The global PTFE seals market is experiencing robust growth, driven by increasing demand for high-performance sealing solutions across industries such as automotive, aerospace, oil and gas, and chemical processing. According to a report by Mordor Intelligence, the global PTFE market was valued at USD 7.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of over 5.6% from 2024 to 2029. This expansion is fueled by PTFE’s exceptional thermal stability, chemical resistance, and low friction properties, making it an ideal material for demanding sealing applications. With industrial automation on the rise and stringent environmental and safety regulations pushing for more reliable components, manufacturers specializing in PTFE seals are strategically expanding production capacities and investing in material innovation. In this evolving landscape, identifying the leading players becomes critical for engineers, procurement specialists, and decision-makers seeking high-quality, durable sealing solutions. The following list highlights the top 10 PTFE seals manufacturers based on market presence, product innovation, global reach, and industry reputation.

Top 10 Ptfe Seals Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 T-Lon Products, Inc.

Domain Est. 1998

Website: t-lon.com

Key Highlights: For over 45 years, T-Lon has specialized in PTFE seal manufacturing excellence. T-Lon Products is proud to be an American Manufacturer….

#2 PTFE Seals, PTFE Lip Seals, PTFE Oil Seals

Domain Est. 2013

Website: ptfedf.com

Key Highlights: As professional PTFE Teflon seals manufacturer, DCW supplies high quality PTFE seals with in-house PTFE technology. Get free quotes now!…

#3 Bal Seal Engineering

Domain Est. 1998

Website: balseal.com

Key Highlights: Custom spring-energized PTFE seals combining advanced polymer materials with canted coil spring technology for superior sealing performance. High-performance….

#4 PTFE Seals & Engineered Products

Domain Est. 1999

Website: mspseals.com

Key Highlights: At MSP Seals, our PTFE seals are manufactured by creating a custom blend of virgin PTFE with different fillers to add or enhance specific physical properties….

#5 Expert PTFE Seals Manufacturer

Domain Est. 2007

Website: fluorotec.com

Key Highlights: High-quality PTFE seals from a trusted PTFE seals manufacturer, designed for durability in extreme conditions. Resistant to chemicals, heat, and pressure….

#6 Manufacturer of PTFE Seals, Sanitary Gaskets & Custom Polymer …

Domain Est. 2018

Website: kelcoind.com

Key Highlights: ISO-certified and proudly Made in the USA, Western Consolidated Technologies (WCT) specializes in precision PTFE seals, sanitary gaskets, and custom polymer ……

#7 PTFE Mechanical Seals or Teflon Sealing Material for Valves

Domain Est. 1995

Website: fst.com

Key Highlights: Freudenberg Sealing Technologies offers special food -grade PTFE materials such as PTFE Y002, from which, radial shaft seal rings can be manufactured….

#8 PTFE Sealing Materials

Domain Est. 1995

Website: discover.parker.com

Key Highlights: FEATURED STANDARD PTFE SEALING PRODUCTS · PTFE Spring-Energized FlexiSeals® · CT-Profile, PTFE Capped Piston Seal · FDA-Compliant Sealing Materials and Products….

#9 PTFE Shaft Seals

Domain Est. 1996

Website: trelleborg.com

Key Highlights: PTFE Shaft Seals · Home · About Us · Manufacturing Capabilities · Engineered Plastics · PTFE Shaft Seals….

