The global market for hydraulic pumps, particularly PTO (Power Take-Off)-driven models, is experiencing steady growth, driven by rising demand across agriculture, construction, and industrial machinery sectors. According to a 2023 report by Mordor Intelligence, the global hydraulic pumps market was valued at USD 8.2 billion and is projected to grow at a CAGR of 4.3% from 2023 to 2028. PTO-driven hydraulic pumps, which leverage engine power from tractors and other heavy equipment, represent a critical segment of this expansion—especially within off-road and agricultural applications. Their reliability, mechanical efficiency, and compatibility with existing machinery continue to bolster adoption. As automation and mechanization accelerate across emerging economies, demand for durable and high-performance PTO hydraulic pumps is expected to rise in tandem. In light of this growth trajectory, identifying the leading manufacturers at the forefront of innovation, quality, and market reach becomes essential for procurement professionals and equipment integrators alike.

Top 10 Pto Driven Hydraulic Pump Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bezares USA: PTOs, hydraulic pumps, valves, tanks

Domain Est. 1996

Website: eaton.com

Key Highlights: Bezares is a global manufacturer of Power Take Offs (PTOs), hydraulic pumps, fittings, tanks, valves and other related mobile hydraulic power components….

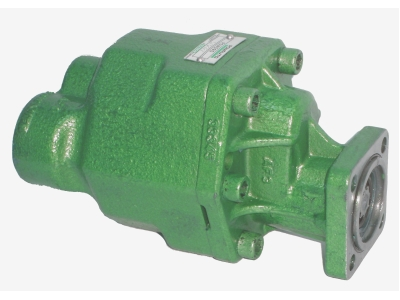

#2 PTO Hydraulic Pump

Domain Est. 2005

Website: aec-srl.com

Key Highlights: Our PTO hydraulic pumps are designed to provide efficient power transfer and reliable performance for a wide range of industrial applications….

#3 Hydraulic Pump and Motor Division

Domain Est. 1995

Website: parker.com

Key Highlights: Parker’s Hydraulic Pump and Motor Division provides a broad selection of piston pumps, hydraulic motors and power units that help our customers meet their ……

#4 PTO Pumps

Domain Est. 1996

Website: princehyd.com

Key Highlights: Prince PTO pumps are specifically designed for PTO drive operation on all sizes of farm tractors. No additional gearbox is required….

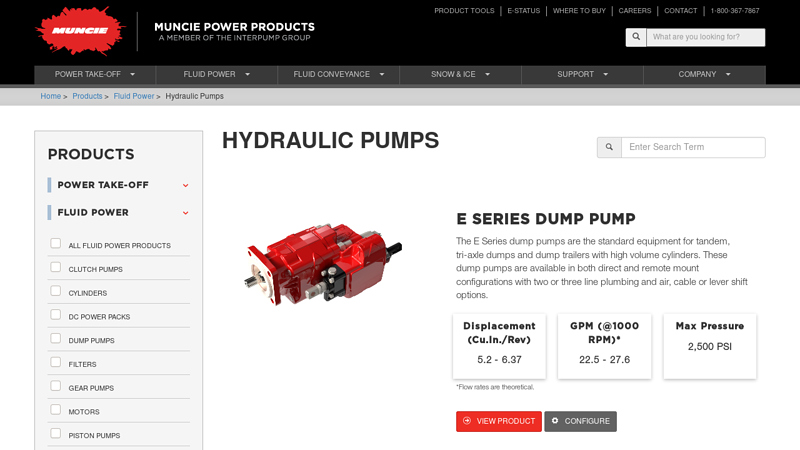

#5 Hydraulic Pumps

Domain Est. 1997

Website: munciepower.com

Key Highlights: Muncie Power Products manufactures premium hydraulic pumps. We offer piston, gear, dump, refuse and clutch pumps to meet any of your hydraulic application ……

#6 Bezares SA

Domain Est. 1997

Website: bezares.com

Key Highlights: All Bezares’ Products. Various hydraulic equipment, PTO adapters, Fittings, Oil coolers, Clutches, Cylinders, Oil filters, and more……..

