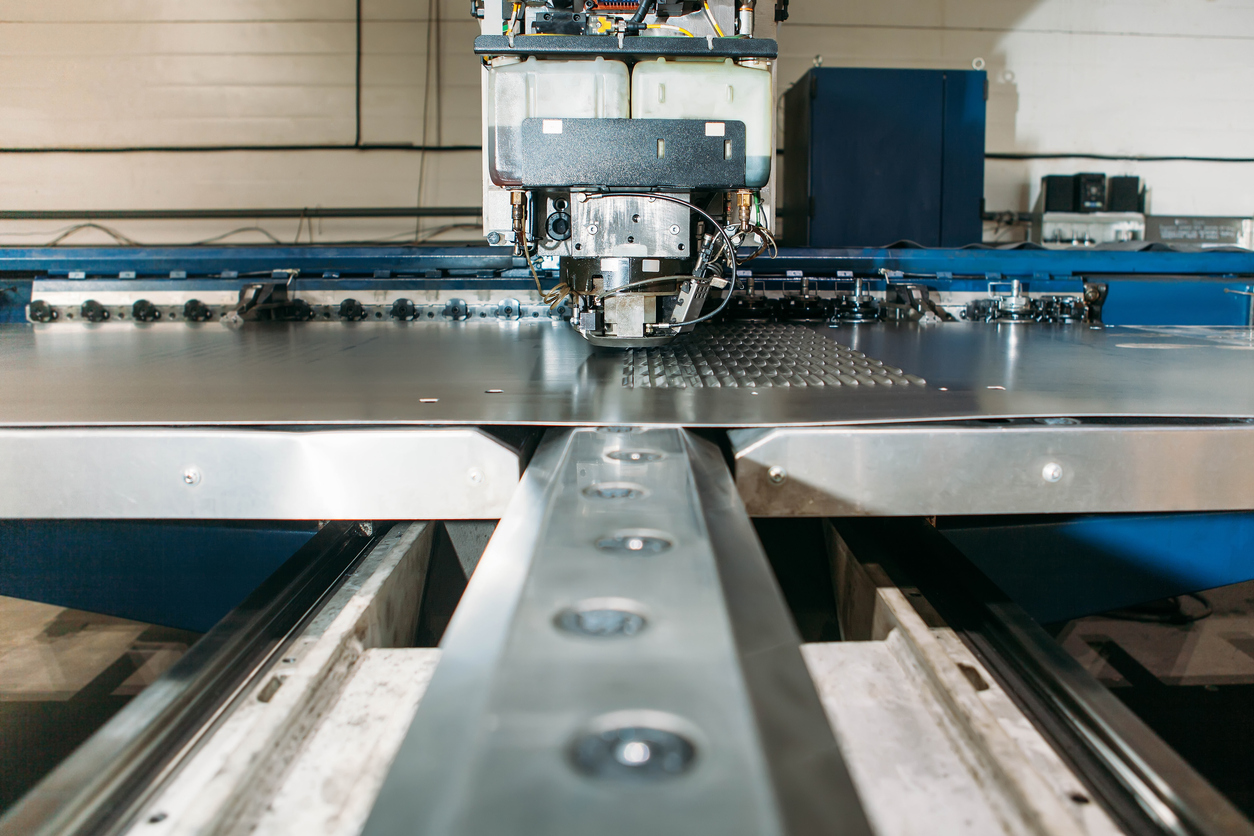

The global metal stamping and fabrication equipment market, which includes punch presses and associated rig systems, is witnessing robust growth driven by rising demand from automotive, aerospace, and manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global press brake and punch press market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, fueled by increased automation and precision engineering requirements in industrial manufacturing. As manufacturers prioritize efficiency, versatility, and integration with Industry 4.0 technologies, the demand for high-performance punch rigs has surged. This growing landscape has elevated the prominence of leading manufacturers that combine innovation, durability, and smart manufacturing capabilities. Based on market presence, technological advancements, and global service reach, here are the top six punch rig manufacturers shaping the future of sheet metal fabrication.

Top 6 Punch Rig Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bullet Weights

Domain Est. 2000

Website: bulletweights.com

Key Highlights: Bullet Weights is reported to have the largest selection of fishing sinker products in the marketplace. Our unique weights are distributed worldwide….

