The global PVC molding market is experiencing steady growth, driven by rising demand for durable, low-maintenance building materials in residential and commercial construction. According to Grand View Research, the global vinyl flooring market—closely tied to PVC trim and molding applications—was valued at USD 48.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth reflects increasing adoption of PVC-based architectural products, including exterior crown molding, due to their resistance to moisture, insects, and warping compared to traditional wood. Additionally, Mordor Intelligence projects ongoing expansion in the construction materials segment, with particular traction in North America and Europe, where energy-efficient and sustainable building practices are accelerating the shift toward synthetic alternatives. As demand rises, a select group of manufacturers has emerged as leaders in innovation, scalability, and product performance within the PVC exterior crown molding space.

Top 8 Pvc Crown Molding Exterior Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metrie Moulding, Trim & Doors

Domain Est. 2003

Website: metrie.com

Key Highlights: For over 100 years, Metrie has been North America’s trusted millwork partner—largest manufacturer of solid wood and composite moulding, trim, and doors….

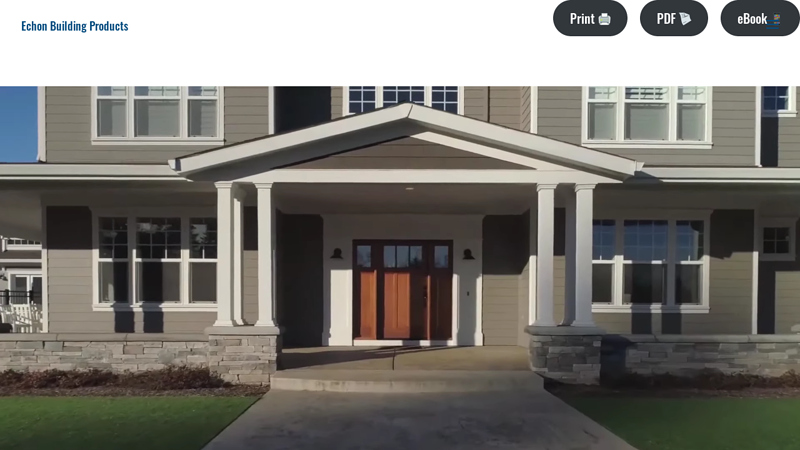

#2 Echon

Domain Est. 2017

Website: echonbuildingproducts.com

Key Highlights: Echon is a leading brand of PVC building materials for over 20 years. We manufacture & supply premium PVC building materials for exterior, ……

#3 Crown Moulding

Domain Est. 1996

Website: fypon.com

Key Highlights: Free deliveryIn Zonda’s 2023 Builder Brand Use Study, Fypon was recognized as the leader in the Decorative Moulding/Trim/Columns: Interior category. Fypon also ranked second ……

#4 Trim & Moulding

Domain Est. 2000

Website: plygem.com

Key Highlights: Ply Gem PVC exterior trim and moulding products are easy to install, durable and virtually maintenance-free—and can be painted to match the color of existing ……

#5 Crown-Molding.com

Domain Est. 2002

Website: crown-molding.com

Key Highlights: Crown-Molding.com has the largest selection of crown moldings, and millwork on the web with over 6,500 products including balustrade systems, dentil molding, ……

#6 Wolf PVC Mouldings & Trim Boards

Domain Est. 2011

Website: wolfhomeproducts.com

Key Highlights: Choose Wolf Home Products for superior PVC exterior mouldings and outdoor trim boards. Premium exterior house trim designed for lasting performance….

#7 Royal® Mouldings

Domain Est. 2013

Website: royalbuildingsolutions.com

Key Highlights: Royal® 100% cellular PVC mouldings do way more than decorate. They insulate and protect while ramping up the curb appeal of any window, eave or doorway….

#8 Moulding

Domain Est. 2018

Website: azekexteriors.com

Key Highlights: AZEK Exterior mouldings have crisp, authentic architectural details and are known for longevity and durability. Available in a variety of profiles….

Expert Sourcing Insights for Pvc Crown Molding Exterior

H2: 2026 Market Trends for PVC Crown Molding in Exterior Applications

The global market for exterior PVC crown molding is poised for notable transformation by 2026, driven by evolving construction practices, material innovation, and shifting consumer preferences. As a cost-effective, durable, and low-maintenance alternative to traditional wood and plaster moldings, polyvinyl chloride (PVC) is increasingly favored in residential and commercial exterior applications. This analysis explores key trends shaping the PVC crown molding exterior market through 2026.

1. Rising Demand in Residential Construction and Renovation

The resurgence of home improvement and new housing projects, especially in North America and Europe, is a primary growth driver. Homeowners are prioritizing curb appeal and architectural detail, with PVC crown molding offering an aesthetically pleasing finish without the maintenance burden of wood. The trend toward outdoor living spaces and upgraded facades further boosts demand for decorative exterior trims.