#10 PTFE seals

Domain Est. 1996

Website: skf.com

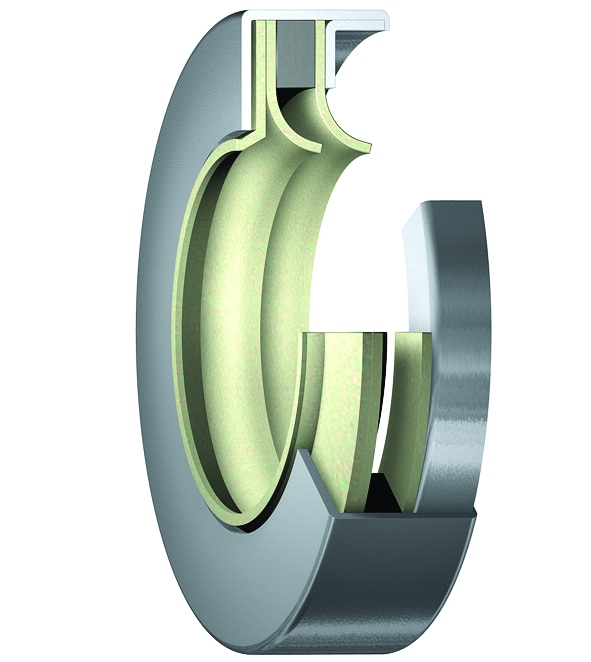

Key Highlights: Radial shaft seals with one or more PTFE sealing lip(s) are designed to withstand aggressive environments, high temperatures, high pressures and dry running….

Expert Sourcing Insights for Ptfe Seals

H2 2026 Market Trends for PTFE Seals

The global market for PTFE (Polytetrafluoroethylene) seals is poised for significant evolution in the second half of 2026, driven by a confluence of technological advancements, shifting industrial demands, and macroeconomic factors. While growth remains steady, H2 2026 is characterized by increased specialization, sustainability pressures, and supply chain recalibration.

1. Accelerated Demand in High-Performance and Emerging Sectors:

* Semiconductor & Advanced Electronics: Demand will surge, particularly in Asia-Pacific (APAC). The relentless push for smaller, faster chips requires ultra-pure, chemically inert PTFE seals for etching, CVD, and PVD tools. Suppliers focusing on high-purity grades (e.g., PTFE-PFA blends) and complex micro-seals will see strong growth.

* Electric Vehicles (EVs) & Battery Manufacturing: The EV boom continues to drive demand for PTFE seals in battery cell production equipment (electrolyte filling, formation), fuel cell components (bipolar plates, gaskets), and high-voltage connectors. Requirements for thermal stability, chemical resistance to electrolytes, and long-term reliability are paramount.

* Renewable Energy: Growth in solar panel manufacturing and critical components for wind turbine gearboxes (requiring seals for greases and harsh environments) provides a stable demand stream. Hydrogen economy developments (production, storage, fueling) will begin to create niche but high-value opportunities for specialized PTFE seals resistant to hydrogen embrittlement.

2. Material Innovation and Hybrid Solutions:

* Enhanced Composites: Beyond standard glass or carbon-filled PTFE, H2 2026 will see increased adoption of advanced fillers like nano-ceramics, graphene, and specialized polymers (e.g., PEEK blends) to achieve superior wear resistance, thermal conductivity, and load-bearing capabilities for demanding applications (e.g., aerospace actuators, deep-well drilling).

* Functionalized PTFE: Development and commercialization of PTFE grades with improved adhesion properties (for overmolding), enhanced electrical properties, or specific surface modifications will gain traction, enabling new sealing solutions and simplifying assembly.

* Multi-Material Seals: Growth in hybrid seals combining PTFE (for chemical/thermal resistance) with elastomers (for primary sealing and elasticity) or metal cores (for strength and spring-back) will accelerate, particularly in automotive and industrial fluid power.

3. Sustainability and Regulatory Pressures Intensify:

* PFAS Scrutiny: Regulatory focus on PFAS (Per- and polyfluoroalkyl substances), which includes PTFE, will peak in H2 2026, especially in North America and the EU. This will drive:

* Increased Demand for Alternatives: Exploration and adoption of non-fluorinated high-performance polymers (e.g., advanced PEEK, PPS, specialized elastomers) where technically feasible.

* Focus on Recyclability & Circularity: Significant investment in PTFE scrap recycling technologies and closed-loop systems. Suppliers will emphasize “regrind” content in less critical applications and develop take-back programs.

* Transparency & Certification: Customers will demand full lifecycle assessments (LCA), PFAS content declarations, and adherence to emerging regulations (e.g., EU REACH restrictions). “Sustainable PTFE” marketing will become crucial.

* Energy Efficiency: Continued pressure to reduce energy consumption in manufacturing will favor PTFE seals with low friction coefficients and long service life, reducing maintenance downtime and energy losses in rotating equipment.

