The global automotive brake components market is experiencing steady expansion, driven by increasing vehicle production, rising safety regulations, and growing demand for advanced braking systems. According to a report by Mordor Intelligence, the global automotive brake system market was valued at USD 28.6 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. As critical components in hydraulic brake systems, proportioning valve bleed tools play a vital role in ensuring optimal brake balance and performance during maintenance and repair. With the complexity of modern braking systems on the rise—especially in light and heavy-duty vehicles—the need for precision bleed tools has become more pronounced. This growing technical demand, supported by market expansion and an emphasis on workshop efficiency, has spurred innovation among manufacturers specializing in proportioning valve service equipment. The following list highlights the top eight manufacturers leading the charge in design, reliability, and technological advancement in proportioning valve bleed tools.

Top 8 Proportioning Valve Bleed Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GM Proportioning Valve Bleeding Tool

Domain Est. 1997

Website: inlinetube.com

Key Highlights: In stock Rating 4.3 (7) This tool prevents accidental trips of the proportioning valve during the brake bleeding process. · Lightweight, durable nylon protects your valve’s threa…

#2 Disc Brake Proportioning Valve Bleeder Tool

Domain Est. 1997

#3 Tool, Proportioning Valve Bleeder, 1964

Domain Est. 1997

Website: opgi.com

Key Highlights: In stock Rating 3.7 (3) Tool, Proportioning Valve Bleeder, 1964-88 GM Vehicles. When bleeding your brakes is required, unscrew the warning light switch proportioning valve and …..

#4 Brakes

Domain Est. 1998

Website: lislecorp.com

Key Highlights: 10900 Brake Bleeder Wrench. 5/16″ x 3/8″ Wrench for Bleeding Air From Brake Cylinders With Bleeder Screws….

#5 Bleed Your Brakes Easily with our Proportioning Valve Bleeding Tool

Domain Est. 1998

Website: mpbrakes.com

Key Highlights: Our simple bleeder tool, which we also include in our combination valve kit, takes seconds to install and ensures a clean and efficient job, eliminating extra ……