#7 Ace Pumps

Domain Est. 1998

Website: acepumps.com

Key Highlights: Our Products · Hydraulic Driven Centrifugal Pumps · PTO Belt Drive Centrifugal Pumps · Gasoline Engine Driven Centrifugal Pumps · Belt Driven Centrifugal Pumps ……

#8 Instant mobile hydraulic power

Domain Est. 1998

Website: deweze.com

Key Highlights: Ranging from 5 to 17 GPM, our Engine-Driven PTO deliver the flow, pressure and power to take on any job. Machine cast for precision, each kit is mounted to the ……

#9 Hydreco

Domain Est. 2000

Website: hydreco.com

Key Highlights: The Hydreco Group offers a range of products for agricultural machinery composed of hydraulic cylinders, gear pumps, control valves, joysticks and machine ……

#10 Tractor Driven PTO Pumps

Domain Est. 2012

Website: absolutewaterpumps.com

Key Highlights: Free deliveryAbsolute water pumps sells pto pumps, tractor driven pto pumps, and self-priming centrifugal pedestal pumps with free freight and no sales ……

Expert Sourcing Insights for Pto Driven Hydraulic Pump

H2: 2026 Market Trends for PTO-Driven Hydraulic Pumps

The global market for PTO (Power Take-Off) driven hydraulic pumps is poised for steady growth and transformation by 2026, driven by evolving industrial demands, technological advancements, and a shift toward more efficient and sustainable machinery. These pumps, which harness mechanical power from engines—typically in agricultural, construction, and utility vehicles—are becoming increasingly integral across multiple sectors. Below are key trends shaping the PTO-driven hydraulic pump market through 2026:

1. Rising Demand in Agriculture and Farming Equipment

The agricultural sector remains the largest consumer of PTO-driven hydraulic pumps. With the global push for increased food production and mechanized farming, tractors and harvesters equipped with PTO systems are seeing higher adoption. By 2026, the integration of smart farming technologies and precision agriculture is expected to boost the need for reliable hydraulic systems, favoring efficient PTO-driven solutions.

2. Expansion in Construction and Municipal Applications

Urbanization and infrastructure development in emerging economies are fueling demand for construction and utility vehicles such as backhoes, snow plows, and refuse trucks—all of which rely on PTO-driven hydraulic pumps. As governments invest in smart cities and public services, the need for durable, high-performance hydraulic systems will rise, supporting market growth.

3. Technological Advancements and Efficiency Improvements

Manufacturers are focusing on enhancing pump efficiency, durability, and compatibility with modern vehicle systems. Innovations such as variable displacement pumps, improved sealing technologies, and integration with electronic control systems are enabling better performance and reduced energy loss. These advancements are expected to drive preference for advanced PTO pumps by 2026.

4. Sustainability and Emissions Regulations

Stricter environmental regulations are prompting equipment manufacturers to optimize fuel efficiency and reduce emissions. PTO-driven hydraulic pumps, which utilize existing engine power without requiring auxiliary engines, contribute to lower carbon footprints. This eco-friendly advantage positions them favorably in markets with strict emissions standards, such as North America and the EU.

5. Regional Growth Dynamics

While North America and Europe maintain strong markets due to mature agricultural and construction sectors, Asia-Pacific is expected to witness the fastest growth. Countries like India, China, and Southeast Asian nations are investing heavily in mechanized agriculture and infrastructure, creating significant opportunities for PTO pump suppliers.

6. Integration with Hydraulic Hybrid Systems

Emerging trends in hybrid machinery are leading to the development of hydraulic hybrid systems that combine PTO-driven pumps with energy recovery mechanisms. These systems improve fuel efficiency and are being tested in refuse collection and delivery vehicles, potentially expanding the application base by 2026.

7. Supply Chain and Aftermarket Opportunities

As the installed base of PTO-equipped machinery grows, so does the aftermarket for replacement pumps, seals, and maintenance services. By 2026, companies offering comprehensive support, including IoT-enabled diagnostics and predictive maintenance, are likely to gain competitive advantage.

