The global laser cleaning market is experiencing robust expansion, driven by increasing demand for environmentally friendly and precision-based surface treatment solutions across industries such as automotive, aerospace, and manufacturing. According to Mordor Intelligence, the laser cleaning market was valued at USD 650 million in 2023 and is projected to grow at a CAGR of over 18% from 2024 to 2029. A key contributor to this growth is the rising adoption of pulsed laser technology for rust and contaminant removal, which offers non-abrasive, chemical-free, and highly efficient performance compared to traditional methods. As industries prioritize sustainability and operational efficiency, pulsed laser rust removal systems have emerged as a preferred solution, fostering innovation and competition among technology providers. This growing market landscape has given rise to a new generation of manufacturers specializing in high-performance, industrial-grade pulsed laser cleaning equipment. Based on market presence, technological innovation, and customer adoption metrics, the following list highlights the top 10 pulsed laser rust removal manufacturers shaping the future of industrial surface preparation.

Top 10 Pulsed Laser Rust Removal Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 P-laser Industrial laser cleaning

Website: p-laser.com

Key Highlights: we engineer and manufacture the most advanced—and most powerful—pulsed industrial laser cleaning systems on the market, built for both manual and automated ……

#2 Laser Cleaning Machine

Website: pulsar-laser.com

Key Highlights: Explore PULSAR Laser P CL laser cleaning machines for industrial rust removal and paint stripping. Compare SHARK P CL, PANDA P CL and FOX P CL….

#3 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#4 Laser cleaning

Website: narran.cz

Key Highlights: We can design and integrate a laser cleaning system into production, build a robotic workstation or supply a mobile laser for a wide range of applications….

#5 Pulse Wave Laser Machines

Website: nuwavelaser.com

Key Highlights: Explore our cutting-edge technology of pulse laser cleaning machines, delivering efficient removal of oil, weld seams, and gear rust….

#6 Argento Lux

Website: argentolux.com

Key Highlights: Our Laser Ablation is the most cost-effective, efficient, and safest method of industrial cleaning, rust removal, paint removal, and surface preparation….

#7 Pulse Laser Cleaning Machine

Website: triumphlaser.com

Key Highlights: A pulse laser cleaning machine is an advanced, highly efficient tool designed for precision cleaning and removal of contaminants such as rust, paint, oil, and ……

#8 Laser Cleaning and Laser Ablation Systems

Website: laserphotonics.com

Key Highlights: Utilize this laser cleaning machine for rust removal and coating removal … A pulsed laser can achieve a higher peak power per pulse than a CW laser….

#9 ZAC Laser Machine

Founded: 2004

Website: zaclaser.com

Key Highlights: ZAC laser is the professional manufacture since 2004 which sell many laser machines such as laser rust removal-laser cleaning machine, laser engraver-laser ……

#10 Top 10 Laser Cleaning Machine Manufacturers in 2025

Website: dplaser.com

Key Highlights: Explore the global laser cleaning machine manufacturers in 2025 and discover why laser cleaning is widely used in industrial manufacturing….

Expert Sourcing Insights for Pulsed Laser Rust Removal

H2: Market Trends in Pulsed Laser Rust Removal for 2026

The pulsed laser rust removal market is poised for significant transformation and growth by 2026, driven by advancements in laser technology, increasing demand for eco-friendly cleaning solutions, and rising industrial automation. This analysis explores key market trends shaping the industry through 2026 under the H2 framework—highlighting drivers, challenges, opportunities, and strategic responses.

-

Heightened Demand for Environmentally Sustainable Solutions

As global environmental regulations tighten, industries are shifting away from chemical and abrasive rust removal methods due to concerns over pollution, worker safety, and waste disposal. Pulsed laser rust removal offers a clean, chemical-free, and non-abrasive alternative, aligning with sustainability goals. By 2026, regulatory pressures and ESG (Environmental, Social, and Governance) commitments are expected to accelerate adoption across sectors such as automotive, aerospace, maritime, and heritage conservation. -

