The global demand for push latch mechanisms has surged in recent years, driven by increasing automation in consumer electronics, automotive interiors, and smart home applications. According to Mordor Intelligence, the global electronic latch market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of 6.2% from 2024 to 2029. This growth is fueled by rising adoption of space-saving and silent closure solutions in premium appliances, furniture, and industrial equipment. As design aesthetics and functional efficiency become key differentiators, manufacturers specializing in push latch mechanisms are at the forefront of innovation, integrating materials like high-grade polymers and spring-tempered steel to enhance durability and performance. With Asia Pacific emerging as a manufacturing and consumption hub, the competitive landscape is rapidly evolving. Below are the top six push latch mechanism manufacturers leading this expansion through technological advancement, global supply chain reach, and consistent product innovation.

Top 6 Push Latch Mechanism Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

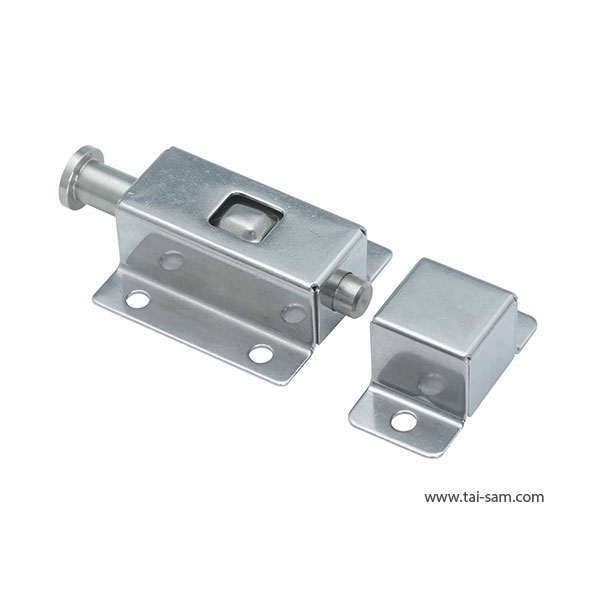

#1 Push Latch

Domain Est. 2020

Website: peirdamper.com

Key Highlights: Push push latches are excellent for space-saving and noiseless movements. Usage: In both automotive and non-automotive applications with limited space….

#2 Push To Close Latch

Domain Est. 1996

Website: southco.com

Key Highlights: Southco Push-to-Close Latches offer simple slam to close convenience while holding panels securely together. Check out our portfolio of push latches!…

#3 TAD

Domain Est. 2000

Website: isc-sl.com

Key Highlights: PUSH LATCH – The TAD closing device is characterized by its slim profile, suitable for 17 × 7.5 mm housings. It is designed to provide a secure and ……

#4 Push Latch

Domain Est. 2006

Website: titusplus.com

Key Highlights: Push Latch. Our touch opening solution for effortless opening of doors and drawers without handles is designed to be used with standard hinges and drawers….

#5 Push to Close Latches

Domain Est. 2012

Website: essentracomponents.com

Key Highlights: A push to close latch is a type of latch that automatically activates when the door is shut. It features a push latch mechanism that keeps the bolt extended….

#6 Innovating Motion

Domain Est. 2021

Website: cultrarogroup.com

Key Highlights: The push push latches function as push-to-open mechanisms, ideal for saving space and achieving silent movements. How push push latches are used….

Expert Sourcing Insights for Push Latch Mechanism

H2: Market Trends for Push Latch Mechanisms in 2026

The global market for push latch mechanisms is poised for significant transformation by 2026, driven by advancements in smart technology, increased demand for minimalist design, and growing automation across industries. These compact, user-friendly mechanical solutions are evolving beyond traditional applications in cabinetry and consumer electronics into smarter, more integrated systems.

One of the dominant trends shaping the 2026 landscape is the integration of push latch mechanisms with smart home and Internet of Things (IoT) ecosystems. As consumers demand seamless and contactless interactions, push latches are increasingly being equipped with sensors and connectivity features that enable remote monitoring, voice activation, and integration with home automation platforms. This shift is particularly evident in high-end residential and commercial interiors, where convenience and aesthetics are paramount.

