The global pulley market is witnessing steady expansion, driven by rising demand across industrial automation, material handling, and renewable energy sectors. According to a 2023 report by Mordor Intelligence, the global pulley market was valued at approximately USD 3.8 billion and is projected to grow at a CAGR of over 4.5% from 2023 to 2028. This growth is fueled by the increasing need for corrosion-resistant and durable components, particularly in harsh environments, which has elevated the demand for stainless steel pulleys. With advantages such as high tensile strength, excellent resistance to oxidation, and low maintenance, stainless steel pulleys are becoming the preferred choice in food processing, pharmaceuticals, marine, and outdoor industrial applications. As the market evolves, manufacturers are focusing on precision engineering, enhanced performance, and compliance with international quality standards. In this competitive landscape, eight leading manufacturers have distinguished themselves through innovation, scalable production, and a strong global footprint—setting the benchmark for quality and reliability in stainless steel pulley manufacturing.

Top 8 Pulley Stainless Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 7/8″ Stainless Steel Pulley

Domain Est. 1995

Website: hogslat.com

Key Highlights: In stock 30-day returns7/8″ Stainless Steel Curtain Pulley Replacement for previous Hog Slat part numbers: 617211 *Use of manufacturer part numbers for reference purposes only….

#2 Industrial Pulley Blocks

Domain Est. 1997

Website: ronstan.com

Key Highlights: Triple block with three 75mm (3″) sheaves, becket, cleat with 30° cleating angle, swivel shackle head and black powder coated 316 stainless steel side plates….

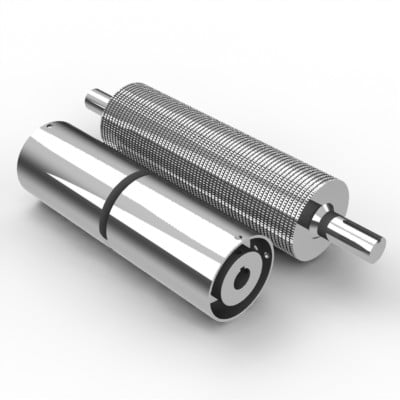

#3 Stainless Steel Pulley Manufacturer in China

Domain Est. 2021

Website: hmaking.com

Key Highlights: HM is a top stainless steel pulley manufacturer, offering a wide range of high-quality and customizable pulleys for various applications….

#4 Stainless Steel Pulley and Swivel Blocks Archives

Domain Est. 1998

Website: suncorstainless.com

Key Highlights: Suncor manufactures stainless steel pulley and swivel blocks that are able to accommodate fibrous rope or wire rope in a variety of sizes ranging from 5/8″ ……

#5 Stainless Steel Pulleys

Domain Est. 1998

Website: pcimfg.com

Key Highlights: PCI has developed distinct classes of stainless steel conveyor pulleys that are designed to meet the requirements where proper material selection is critical….

#6 Stainless Steel Pulleys

Domain Est. 1998

Website: delanoconveyor.com

Key Highlights: We have diameters available 2″ all the way through 72″. Our stainless pulleys are manufactured from the highest quality heavy wall, pipe and gauge tubing….

#7

Domain Est. 2000

Website: americanpulley.com

Key Highlights: Welcome to American Pulley. We are your premiere Pulley Manufacturing company. All of our products are proudly American made and manufactured in Alabama….

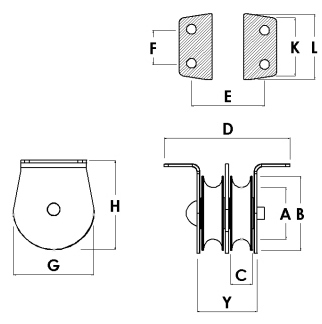

#8 3.5” Flat Mount Stainless Steel Pulley; Snatch; 2 Sheaves

Domain Est. 2000

Website: blockdivision.com

Key Highlights: 3-1/2” Flat mount pulley block with removable snatch pin; double 5/8” wide machine sheaves with oil impregnated bushing, grooved for 3/8” maximum cable or ……

Expert Sourcing Insights for Pulley Stainless

H2: Market Trends for Pulley Stainless in 2026

As we approach 2026, the global market for stainless steel pulleys—commonly referred to as “Pulley Stainless”—is poised for significant transformation, driven by technological innovation, evolving industrial demands, and macroeconomic shifts. This analysis outlines key trends shaping the Pulley Stainless market in the second half of 2025 and into 2026, providing strategic insights for manufacturers, suppliers, and end users.

