The global wire and cable connectors market is experiencing robust growth, driven by rising demand across automotive, industrial machinery, and consumer electronics sectors. According to Grand View Research, the global electrical connectors market size was valued at USD 81.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. With increasing electrification and automation trends, specialized connectors—including color-coded variants like purple wire connectors—are gaining prominence for their role in ensuring organized, safe, and efficient electrical systems. Purple connectors, often used in high-performance or proprietary applications such as telecommunications and medical devices, require precision manufacturing and compliance with stringent industry standards. As demand grows, a select group of manufacturers has emerged as leaders in producing high-quality purple wire connectors, combining innovation, scalability, and global supply chain reach. Based on market presence, product quality, and application-specific engineering, here are the top five manufacturers leading this niche segment.

Top 5 Purple Wire Connectors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

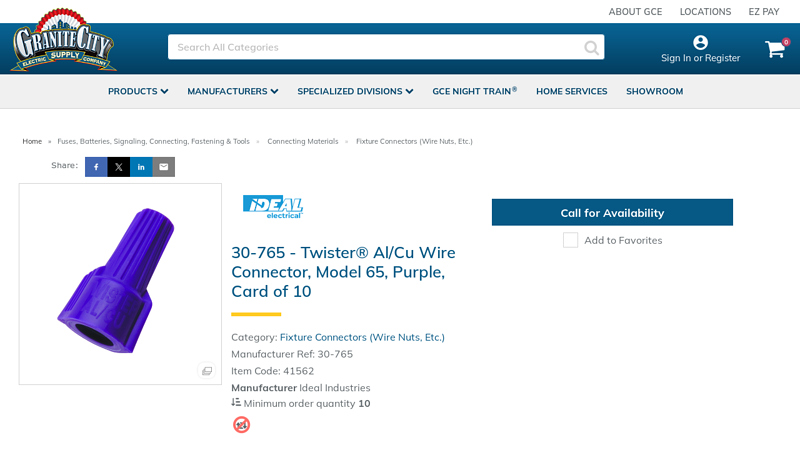

#1 30

Domain Est. 1998

Website: granitecityelectric.com

Key Highlights: 30-765 – Twister® Al/Cu Wire Connector, Model 65, Purple, Card of 10 ; Manufacturer Ideal Industries ; Manufacturer Ref 30-765 ; Minimum order quantity 10….

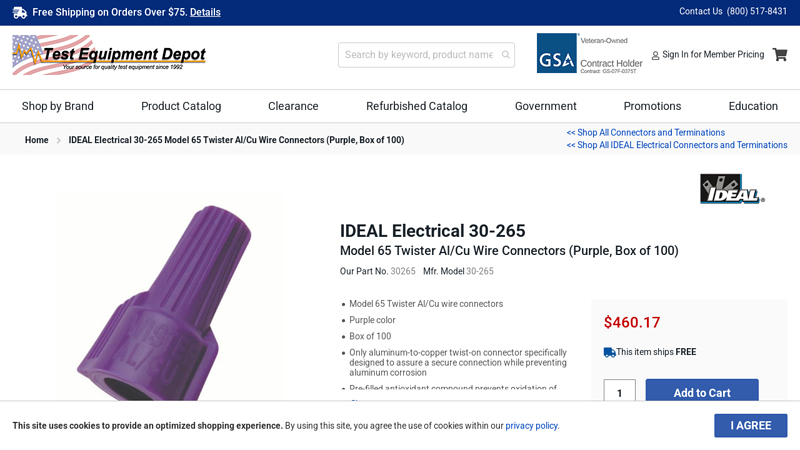

#2 IDEAL Electrical 30

Domain Est. 1998

#3 King Innovation AlumiConn 2

Domain Est. 2001

Website: atlanticlighting.com

Key Highlights: In stock Rating 5.0 6 It coats aluminum wires with a thin layer of silicone sealant to provide resistance from oxidation and uses set screws to break up surface oxides and provid…

#4 Mechanical Connectors

Domain Est. 2002

Website: kinginnovation.com

Key Highlights: Mechanical Connectors ; Dryconn Split Bolt Housing Aqua. Part # 69105. DRYCONN SPLIT BOLT HOUSING AQUA; 10/BAG 4 BAGS/MASTER ; Yellow Split Bolt Housing (10-Pack)….

#5 Wire Connectors

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsOur complete line includes Twist-On Wire Connectors, Push-In Wire Connectors, Grounding Wire Connectors, DataCom Wire Connectors, among others….

Expert Sourcing Insights for Purple Wire Connectors

H2: 2026 Market Trends for Purple Wire Connectors

The global market for wire connectors, including color-coded variants such as purple wire connectors, is poised for notable evolution by 2026. Driven by advancements in electrical safety standards, growth in construction and renewable energy sectors, and increased demand for organized and code-compliant electrical installations, purple wire connectors are expected to gain strategic importance. The following analysis explores key trends shaping the market for purple wire connectors through 2026.