Conclusion

The PTO-driven hydraulic pump market is set for moderate but consistent growth through 2026, supported by industrial mechanization, technological innovation, and sustainability trends. Companies that invest in R&D, expand into emerging markets, and offer integrated, efficient solutions will be well-positioned to capitalize on these evolving dynamics.

Common Pitfalls When Sourcing PTO-Driven Hydraulic Pumps (Quality and IP)

Sourcing a PTO-driven hydraulic pump requires careful consideration to ensure reliability, performance, and longevity. Overlooking key aspects can lead to operational failures, safety hazards, and increased costs. Below are common pitfalls related to quality and Ingress Protection (IP) ratings.

Poor Build Quality and Material Selection

One of the most frequent issues is selecting a pump constructed with substandard materials or poor manufacturing practices. Low-quality pumps may use inferior metals, seals, or gears that wear quickly under pressure or in harsh environments. This leads to premature failure, leaks, and reduced efficiency. Always verify the manufacturer’s reputation, material specifications (e.g., cast iron vs. aluminum housings), and whether components meet industry standards like ISO or SAE.

Inadequate Ingress Protection (IP) Rating for Operating Environment

The IP rating indicates a pump’s resistance to dust and moisture. A common mistake is choosing a pump with an IP rating too low for its application. For example, using an IP54-rated pump in a washdown or dusty agricultural setting may result in contamination of internal components, leading to corrosion or mechanical failure. Always match the IP rating to the environment—IP65 or higher is recommended for outdoor, high-moisture, or dirty conditions.

Misalignment of PTO Shaft and Pump Input

Even with a high-quality pump, improper installation due to misalignment between the PTO shaft and pump input can cause excessive vibration, seal damage, and bearing wear. This pitfall stems from skipping proper measurement and alignment procedures during installation. Ensure compatibility between the PTO spline count, rotation direction, and pump input shaft dimensions.

Overlooking Certification and Compliance

Some suppliers offer non-certified pumps that may not meet safety or performance standards. Lack of certifications such as CE, ISO, or regional compliance marks increases the risk of sourcing counterfeit or unsafe equipment. Always request documentation and verify that the pump complies with relevant safety and performance regulations.

Insufficient Attention to Duty Cycle and Pressure Ratings

Purchasers may focus on initial cost and overlook whether the pump is rated for continuous operation or high-pressure demands. Using a pump beyond its designed duty cycle or pressure limits results in overheating, seal failure, and shortened service life. Match the pump’s specifications precisely to the operational requirements of the machinery.

Inadequate After-Sales Support and Warranty

Low-cost pumps often come from suppliers with limited technical support or warranty coverage. If issues arise, the lack of spare parts, service documentation, or responsive support can lead to extended downtime. Prioritize suppliers offering clear warranty terms and accessible technical assistance.

By avoiding these common pitfalls—particularly those related to build quality and appropriate IP protection—you can ensure reliable performance and a longer service life for your PTO-driven hydraulic pump.

