The global protective coatings market is experiencing robust growth, driven by increasing demand across industries such as automotive, electronics, and consumer goods—many of which rely heavily on plastic components requiring durable surface protection. According to Grand View Research, the global protective coatings market size was valued at USD 24.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising awareness of material longevity, performance enhancement, and corrosion resistance, particularly for non-metallic substrates like plastics. As manufacturers seek to improve scratch resistance, UV stability, and chemical durability of plastic surfaces, the need for advanced protective coatings has become critical. In this competitive and evolving landscape, selecting the right coating solution can significantly impact product quality, lifespan, and customer satisfaction. Based on performance metrics, application efficiency, and market adoption, the following are the top 10 protective coatings tailored for plastic manufacturers.

Top 10 Protective Coating For Plastic Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Belzona Industrial Protective Coatings and Composites

Domain Est. 1995

Website: belzona.com

Key Highlights: Specialising in the design and manufacture of repair composite materials and protective coatings for machinery, equipment, buildings and structures….

#2 Plasti Dip

Domain Est. 1996

Website: plastidip.com

Key Highlights: Plasti Dip offers specialty rubber coating products that can be used for crafts, home improvement, automotive customization and more. Check us out today….

#3 Plastic Coating Services

Domain Est. 1997

Website: tspinc.com

Key Highlights: TSP offers siloxane hard coating services for customer supplied polycarbonate and acrylic sheet, and injection molded or formed plastic 3D parts….

#4 Plastic Coatings Corporation

Domain Est. 2007

Website: jaxsancoatings.com

Key Highlights: Plastic Coatings Corporation is a leading manufacturer of premier waterproofing and protective coatings for diversified industries….

#5 Protective Hard Coatings

Domain Est. 1996

Website: brewerscience.com

Key Highlights: Protective hard coatings are commonly used to protect plastic components otherwise susceptible to abrasion, hazing, or foreign substances….

#6 Plastic Coating Provider

Domain Est. 1999

Website: enduracoatings.com

Key Highlights: Endura offers plastic coatings that provide solutions to wear, friction, corrosion & sticking for application in industries such as packaging, ……

#7 Conductive Coating on Plastic and Plating on Plastic

Domain Est. 1999

Website: cybershieldinc.com

Key Highlights: Cybershield is a recognized world leader in conductive coating on plastic. This includes our plating plastic capabilities where we can plate plastic resins….