1. Rising Adoption in Specialized Electrical Applications

Purple wire connectors are typically used to denote specific circuit functions—often associated with traveler wires in three- or four-way switches or in smart home systems. As smart home technologies and advanced lighting controls become mainstream, demand for color-coded connectors like purple is projected to rise. By 2026, increased deployment of home automation systems will drive the need for standardized, color-differentiated wiring practices, positioning purple connectors as essential components in ensuring system clarity and reducing installation errors.

2. Expansion of Residential and Commercial Construction

Global construction activity, particularly in emerging economies and North America, is forecasted to grow steadily through 2026. With stricter electrical codes emphasizing safety and traceability, electricians are increasingly relying on color-coded wire connectors to maintain consistency and reduce faults. Purple connectors will benefit from this trend, especially in complex residential wiring where multi-way switching is common. Builders and contractors are expected to adopt standardized color-coding practices, further integrating purple connectors into electrical supply chains.

3. Regulatory and Safety Standards Driving Demand

Electrical safety standards from organizations such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) are likely to place greater emphasis on visual circuit identification. While not always mandated, the use of color-coded connectors like purple supports compliance and facilitates inspections. As regulatory scrutiny increases, particularly in high-safety environments such as hospitals, schools, and industrial facilities, the use of purple and other specialty connectors will be encouraged to improve maintenance and reduce downtime.

4. Innovation in Connector Materials and Design

Manufacturers are investing in improved materials—such as flame-retardant thermoplastics and corrosion-resistant coatings—to enhance the performance and durability of wire connectors. By 2026, expect to see purple connectors with enhanced insulation properties, better torque specifications, and compatibility with both copper and aluminum wiring. Additionally, compact and push-in style connectors in purple variants may emerge to meet demand for faster, tool-free installations in modern electrical projects.

5. Growth in Renewable Energy and EV Infrastructure

The expansion of solar power installations and electric vehicle (EV) charging stations will indirectly influence the wire connector market. While purple connectors are not typically used in primary power distribution in these systems, their role in control and signaling circuits—especially in integrated building energy management systems—will grow. As energy systems become more interconnected, the need for clearly differentiated wiring, including purple-coded connections, will increase for diagnostics and serviceability.

6. Market Consolidation and Brand Differentiation

Major electrical component manufacturers such as Ideal Industries, 3M, and Thomas & Betts are expected to expand their color-coded connector product lines, including purple variants, to capture niche market segments. By 2026, branding, packaging, and marketing efforts will emphasize ease of use, safety compliance, and compatibility with smart technologies. Retailers and distributors may also begin offering bundled kits for multi-way switching, further boosting purple connector visibility and sales.

Conclusion

By 2026, the market for purple wire connectors will be shaped by technological advancements, regulatory developments, and the rising complexity of electrical systems. While still a specialized product, purple connectors are set to play a more prominent role in ensuring electrical safety, system efficiency, and installer productivity. Stakeholders across manufacturing, distribution, and installation should anticipate increased demand and consider strategic positioning in this evolving segment.

Common Pitfalls When Sourcing Purple Wire Connectors (Quality, IP)

Sourcing purple wire connectors—often used in specialized electrical or industrial applications—can present several challenges, particularly concerning quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps avoid costly delays, safety issues, or legal complications.

Inconsistent Quality Standards

One of the most frequent issues is receiving connectors that fail to meet required performance or durability standards. Many suppliers, especially those from less regulated markets, may offer products that look identical but use inferior materials (e.g., substandard brass contacts or low-grade thermoplastics). This can result in poor conductivity, overheating, or mechanical failure under stress. Always verify compliance with recognized standards such as UL, IEC, or RoHS, and request test reports or third-party certifications.

Misrepresentation of IP Protection

Purple wire connectors may be part of patented designs or trademarked product lines. A key pitfall is sourcing connectors labeled as “compatible” or “generic” versions that inadvertently infringe on existing IP. Some suppliers may falsely claim their products are IP-free or provide misleading documentation. This exposes buyers to legal risks, including cease-and-desist orders or customs seizures. Conduct due diligence by consulting legal experts and verifying the original equipment manufacturer’s (OEM) IP status before large-scale procurement.

Lack of IP-Rated (Ingress Protection) Verification

The term “IP” can also refer to Ingress Protection ratings, indicating a connector’s resistance to dust and moisture. A common mistake is assuming that all purple connectors labeled “IP67” or “IP68” are genuinely rated—some suppliers falsify or self-assign these ratings without proper testing. Using unverified connectors in outdoor or harsh environments can lead to system failures or safety hazards. Always demand certified test results from accredited laboratories and inspect for proper sealing mechanisms like O-rings and gaskets.