Logistics & Compliance Guide for PTO-Driven Hydraulic Pump

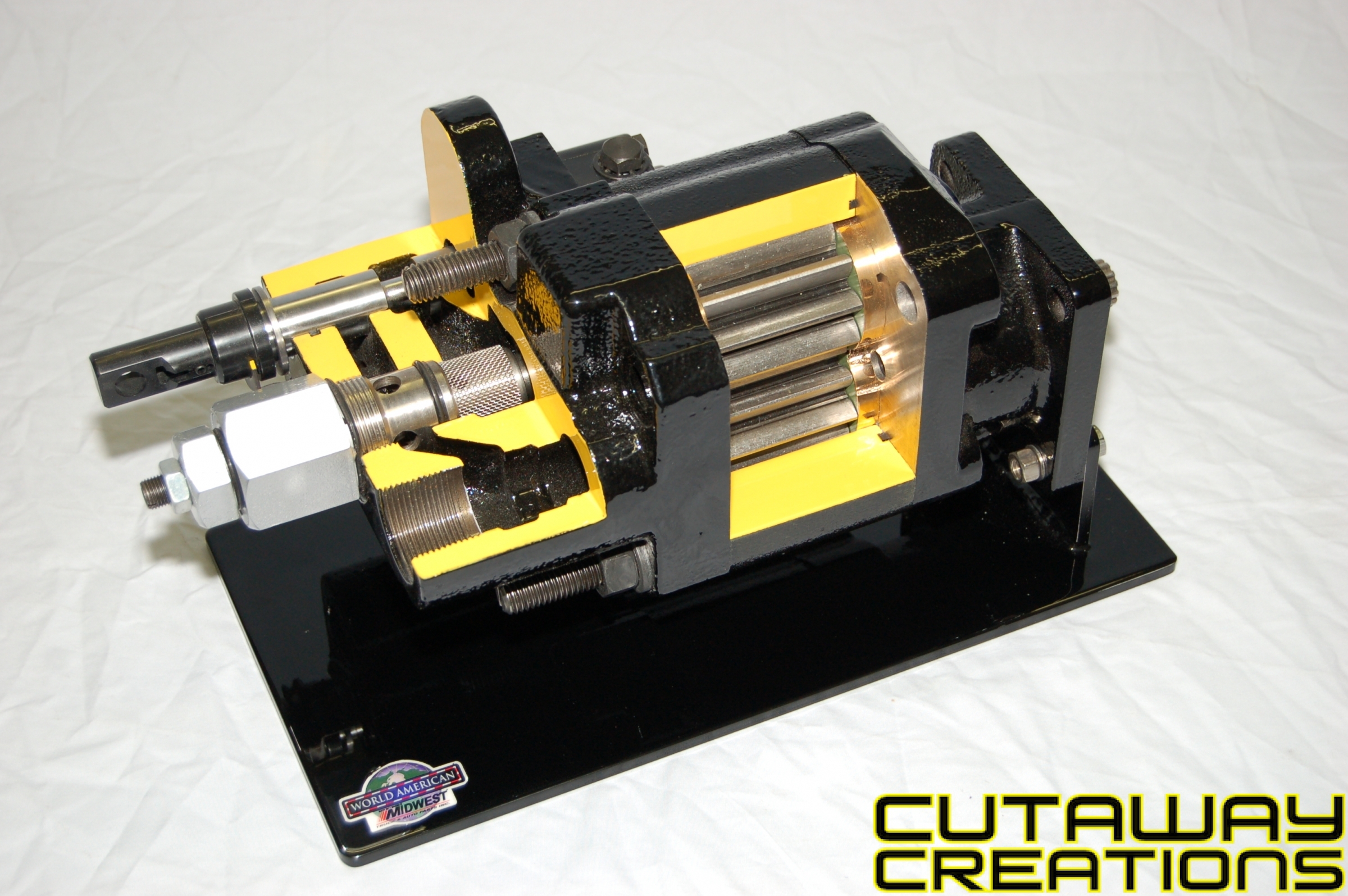

Product Overview

A PTO (Power Take-Off) driven hydraulic pump is a mechanical device that converts power from a vehicle’s transmission into hydraulic energy. These pumps are commonly used in trucks, agricultural machinery, and industrial equipment to operate hydraulic systems such as lifts, dump beds, and winches. Proper logistics planning and regulatory compliance are critical to ensure safe, efficient, and legal transportation and use.

Packaging & Handling Requirements

- Secure Packaging: Pumps must be packed in robust wooden crates or heavy-duty corrugated boxes with internal foam or foam inserts to prevent vibration damage during transit.

- Moisture Protection: Use moisture-resistant wrapping (e.g., VCI paper or plastic) and include desiccants in packaging to prevent corrosion.

- Labeling: Clearly label packages with “Fragile,” “This Side Up,” and handling instructions. Include model number, weight, and serial number on the exterior.

- Lifting Points: Use only designated lifting points or slings when moving larger units. Never lift by hoses, valves, or shafts.