Technological Advancements Enhancing Efficiency and Precision

Ongoing innovations in fiber and ultrafast pulsed laser systems are improving ablation efficiency, reducing processing time, and enabling selective rust removal without damaging underlying substrates. By 2026, integration with artificial intelligence (AI) and machine vision is anticipated to allow real-time monitoring and adaptive control, significantly boosting precision and throughput in industrial applications. -

Expansion into New Industrial Verticals

While initially adopted in high-value niche applications, pulsed laser rust removal is broadening into mainstream manufacturing and maintenance. The oil and gas, rail, and renewable energy sectors are expected to increase investments in laser cleaning systems for infrastructure maintenance. Additionally, the restoration of historical artifacts and monuments is emerging as a growing application segment due to the technology’s non-invasive nature. -

Cost Reduction and Accessibility Improvements

Although high initial equipment costs have been a barrier, economies of scale, increased competition, and modular system designs are driving down prices. By 2026, more compact, portable, and user-friendly systems are expected to enter the market, making the technology accessible to small and medium-sized enterprises (SMEs), not just large industrial players. -

Regional Growth and Manufacturing Localization

Asia-Pacific, particularly China and India, is projected to lead market growth due to rapid industrialization, government support for green manufacturing, and domestic production of laser components. North America and Europe will maintain strong positions, driven by aerospace and defense applications and stringent environmental policies. Localization of supply chains and service networks will be critical for market penetration. -

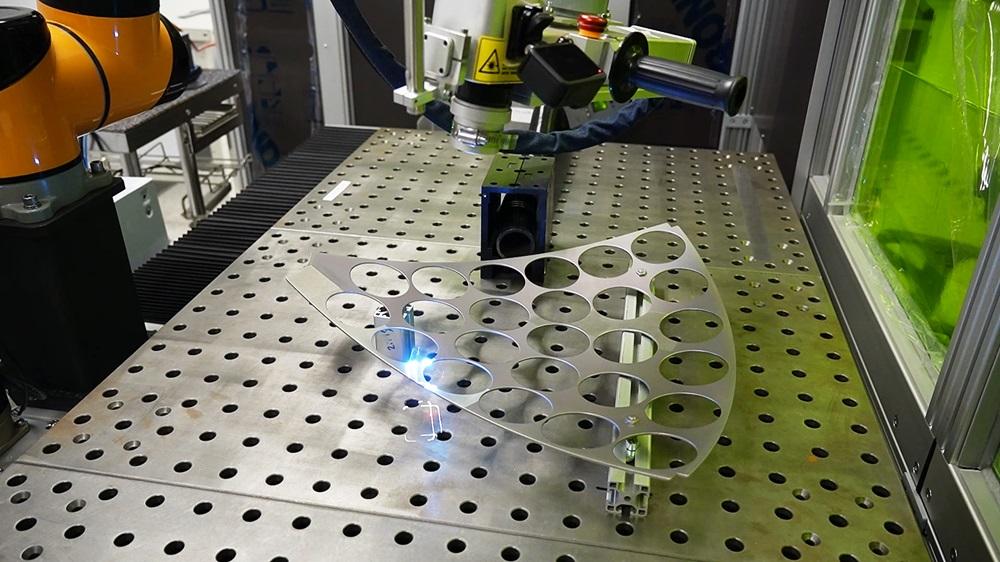

Integration with Industry 4.0 and Smart Manufacturing

Pulsed laser systems are increasingly being integrated into automated production lines and robotic platforms. By 2026, connectivity with IoT platforms and digital twins will enable predictive maintenance, remote operation, and data-driven process optimization, enhancing overall operational efficiency. -

Challenges: Standardization and Workforce Training

Despite technological progress, industry-wide standards for laser cleaning parameters and safety protocols remain underdeveloped. Additionally, a shortage of skilled technicians capable of operating and maintaining advanced laser systems poses a challenge. By 2026, collaboration between manufacturers, educational institutions, and regulatory bodies will be essential to address these gaps.

In conclusion, the pulsed laser rust removal market in 2026 will be characterized by rapid technological evolution, expanding applications, and strong tailwinds from sustainability mandates. Companies that invest in R&D, adopt scalable business models, and address training and regulatory challenges will be best positioned to capture growth in this high-potential sector.