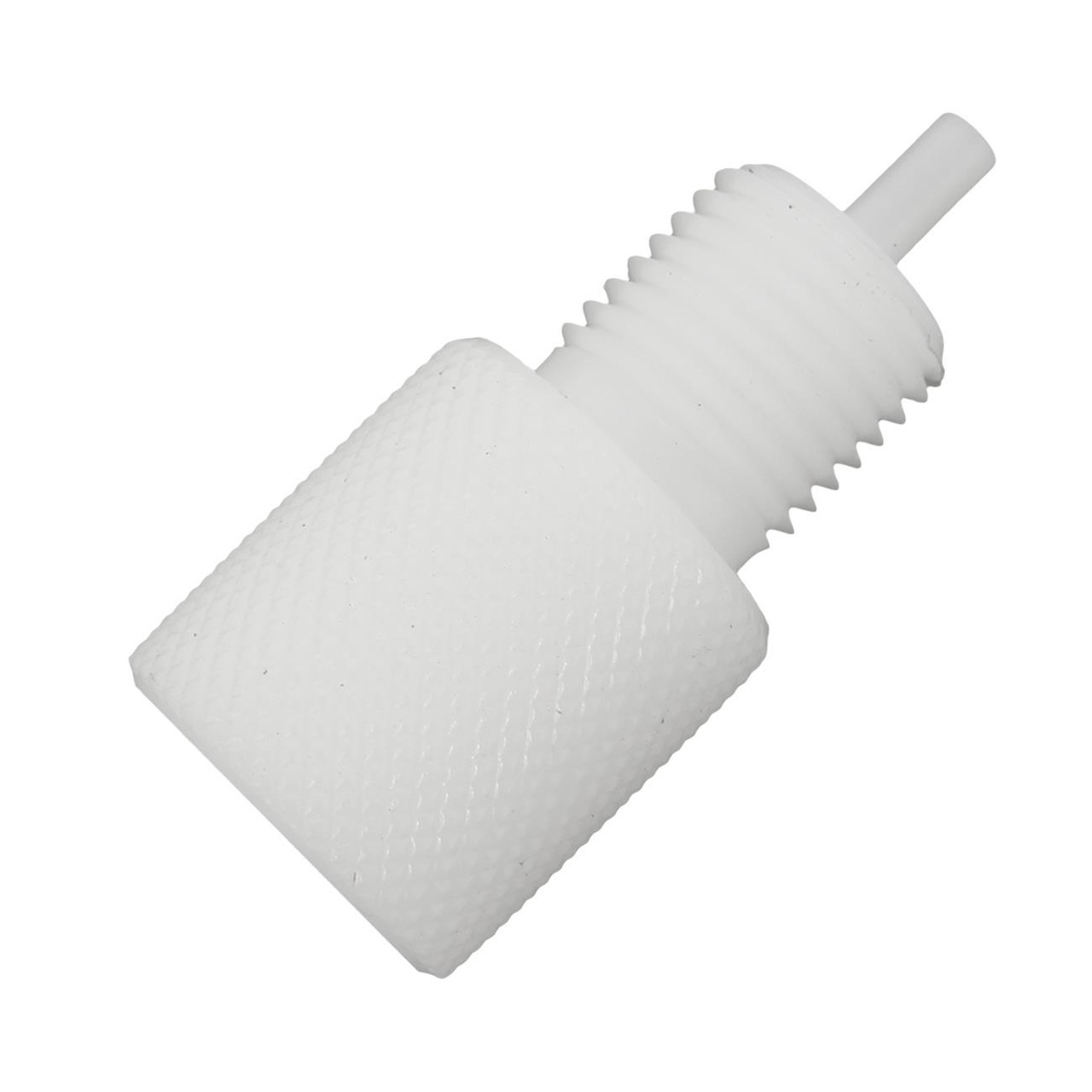

#6 Proportioning Valve Bleeding Tool

Domain Est. 2002

Website: bjsoffroad.com

Key Highlights: Tool is made of lightweight, durable nylon to protect the threads on your valve from damage due to accidental cross-threading….

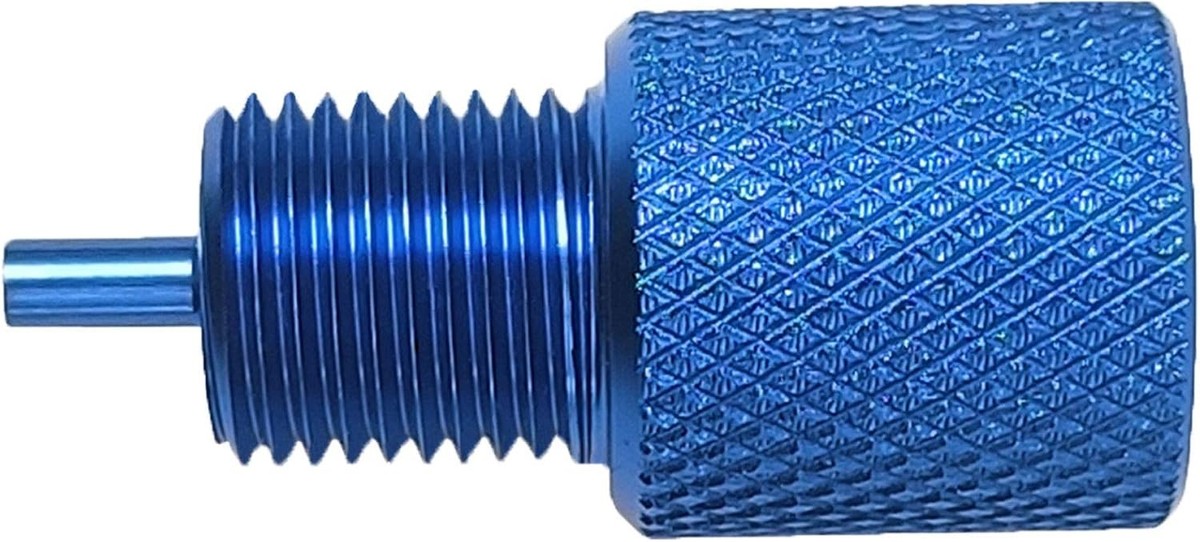

#7 Proportioning Valve Bleeding Tool for Trucks

Domain Est. 2002

Website: carolinaclassictrucks.com

Key Highlights: In stock 1–10 day deliveryUse this brake proportioning valve bleeding tool to lock the valve in place and keep it from tripping when bleeding your brake system. Order this tool her…

