The global laser diode market, which includes pulse laser technologies, is experiencing robust growth driven by increasing demand across industrial, medical, telecommunications, and defense sectors. According to a 2023 report by Mordor Intelligence, the laser diode market was valued at USD 13.5 billion in 2022 and is projected to grow at a CAGR of over 10.5% from 2023 to 2028. This expansion is fueled by advancements in optoelectronics, rising adoption of laser-based systems in manufacturing automation, and the proliferation of LiDAR in autonomous vehicles. As pulsed lasers offer precise control and high peak power for applications such as material processing, medical aesthetics, and scientific research, demand for reliable and innovative manufacturers has intensified. With North America and Asia Pacific leading in R&D investments and industrial integration, the competitive landscape is evolving rapidly. Based on market presence, technological innovation, product range, and industry reputation, the following nine companies represent the forefront of pulse laser manufacturing globally.

Top 9 Pulse Lazer Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Pulse Laser & Industrial Systems

Website: pulselaserandindustrial.com

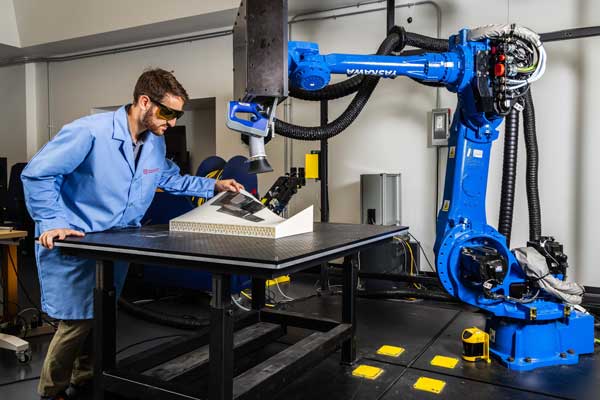

Key Highlights: Originally founded in Brisbane, Australia in 1992 as Pulse Laser Systems, we’ve spent over 30 years delivering exceptional service, products, and communication….

#2 Pulse Laser Systems

Website: pulselasersystems.com.au

Key Highlights: Explore the world of Laser machinery. Serving Australia wide. we supply laser welding equipment and industrial machines such as Oree, Aeon, LTT and more….

#3 Applied Energetics

Website: appliedenergetics.com

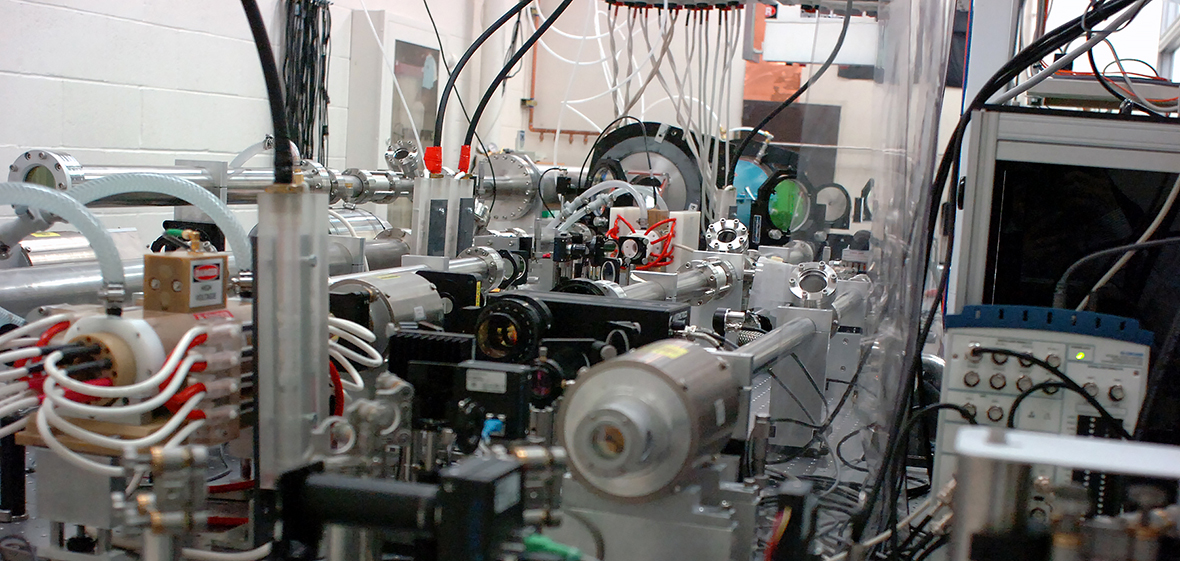

Key Highlights: At Applied Energetics, we discover innovative and novel ultrashort pulse laser design techniques. Building on significant experience in advanced optical science ……

