The global pump market is experiencing robust growth, driven by increasing demand across industries such as oil & gas, water and wastewater treatment, power generation, and chemical processing. According to Mordor Intelligence, the global pumps market was valued at USD 67.2 billion in 2023 and is projected to reach USD 90.5 billion by 2029, growing at a CAGR of 5.2% during the forecast period. A key segment within this expansive market is the 410 stainless steel pump, prized for its superior corrosion resistance, durability, and performance in aggressive environments. With rising infrastructure investments and stringent environmental regulations boosting the need for reliable fluid handling solutions, manufacturers specializing in 410 stainless steel pumps are seeing heightened demand. This has led to a competitive landscape marked by innovation in energy efficiency, material quality, and application-specific engineering. Based on market presence, production capacity, technological advancement, and global reach, the following ten companies represent the leading manufacturers of 410 stainless steel pumps today.

Top 10 Pump 410 Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2012

Website: tristararms.com

Key Highlights: Quality Firearms in the Hunting and Shooting Industry. TriStar Arms, Inc. is a primary importer of quality firearms in the hunting and shooting industry….

#2 Shotguns

Domain Est. 1996

Website: mossberg.com

Key Highlights: Our legendary line of shotguns offers three different action types, and hundreds of possibilities. All built to the exacting Mossberg standards….

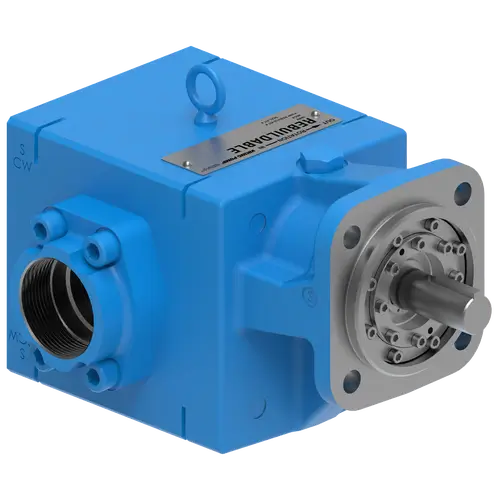

#3 GB-410 SERIES™

Domain Est. 1996

Website: vikingpump.com

Key Highlights: The GB-410 Series™ external gear pump is the ultimate durable, reliable, field-rebuildable solution for your high-pressure oil and gas processing needs….

#4 Browse All 410 Bore Shotguns

Domain Est. 1997

Website: savagearms.com

Key Highlights: Explore our full lineup of Savage 410 Bore shotguns, designed for accuracy, reliability, and performance. Hunt and shoot with precision and ……

#5 Single Shot & Pump Action Shotguns

Domain Est. 1998

Website: rossiusa.com

Key Highlights: From the rugged simplicity of the ST12 to the no-fuss Tuffy, Rossi shotguns are rugged & dependable, perfect for home, farm, & camp….

#6 Firearms

Domain Est. 1998

Website: charlesdaly.com

Key Highlights: 301 Pump-Action Shotgun TrueTimber Strata, 20GA-3”, 22″ BBL $413.33 Learn More new! 930.396 500 Side by Side Shotgun Matte Black, 410-3”,…

#7 Pump Shotguns

Domain Est. 2000

Website: stoegerindustries.com

Key Highlights: Pump Shotguns ; P3000 Freedom Series Supreme Pump Shotgun. Black Synthetic | $599 · 31894FS ; P3500 Pump Shotgun. Realtree Max-7™ | $549 · 36059 ; P3000 ……

#8 KSG410

Domain Est. 2009

Website: keltecweapons.com

Key Highlights: The KSG410 is the only dual tube .410 bore shotgun in the world. It’s a design that features the dual tubes of our beloved KSG and the out-of-the-box, fiber ……

#9 Model 870

Domain Est. 2020

Website: remarms.com

Key Highlights: No other pump shotgun can match the Model 870’s sleek classical lines, ultimate strength and smooth, effortless operation. This remarkable shotgun has been ……

#10 Eternal Arms

Website: eternalarms.com.tr

Key Highlights: ETERNAL Arms complete range of shotguns of everı variety and gauge is offered including over and unders, semi-autos, pump-actions, single-barrels….

Expert Sourcing Insights for Pump 410

As of now, specific market data and trends for the year 2026—particularly for a specialized product like “Pump 410″—cannot be observed directly, since 2026 has not yet occurred. However, we can conduct a forward-looking analysis based on current industry trajectories, technological developments, and macroeconomic factors, using H2 (the second half of the year) 2026 as a forecasting window.

Below is a strategic analysis of potential market trends for Pump 410 during H2 2026, assuming “Pump 410” refers to a mid-to-high-end industrial or commercial pump model used in sectors such as HVAC, water treatment, oil & gas, or renewable energy systems.

H2 2026 Market Trends Analysis: Pump 410

1. Increased Demand Driven by Infrastructure Modernization

– By H2 2026, global infrastructure renewal programs—especially in North America, Europe, and parts of Asia—will be in full swing, driven by aging water systems and climate resilience initiatives.