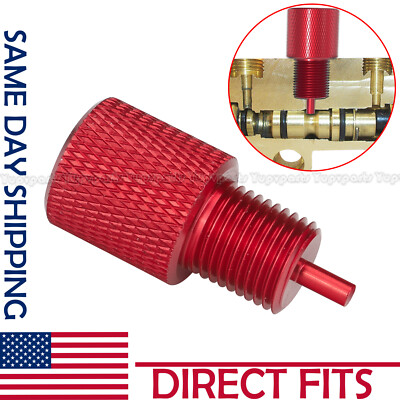

#8 Brake Prop Proportioning Valve Bleed Bleeder Tool for DISC DRUM …

Domain Est. 2014

Website: automaximizer.com

Key Highlights: In stock Free deliveryBrake Prop Proportioning Valve Bleed Bleeder Tool for DISC DRUM PV2 / PV4 AC 172. $9.99 ……

Expert Sourcing Insights for Proportioning Valve Bleed Tool

2026 Market Trends for Proportioning Valve Bleed Tool

The market for proportioning valve bleed tools is poised for steady evolution by 2026, driven by shifts in vehicle technology, repair methodologies, and technician demands. While a niche product within the broader automotive service equipment sector, several key trends are expected to shape its trajectory.

Advancements in Brake System Complexity Drive Tool Specialization

As vehicles increasingly integrate advanced driver assistance systems (ADAS) and electronic brake distribution (EBD), traditional mechanical proportioning valves are being supplemented or replaced by electronic control modules. However, many vehicles—especially light trucks, performance cars, and older models—still utilize hydraulic proportioning valves requiring manual bleeding. This duality will sustain demand for precision bleed tools capable of handling both conventional and hybrid systems. By 2026, tools with integrated diagnostic feedback, compatibility with electronic brake reset procedures, and modular designs for various valve types will gain prominence. Manufacturers will focus on developing smart bleed tools that interface with diagnostic scanners, ensuring proper brake balance after service, particularly critical in ADAS-equipped vehicles.

Growth in DIY and Independent Repair Channels Fuels Demand for User-Friendly Designs

The expansion of the DIY automotive repair market and the resilience of independent repair shops will drive demand for cost-effective, intuitive proportioning valve bleed tools. By 2026, tools emphasizing ease of use, clear instructional integration (e.g., QR codes linking to video tutorials), and universal fitment will capture significant market share. Compact, multi-functional kits that include bleed screws, adapters, and vacuum assist features will appeal to technicians seeking efficiency. Additionally, online distribution platforms and video-based content will amplify product visibility, favoring brands that invest in digital marketing and customer education.

Emphasis on Efficiency and Downtime Reduction in Professional Settings

Fleet operators and commercial repair centers will prioritize tools that minimize labor time and ensure first-time fix rates. In this context, automated or semi-automated proportioning valve bleeding solutions—such as pressure-based or vacuum-assisted systems with preset sequences—will see increased adoption. Compatibility with shop management software for service logging and tool calibration tracking may emerge as differentiating features. By 2026, integration with broader brake service workflows, including fluid exchange and ABS bleeding, will enhance the value proposition of advanced bleed tools in high-volume environments.

Sustainability and Material Innovation Influence Product Development

Environmental regulations and corporate sustainability goals will influence tool manufacturing. Expect a rise in tools made from recycled or recyclable materials, with longer service lives and modular components to reduce waste. Reusable fluid containment systems and low-leakage designs will align with eco-conscious repair practices. Additionally, battery-powered or hand-cranked tools may gain favor over air-powered versions in shops aiming to reduce energy consumption.