4. Supply Chain Resilience and Regionalization:

* Nearshoring/Regionalization: Geopolitical tensions and lessons from recent disruptions will push industrial customers (especially in automotive and aerospace) to diversify supply chains. This benefits PTFE seal manufacturers with regional production facilities (e.g., local plants in North America, Europe, and APAC) over purely centralized suppliers.

* Raw Material Volatility: Prices for key raw materials (fluorspar, HF) and energy will remain somewhat volatile. Suppliers with strong vertical integration (e.g., captive fluoropolymer resin production) or long-term supply agreements will have a competitive advantage.

* Digital Supply Chains: Adoption of digital platforms for inventory management, predictive logistics, and supplier collaboration will increase, improving responsiveness and visibility.

5. Digitalization and Smart Seals:

* Predictive Maintenance: While not mainstream for standard seals, H2 2026 will see pilot projects and niche adoption of PTFE seals integrated with sensors (e.g., strain gauges, temperature sensors, or wireless RFID tags) for condition monitoring in critical, high-value applications (e.g., aerospace, nuclear). This provides data for predictive maintenance, reducing unplanned downtime.

* Advanced Manufacturing: Wider use of additive manufacturing (3D printing) for complex, custom PTFE seal prototypes and low-volume production runs. AI and machine learning will be increasingly used in quality control (defect detection) and process optimization.

Conclusion:

H2 2026 for the PTFE seal market is defined by strategic divergence. While volume growth continues in established industries, the most significant opportunities lie in high-value, specialized applications within semiconductors, EVs, and renewables. Success will depend on innovation in materials (composites, hybrids), navigating the sustainability imperative (PFAS response, recycling), building resilient regional supply chains, and embracing digitalization. Suppliers that proactively address these trends, particularly the sustainability challenges, will be best positioned for long-term growth, while those relying solely on commodity PTFE seals may face margin pressure. The market is moving towards smarter, more sustainable, and highly engineered solutions.

Common Pitfalls Sourcing PTFE Seals: Quality and Intellectual Property Risks

When sourcing PTFE (Polytetrafluoroethylene) seals, overlooking key quality and intellectual property (IP) considerations can lead to significant performance failures, safety hazards, and legal liabilities. Being aware of these common pitfalls helps ensure reliable supply and protects your organization.

Poor Material Quality and Inconsistent Properties

One of the most frequent issues is sourcing PTFE seals made from substandard or inconsistently processed material. Low-quality PTFE may contain impurities, voids, or inconsistent molecular weight, leading to reduced chemical resistance, poor thermal stability, and premature seal failure. Buyers may receive products labeled as “PTFE” that are actually regrind material or blends lacking the performance characteristics of virgin, high-purity PTFE. This compromises seal integrity in demanding applications such as high-pressure, high-temperature, or corrosive environments.

Non-Compliance with Industry Standards

Many suppliers fail to adhere to recognized industry standards (e.g., ASTM D1710, ISO 3601, or FDA/USP Class VI for pharmaceutical use). Without proper certification or traceability, there is no assurance that the seals meet dimensional tolerances, purity requirements, or application-specific performance criteria. Relying on undocumented or uncertified suppliers increases the risk of receiving non-compliant parts that can result in system leaks, contamination, or regulatory non-conformance.