#4 Laser Texturing

Website: pulsetechnologies.com

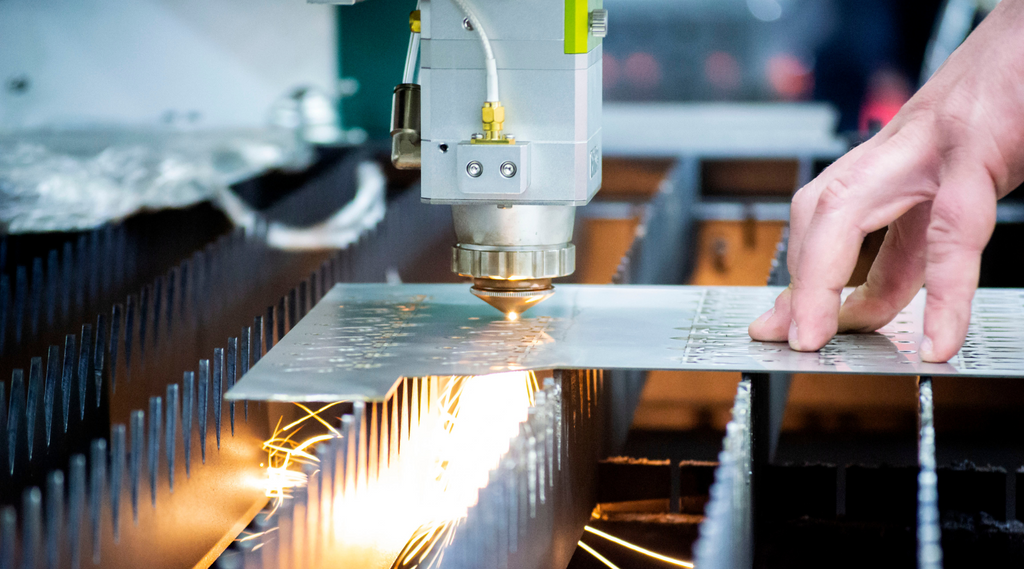

Key Highlights: We’ve developed advanced laser texturing techniques to create controlled surface roughness for improved bonding strength….

#5 Pulse Industries Ltd.

Website: pulseindustries.ca

Key Highlights: Mobile laser cleaning and sandblasting alternative company servicing Alberta to clean a variety of surfaces including equipment, vehicles, ……

#6 Laser Tech

Website: lasertech.com

Key Highlights: Laser Tech is a global leader in innovative laser speed & distance measurement equipment bringing efficiency & improved safety to your industry….

#7 PulseMedica

Website: pulsemedica.com

Key Highlights: Discover PulseMedica’s revolutionary 3D image-guided laser treatment device. Platform solution for treating eye floaters and vitreoretinal disease….

#8 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#9 Spectra

Website: spectra-physics.com

Key Highlights: Spectra-Physics is a brand within the MKS Photonics Solution division. The Spectra-Physics product portfolio consists of a broad spectrum of lasers….

Expert Sourcing Insights for Pulse Lazer

H2 2026 Market Trends Analysis for Pulse Laser

As we approach the second half of 2026, the global market for pulsed lasers is poised for significant transformation, driven by technological advancements, evolving industrial demands, and strategic shifts across key application sectors. For companies like Pulse Laser (assuming “Pulse Lazer” refers to a manufacturer or provider of pulsed laser systems), understanding and adapting to these trends is critical for maintaining competitiveness and capturing growth opportunities.

1. Dominance of Ultrafast Lasers in Precision Manufacturing

By H2 2026, ultrafast lasers (picosecond and femtosecond) are expected to solidify their position as the technology of choice in high-precision industrial applications. Sectors like semiconductor manufacturing, advanced electronics, and medical device fabrication will continue to demand minimal thermal impact and sub-micron accuracy. Pulse Laser can capitalize on this by:

– Expanding product lines with higher repetition rates and improved wall-plug efficiency.

– Developing application-specific turnkey systems for micro-machining, surface texturing, and OLED repair.

– Focusing on reliability and ease of integration into automated production lines.

2. Growth in Electric Vehicle (EV) and Battery Manufacturing

The surge in EV production is directly fueling demand for pulsed lasers in battery electrode structuring, welding, and quality inspection. In H2 2026, manufacturers will prioritize throughput and yield. Pulse Laser should:

– Optimize nanosecond and picosecond lasers for high-speed battery electrode cutting and cleaning.

– Offer scalable laser solutions with integrated process monitoring and AI-driven quality control.

– Strengthen partnerships with battery cell and pack manufacturers in North America, Europe, and Asia.

3. Advancements in Solid-State and Fiber Laser Efficiency

Energy efficiency and total cost of ownership (TCO) will be paramount. Solid-state and fiber-based pulsed lasers will continue to improve in power stability, beam quality, and cooling efficiency. Pulse Laser can:

– Invest in next-generation pump diodes and thermal management systems.