In summary, the 2026 proportioning valve bleed tool market will be characterized by technological adaptation, user-centric design, and integration with modern vehicle systems. Success will depend on manufacturers’ ability to balance innovation with practicality, ensuring tools meet the evolving needs of both professional technicians and informed DIYers in an increasingly complex automotive landscape.

Common Pitfalls When Sourcing a Proportioning Valve Bleed Tool (Quality and Intellectual Property)

Sourcing a Proportioning Valve Bleed Tool—especially for automotive brake systems—requires careful attention to both quality standards and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, safety risks, legal disputes, and damage to brand reputation. Below are the most common pitfalls in these critical areas.

Poor Quality Materials and Construction

One of the most frequent issues is the use of substandard materials or imprecise manufacturing. Low-quality bleed tools may feature plastic fittings prone to cracking under pressure, rubber seals that degrade quickly when exposed to brake fluid, or poorly machined threads that cause leaks. These flaws compromise the tool’s reliability, leading to incomplete brake bleeding, air retention in the system, or even damage to the vehicle’s proportioning valve. Always verify material specifications (e.g., compatibility with DOT 3/4/5.1 fluids) and insist on quality certifications or test reports.

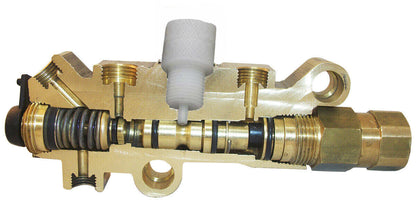

Inadequate Design for Specific Vehicle Applications

Not all proportioning valves are the same—different manufacturers and models require specific adapter sizes, thread types (e.g., M10x1.0, 3/8-24), and pressure tolerances. A common pitfall is sourcing a “universal” bleed tool that doesn’t properly fit the intended vehicle platforms. This can result in stripped threads, fluid leaks, or failure to build sufficient pressure for effective bleeding. Due to the risk of cross-compatibility issues, ensure the tool is engineered for the exact OEM specifications of target vehicles.

Copying OEM Designs Without IP Clearance

Many proportioning valve bleed tools closely mimic original equipment manufacturer (OEM) designs, such as those from Bosch, ATE, or Denso. Reproducing these designs without proper licensing or patent analysis can lead to intellectual property infringement. Design patents, utility patents, and even trade dress protections may apply. Sourcing from suppliers who cannot demonstrate freedom-to-operate (FTO) or who offer “OEM-style” tools without legal validation exposes buyers to litigation, product seizures, and costly redesigns.

Lack of Compliance with Industry Standards

Reputable bleed tools should meet relevant industry standards for pressure testing, fluid compatibility, and safety. Tools sourced from unverified suppliers may lack documentation proving compliance with ISO, SAE, or OEM technical specifications. This becomes a critical risk when the tool is used in professional repair environments, where liability for brake system failure could be traced back to faulty equipment. Always request compliance documentation and verify testing procedures.

Insufficient Supplier Due Diligence

Choosing suppliers based solely on price or speed—especially from regions with weak IP enforcement—increases the risk of receiving counterfeit or non-conforming products. Suppliers may falsely claim certifications or provide misleading product samples. Conduct thorough audits, request prototypes for testing, and verify manufacturing capabilities before committing to large orders. Engaging third-party inspection services can help mitigate this risk.

Failure to Protect Custom Tooling or Designs

If you develop a proprietary bleed tool design for specific needs, failing to secure patents or design rights leaves it vulnerable to imitation. Additionally, unclear contracts with manufacturers may result in ownership disputes or unauthorized production and resale of the tool. Ensure robust IP agreements are in place, including clauses on confidentiality, ownership, and non-compete terms.

Avoiding these pitfalls requires a balanced approach: prioritize quality verification, conduct thorough IP assessments, and build relationships with reputable, transparent suppliers. Investing time upfront in due diligence can prevent costly setbacks and ensure safe, compliant, and legally sound tool sourcing.