Another key driver is the rising emphasis on space-saving and tool-free designs in furniture and appliances. With urbanization and compact living spaces becoming more common, manufacturers are favoring push-to-open mechanisms in cabinets, drawers, and access panels to eliminate the need for external handles. This trend is reinforcing demand in the furniture, kitchen appliance, and architectural hardware sectors.

Additionally, the industrial and automotive sectors are adopting push latch systems for enhanced ergonomics and reliability. In automotive interiors, for example, push latches are being used in glove compartments, center consoles, and storage units to support sleek, flush-mounted designs. The push toward electric vehicles (EVs) further amplifies this trend, as manufacturers seek lightweight, durable components that contribute to energy efficiency.

Material innovation and sustainability are also influencing product development. By 2026, there is a growing preference for recyclable metals and engineering plastics in latch construction, aligning with broader environmental regulations and corporate sustainability goals. Manufacturers are investing in corrosion-resistant and low-maintenance designs to extend product life cycles and reduce environmental impact.

Regionally, the Asia-Pacific market is expected to lead growth due to rapid urbanization, expanding construction activities, and increasing disposable incomes. Meanwhile, North America and Europe continue to drive innovation, particularly in smart and automated latch solutions.

In summary, the 2026 push latch mechanism market is characterized by smart integration, design minimalism, industrial adaptation, and sustainable engineering. Companies that invest in R&D, embrace connectivity, and align with eco-conscious manufacturing practices are likely to gain a competitive advantage in this evolving landscape.

Common Pitfalls Sourcing Push Latch Mechanisms (Quality, IP)

Inadequate Quality Control and Material Standards

One of the most frequent issues when sourcing push latch mechanisms is inconsistent quality control, particularly with suppliers from low-cost manufacturing regions. Buyers may encounter variations in material strength, plating thickness, or spring tension, leading to premature failure or inconsistent performance. Without clear specifications and third-party inspection protocols, components may not meet durability or load requirements, resulting in field failures and increased warranty claims.

Lack of Intellectual Property Protection

Sourcing push latch mechanisms, especially custom or patented designs, carries significant IP risks. Suppliers may replicate proprietary designs without authorization or incorporate patented features from third parties, exposing the buyer to legal liability. Failing to conduct proper IP due diligence or secure licensing agreements can lead to infringement claims, product recalls, or blocked shipments, particularly in regulated markets like North America or the EU.

Insufficient Design Validation and Testing

Many push latch failures stem from inadequate functional testing during the sourcing phase. Suppliers may provide samples that perform well in controlled environments but fail under real-world conditions such as temperature fluctuations, repeated actuation, or exposure to dust and moisture. Without access to standardized testing data (e.g., cycle life, ingress protection ratings), buyers risk integrating unreliable mechanisms into end products.

Hidden Tooling and MOQ Costs

Push latch mechanisms often require custom molds or tooling, especially for plastic or stamped metal components. Suppliers may understate tooling costs or lock buyers into high minimum order quantities (MOQs) to amortize these expenses. This can limit design flexibility, increase inventory risk, and make it difficult to switch suppliers later without significant financial loss.

Supply Chain and Component Traceability Gaps

Reliance on sub-tier suppliers for springs, latches, or electronic components (in smart latches) can create traceability issues. Lack of transparency in the supply chain increases the risk of counterfeit parts, inconsistent quality, and compliance failures (e.g., RoHS, REACH). Without clear component sourcing documentation, resolving field issues or managing recalls becomes significantly more complex.

Poor Communication and Specification Misalignment

Ambiguous technical specifications—such as actuation force, stroke length, or mounting dimensions—often lead to mismatches between expected and delivered performance. Language barriers, time zone differences, and inconsistent engineering standards can compound these issues, resulting in costly redesigns or delays in product launch timelines.