1. Rising Demand in Renewable Energy and Electric Mobility

The expansion of renewable energy infrastructure—particularly solar tracking systems and wind turbine mechanisms—is accelerating the adoption of stainless steel pulleys. These components offer superior corrosion resistance, durability, and low maintenance, making them ideal for outdoor and harsh environments. Similarly, the growth of electric vehicles (EVs) and lightweight automated transport systems is increasing demand for high-performance pulleys in belt-driven systems and auxiliary components. By 2026, the clean energy and EV sectors are projected to account for over 30% of Pulley Stainless demand.

2. Automation and Industry 4.0 Integration

The global push toward smart manufacturing and Industry 4.0 is driving demand for precision-engineered pulleys compatible with automated assembly lines, robotics, and IoT-enabled machinery. Stainless steel pulleys are favored for their reliability in continuous operation and resistance to wear. In H2 2026, expect increased integration of pulley systems with sensors and predictive maintenance platforms—enabling real-time monitoring of belt tension, alignment, and wear.

3. Supply Chain Resilience and Regionalization

Post-pandemic supply chain disruptions and geopolitical tensions have prompted a shift toward regional sourcing and nearshoring. In H2 2026, manufacturers in North America and Europe are increasingly partnering with local pulley producers to reduce lead times and mitigate risks. This trend supports the growth of mid-tier stainless pulley fabricators specializing in customized, high-mix/low-volume production.

4. Sustainability and Circular Economy Pressures

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are influencing material choices. Stainless steel, being 100% recyclable and long-lasting, aligns well with sustainability mandates. In H2 2026, expect more OEMs to specify recycled-content stainless steel pulleys and demand lifecycle assessments from suppliers. Water-saving manufacturing processes and low-carbon production methods will become competitive differentiators.

5. Material and Design Innovation

Developments in high-strength, lightweight stainless alloys (e.g., lean duplex grades) are enabling pulleys that offer improved strength-to-weight ratios and enhanced performance in corrosive environments. Additive manufacturing is also beginning to play a role in prototyping and producing complex pulley geometries. By late 2026, we anticipate pilot deployments of 3D-printed stainless pulleys in aerospace and medical applications.

6. Competitive Landscape and Pricing Pressures

The Pulley Stainless market remains fragmented, with competition intensifying between established European and North American suppliers and low-cost manufacturers in Asia. While price pressure persists, value is increasingly shifting toward customization, technical support, and integrated solutions. Leading players are differentiating through digital platforms for configuration, quoting, and inventory management.

Conclusion

In H2 2026, the Pulley Stainless market will be characterized by strong demand from high-growth sectors, a focus on operational resilience, and innovation in materials and digital integration. Companies that align with sustainability goals, embrace smart manufacturing, and offer tailored solutions are best positioned to capture market share. As industrial ecosystems evolve, stainless steel pulleys will remain a critical enabler of efficient, durable, and future-ready mechanical systems.

Common Pitfalls When Sourcing Pulley Stainless (Quality, IP)

Sourcing pulley components made from stainless steel involves several critical considerations, particularly concerning material quality and intellectual property (IP) protection. Overlooking these aspects can lead to supply chain disruptions, product failures, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Quality-Related Pitfalls

Inadequate Material Certification

Failing to require proper material test reports (MTRs) or mill certificates can result in receiving substandard stainless steel. Suppliers may claim compliance with grades like 304 or 316 without providing verifiable proof, leading to corrosion resistance issues or mechanical failure in critical applications.

Inconsistent Manufacturing Standards

Pulleys produced without adherence to international standards (e.g., ISO, DIN, or ASTM) may exhibit dimensional inaccuracies, poor surface finish, or inconsistent heat treatment. This variability compromises performance, especially in high-precision or high-load environments.

Lack of In-Process Quality Control

Relying solely on final inspection instead of implementing supplier-side quality control processes increases the risk of batch-wide defects. Without regular audits or process validation, defects like micro-cracks, porosity, or incorrect machining tolerances may go undetected.

Corrosion Resistance Misrepresentation

Some suppliers may use lower-grade or counterfeit stainless steel that appears visually similar but lacks the required chromium, nickel, or molybdenum content. This leads to premature rusting or pitting, especially in humid or chemically aggressive environments.

Intellectual Property-Related Pitfalls

Failure to Secure IP Rights in Contracts

Not clearly defining ownership of custom-designed pulleys in procurement agreements can result in the supplier retaining design rights. This limits your ability to switch manufacturers or scale production without legal complications or licensing fees.