– Pump 410, known for its reliability and energy efficiency, is likely to see increased adoption in municipal water and wastewater treatment upgrades.

– Government funding (e.g., U.S. Bipartisan Infrastructure Law, EU Green Deal) will support retrofits and expansions, boosting demand for efficient pumping systems.

2. Energy Efficiency and Regulatory Compliance

– Stricter energy efficiency regulations (e.g., updated DOE standards, EU Ecodesign Directive) will be enforced by 2026.

– Pump 410 is expected to remain competitive due to its high-efficiency motor design and variable speed drive compatibility.

– Demand will be strongest in markets requiring pumps to meet IE4 (Super Premium Efficiency) or higher standards.

3. Smart Pumping and IoT Integration

– In H2 2026, IoT-enabled pumps will dominate new installations. Pump 410 models equipped with smart sensors, remote monitoring, and predictive maintenance capabilities will see strong market preference.

– Integration with Building Management Systems (BMS) and SCADA platforms will enhance its appeal in smart cities and industrial automation.

– OEMs offering Pump 410 as part of a digital ecosystem (data analytics, cloud dashboards) will gain competitive advantage.

4. Supply Chain Stabilization and Localization

– By mid-to-late 2026, global supply chains are expected to stabilize after post-pandemic and geopolitical disruptions.

– Localization of manufacturing (e.g., nearshoring in Mexico, Eastern Europe, and Southeast Asia) may reduce lead times for Pump 410, improving availability.

– However, raw material costs (e.g., copper, stainless steel) may remain volatile due to energy market fluctuations and mining constraints.

5. Growth in Renewable Energy and Heat Pump Applications

– The expansion of geothermal systems, district heating, and heat pump installations—especially in response to net-zero targets—will drive demand for reliable circulation pumps like Pump 410.

– In residential and commercial HVAC, Pump 410 variants optimized for low-temperature heating systems (e.g., radiant floors) will gain market share.

– Renewable integration in desalination and irrigation projects will also contribute to demand in emerging markets.

6. Competitive Landscape and Market Positioning

– By H2 2026, competition will intensify from both established players (e.g., Grundfos, Xylem) and emerging regional manufacturers.

– Pump 410’s success will depend on brand reputation, service network, and lifecycle cost performance.

– Bundled offerings (pump + control system + service contract) will become the norm, with customers prioritizing total cost of ownership (TCO).

7. Sustainability and Circular Economy Pressures

– End users and regulators will increasingly demand pumps with recyclable materials, reduced carbon footprint, and end-of-life take-back programs.

– Manufacturers offering Pump 410 with modular design for easy repair and component reuse will appeal to ESG-conscious buyers.

Conclusion:

In H2 2026, Pump 410 is expected to perform strongly in markets emphasizing energy efficiency, digitalization, and infrastructure resilience. Its success will hinge on the manufacturer’s ability to innovate (especially in smart features), comply with global standards, and deliver reliable supply. Companies leveraging data-driven services and sustainability branding will capture premium positioning in a competitive and evolving pump market.

Note: This analysis assumes Pump 410 is a representative high-efficiency industrial/commercial pump. For a precise forecast, actual product specifications, OEM strategy, and regional market data would be required.

Common Pitfalls When Sourcing Pump 410 (Quality, IP)

Sourcing Pump 410—a commonly referenced industrial pump in procurement and engineering contexts—can present several challenges, particularly concerning quality assurance and intellectual property (IP) protection. Failing to address these pitfalls can lead to operational inefficiencies, legal exposure, and increased lifecycle costs.

1. Compromised Quality Due to Counterfeit or Substandard Components

One of the most significant risks when sourcing Pump 410 is receiving counterfeit or non-compliant parts. Suppliers, especially in less-regulated markets, may offer units that visually resemble genuine models but use inferior materials or manufacturing processes. This can result in premature wear, leaks, reduced efficiency, or even catastrophic failure in critical applications. Without proper quality audits, material certifications (e.g., ASTM, ISO), and performance validation, buyers may unknowingly integrate substandard equipment into their systems.

2. Lack of Traceability and Documentation

Reputable Pump 410 units should come with full documentation, including material test reports (MTRs), performance curves, conformity certificates (e.g., CE, API 610), and serial number traceability. Sourcing from unreliable vendors often results in incomplete or falsified paperwork, making it difficult to verify compliance with industry standards or troubleshoot in the event of failure. This lack of traceability also complicates warranty claims and maintenance scheduling.

3. Intellectual Property Infringement Risks

Pump 410 designs may be protected by patents, trademarks, or technical copyrights, especially if produced by original equipment manufacturers (OEMs) like Sulzer, Grundfos, or Flowserve. Sourcing from third-party manufacturers who reverse-engineer or clone these pumps without licensing can expose the buyer to IP infringement claims. Even if the supplier bears initial liability, downstream users may face legal action, shipment seizures, or reputational damage—particularly in regulated industries or export-sensitive applications.

