The global pulley and power transmission components market is experiencing steady growth, driven by increasing demand across industrial, automotive, and manufacturing sectors. According to Grand View Research, the global power transmission equipment market was valued at USD 59.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This expansion is fueled by rising industrial automation, infrastructure development, and the need for energy-efficient mechanical systems. Pulley engines—critical components in belt-driven power transmission—play a vital role in ensuring operational efficiency across applications ranging from conveyor systems to automotive engines. As demand escalates, leading manufacturers are innovating with advanced materials and precision engineering to meet performance and durability requirements. In this evolving landscape, the following seven companies have emerged as top pulley engine manufacturers, combining market share leadership, technological innovation, and global reach.

Top 7 Pulley Engine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pulleys

Domain Est. 2002

Website: steinmanufacturing.com

Key Highlights: We have front crankshaft pulleys to fit most of the late model industrial & irrigation engines. They are manufactured from cast iron or steel….

#2 Timing Belt Pulleys

Domain Est. 1994

Website: gates.com

Key Highlights: Gates timing belt pulleys are precisely engineered for positive press fit with minimum belt wobble, designed to optimize the performance and durable working ……

#3 Fenner Precision Polymers

Domain Est. 1996

Website: fenner.com

Key Highlights: Fenner Precision Polymers specializes in manufacturing critical components that power and propel industries forward….

#4 INA tensioner and deflection pulleys

Domain Est. 1998

Website: vehiclelifetimesolutions.schaeffler.com

Key Highlights: INA mechanical and automatic tensioner pulleys ensure constant belt tension under all external conditions and with frequent load changes in everyday operation….

#5 Dayco

Domain Est. 1998

Website: dayco.com

Key Highlights: Dayco is a global leader in the research, design, manufacture and distribution of essential engine drive systems and aftermarket services for automotive, truck, ……

#6 Engineered Pulleys

Domain Est. 1998

Website: prok.com

Key Highlights: PROK offers a wide range of engineered conveyor pulley solutions, available in custom designs to meet specific customer requirements….

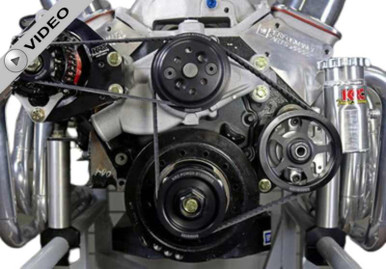

#7 KRC Power Steering Racing Pumps & Racing Engine Pulley Kits

Domain Est. 2001

Website: krcpower.com

Key Highlights: KRC Power Steering Manufactures Quality Racing Power Steering Pumps, racing power steering fluid, racing engine pulleys and engine brackets for Racing and ……

Expert Sourcing Insights for Pulley Engine

H2: Market Trends for Pulley Engine by 2026

By 2026, the market for pulley engines—mechanical components used in power transmission across industries such as automotive, industrial manufacturing, HVAC, and agriculture—is expected to experience steady growth driven by technological advancements, energy efficiency demands, and evolving industrial automation trends. Below is an analysis of key market trends shaping the pulley engine sector through 2026:

1. Rising Demand in Automotive and Electric Vehicles (EVs)

The automotive industry remains a major consumer of pulley engine systems, particularly in internal combustion engines (ICEs) for belt-driven accessories like alternators, air conditioning compressors, and water pumps. However, with the global shift toward electric vehicles (EVs), traditional pulley engine usage in powertrains is declining. Despite this, pulley systems are still being integrated into EV thermal management and auxiliary systems. Innovations in compact, lightweight pulley designs are being tailored for hybrid and electric platforms, ensuring continued relevance.

2. Growth in Industrial Automation and Manufacturing

The expansion of smart factories and Industry 4.0 is increasing the need for reliable, high-efficiency power transmission systems. Pulley engines are being optimized for use in conveyor systems, robotics, and automated assembly lines. The trend toward modular and maintenance-free pulley systems—featuring advanced materials like fiber-reinforced polymers and precision-machined aluminum—will drive adoption in high-throughput environments.

3. Emphasis on Energy Efficiency and Sustainability

Global regulatory pressures to reduce energy consumption are pushing industries to adopt more efficient mechanical drive systems. Variable speed pulley engines and systems incorporating adjustable pulley ratios are gaining traction for their ability to match output to load requirements, reducing energy waste. Additionally, manufacturers are focusing on recyclable materials and longer product lifecycles to align with ESG (Environmental, Social, and Governance) goals.

4. Technological Integration and Smart Monitoring

By 2026, the integration of IoT (Internet of Things) sensors into pulley systems is expected to become more common. Smart pulley engines equipped with vibration, temperature, and wear sensors enable predictive maintenance, reducing downtime and operational costs. This digital transformation is particularly impactful in sectors like mining, oil & gas, and heavy manufacturing.

5. Regional Market Dynamics

Asia-Pacific, led by China, India, and Southeast Asia, is projected to dominate the pulley engine market due to rapid industrialization, infrastructure development, and automotive production. North America and Europe will focus on retrofitting legacy systems with high-efficiency pulley technologies and supporting green manufacturing initiatives. Meanwhile, emerging markets in Latin America and Africa will see gradual growth as industrial capacity expands.

6. Competitive Landscape and Innovation

Key players such as Gates Corporation, Bosch Rexroth, SKF, and Mitsuboshi Belting are investing in R&D to develop high-performance, corrosion-resistant pulley engines with improved torque transmission and reduced slippage. Collaborations with OEMs and system integrators are accelerating the adoption of custom-engineered pulley solutions for niche applications.