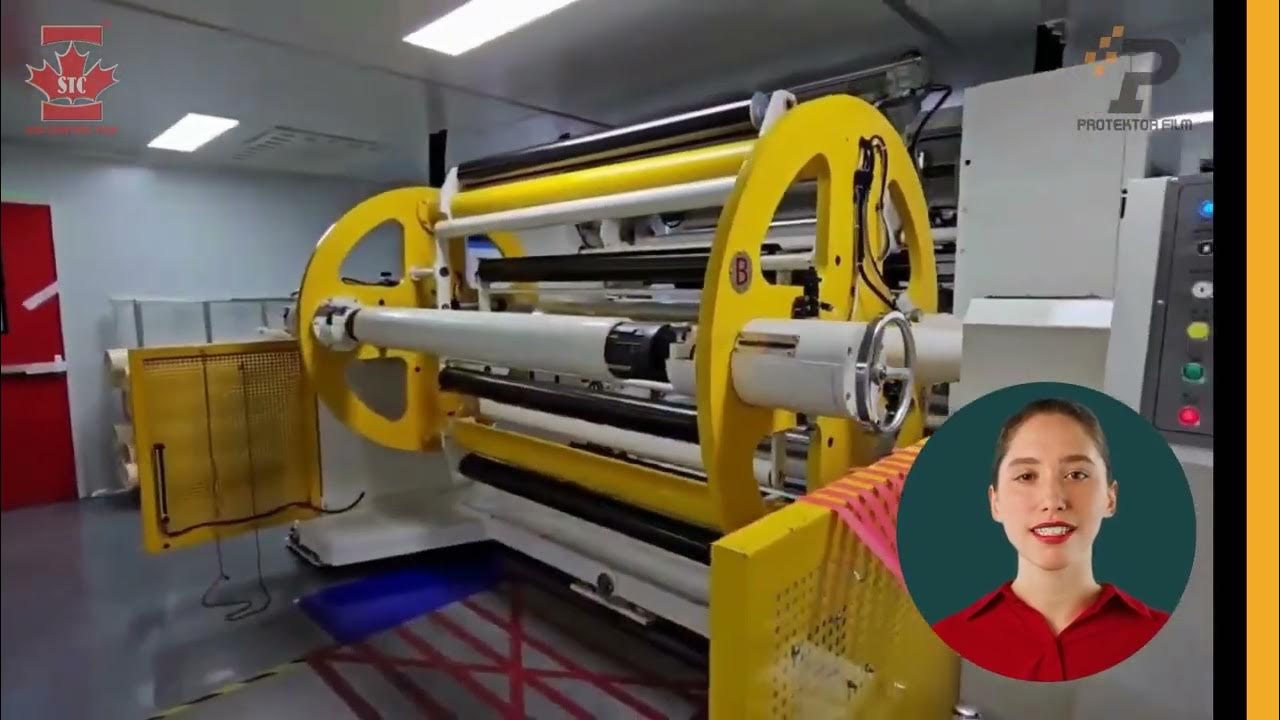

#8 Temporary Protection Films

Domain Est. 2004

Website: pregis.com

Key Highlights: Temporary protection films are designed to protect critical surfaces from scratching & contamination. These pressure sensitive adhesive films adhere to ……

#9 Performix Coatings

Domain Est. 2016

Website: performixcoatings.com

Key Highlights: Performix® Coatings specializes in developing and manufacturing our own unique flexible protective coatings for various industries….

#10 Polymer Coating (& Fluoropolymer) Solutions FDA Approved

Domain Est. 2017

Website: aalberts-st.com

Key Highlights: Fluoropolymer coatings offer first-class protection against atmospheric corrosion, contact corrosion and condensation corrosion. Depending on the specific ……

Expert Sourcing Insights for Protective Coating For Plastic

H2: 2026 Market Trends for Protective Coatings for Plastic

The global market for protective coatings for plastic is poised for significant transformation by 2026, driven by advancements in material science, increasing environmental regulations, and rising demand across end-use industries such as automotive, electronics, construction, and consumer goods. Key trends shaping the market include:

-

Growth in Sustainable and Eco-Friendly Coatings

By 2026, there will be a pronounced shift toward bio-based, low-VOC (volatile organic compound), and waterborne protective coatings. Regulatory pressures—especially in North America and Europe—are pushing manufacturers to reduce emissions and adopt greener alternatives. Innovations in biodegradable resins and non-toxic additives are expected to expand the availability of environmentally responsible coating solutions. -

Rising Demand in Automotive and Electronics Sectors

The automotive industry continues to increase its use of plastic components to reduce vehicle weight and improve fuel efficiency. Protective coatings that enhance scratch resistance, UV stability, and chemical resistance are in high demand. Similarly, in the electronics sector, the proliferation of smartphones, wearables, and IoT devices is driving the need for durable, anti-fingerprint, and anti-reflective coatings on plastic housings. -

Advancements in Nanotechnology and Smart Coatings

Nanocoatings are anticipated to play a pivotal role by 2026. These ultra-thin, high-performance layers offer enhanced barrier properties, self-cleaning capabilities, and antimicrobial functionality. Smart coatings that respond to environmental stimuli (e.g., temperature, humidity) are also emerging, particularly in medical devices and high-tech consumer products. -

Expansion in Emerging Markets

Asia-Pacific—especially China, India, and Southeast Asia—is expected to lead market growth due to rapid industrialization, urbanization, and increasing disposable incomes. Local manufacturing hubs for electronics and automotive parts are accelerating the demand for high-performance plastic coatings, encouraging global suppliers to establish regional production facilities. -

Integration of Digitalization and Industry 4.0

Coating manufacturers are adopting digital tools for quality control, predictive maintenance, and process optimization. By 2026, AI-driven formulation design and IoT-enabled application systems are expected to improve efficiency, reduce waste, and enable customized coating solutions tailored to specific plastic substrates. -

Focus on Multi-Functional Coatings

There is growing demand for coatings that offer multiple benefits—such as UV protection, flame retardancy, and electrical conductivity—in a single application. This trend is particularly strong in aerospace, defense, and medical applications, where performance and reliability are critical.