2. Advancements in Material Technology

By 2026, manufacturers are expected to introduce next-generation PVC formulations with enhanced UV resistance, improved thermal stability, and superior impact strength. These innovations aim to address previous limitations such as color fading and expansion/contraction in extreme temperatures. Co-extruded PVC with capped composite layers is gaining traction, offering longer lifespans and better weatherability.

3. Sustainability and Environmental Considerations

Environmental concerns are reshaping the market. While traditional PVC has faced criticism for its environmental footprint, the industry is responding with recyclable PVC compounds and bio-based additives. Regulatory pressures and green building certifications (e.g., LEED, BREEAM) are encouraging manufacturers to adopt eco-friendly production methods, influencing consumer and contractor choices.

4. Growth in Prefabricated and Modular Construction

The rise of off-site construction methods aligns well with PVC crown molding’s lightweight, consistent dimensions, and ease of installation. Pre-finished PVC trims are being integrated into modular home designs, reducing on-site labor and waste. This trend is expected to accelerate, particularly in urban housing developments and affordable housing sectors.

5. Regional Market Dynamics

North America remains the largest market due to high adoption rates in single-family homes and favorable climate conditions in certain regions. However, Asia-Pacific is projected to witness the fastest growth, fueled by rapid urbanization, expanding middle-class populations, and increasing use of Western architectural styles in countries like China, India, and Vietnam.

6. Competitive Landscape and Brand Differentiation

By 2026, consolidation among PVC molding manufacturers is anticipated, with leading brands focusing on product differentiation through design versatility, color options, and compatibility with smart cladding systems. Customizable profiles and digital templating technologies are enabling more intricate designs, blurring the line between PVC and high-end architectural finishes.

7. Price Sensitivity and Raw Material Volatility

Fluctuations in feedstock prices (e.g., ethylene and chlorine) remain a concern. However, economies of scale and improved manufacturing efficiency are helping stabilize prices. PVC molding continues to hold a price advantage over wood, fiber cement, and composite alternatives, supporting its adoption in price-sensitive markets.

Conclusion

The 2026 outlook for exterior PVC crown molding is positive, underpinned by technological innovation, sustainability efforts, and strong demand in both new construction and renovation markets. As the material evolves to meet higher performance and environmental standards, PVC crown molding is set to solidify its position as a go-to solution for modern exterior architectural detailing.

Common Pitfalls When Sourcing PVC Crown Molding for Exterior Applications

Sourcing PVC crown molding for exterior use requires careful consideration to ensure durability, aesthetics, and long-term performance. Overlooking key factors can lead to premature failure, costly replacements, and compromised building integrity. Below are common pitfalls to avoid:

Poor Material Quality and UV Resistance

Not all PVC is created equal, especially for outdoor use. Low-quality PVC often lacks sufficient UV stabilizers and impact modifiers, leading to rapid degradation when exposed to sunlight. This results in discoloration (yellowing or fading), brittleness, cracking, and warping over time. Always verify that the PVC molding is specifically formulated for exterior applications and includes UV inhibitors to withstand prolonged sun exposure.

Inadequate Impact and Weather Resistance

Exterior crown molding is subject to temperature fluctuations, moisture, wind, and physical impacts. Inferior PVC products may become brittle in cold climates or soften and sag in extreme heat. Ensure the product has proven resistance to thermal expansion, contraction, and impact—critical for maintaining structural integrity and appearance across seasons.

Lack of Intellectual Property (IP) Compliance

Sourcing PVC molding from manufacturers or suppliers that infringe on patented designs or trademarks can expose your project or company to legal risks. Some premium profiles and interlocking systems are protected by intellectual property rights. Always confirm that the product and its design do not violate existing patents or trademarks, and request documentation of IP clearance when necessary.

Insufficient Product Testing and Certifications

Reputable exterior PVC molding should come with third-party testing data and industry certifications (e.g., ASTM standards for building materials). Avoid suppliers who cannot provide evidence of performance testing for moisture absorption, tensile strength, and thermal stability. Lack of certification often indicates substandard manufacturing processes and unreliable performance.

Inconsistent Profile and Dimensional Accuracy

Poor manufacturing control can result in inconsistent profile dimensions and warping across batches. This makes installation difficult, leads to visible gaps or misalignments, and undermines the professional finish. Always request sample pieces to assess dimensional consistency and profile precision before placing large orders.

Limited Color and Finish Options with Poor Longevity

Some budget PVC moldings offer limited color choices that are prone to fading or chalking. Even pre-finished options may use low-quality paints or coatings not designed for exterior conditions. Opt for products with co-extruded colors or high-quality, fade-resistant finishes backed by long-term warranties.

Inadequate Supplier Support and Warranty

Choosing a supplier without technical support, detailed installation guidelines, or a solid warranty increases project risk. A reliable supplier should offer clear documentation, responsive customer service, and a warranty that covers material defects and performance issues under normal conditions.