Conclusion

By 2026, the pulley engine market will be characterized by innovation, digital integration, and adaptation to electrification trends. While traditional applications may decline in some sectors, new opportunities in automation, energy efficiency, and smart manufacturing will sustain demand. Companies that prioritize R&D, sustainability, and digital capabilities will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing a Pulley Engine

When sourcing a pulley engine—whether for industrial machinery, automotive applications, or custom engineering projects—organizations often encounter significant challenges related to quality and intellectual property (IP). Overlooking these aspects can lead to performance issues, legal disputes, and increased total cost of ownership. Below are two major pitfalls to avoid.

Quality Inconsistencies and Lack of Standards

One of the most frequent issues when sourcing pulley engines is inconsistent quality, especially when dealing with multiple suppliers or low-cost manufacturers. Poorly manufactured pulley engines may suffer from imprecise machining, substandard materials, or inadequate balancing, leading to premature wear, vibration, and system failure. Additionally, the absence of adherence to industry standards (such as ISO, DIN, or ANSI) can result in incompatibility with existing machinery and safety risks. Without rigorous quality control processes, including material certifications and performance testing, buyers risk integrating unreliable components into critical systems.

Intellectual Property Risks and Unauthorized Replication

Sourcing pulley engines—particularly from overseas or third-party suppliers—poses significant intellectual property (IP) concerns. There is a risk of inadvertently purchasing counterfeit or reverse-engineered products that infringe on patented designs or proprietary technology. This not only exposes the buyer to legal liability but may also compromise performance and supportability. Furthermore, sharing custom specifications or design modifications with unvetted suppliers could lead to IP theft or unauthorized replication. Ensuring that suppliers respect IP rights and providing proper contractual protections (e.g., non-disclosure agreements and IP indemnification clauses) is essential to mitigate these risks.

Logistics & Compliance Guide for Pulley Engine

This guide outlines the essential logistics and compliance considerations for operating and maintaining the Pulley Engine. Adherence to these guidelines ensures safe, efficient, and legally compliant operations.

1. Transportation & Handling

Ensure the Pulley Engine is securely packaged and transported using appropriate lifting equipment. Use certified slings and hoists rated for the engine’s weight. During transit, protect sensitive components from moisture, dust, and impact. Avoid tilting beyond the manufacturer’s specified angle to prevent internal damage.

2. Storage Requirements

Store the Pulley Engine in a dry, temperature-controlled environment (10°C to 35°C recommended). Keep it elevated off the ground on pallets and covered with breathable protective wrapping. Ensure adequate ventilation to prevent condensation. Record storage dates and perform quarterly visual inspections.

3. Import & Export Compliance

Verify all export controls and import regulations applicable to the Pulley Engine based on destination country. Obtain necessary export licenses (e.g., under EAR or ITAR, if applicable). Accurately complete shipping documentation, including commercial invoice, packing list, and certificate of origin. Classify the engine using the correct HS code.

4. Safety & Installation Standards

Installation must comply with OSHA (U.S.) or equivalent local safety regulations. Ensure all personnel are trained and wear appropriate PPE. Follow the manufacturer’s installation manual precisely, including alignment, anchoring, and clearance requirements. Perform a safety audit prior to commissioning.

5. Environmental Regulations

Dispose of packaging materials according to local recycling and waste disposal laws. Handle lubricants and cleaning agents in compliance with EPA or equivalent environmental standards. Prevent fluid leaks during maintenance and use spill containment systems where required.

6. Maintenance & Recordkeeping

Conduct scheduled maintenance per the manufacturer’s timetable. Maintain detailed logs of inspections, repairs, parts replacements, and performance tests. Retain records for a minimum of seven years for audit and compliance verification purposes.

7. Regulatory Certifications

Ensure the Pulley Engine holds all required certifications (e.g., CE, UL, ISO 9001) for operation in the target market. Keep certification documents current and available for inspection. Notify regulatory bodies of any design or operational changes that may affect compliance status.

8. Personnel Training & Documentation

Provide documented training to all operators and maintenance staff on safe operation, emergency procedures, and compliance responsibilities. Training records must include dates, topics covered, and attendee signatures. Re-train personnel annually or after significant system changes.

9. Incident Reporting & Corrective Actions

Establish a protocol for reporting malfunctions, safety incidents, or compliance deviations. Investigate all incidents promptly and document root causes and corrective actions. Report serious incidents to relevant authorities as required by law.

10. Audit & Continuous Improvement

Conduct annual internal audits of logistics and compliance procedures. Use audit findings to update policies and improve operational practices. Stay informed about changes in international trade laws, safety standards, and environmental regulations affecting the Pulley Engine.

Conclusion on Sourcing a Pulley Engine:

Sourcing a pulley engine requires a strategic approach that balances performance requirements, cost-efficiency, and long-term reliability. After evaluating potential suppliers, technical specifications, quality standards, and lead times, it is evident that selecting the right pulley engine involves more than just competitive pricing. The chosen source must offer consistent product quality, technical support, and the ability to meet delivery schedules.

Prioritizing reputable manufacturers with proven track records in durability and precision engineering ensures optimal integration into the intended mechanical system. Additionally, considering factors such as material composition, customization options, and after-sales service will contribute to reduced downtime and maintenance costs.

In conclusion, a successful sourcing decision for a pulley engine hinges on thorough due diligence, clear communication with suppliers, and alignment with operational needs. By focusing on quality, reliability, and partnership, organizations can secure a pulley engine solution that enhances performance and supports long-term operational efficiency.