Supply Chain Transparency Issues

Many suppliers source components through opaque supply chains, making it difficult to trace material origins or manufacturing processes. This lack of transparency increases the risk of counterfeit parts or non-compliant materials (e.g., restricted substances under REACH). Establish clear traceability requirements in contracts and consider on-site audits of supplier facilities.

Inadequate Documentation and Support

Poor technical documentation—such as missing dimensional drawings, torque specifications, or installation guidelines—can hinder integration and maintenance. Additionally, suppliers may offer limited technical support, making troubleshooting difficult. Prioritize vendors who provide comprehensive datasheets, application notes, and accessible engineering support.

Avoiding these pitfalls requires thorough vetting of suppliers, insistence on verifiable certifications, and proactive IP and compliance checks before finalizing procurement.

Logistics & Compliance Guide for Purple Wire Connectors

This guide outlines the essential logistics and compliance considerations for handling, transporting, and using Purple Wire Connectors. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational safety.

Product Identification and Specifications

Purple Wire Connectors are specialized electrical components designed for secure and reliable wire splicing and termination. Key specifications include:

– Color: Purple (indicating specific voltage or application per industry standards)

– Material: Flame-retardant thermoplastic housing with tin-plated copper contact

– Voltage Rating: Typically 600V AC/DC

– Temperature Range: -40°C to +105°C

– Compliance Standards: UL 486A-B, CSA 22.2 No. 158, RoHS, REACH

Storage and Handling

Proper storage and handling preserve connector performance and safety:

– Store in original, sealed packaging in a dry, climate-controlled environment

– Avoid exposure to direct sunlight, moisture, and extreme temperatures

– Handle with clean, dry hands or gloves to prevent contamination

– Do not mix with connectors of other colors or types to prevent misapplication

Transportation Requirements

Ensure safe and compliant shipping practices:

– Use sturdy, labeled packaging marked with electrostatic discharge (ESD) protection symbols if applicable

– Maintain ambient temperature during transit within -20°C to +60°C

– Label shipments with handling instructions: “Fragile,” “Keep Dry,” and “Do Not Crush”

– Comply with IATA/IMDG regulations if shipping internationally or via air

Regulatory Compliance

Purple Wire Connectors must meet the following regulatory requirements:

– UL Certification: Listed under UL 486A-B for wire connectors

– CSA Certification: Certified to CSA 22.2 No. 158 for use in Canada

– RoHS Compliance: Free of lead, mercury, cadmium, and other restricted substances

– REACH Compliance: Registered under EU Regulation (EC) No 1907/2006

– Conflict Minerals: Sourced in accordance with Dodd-Frank Act Section 1502

Documentation and Traceability

Maintain complete documentation for compliance audits and quality control:

– Retain Certificates of Compliance (CoC) and test reports from the manufacturer

– Track lot and batch numbers for full traceability

– Provide Material Safety Data Sheets (MSDS/SDS) upon request

– Ensure labeling includes part number, date code, and compliance marks (UL, CSA, CE)

Installation and Use Compliance

Follow these guidelines to ensure safe and compliant installation:

– Use only for intended wire types and gauge ranges (e.g., 14–10 AWG)

– Install per manufacturer instructions and local electrical codes (NEC, CEC)

– Inspect connectors before use for damage or deformation

– Do not reuse or modify connectors after initial installation

Environmental and Disposal Considerations

Dispose of unused or damaged connectors responsibly:

– Recycle through approved electronic waste (e-waste) programs

– Do not incinerate; components may release hazardous fumes

– Comply with local regulations for disposal of plastic and metal components

Supplier and Quality Assurance

Procure Purple Wire Connectors only from authorized, certified suppliers:

– Verify supplier certifications and quality management systems (ISO 9001)

– Conduct periodic audits and sample testing

– Report non-conforming products immediately to the manufacturer

For questions or compliance verification, contact the manufacturer’s technical support team or visit the official product compliance portal.

Conclusion on Sourcing Purple Wire Connectors:

After evaluating various suppliers, material specifications, and industry requirements, it has been determined that purple wire connectors can be reliably sourced from specialized electrical component distributors and manufacturers that adhere to industry standards such as UL, CSA, and RoHS compliance. These connectors, often used to denote specific circuit types (e.g., data lines, control signals, or safety-rated circuits), must meet required electrical ratings, temperature resistance, and durability standards to ensure safe and effective performance.

Key factors in selecting a supplier include product availability, cost-effectiveness, minimum order quantities, lead times, and technical support. Major electronics distributors such as Molex, TE Connectivity, and Digi-Key offer high-quality purple connectors with consistent color coding and reliable performance. Local sourcing and OEM partnerships were also considered to reduce supply chain risks and support scalability.

In conclusion, sourcing purple wire connectors is feasible through reputable suppliers that provide certified, high-performance products. It is recommended to establish long-term relationships with one or two key suppliers to ensure consistency, quality control, and timely delivery for ongoing and future projects. Proper documentation and verification of color-coding standards should be maintained to support safety, compliance, and ease of maintenance in final applications.