Transportation & Shipping

- Mode of Transport: Suitable for road, sea, and air transport. For air freight, confirm weight and dimensional restrictions with carriers.

- Securing Cargo: On trucks or containers, secure pumps with straps or braces to prevent shifting. Use dunnage to protect from floor contact.

- Temperature Control: Avoid exposure to extreme temperatures (below -20°C or above 60°C) during transit. Store in climate-controlled environments when possible.

- Documentation: Include commercial invoice, packing list, bill of lading, and any export declarations. Ensure HS code (e.g., 8413.50 for hydraulic pumps) is correctly declared.

Import/Export Compliance

- Customs Regulations: Comply with import/export rules in both origin and destination countries. Verify licensing requirements (e.g., EAR for U.S. exports).

- Tariff Classifications: Confirm correct HTS/HS code classification to determine duties and taxes.

- Restricted Parties Screening: Ensure no entities involved (suppliers, buyers, intermediaries) are on denied persons lists (e.g., U.S. OFAC, EU sanctions lists).

- Dual-Use Considerations: While most PTO pumps are non-controlled, verify if specific configurations (e.g., high-pressure military-grade) could fall under dual-use regulations.

Safety & Environmental Compliance

- REACH & RoHS (EU): Ensure materials used (e.g., seals, coatings) comply with REACH SVHC and RoHS restrictions on hazardous substances.

- EPA & DOT (USA): Adhere to transportation safety standards under DOT regulations. No specific EPA certification is required for the pump itself, but compliance with vehicle integration standards may apply.

- Labeling Requirements: Include CE marking (for EU), EAC (for EAEU), or other regional conformity marks as applicable.

- Hydraulic Fluid Handling: If shipped with fluid, comply with IATA/IMDG regulations for hazardous materials. Most hydraulic oils are classified as Class 9 (miscellaneous dangerous goods).

Installation & Operational Compliance

- Manufacturer Guidelines: Follow the OEM’s installation manual for shaft alignment, coupling, and torque specifications to avoid mechanical failure.

- Vehicle Integration: Ensure compliance with local vehicle safety standards (e.g., FMVSS in the U.S., UNECE in Europe) when installing on commercial vehicles.

- Operator Training: Provide training on safe operation, maintenance, and emergency shutdown procedures.

- Pressure Safety: Install pressure relief valves and ensure system pressure does not exceed pump and hose ratings (per ISO 4413 for fluid power systems).

Documentation & Record Keeping

- Technical Dossiers: Maintain compliance documentation including EU Declaration of Conformity, test reports, and material declarations.

- Shipping Records: Retain bills of lading, customs filings, and insurance documents for a minimum of 5 years.

- Warranty & Service Logs: Keep records of repairs, replacements, and customer support interactions for traceability.

Disposal & End-of-Life

- WEEE Compliance (EU): If classified as electrical equipment (due to sensors or controls), follow WEEE guidelines for recycling.

- Hydraulic Fluid Disposal: Drain and dispose of hydraulic oil per local environmental regulations (e.g., EPA in the U.S., Environment Agency in the UK).

- Metal Recycling: The pump body (typically cast iron or aluminum) should be recycled through certified metal reprocessing facilities.

For continued compliance, regularly review updates to international trade laws, environmental directives, and transportation safety standards relevant to your operating regions.

Conclusion for Sourcing PTO-Driven Hydraulic Pumps

Sourcing a PTO-driven hydraulic pump requires careful consideration of several key factors including compatibility with the existing power take-off system, required flow rate and pressure, duty cycle, mounting configuration, and environmental conditions. Selecting the right pump ensures optimal performance, efficiency, and longevity of the entire hydraulic system. It is essential to work with reputable suppliers or manufacturers who provide reliable technical support, quality certifications, and warranty coverage. Additionally, evaluating total cost of ownership—factoring in initial cost, maintenance needs, and energy efficiency—leads to a more informed and cost-effective decision. By aligning technical specifications with application requirements and prioritizing durability and serviceability, organizations can ensure a successful integration of PTO-driven hydraulic pumps into their machinery, enhancing productivity and operational reliability.