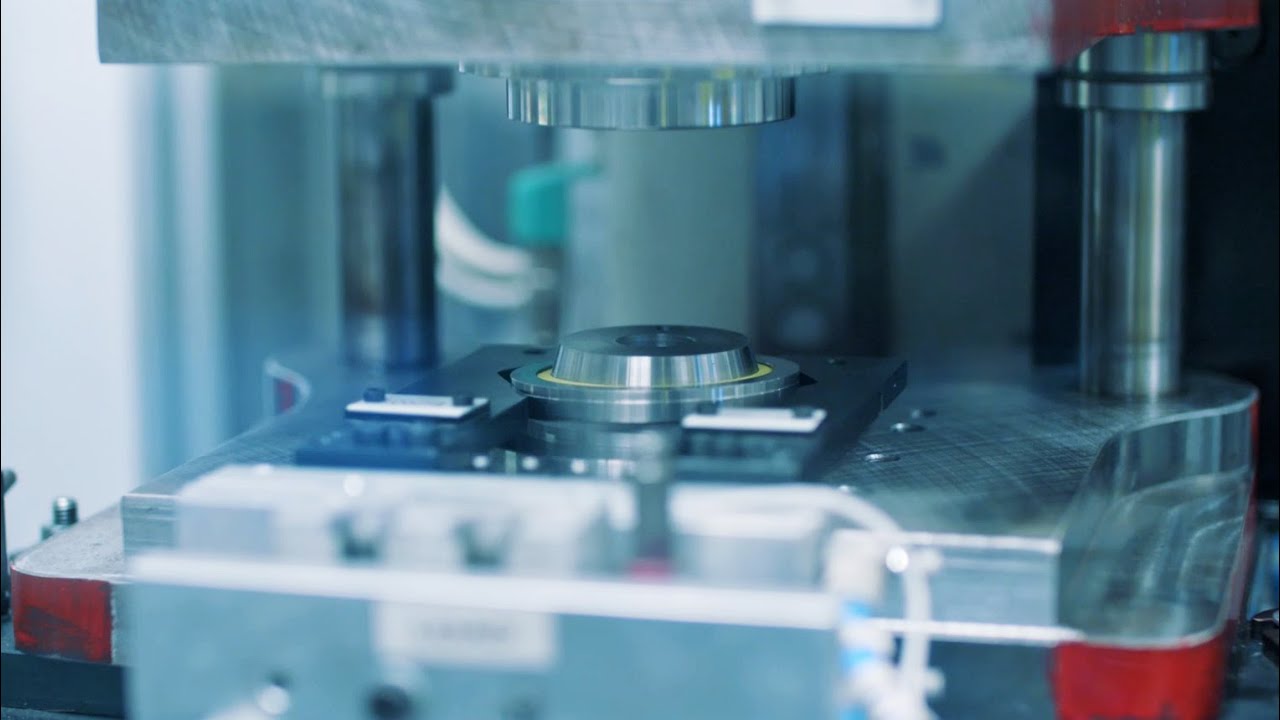

Inadequate Manufacturing Controls and Process Validation

PTFE’s unique properties require specialized machining and forming techniques. Poor control over sintering temperatures, cooling rates, or machining parameters can introduce internal stresses, dimensional inaccuracies, or surface defects. Suppliers lacking robust quality management systems (e.g., ISO 9001) or process validation may deliver inconsistent batches, even if initial samples appear acceptable. This variability undermines reliability in critical sealing applications.

Counterfeit or Misrepresented Products

The high value and technical demand for PTFE seals make them a target for counterfeiting. Some suppliers may falsely claim their seals are made from premium-grade or brand-name PTFE (e.g., DuPont™ Teflon®) without authorization. These counterfeit products often underperform and may infringe on trademarks, exposing the buyer to reputational damage and potential legal claims.

Intellectual Property Infringement Risks

Using or sourcing custom-designed PTFE seals without proper IP clearance can lead to infringement of patented designs, geometries, or manufacturing methods. Some suppliers replicate proprietary seal profiles from OEMs or competitors without licensing. Purchasing such products—even unknowingly—can expose your company to third-party litigation, import bans, or forced redesigns. Conducting IP due diligence and requiring suppliers to warrant non-infringement is essential.

Lack of Traceability and Documentation

Reputable sourcing requires full material traceability, including lot numbers, test reports, and compliance certificates. Many low-cost suppliers provide little or no documentation, making it difficult to validate quality, investigate field failures, or meet audit requirements in regulated industries (e.g., aerospace, medical devices). This lack of transparency increases risk and complicates root cause analysis.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough supplier audits, demand material certifications, verify compliance with relevant standards, and include IP protection clauses in procurement contracts. Investing in qualified, transparent suppliers ultimately ensures the performance, safety, and legal compliance of PTFE seals in critical applications.

Logistics & Compliance Guide for PTFE Seals

Overview

PTFE (Polytetrafluoroethylene) seals are critical components in industries requiring high chemical resistance, thermal stability, and low friction. Proper logistics and compliance management are essential to maintain product integrity, ensure regulatory adherence, and support safe handling and delivery.