Logistics & Compliance Guide for Push Latch Mechanism

This guide outlines essential logistics and compliance considerations for the handling, transportation, import/export, and regulatory adherence of Push Latch Mechanisms. Proper management ensures product integrity, legal conformity, and efficient supply chain operations.

Product Classification & Documentation

Ensure accurate classification of the push latch mechanism under the Harmonized System (HS) code for customs declaration. Common classifications may fall under headings for mechanical fasteners or hardware components (e.g., HS 8302.50 or similar, depending on material and application). Maintain detailed technical specifications, bills of materials (BOM), and certificates of conformity to support customs clearance and regulatory audits.

Material Compliance & Restrictions

Verify that all constituent materials (e.g., zinc alloy, stainless steel, plastic components) comply with regional environmental and safety regulations. Key standards include:

– RoHS (EU): Restriction of Hazardous Substances in electrical and electronic equipment.

– REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals.

– Proposition 65 (California, USA): Warning requirements for chemicals known to cause cancer or reproductive harm.

Ensure material declarations (SDS or IMDS) are available and up to date.

Packaging & Shipping Requirements

Use packaging that prevents damage during transit, especially to the latch’s spring mechanism and plunger. Employ anti-corrosion measures (e.g., VCI packaging) if shipping to humid environments. Clearly label packages with product identifiers, handling instructions (e.g., “Fragile,” “Do Not Stack”), and compliance marks as required. Optimize packaging dimensions and weight to reduce freight costs and environmental impact.

Import/Export Controls

Assess whether the push latch mechanism is subject to export control regulations such as:

– EAR (Export Administration Regulations, USA): Verify if the mechanism contains controlled technology or is destined for restricted entities or countries.

– Customs Valuation: Declare accurate transaction values to avoid delays or penalties.

Utilize export licenses or authorizations when necessary, especially for dual-use applications.

Certifications & Industry Standards

Obtain relevant certifications based on the application sector:

– UL/CSA: For use in North American electrical enclosures.

– CE Marking: Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– IP Ratings: If the latch is part of an enclosure, ensure compatibility with the overall ingress protection rating.

Maintain technical documentation and conformity assessment records for market surveillance.

End-of-Life & Environmental Responsibility

Design for recyclability and comply with waste management directives such as:

– WEEE (EU): Waste Electrical and Electronic Equipment – ensure proper labeling and support take-back programs if applicable.

Adhere to local recycling laws in destination markets and provide disposal guidelines to customers.

Supply Chain Traceability

Implement a traceability system to track batch numbers, manufacturing dates, and material sources. This supports quality control, recall management, and compliance reporting. Require suppliers to provide compliance documentation and audit trails.

Regulatory Updates & Monitoring

Regularly monitor changes in international trade regulations, customs procedures, and environmental standards. Assign responsibility within your organization for compliance updates and maintain a compliance calendar for certifications and renewals.

Adhering to this logistics and compliance framework ensures smooth global distribution of push latch mechanisms while minimizing legal and operational risks.

Conclusion for Sourcing Push Latch Mechanism:

After a thorough evaluation of various suppliers, product specifications, cost structures, and quality standards, it has been concluded that sourcing push latch mechanisms from a combination of pre-qualified international and local suppliers offers the optimal balance between cost-efficiency, reliability, and supply chain resilience. Key factors such as material durability, operational force, cycle life, IP rating, and ease of installation were prioritized to ensure compatibility with end-product requirements.

Supplier vetting confirmed that manufacturers compliant with ISO standards and possessing consistent quality control processes deliver the most reliable performance. Additionally, maintaining dual sourcing options mitigates risks related to logistics disruptions and lead time variability.

Ultimately, selecting a push latch mechanism supplier should not be based solely on price, but on a holistic assessment of technical fit, long-term reliability, after-sales support, and responsiveness. Final sourcing decisions will support product quality, customer satisfaction, and operational efficiency across the manufacturing and assembly process.