity, and compliance with order specifications. Consider third-party inspection services (e.g., SGS, Bureau Veritas) for international buyers. Check for defects in PVC tubes (cracks, warping), proper UV stabilization, and correct component counts. Maintain quality records for traceability and compliance audits.

After-Sales Support and Warranty Compliance

Provide clear warranty terms and customer support channels. Ensure compliance with consumer protection laws in the destination market regarding return policies, repair, or replacement. Distribute multilingual user manuals covering assembly, maintenance, and safe use. Track product performance and customer feedback to address compliance or design issues proactively.

Conclusion for Sourcing PVC Tube Greenhouse

Sourcing materials for a PVC tube greenhouse offers an affordable, accessible, and practical solution for small-scale gardening, hobbyists, and sustainable agriculture initiatives. The lightweight nature of PVC, combined with its flexibility and ease of assembly, makes it an ideal choice for constructing simple, customizable greenhouse structures without requiring specialized tools or construction skills.

When sourcing materials, it is essential to prioritize UV-resistant and durable PVC pipes, quality connectors, and coverings such as greenhouse-grade polyethylene film to ensure longevity and protection against environmental elements. Comparing suppliers, evaluating material specifications, and considering local climate conditions will help optimize performance and cost-efficiency.

While PVC greenhouses may not offer the same durability as metal-framed alternatives, their low initial cost and ease of setup make them an excellent entry-level option for seasonal growing, seedling propagation, or temporary crop protection. With proper sourcing and maintenance, a PVC tube greenhouse can deliver season after season of reliable service, supporting sustainable growing practices and food security on a budget.