Use of Counterfeit or Copied Designs

Sourcing from suppliers who replicate patented pulley designs exposes your business to infringement claims. Even if unintentional, using IP-violating components can lead to product recalls, fines, or litigation from original equipment manufacturers (OEMs).

Insufficient Non-Disclosure Agreements (NDAs)

Sharing design specifications without a robust NDA in place risks unauthorized use or disclosure of proprietary features. This is particularly critical when sourcing custom or innovative pulley configurations.

Geographical IP Enforcement Gaps

Sourcing from regions with weak IP enforcement increases the likelihood of design theft or unauthorized production. Even with legal contracts, enforcing IP rights abroad can be costly and ineffective, undermining competitive advantage.

Mitigation Strategies

To avoid these pitfalls, implement a structured sourcing process that includes verified supplier audits, mandatory material certifications, clear IP clauses in contracts, and ongoing quality monitoring. Engaging legal counsel to review agreements and using trusted partners with proven compliance records can significantly reduce risks associated with both quality and intellectual property.

Logistics & Compliance Guide for Pulley Stainless

This guide outlines the essential logistics and compliance protocols for operations involving Pulley Stainless products. Adherence ensures smooth supply chain execution, regulatory compliance, and product integrity.

Product Handling & Storage

Handle Pulley Stainless components with clean gloves or tools to avoid surface contamination. Store in a dry, indoor environment, protected from moisture, dust, and corrosive agents. Keep materials separated from carbon steel to prevent cross-contamination and galvanic corrosion. Use non-metallic slings and lifting equipment to avoid surface damage during handling.

Packaging & Shipping Requirements

All Pulley Stainless items must be packaged to prevent mechanical damage and environmental exposure during transit. Use moisture-resistant wrapping, protective caps on threaded parts, and secure cushioning within sturdy, labeled containers. Clearly mark packages with product details, handling instructions (e.g., “Fragile,” “Do Not Stack”), and relevant compliance labels. Ensure compliance with international shipping regulations (e.g., IMDG for sea freight, IATA for air) when applicable.

Regulatory Compliance

Pulley Stainless products must meet all relevant industry and regional standards, including ASTM, ISO, and EN specifications for stainless steel materials. Certifications such as Material Test Reports (MTRs) and Mill Certificates must accompany shipments upon request. Ensure compliance with REACH, RoHS, and other environmental regulations for restricted substances. Export documentation must reflect accurate Harmonized System (HS) codes and country-of-origin declarations.

Customs & Documentation

Provide complete and accurate commercial invoices, packing lists, and bills of lading for all shipments. Include full product descriptions, quantities, weights, values, and end-use information. For international shipments, verify import requirements in the destination country, including customs duties, import licenses, or conformity assessments (e.g., CE marking, CRN for Canada). Retain all logistics and compliance documentation for a minimum of five years.

Quality Assurance & Traceability

Maintain full traceability of Pulley Stainless products from raw material sourcing through manufacturing and delivery. Implement a documented quality management system (e.g., ISO 9001) to ensure consistency. Conduct regular audits of logistics partners to confirm adherence to handling, storage, and compliance standards. Report and investigate any non-conformances promptly.

Environmental & Safety Considerations

Dispose of packaging materials in accordance with local environmental regulations. Train personnel in safe handling procedures, including proper use of personal protective equipment (PPE). Ensure transportation partners comply with safety standards for hazardous materials if applicable (e.g., lubricants or cleaning agents used with pulleys). Minimize carbon footprint through optimized routing and sustainable packaging practices.

Conclusion on Sourcing Stainless Steel Pulleys:

Sourcing stainless steel pulleys requires a strategic approach that balances material quality, corrosion resistance, mechanical performance, and cost-efficiency. Stainless steel pulleys offer superior durability, especially in harsh environments involving moisture, chemicals, or outdoor exposure, making them ideal for marine, food processing, pharmaceutical, and industrial applications. When sourcing, it is essential to prioritize suppliers with certifications (such as ISO standards), material traceability, and consistent manufacturing processes to ensure product reliability.

Key considerations include selecting the appropriate grade of stainless steel (e.g., 304 for general use or 316 for enhanced corrosion resistance), verifying dimensional accuracy, and assessing surface finish requirements. Additionally, evaluating supplier lead times, MOQs (Minimum Order Quantities), and after-sales support can significantly impact overall procurement success.

In conclusion, investing time in identifying reputable suppliers, conducting sample testing, and building long-term partnerships ensures a reliable supply of high-quality stainless steel pulleys that meet technical specifications and contribute to the efficiency and longevity of the final application.