Common Pitfalls in Sourcing Pulsed Laser Rust Removal Systems: Quality and Intellectual Property Risks

Sourcing pulsed laser rust removal systems presents significant opportunities for efficient, eco-friendly surface cleaning, but also carries critical risks related to quality and intellectual property (IP). Overlooking these pitfalls can lead to poor performance, safety hazards, legal exposure, and financial loss.

Quality-Related Pitfalls

Inadequate Technical Verification

Many suppliers, particularly from regions with less stringent manufacturing standards, may exaggerate laser power, pulse energy, beam quality, or cleaning speed. Without independent verification through third-party testing or rigorous on-site demonstrations using your specific materials and rust types, you risk acquiring underperforming equipment. Always demand test reports conforming to international standards (e.g., ISO) and conduct real-world trials before finalizing purchases.

Substandard Components and Build Quality

Low-cost systems may use inferior optical components (e.g., lenses, scanners), under-spec’d cooling systems, or subpar electrical components. These can degrade rapidly, leading to frequent downtime, reduced cleaning efficiency, or complete system failure. Inspect build quality closely and request detailed component specifications and warranties.

Insufficient Safety Features

Pulsed lasers pose serious eye and skin hazards. Some suppliers may omit or under-spec critical safety systems such as proper interlocks, Class 1 enclosures, laser emission indicators, or fail-safe beam shutters. Ensure compliance with IEC 60825 and local laser safety regulations, and verify that safety certifications are authentic and up to date.

Poor Thermal Management and Reliability

Inadequate cooling systems in low-quality units cause thermal lensing and power drop during sustained operation. This reduces cleaning consistency and damages internal components over time. Confirm that the system includes robust active cooling (e.g., closed-loop chillers) and has been tested for continuous operation under industrial conditions.

Lack of Service and Support Infrastructure

Even high-quality lasers require maintenance. Sourcing from suppliers without local technical support, spare parts availability, or trained service engineers can result in extended downtimes. Evaluate the supplier’s service network, response times, and availability of technical documentation before purchase.

Intellectual Property (IP) Risks

Sourcing Counterfeit or IP-Infringing Equipment

Some suppliers offer systems that mimic the design or functionality of patented technologies without proper licensing. Purchasing such equipment may expose your business to IP infringement claims, especially in regions with strong IP enforcement (e.g., EU, US, Japan). Conduct due diligence by verifying the manufacturer’s original equipment design, checking patent databases, and requesting IP compliance documentation.

Unclear Ownership of Customizations or Software

If you request software modifications or hardware adaptations, ensure contractual clarity on IP ownership. Some suppliers may retain rights to custom code or design changes, limiting your ability to modify, repair, or transfer the system in the future. Define IP ownership terms explicitly in procurement agreements.

Reverse Engineering and Technology Leakage

When working with certain manufacturers—especially those offering custom development—there is a risk they may reverse engineer your innovations or use your application data to develop competing products. Protect your business by using non-disclosure agreements (NDAs), limiting technical disclosures, and choosing partners with a verifiable reputation for respecting IP.

Weak or Missing Licensing Agreements

Software controlling laser parameters, scanning paths, or safety systems may be based on proprietary algorithms. Absence of a clear software license can restrict usage rights or lead to legal disputes. Insist on a formal software license agreement outlining permitted use, updates, and support.

To mitigate these risks, prioritize suppliers with proven track records, transparent technical specifications, verifiable certifications, and robust legal compliance. Engage legal counsel to review contracts and IP clauses, and consider third-party technical audits before finalizing procurement.

Logistics & Compliance Guide for Pulsed Laser Rust Removal

Equipment Transportation and Handling

Transporting pulsed laser rust removal systems requires careful planning due to their sensitive components and power requirements. The equipment should be securely packed in shock-absorbent, anti-static packaging and transported in climate-controlled vehicles to prevent damage from moisture, extreme temperatures, or vibration. Use pallets and secure strapping during transit to avoid shifting. For international shipments, ensure compliance with IATA/IMDG regulations if batteries or high-voltage components are included. Always de-energize and discharge capacitors before transportation. Maintain a handling log to track equipment status and movement.