In summary, the protective coatings for plastic market in 2026 will be characterized by innovation, sustainability, and regional diversification. Companies that invest in R&D, adhere to environmental standards, and adapt to evolving end-user requirements will be best positioned for long-term success.

Common Pitfalls When Sourcing Protective Coatings for Plastic: Quality and Intellectual Property Risks

Sourcing protective coatings for plastic components involves navigating complex technical and legal challenges. Overlooking key aspects related to quality assurance and intellectual property (IP) can lead to product failures, regulatory non-compliance, and legal disputes. Below are common pitfalls in these two critical areas.

Quality-Related Pitfalls

Inadequate Substrate Compatibility Testing

Plastics vary widely in chemical composition and surface energy. A coating that performs well on polycarbonate may fail on polypropylene due to poor adhesion. Sourcing without comprehensive compatibility testing—such as cross-hatch adhesion, peel strength, and chemical resistance tests—risks delamination, cracking, or premature degradation under environmental stress.

Overlooking Environmental and Application-Specific Requirements

Coatings must withstand their intended operating environment (e.g., UV exposure, temperature fluctuations, abrasion, or chemical exposure). Selecting a coating based on general performance data without verifying suitability for the actual use case—such as outdoor automotive parts or medical devices—can lead to premature coating failure and product recalls.

Insufficient Batch-to-Batch Quality Control

Low-cost suppliers may lack robust quality management systems, resulting in inconsistent coating properties like thickness, curing behavior, or optical clarity. Without strict supplier audits and incoming inspection protocols, variations in viscosity, solids content, or cure time can disrupt manufacturing processes and compromise final product performance.

Misalignment in Cure Process Specifications

Many protective coatings require precise curing conditions (time, temperature, UV intensity). Sourcing coatings without verifying compatibility with existing production line capabilities—such as oven dwell time or UV lamp wavelength—can result in incomplete curing, leading to poor durability or outgassing issues.

Intellectual Property-Related Pitfalls

Unlicensed Use of Proprietary Formulations

Some suppliers may offer coatings that mimic patented chemistries (e.g., fluoropolymers or silicones) without proper licensing. Using such coatings exposes the buyer to infringement claims, even if unaware. Failing to conduct due diligence on formulation origins and licensing status can result in costly litigation and supply chain disruption.

Ambiguous or Incomplete Technology Transfer Agreements

When co-developing or customizing a coating, unclear IP ownership clauses in contracts can lead to disputes. For example, without a written agreement specifying that developed formulations are owned by the buyer or licensed for exclusive use, the supplier may reuse the technology for competitors.

Lack of Freedom-to-Operate (FTO) Analysis

Before scaling up production, it’s essential to confirm that the chosen coating and its application method do not infringe existing patents. Skipping an FTO analysis increases the risk of post-launch legal challenges, especially in regulated industries like aerospace or medical devices where IP is aggressively protected.

Inadequate Documentation and Traceability

Proper IP protection and quality traceability require detailed records—material safety data sheets (MSDS), certificates of conformance, patent numbers, and formulation disclosures. Sourcing from suppliers who do not provide full documentation limits the buyer’s ability to defend IP rights or meet regulatory audits.

Avoiding these pitfalls requires a proactive approach: conducting technical validation, performing supplier audits, securing clear IP agreements, and ensuring full documentation transparency throughout the sourcing process.

Logistics & Compliance Guide for Protective Coating for Plastic

Product Overview

Protective coatings for plastic are specialized formulations designed to enhance surface durability, resistance to UV radiation, chemicals, abrasion, and environmental degradation. These coatings are commonly used in automotive, electronics, consumer goods, and industrial applications. Proper logistics and compliance management are essential to ensure product integrity, worker safety, and adherence to regulatory standards.

Classification & Regulatory Compliance

Protective coatings for plastic often contain solvents, resins, and additives that may be subject to national and international regulations. Key compliance areas include:

- GHS (Globally Harmonized System): Ensure Safety Data Sheets (SDS) are GHS-compliant, including hazard pictograms, signal words, and precautionary statements.

- REACH (EU): Verify that all chemical substances are registered, evaluated, and authorized under REACH regulations if supplied within the European Union.

- TSCA (USA): Confirm that all chemical components are listed on the TSCA Inventory for distribution in the United States.