Packaging Requirements

- Use non-abrasive, moisture-resistant packaging materials (e.g., sealed polyethylene bags, desiccant packs if needed).

- Clearly label packaging with product identification, material type (PTFE), lot number, and handling instructions.

- Protect seals from dust, oils, and mechanical damage using rigid containers or partitioned trays.

- Avoid packaging materials containing plasticizers or contaminants that may migrate into PTFE.

Storage Conditions

- Store in a clean, dry, temperature-controlled environment (15–25°C recommended).

- Keep away from direct sunlight, UV exposure, and sources of heat or ozone.

- Do not stack heavy items on PTFE seal packaging to prevent deformation.

- Limit storage duration; follow FIFO (First In, First Out) principles to prevent aging.

Transportation Guidelines

- Use enclosed, climate-controlled vehicles when possible, especially for extended transit.

- Protect against shock, vibration, and extreme temperatures during shipping.

- Secure packages to prevent movement within transport containers.

- Comply with international shipping standards (e.g., ISTA, IATA, IMDG) when applicable.

Regulatory Compliance

- Ensure PTFE seals meet relevant industry standards (e.g., ASTM D4894, ISO 13000).

- Confirm compliance with RoHS, REACH, and FDA (if used in food or pharmaceutical applications).

- Provide Material Safety Data Sheets (MSDS/SDS) upon request.

- Adhere to export control regulations (e.g., ECCN 1C997 under EAR for certain fluoropolymers).

Documentation & Traceability

- Maintain full traceability with batch/lot numbers, manufacturing dates, and inspection records.

- Include certificates of conformance (CoC) or material certifications with shipments.

- Document storage conditions and handling procedures to support quality audits.

- For regulated industries (e.g., aerospace, medical), comply with AS9100 or ISO 13485 requirements.

Handling & Safety

- Personnel should wear clean gloves to avoid contamination during handling.

- Avoid contact with sharp tools or surfaces that may nick or cut PTFE seals.

- Use dedicated tools and clean workspaces to prevent cross-contamination.

- Follow internal safety protocols; PTFE is generally inert but fine particles generated during machining may require respiratory protection.

Import/Export Considerations

- Verify customs classification (HS Code: typically 3920.93 for PTFE articles).

- Prepare proper export documentation, including commercial invoices and packing lists.

- Check destination country regulations for polymer-based components (e.g., environmental or chemical controls).

- Consult with legal or compliance officers for shipments to restricted regions.

Environmental & Disposal Compliance

- Unused or end-of-life PTFE seals should not be incinerated without proper emissions controls due to potential release of toxic fumes (e.g., HF).

- Follow local waste disposal regulations; PTFE is not biodegradable but may be recycled through specialized facilities.

- Maintain records of waste disposal in accordance with ISO 14001 or local environmental laws.

Audit & Quality Assurance

- Conduct regular internal audits of storage, handling, and shipping processes.

- Verify compliance with customer-specific requirements (e.g., automotive PPAP, aerospace NADCAP).

- Review logistics partners for certification (e.g., ISO 9001) and secure chain-of-custody practices.

Adhering to this guide ensures the reliability, safety, and regulatory compliance of PTFE seals throughout the supply chain.

Conclusion for Sourcing PTFE Seals

Sourcing PTFE (Polytetrafluoroethylene) seals requires a careful evaluation of material specifications, application requirements, supplier reliability, and cost-efficiency. PTFE seals are highly valued for their exceptional chemical resistance, wide temperature range, low friction, and long service life, making them ideal for demanding environments across industries such as aerospace, pharmaceuticals, automotive, and chemical processing.

When selecting a supplier, it is essential to prioritize quality certifications (such as ISO 9001), material traceability, and the ability to customize seals to meet specific dimensional and performance needs. Additionally, considering fillers (e.g., glass, carbon, or bronze) can enhance PTFE’s mechanical properties for particular applications.

Ultimately, a strategic sourcing approach—balancing performance, durability, and total cost of ownership—ensures reliable sealing solutions that contribute to operational efficiency and reduced downtime. Establishing long-term partnerships with reputable manufacturers or distributors supports consistent quality and innovation in PTFE seal technology.