#2 PUNCH RIGS

Domain Est. 2009

Website: realfishbait.com

Key Highlights: Free delivery over $50Features: ✓ 1/PK THE REAL FISH ADVANTAGE: All-In-One Drop Shot and Punching rig through heavy mats, Join the many professionals anglers who are already ……

#3 Punch Rig 101: The Right Way To Rig It Up

Domain Est. 2011

Website: mysterytacklebox.com

Key Highlights: Choose the right bullet weight for your punch rig. The thicker the vegetation you’re fishing is, the heavier weight you’ll need to get your bait ……

#4 Eupheng Punch Shot Rig Kit, Tokyo Style Rig Drop Shot Punch Rig …

Domain Est. 2012

Website: clinicahelenacosta.com.br

Key Highlights: The Punch Shot Rig Consists Of A Split Ring Connected To A Swivel (tied To Your Line), A Rigid Drop Wire (connected To A Weight), And A Hook (with A Soft ……

#5 The Punch Shot Rig

Domain Est. 2013

Website: harmonyfishing.com

Key Highlights: Free delivery over $15 30-day returns…

#6 Punch Rig Gear Guide

Domain Est. 1998

Website: tacklewarehouse.com

Key Highlights: 4.8 1.2K · Free delivery over $50 · Free 365-day returnsNov 4, 2025 · In this article, we identify the ideal setup to effectively fish punch rigs in heavy cover, provide detail…

Expert Sourcing Insights for Punch Rig

H2: Market Trends for Punch Rig in 2026

As the global energy landscape continues to evolve, the Punch Rig sector—commonly associated with drilling equipment used in oil and gas exploration—is anticipated to experience a transformation driven by technological innovation, energy transition dynamics, and regional market shifts by 2026. The second half (H2) of 2026 is expected to reflect the culmination of strategic adaptations made throughout the year in response to macroeconomic and sector-specific trends.

1. Increased Demand in Emerging Markets

H2 2026 will likely see sustained demand for punch rigs in emerging economies, particularly in Africa, Latin America, and parts of Southeast Asia. These regions are advancing their domestic energy security initiatives, leading to increased exploration and development of onshore and shallow offshore reserves. Countries like Guyana, Namibia, and Angola are expected to ramp up drilling activities, supporting a robust need for reliable and cost-effective punch rig solutions.

2. Technological Advancements and Automation

By H2 2026, the integration of automation, real-time data analytics, and remote monitoring in punch rig operations will become more widespread. Operators are increasingly adopting smart rig technologies to enhance drilling precision, reduce downtime, and improve safety. Automation not only increases operational efficiency but also addresses labor shortages and rising operational costs, making punch rigs more competitive in hybrid energy portfolios.

3. Energy Transition Pressures and Dual-Purpose Rigs

While the long-term shift toward renewable energy continues, fossil fuels will remain significant in the global energy mix through 2026. However, punch rig manufacturers are adapting to sustainability mandates by developing dual-purpose rigs capable of supporting both conventional drilling and geothermal energy exploration. This diversification is expected to expand market opportunities, especially in regions investing in geothermal as part of their clean energy strategies.

4. Supply Chain Optimization and Localization

Following ongoing supply chain disruptions in prior years, H2 2026 will likely emphasize localized manufacturing and strategic inventory management. Companies are partnering with regional suppliers to reduce lead times and tariffs, particularly in high-growth markets. This trend supports faster deployment of punch rigs and improves responsiveness to project timelines.

5. Regulatory and Environmental Compliance

Environmental regulations are tightening globally, and by H2 2026, punch rig operators will face stricter emissions standards and reporting requirements. The industry is responding with cleaner-burning engines, electrified rig components, and carbon capture integration pilots. Compliance will be a key differentiator for contractors bidding on new projects, especially those involving state-owned or ESG-focused energy firms.

6. Pricing and Utilization Rates

With a rebound in global oil prices projected in late 2025 and sustained into H2 2026, utilization rates for punch rigs are expected to rise. Increased upstream capital expenditure (CAPEX) from both national oil companies (NOCs) and independents will drive demand, leading to improved day rates and contract stability. However, competition from automated and super-spec rigs may pressure margins for older punch rig fleets.

Conclusion

H2 2026 represents a pivotal phase for the punch rig market, characterized by technological maturation, geographic expansion, and adaptation to the energy transition. Companies that invest in innovation, sustainability, and operational agility are poised to capture significant market share. While challenges remain, the outlook for punch rigs remains cautiously optimistic, supported by enduring energy demand and strategic diversification into low-carbon applications.

Common Pitfalls Sourcing Punch Rig (Quality, IP)

Sourcing a punch rig—whether for industrial tooling, manufacturing, or specialized fabrication—carries inherent risks, particularly concerning quality inconsistencies and intellectual property (IP) vulnerabilities. Failing to address these pitfalls can lead to project delays, legal disputes, and compromised product performance.

Poor Quality Control and Inconsistent Manufacturing Standards

One of the most frequent issues when sourcing punch rigs is encountering subpar quality due to inadequate manufacturing controls. Suppliers, especially those in low-cost regions, may cut corners on materials, heat treatment, or precision machining. This results in punch rigs that wear out quickly, fail under pressure, or produce inconsistent results. Without strict quality assurance protocols—such as ISO certification, in-process inspections, or material traceability—buyers risk receiving components that don’t meet design specifications or durability requirements.