Avoiding these pitfalls ensures that your exterior PVC crown molding delivers both aesthetic appeal and lasting performance in demanding outdoor environments.

Logistics & Compliance Guide for PVC Crown Molding (Exterior)

Product Overview and Classification

PVC crown molding for exterior applications is a lightweight, durable trim product used in architectural detailing. Made from polyvinyl chloride (PVC), it resists moisture, rot, and insect damage, making it ideal for outdoor use. Proper classification under international and domestic trade systems is essential for compliance. The product typically falls under Harmonized System (HS) Code 3925.90 (Other articles of plastics, building components), though final classification should be confirmed based on regional regulations and specific product composition.

International Shipping and Transportation

When shipping PVC crown molding internationally, ensure packaging protects against moisture, UV exposure, and physical damage during transit. Use weather-resistant wrapping and secure palletization to prevent shifting. Choose carriers experienced in handling building materials, and maintain stable temperature control where possible. For air freight, comply with IATA regulations; for ocean freight, adhere to IMO and containerization standards. Provide accurate shipping documentation, including commercial invoices, packing lists, and bills of lading with detailed product descriptions.

Import/Export Regulations

Verify compliance with import and export regulations in both origin and destination countries. Key considerations include:

– Customs Declarations: Accurately declare product value, quantity, and HS code.

– Tariff Classifications: Confirm applicable duties and tax rates based on bilateral trade agreements.

– Restrictions: Ensure no bans or quotas apply to PVC construction products in the target market.

– Licensing: Obtain any required export licenses, particularly when shipping to regulated markets.

Environmental and Chemical Compliance

PVC products must comply with environmental and chemical safety standards:

– REACH (EU): Register substances of very high concern (SVHCs) and ensure compliance with Annex XVII restrictions.

– RoHS (EU): Although primarily for electronics, verify that no restricted heavy metals (e.g., lead, cadmium) are present above thresholds.

– TSCA (USA): Comply with the Toxic Substances Control Act, particularly regarding phthalates and other regulated chemicals.

– Proposition 65 (California): Provide clear warnings if the product contains chemicals known to cause cancer or reproductive harm.

Building Code and Safety Standards

Exterior PVC crown molding must meet regional building code requirements:

– ICC-ES AC152 (International Code Council): Evaluate acceptance criteria for plastic trim products, including flame spread, smoke development, and weathering resistance.

– ASTM Standards: Comply with relevant ASTM tests such as D635 (flammability), D1790 (impact resistance), and G154 (accelerated weathering).

– Local Codes: Confirm compliance with municipal or state building regulations, especially in high-wind or fire-prone areas.

Labeling and Product Documentation

Proper labeling is critical for compliance and customer use:

– Include manufacturer name, product type, dimensions, color code, batch number, and compliance markings (e.g., ASTM, ICC-ES).

– Attach installation instructions and safety data sheets (SDS) per OSHA’s Hazard Communication Standard (HazCom).

– For international shipments, provide multilingual labeling as required by destination country regulations.

Waste Management and End-of-Life Disposal

Address environmental responsibilities at end-of-life:

– Inform customers about recyclability; many PVC products can be recycled through designated programs.

– Comply with WEEE (if applicable) and national waste directives such as the EU Waste Framework Directive.

– Avoid landfill disposal where recycling infrastructure exists and promote responsible disposal practices.

Certification and Third-Party Verification

Obtain necessary certifications to validate product compliance:

– UL or Intertek Listing: For fire performance and building material safety.

– ICC-ES Evaluation Reports: Required for code compliance in many U.S. jurisdictions.

– EPD (Environmental Product Declaration): Optional but valuable for green building projects (e.g., LEED certification).

Conclusion

Successful logistics and compliance for exterior PVC crown molding require attention to international trade rules, environmental regulations, building codes, and safety standards. Proactive documentation, accurate classification, and third-party certifications ensure smooth distribution and market acceptance worldwide. Regularly review regulatory updates to maintain ongoing compliance.

Conclusion for Sourcing PVC Crown Molding for Exterior Use

Sourcing PVC crown molding for exterior applications offers a durable, low-maintenance, and aesthetically versatile solution for architectural trim. Unlike traditional wood, PVC resists moisture, rot, insects, and warping, making it ideal for withstanding harsh outdoor conditions. Its ability to hold paint well and maintain structural integrity over time ensures long-term visual appeal and performance.

When sourcing exterior PVC crown molding, it is essential to select high-quality, UV-stabilized products specifically designed for outdoor use. Reputable manufacturers and suppliers should provide product specifications confirming weather resistance, dimensional stability, and compatibility with local climate conditions. Additionally, proper installation practices—including correct fastening, sealing, and expansion allowances—are critical to maximizing longevity and appearance.

Overall, investing in premium PVC crown molding from reliable sources not only enhances the curb appeal of a building but also reduces lifecycle maintenance costs. With the right material selection and installation, PVC crown molding proves to be a practical and attractive choice for exterior architectural detailing.