Logistics & Compliance Guide for Proportioning Valve Bleed Tool

Purpose

This guide outlines the logistics handling, transportation, storage, and compliance requirements for the Proportioning Valve Bleed Tool (PVBT), ensuring safe and regulatory-compliant operations across the supply chain.

Regulatory Compliance

The Proportioning Valve Bleed Tool must comply with applicable regional and international regulations, including but not limited to:

– RoHS (Restriction of Hazardous Substances): Confirmed compliant; no restricted substances above threshold levels.

– REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): All materials are registered and evaluated per EU REACH regulations.

– WEEE (Waste Electrical and Electronic Equipment): Product marked with WEEE symbol; must be disposed of via approved e-waste channels.

– ITAR/EAR (if applicable): This tool is not subject to International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR), unless modified or bundled with controlled components.

Ensure documentation (compliance certificates, Declarations of Conformity) is available upon request.

Packaging & Labeling

- Primary Packaging: Each tool is sealed in anti-static polyethylene bag to prevent electrostatic discharge (ESD) damage.

- Secondary Packaging: Packed in recyclable corrugated cardboard box with foam inserts for shock absorption.

- Labels Required:

- Product name and part number

- Manufacturer information

- CE, RoHS, and WEEE symbols

- “Fragile – Handle with Care”

- “Do Not Stack” (if applicable)

- Barcode/QR code for traceability

Storage Conditions

- Temperature: Store between 5°C and 40°C (41°F to 104°F).

- Humidity: Relative humidity below 75%, non-condensing.

- Environment: Dry, clean, and well-ventilated area; avoid exposure to chemicals, dust, or direct sunlight.

- Shelf Life: Indefinite when stored under specified conditions. Inspect before use if stored over 24 months.

Transportation Requirements

- Mode of Transport: Suitable for road, air, and sea freight.

- Stacking: Maximum of 5 cartons high when palletized. Use edge protectors and stretch wrap.

- Hazard Classification: Non-hazardous; not subject to ADR, IATA, or IMDG regulations.

- Documentation: Commercial invoice, packing list, and certificate of compliance must accompany shipments.

- Tracking: Each shipment must include a unique tracking number and be logged in the inventory management system.

Import/Export Considerations

- HS Code: 8481.80 (Other taps, cocks, valves, and similar appliances) – verify locally as classification may vary.

- Customs Clearance: Provide accurate product description, value, and country of origin (e.g., “Proportioning Valve Bleed Tool, Made in Germany”).

- Duties & Taxes: Import duties and VAT/GST apply per destination country; consult local customs authority.

Handling & Worker Safety

- Training: Personnel must be trained in manual handling techniques to prevent injury.

- PPE: Gloves recommended during unpacking and inspection.

- Lifting: Use mechanical aids (e.g., pallet jack) for loads exceeding 20 kg (44 lbs).

End-of-Life & Disposal

- Return to manufacturer or authorized recycling facility.

- Do not dispose of in household waste.

- Follow local e-waste disposal regulations; refer to WEEE directive in EU regions.

Contact Information

For compliance inquiries, logistics support, or documentation requests:

Compliance Officer

Email: [email protected]

Phone: +1 (555) 123-4567

Last Updated: April 2025

In conclusion, sourcing a proportioning valve bleed tool is a critical step in ensuring the proper maintenance and performance of a vehicle’s braking system. This specialized tool facilitates accurate and efficient bleeding of the proportioning or metering valve, which regulates hydraulic pressure to the rear brakes and prevents wheel lockup during braking. By selecting a high-quality, compatible bleed tool—preferably one designed for the specific make and model of the vehicle—technicians can ensure air is effectively removed from the system, restoring optimal brake function and enhancing overall safety. Investing time and resources into sourcing the right tool not only improves the efficiency of brake service but also contributes to long-term reliability and customer satisfaction. Ultimately, the correct proportioning valve bleed tool is a worthwhile addition to any automotive toolkit, supporting precision, safety, and professional-grade results.