Lack of Intellectual Property Protection

Sourcing punch rigs often involves sharing detailed engineering drawings, CAD models, and proprietary design features. If proper IP safeguards are not in place, there’s a high risk of design theft or unauthorized replication. Suppliers may reverse-engineer the punch rig design and sell it to competitors, or use the IP to develop their own product lines. This is especially concerning when working with third-party manufacturers lacking formal confidentiality agreements or IP clauses in contracts.

Inadequate Verification of Supplier Capability and Experience

Choosing a supplier based solely on price or lead time without vetting their technical expertise can lead to significant setbacks. Some suppliers may lack experience in manufacturing high-tolerance tooling or working with specific materials required for punch rig applications. Without verifying a supplier’s track record, equipment capabilities, and quality systems, buyers expose themselves to poor performance, rework, and costly redesigns.

Hidden Costs from Rework and Downtime

Low initial pricing can be misleading if the punch rig requires extensive rework upon delivery. Poorly machined components or incorrect tolerances may necessitate adjustments or replacements, leading to unplanned costs and production delays. Additionally, unreliable punch rigs contribute to machine downtime and reduced operational efficiency, further eroding cost savings from the initial purchase.

Insufficient Documentation and Traceability

A common oversight is the absence of comprehensive documentation—such as material certifications, inspection reports, or design validation records. Without these, it becomes difficult to verify compliance with industry standards or troubleshoot performance issues. Lack of traceability also complicates warranty claims and accountability in the event of failure.

Failure to Secure IP Ownership in Contracts

Even with confidentiality agreements, many sourcing contracts fail to clearly assign ownership of the developed tooling or design improvements. Ambiguity in contracts can lead to disputes over who owns the punch rig design, especially if modifications are made during production. Buyers should ensure contracts explicitly state that IP created during the sourcing process remains their exclusive property.

Conclusion

To mitigate these pitfalls, buyers must conduct thorough supplier due diligence, enforce rigorous quality standards, and implement strong legal protections for intellectual property. Clear communication, detailed specifications, and contractual safeguards are essential to ensure both the quality and security of sourced punch rigs.

Logistics & Compliance Guide for Punch Rig

This guide outlines the essential logistics and compliance considerations for the transportation, operation, and maintenance of a Punch Rig. Adherence to these protocols ensures safety, regulatory compliance, and operational efficiency.

Transportation & Handling

Ensure the Punch Rig is properly secured during transit using approved lifting points and certified rigging equipment. All components must be immobilized to prevent shifting. Verify that transport vehicles comply with local weight, dimension, and road safety regulations. Complete and carry all required transport documentation, including load manifests and permits for oversized loads if applicable.

Regulatory Compliance

Comply with all relevant national, regional, and local regulations, including OSHA (Occupational Safety and Health Administration), MSHA (Mine Safety and Health Administration) if applicable, and environmental protection standards. Maintain up-to-date equipment certifications, operator licenses, and safety training records. Conduct regular compliance audits to ensure ongoing adherence.

Site Safety & Operations

Implement a site-specific safety plan prior to deployment. Conduct pre-operation safety checks, including structural integrity, hydraulic systems, and emergency shutdown functions. All personnel must wear appropriate PPE (Personal Protective Equipment). Establish exclusion zones during operation and ensure clear communication among crew members using standardized signals.

Environmental Considerations

Minimize environmental impact by preventing fluid leaks and properly disposing of waste materials, including lubricants and filters. Use secondary containment systems where necessary. Comply with spill prevention and response regulations. Document all environmental inspections and mitigation measures.

Maintenance & Documentation

Follow the manufacturer’s maintenance schedule rigorously. Keep a detailed maintenance log recording inspections, repairs, and part replacements. Store all compliance documents, maintenance records, and operator certifications on-site or in a secure digital system accessible for audits.

Training & Personnel

Only trained and authorized personnel may operate the Punch Rig. Provide regular training on equipment operation, emergency procedures, and compliance updates. Maintain training records for all personnel involved in rig operations.

Emergency Preparedness

Develop and communicate an emergency response plan covering fire, equipment failure, and medical incidents. Ensure emergency equipment (fire extinguishers, first aid kits, communication devices) is available and operational. Conduct periodic drills to validate response readiness.

Conclusion for Sourcing Punch Rig

After a comprehensive evaluation of technical specifications, supplier capabilities, cost implications, lead times, and quality assurance processes, the sourcing of a punch rig has been strategically aligned with project requirements and operational goals. The selected supplier demonstrates proven expertise, reliable delivery performance, and compliance with industry standards, ensuring long-term durability and efficiency of the equipment.

This sourcing decision supports enhanced manufacturing precision, scalability, and reduced downtime, ultimately contributing to improved production throughput and cost-effectiveness. Moving forward, establishing a strong supplier relationship, coupled with continuous performance monitoring, will be key to maintaining supply chain resilience and operational excellence.

In conclusion, the punch rig sourcing initiative marks a critical step toward optimizing production capabilities and achieving sustainable competitive advantage.