– Develop compact, air-cooled models for space-constrained applications.

– Provide detailed TCO calculators to demonstrate long-term savings to industrial clients.

4. Expansion into Biophotonics and Medical Applications

Pulsed lasers are gaining traction in non-invasive medical treatments, such as dermatology (tattoo removal, pigmentation), ophthalmology, and aesthetic surgery. Regulatory approvals and safety standards will be key. Pulse Laser should:

– Pursue FDA and CE certifications for medical-grade systems.

– Collaborate with dermatology clinics and medical device OEMs.

– Focus on user-friendly interfaces and customizable pulse parameters.

5. Integration of AI and Smart Manufacturing

Industry 4.0 adoption will accelerate, with pulsed lasers becoming nodes in smart factories. In H2 2026, demand for lasers with embedded sensors and data connectivity will rise. Pulse Laser must:

– Equip systems with IoT capabilities for remote monitoring and predictive maintenance.

– Partner with Industry 4.0 platform providers to ensure seamless integration.

– Utilize AI to optimize laser parameters in real-time based on feedback.

6. Sustainability and Green Manufacturing

Environmental regulations and corporate sustainability goals will influence purchasing decisions. Pulse Laser can differentiate by:

– Highlighting energy-efficient designs and recyclable components.

– Offering laser remanufacturing and upgrade programs.

– Reducing hazardous materials in production processes.

7. Geopolitical and Supply Chain Resilience

Ongoing supply chain volatility and regional trade policies (e.g., U.S. CHIPS Act, EU Green Deal) will impact component sourcing and market access. Pulse Laser should:

– Diversify supply chains for critical components like optics and semiconductors.

– Consider localized production or assembly in key markets.

– Monitor export controls on laser technology, especially high-power systems.

Strategic Recommendations for Pulse Laser

To thrive in H2 2026, Pulse Laser should:

– Prioritize R&D in ultrafast and fiber laser technologies.

– Expand into high-growth verticals: EVs, medical devices, and renewable energy.

– Embrace digitalization with smart, connected laser systems.

– Strengthen customer support with application engineering and training.

– Position the brand around reliability, efficiency, and sustainability.

By aligning with these key H2 2026 trends, Pulse Laser can enhance its market position, drive innovation, and achieve sustainable growth in an increasingly competitive and dynamic landscape.

Common Pitfalls Sourcing Pulse Lasers: Quality and Intellectual Property Risks

Sourcing pulse lasers, especially for industrial, medical, or research applications, involves navigating several critical challenges. Two of the most significant pitfalls revolve around quality assurance and intellectual property (IP) protection. Overlooking these areas can lead to performance failures, project delays, legal disputes, and significant financial loss.

Quality-Related Pitfalls

Inconsistent Pulse Performance

Pulse lasers must deliver stable pulse energy, duration, and repetition rates. Low-cost or unverified suppliers may provide lasers with fluctuating output, leading to unreliable results in applications like material processing or scientific measurement. Always request detailed performance data sheets and verify specifications under real-world conditions.

Poor Beam Quality and Alignment

Beam profile (e.g., M² factor), pointing stability, and alignment consistency are crucial. Inferior lasers may suffer from mode instability or thermal drift, compromising precision. Suppliers without rigorous quality control often fail to meet beam quality standards, resulting in subpar system integration and reduced application accuracy.

Lack of Environmental and Operational Reliability

Pulse lasers used in demanding environments must withstand temperature fluctuations, vibrations, and continuous operation. Sourcing from manufacturers without robust environmental testing can result in shortened lifespan, frequent downtime, or field failures—especially if cooling, power supply, and thermal management are poorly engineered.

Insufficient Documentation and Support

Reliable suppliers provide comprehensive technical documentation, calibration certificates, and responsive technical support. Missing or inadequate documentation makes integration difficult and troubleshooting time-consuming, increasing the total cost of ownership.

Intellectual Property (IP) Risks

Unauthorized Use of Protected Technology

Some suppliers, especially in less-regulated markets, may incorporate patented laser diodes, driver circuits, or control software without proper licensing. Purchasing such systems exposes the buyer to potential IP infringement claims, especially in export-controlled or highly competitive industries.

Lack of IP Ownership Clarity

When customizing or integrating pulse lasers into larger systems, it’s essential to confirm who owns the IP—especially for firmware, control algorithms, or mechanical designs. Ambiguous contracts may result in shared or lost IP rights, limiting future product development or commercialization.

Counterfeit or Reverse-Engineered Components

Low-cost suppliers may use counterfeit or reverse-engineered components that mimic genuine parts. These can fail prematurely or violate IP laws. Due diligence, including component traceability and supplier audits, is necessary to avoid legal exposure and performance issues.