Site Preparation and Installation

Prior to installation, conduct a site survey to verify adequate space, ventilation, electrical supply (typically 208–480V, three-phase), and structural support. Ensure the work area is clean, dry, and free from flammable materials. Install grounding systems per manufacturer specifications to prevent electrical hazards. Verify that laser interlocks, emergency stops, and beam shielding (e.g., enclosures or curtains) are correctly positioned. Confirm that exhaust or fume extraction systems are operational to capture particulate matter generated during rust ablation. All setup procedures must follow the equipment manual and be performed by qualified technicians.

Regulatory Compliance and Safety Standards

Pulsed laser systems are subject to multiple safety and environmental regulations. Comply with OSHA 29 CFR 1910.133 (eye and face protection) and ANSI Z136.1 (Safe Use of Lasers). Classify the laser per the IEC 60825-1 standard and affix appropriate warning labels. Register the equipment with relevant national or local authorities if required (e.g., FDA/CDRH in the U.S. for laser products). Implement a Laser Safety Program, including a designated Laser Safety Officer (LSO), hazard assessments, and controlled access zones. Provide ANSI-compliant laser safety eyewear specific to the laser’s wavelength (commonly in the near-infrared range, e.g., 1064 nm).

Operator Training and Certification

Only trained and authorized personnel may operate pulsed laser rust removal systems. Conduct comprehensive training covering laser hazards, emergency procedures, proper use of personal protective equipment (PPE), and system operation. Include hands-on practice and written assessment. Maintain training records and ensure refresher courses are conducted annually. Operators must understand beam path control, reflection risks, and fire prevention protocols. Certification should be documented and kept on file for audit purposes.

Environmental and Waste Management

Laser rust removal generates metal particulates and potentially hazardous fumes. Use local exhaust ventilation (LEV) with HEPA filtration to capture airborne contaminants. Dispose of collected waste as hazardous material if heavy metals (e.g., lead, chromium) are present, following EPA or local environmental regulations (e.g., RCRA in the U.S.). Conduct air quality monitoring when necessary. Prevent runoff of debris into drains. Maintain waste disposal logs and retain manifests for at least three years. Recycle metal particulates where feasible through approved facilities.

Documentation and Audit Readiness

Maintain comprehensive documentation including equipment manuals, maintenance logs, safety procedures, training records, compliance certificates, and incident reports. Conduct routine internal audits to verify adherence to safety and operational protocols. Prepare for external inspections by regulatory bodies by ensuring all documentation is current and accessible. Keep a compliance binder onsite and designate a responsible person for audit coordination.

International Shipping and Import Regulations

For cross-border movement of laser equipment, comply with export control regulations such as the U.S. Export Administration Regulations (EAR) or EU Dual-Use Regulation, particularly if the laser exceeds certain power thresholds. Obtain necessary export licenses when required. Declare the equipment accurately with Harmonized System (HS) codes (e.g., 9013.20 for laser machines). Ensure importers have the technical capability to meet local safety and electrical standards (e.g., CE, UKCA, CCC). Provide multilingual operation and safety manuals as needed.

Conclusion for Sourcing Pulsed Laser Rust Removal

Sourcing pulsed laser technology for rust removal presents a forward-thinking, efficient, and environmentally sustainable alternative to traditional cleaning methods such as sandblasting, chemical treatments, or mechanical abrasion. Pulsed lasers offer precision, minimal substrate damage, and the ability to selectively remove rust without affecting the underlying material, making them ideal for delicate or high-value components in industries such as aerospace, automotive, cultural heritage restoration, and manufacturing.

When sourcing this technology, key considerations include laser pulse energy, frequency, wavelength, beam quality, and system integration capabilities. It is also important to evaluate the supplier’s technical support, system reliability, safety certifications, and after-sales service. While the initial investment may be higher than conventional methods, the long-term benefits—such as reduced operating costs, no consumables, compliance with environmental regulations, and improved worker safety—justify the cost.

Ultimately, sourcing a high-quality pulsed laser rust removal system represents a strategic investment in sustainable, precise, and scalable surface treatment solutions, positioning organizations at the forefront of industrial innovation and environmental responsibility. Careful vendor selection and proper system validation will ensure optimal performance and return on investment.