- VOC Regulations: Adhere to volatile organic compound (VOC) limits set by local environmental agencies (e.g., EPA in the U.S., EU Paints Directive).

Packaging & Labeling Requirements

Proper packaging and labeling are critical for safety and regulatory compliance:

- Use UN-certified containers suitable for flammable or hazardous liquids, if applicable.

- Label all packages with:

- Product name and identifier

- Hazard pictograms (e.g., flammability, health hazards)

- Signal word (e.g., “Danger” or “Warning”)

- Precautionary and hazard statements

- Lot number and batch traceability

- Supplier contact information

- Include tamper-evident seals and ensure closures are secure to prevent leaks.

Transportation & Shipping

Transportation regulations vary by mode (road, air, sea) and jurisdiction:

- UN Number & Proper Shipping Name: Assign the correct UN number (e.g., UN1263 for flammable liquids, n.o.s.) and shipping name based on formulation.

- Hazard Class: Typically Class 3 (Flammable Liquids); verify based on flash point and composition.

- Regulatory Frameworks: Comply with:

- ADR (Europe – road)

- IMDG (sea)

- IATA (air)

- 49 CFR (USA – DOT regulations)

- Use certified carriers experienced in handling hazardous materials.

- Provide transport documents, including Dangerous Goods Declaration and SDS.

Storage Guidelines

Proper storage prevents degradation and ensures safety:

- Store in a cool, dry, well-ventilated area away from direct sunlight and heat sources.

- Maintain temperatures within the manufacturer’s recommended range (typically 5–30°C).

- Keep away from oxidizers, ignition sources, and incompatible materials.

- Use spill containment pallets and secondary containment systems.

- Limit storage duration according to shelf life; observe first-in, first-out (FIFO) inventory practices.

Handling & Worker Safety

Ensure safe handling procedures are implemented:

- Provide appropriate PPE: chemical-resistant gloves, safety goggles, respirators (if ventilation is inadequate), and protective clothing.

- Train personnel on SDS review, emergency response, and spill containment.

- Use in well-ventilated areas or with local exhaust ventilation.

- Prohibit eating, drinking, or smoking in handling areas.

Environmental & Waste Management

Environmental compliance is critical throughout the product lifecycle:

- Prevent releases into soil, water, or drains.

- Collect and manage spills using absorbent materials compatible with solvents.

- Dispose of waste (empty containers, contaminated materials) in accordance with local hazardous waste regulations.

- Recycle packaging when possible and use authorized waste disposal contractors.

Documentation & Recordkeeping

Maintain comprehensive records to support compliance and traceability:

- Up-to-date Safety Data Sheets (SDS) for each product formulation.

- Batch records and Certificates of Analysis (CoA).

- Shipping documentation and transport manifests.

- Training logs for personnel handling hazardous materials.

- Regulatory compliance certifications (e.g., REACH, TSCA compliance statements).

Emergency Response

Prepare for potential incidents:

- Ensure access to spill kits, fire extinguishers (Class B), and eyewash stations.

- Post emergency contact numbers and procedures onsite.

- Train staff on evacuation, first aid, and reporting procedures.

- Report significant spills or exposures to relevant authorities as required.

Conclusion

Effective logistics and compliance management for protective coatings for plastic ensures product safety, regulatory adherence, and environmental protection. Regular audits, staff training, and engagement with regulatory updates are essential to maintain compliance across global supply chains.

In conclusion, sourcing protective coatings for plastic requires a careful evaluation of several key factors, including adhesion performance, environmental resistance, flexibility, UV stability, chemical inertness, and compliance with regulatory standards. The compatibility of the coating with the specific type of plastic substrate is critical to ensure long-term durability and functional performance. Additionally, considerations such as application method, curing process, cost-effectiveness, and supplier reliability play a vital role in selecting the right coating solution.

Sustainable and environmentally friendly options, such as water-based or low-VOC formulations, are increasingly important in today’s market, both for regulatory compliance and corporate social responsibility. Engaging with reputable suppliers who offer technical support, consistent quality, and customization capabilities can further enhance the success of the coating integration.

Ultimately, the optimal protective coating for plastic should extend product lifespan, maintain aesthetic integrity, and meet performance requirements under real-world conditions. A strategic sourcing approach—balancing technical specifications, cost, and sustainability—will ensure a reliable and effective solution tailored to the application’s unique demands.