Inadequate Warranty and Liability Coverage

Many low-tier suppliers offer limited or no warranty for IP-related issues. If a laser system is found to infringe on third-party patents, the buyer—not the supplier—may bear legal and financial responsibility. Ensure contracts include IP indemnification clauses.

Mitigation Strategies

To avoid these pitfalls, conduct thorough supplier vetting, request third-party test validation, insist on detailed technical and compliance documentation, and involve legal counsel in contract reviews—especially regarding IP rights and liabilities. Prioritizing reputable manufacturers with proven track records in quality control and IP compliance is essential for long-term success.

Logistics & Compliance Guide for Pulse Lazer

This guide outlines the essential logistics procedures and compliance requirements for Pulse Lazer, ensuring efficient operations and adherence to applicable regulations.

Order Fulfillment Process

All customer orders are processed within 1–2 business days of receipt. Pulse Lazer utilizes integrated inventory management software to confirm product availability. Once confirmed, orders are picked, packed, and labeled with appropriate shipping documentation, including itemized packing slips and tracking numbers. High-demand products are prioritized to minimize fulfillment delays.

Shipping & Carrier Management

Pulse Lazer partners with certified logistics carriers (e.g., FedEx, UPS, DHL) based on destination, delivery speed, and cost-efficiency. Standard, expedited, and international shipping options are available. All shipments are insured and tracked. Packaging complies with carrier standards to ensure product safety and reduce environmental impact through minimal, recyclable materials.

International Compliance

For cross-border shipments, Pulse Lazer adheres to export regulations set by relevant authorities (e.g., U.S. Department of Commerce, EU customs). Required documentation includes commercial invoices, packing lists, and export declarations. Products are classified using appropriate HS codes. Restricted destinations are monitored via automated compliance screening tools to prevent unauthorized shipments.

Product Safety & Regulatory Standards

All laser products comply with applicable safety standards, including FDA 21 CFR 1040.10 (U.S.) and IEC 60825 (international). Each unit undergoes quality control testing and bears required warning labels, certification marks, and compliance documentation. Pulse Lazer maintains up-to-date technical files and ensures conformity with RoHS, REACH, and other environmental directives.

Inventory & Warehouse Compliance

Warehouse operations follow OSHA safety guidelines and implement fire prevention protocols. Inventory is stored in a climate-controlled environment to protect sensitive components. Regular audits ensure accurate stock levels and traceability. Access to storage areas is restricted and monitored via security systems to prevent tampering or theft.

Data Security & GDPR/CCPA Compliance

Customer and transaction data collected during logistics operations are encrypted and stored securely. Pulse Lazer complies with GDPR and CCPA requirements by obtaining consent for data processing, enabling data access requests, and ensuring third-party logistics partners adhere to strict data protection agreements.

Returns & Reverse Logistics

A structured returns process is in place for defective or incorrect shipments. Customers must request a Return Merchandise Authorization (RMA) before sending products back. Returned items are inspected, and compliance with safety standards is verified before refurbishment, resale, or disposal. All returns are logged for quality tracking and regulatory reporting.

Sustainability & Environmental Responsibility

Pulse Lazer is committed to reducing its carbon footprint by optimizing shipping routes, using eco-friendly packaging, and participating in equipment recycling programs. Waste materials from logistics operations are sorted and disposed of in accordance with local environmental regulations.

Audit & Continuous Improvement

Internal compliance audits are conducted quarterly to verify adherence to logistics policies and regulatory requirements. Findings are reviewed by management, and corrective actions are implemented promptly. Feedback from customers and partners is used to refine processes and enhance service reliability.

Conclusion on Sourcing Pulsed Lasers

Sourcing pulsed lasers requires a careful evaluation of technical specifications, application requirements, budget constraints, and supplier reliability. Pulsed lasers are critical in diverse fields such as medical treatments, industrial machining, scientific research, and defense technologies, necessitating a tailored approach to procurement. Key factors to consider include pulse duration, wavelength, repetition rate, power output, beam quality, and cooling requirements.

When sourcing, it is essential to engage with reputable manufacturers or distributors that offer technical support, warranty options, and compliance with relevant international standards (e.g., FDA, CE, IEC). Evaluating both domestic and global suppliers can provide cost advantages and access to advanced technologies, though logistics, lead times, and after-sales service must be taken into account.

Additionally, emerging trends such as fiber-based pulsed lasers and ultrafast laser systems present opportunities for improved performance and efficiency. Therefore, future-proofing the procurement decision by considering scalability and technological advancements is advisable.

In conclusion, successful sourcing of pulsed lasers relies on a strategic balance between performance needs and supply chain considerations, ensuring reliable, high-quality equipment that meets both current and long-term operational goals.