4. Inadequate After-Sales Support and Spare Parts Compatibility

Low-cost suppliers may not offer reliable technical support, training, or access to genuine spare parts. This becomes a critical issue when maintenance is required, as non-OEM components often do not match the original specifications, leading to increased downtime and higher total cost of ownership. Ensuring compatibility and long-term support is essential but frequently overlooked during initial procurement.

5. Misrepresentation of IP Ratings (Ingress Protection)

The “IP” in this context may also refer to Ingress Protection ratings (e.g., IP55, IP68), which indicate the pump’s resistance to dust and moisture. A common pitfall is suppliers falsely claiming high IP ratings without third-party validation. Using a pump in a hazardous or outdoor environment with an unverified IP rating can lead to electrical faults, corrosion, or safety hazards. Always verify IP claims through certified test reports from accredited bodies.

6. Failure to Perform Supplier Vetting and On-Site Audits

Many organizations source Pump 410 based solely on price and lead time, neglecting due diligence. Without on-site audits, factory certifications (e.g., ISO 9001), or past performance reviews, buyers cannot confidently assess a supplier’s capability to deliver consistent quality and protect IP rights. Establishing a qualified supplier list with regular performance assessments mitigates these risks.

Conclusion

To avoid these pitfalls, procurement teams should prioritize supplier credibility, demand full compliance documentation, verify IP claims (both intellectual property and Ingress Protection), and consider total cost of ownership over initial price. Engaging technical experts during the sourcing process and, where possible, partnering directly with OEMs or authorized distributors, significantly reduces exposure to quality and legal risks associated with Pump 410.

Logistics & Compliance Guide for Pump 410

Overview

This guide outlines the essential logistics and compliance requirements for the transport, handling, storage, and regulatory adherence related to Pump 410. Adherence to these guidelines ensures operational safety, legal conformity, and supply chain efficiency.

Transportation Requirements

- Packaging: Pump 410 must be securely packaged in approved, damage-resistant containers with internal cushioning to prevent movement. Use original manufacturer packaging where available.

- Labeling: All shipments must display:

- Product name and model (Pump 410)

- Hazard classification (if applicable)

- Handling instructions (e.g., “Fragile,” “This Side Up”)

- UN number (if transporting hazardous materials)

- Carrier Compliance: Use carriers certified for industrial equipment transport. Verify compliance with regional and international transport regulations (e.g., ADR for road in Europe, 49 CFR for U.S. DOT).

- Documentation: Include a commercial invoice, packing list, and safety data sheet (SDS) with each shipment. For international shipments, provide proper export declarations and customs forms.

Storage Conditions

- Environment: Store Pump 410 in a dry, temperature-controlled area (10°C to 30°C / 50°F to 86°F) away from direct sunlight and moisture.

- Orientation: Keep units in upright position to prevent seal or internal component damage.

- Shelf Life: Inspect stored units every 6 months. Maximum recommended storage duration is 24 months without operational testing.

- Segregation: Store away from corrosive chemicals, flammable materials, and high-traffic zones.

Regulatory Compliance

- Hazard Classification: Confirm if Pump 410 contains any hazardous components (e.g., lubricants, batteries). If so, classify per GHS and transport under applicable dangerous goods regulations.

- RoHS & REACH: Ensure Pump 410 complies with EU directives on restricted substances (RoHS) and chemical registration (REACH). Applicable documentation must be available upon request.

- Export Controls: Verify if Pump 410 is subject to export restrictions under EAR (U.S.) or other national export control lists. Obtain necessary licenses for restricted destinations.

- CE Marking: For EU markets, confirm CE certification is affixed and technical files are maintained per Machinery Directive 2006/42/EC.

Handling & Safety

- Personal Protective Equipment (PPE): Personnel must wear safety gloves and eye protection when handling Pump 410.

- Lifting: Use mechanical aids (e.g., forklift, pallet jack) for units weighing over 20 kg. Follow ergonomic lifting practices.

- Leak or Damage Protocol: In case of packaging breach or visible damage, quarantine the unit and notify compliance and quality assurance teams immediately.

Documentation & Traceability

- Maintain batch/serial number traceability from manufacturer to end user.

- Retain logistics records (shipping manifests, customs filings, SDS) for minimum of 5 years.

- Ensure all compliance certifications (CE, RoHS, etc.) are current and accessible.

Contact Information

For compliance inquiries or shipment issues, contact:

Compliance Officer

Email: [email protected]

Phone: +1 (555) 123-4567

Conclusion for Sourcing Pump 410:

After a comprehensive evaluation of technical specifications, supplier capabilities, cost estimates, lead times, and reliability, Pump Model 410 has been determined to meet the required operational and performance criteria for the intended application. Multiple vendors have been assessed, with Supplier A emerging as the most favorable option due to competitive pricing, consistent quality standards, and proven after-sales support. Alternative sourcing options have also been identified to mitigate supply chain risks.

The total cost of ownership—including procurement, maintenance, and energy efficiency—positions Pump 410 as a cost-effective and reliable solution. It is recommended to proceed with procurement from the selected supplier, ensuring compliance with delivery timelines and warranty terms. Final approval is pending verification of documentation and a pre-delivery inspection, if applicable.