The global propane accessories market, including tools such as propane bottle splitters, is experiencing steady growth driven by rising demand for portable fuel solutions in residential, recreational, and industrial applications. According to Grand View Research, the global LPG market was valued at USD 138.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 3.2% from 2023 to 2030. This growth trajectory supports increased innovation and manufacturing capacity in downstream propane handling equipment. As consumer reliance on propane for grilling, heating, and off-grid power continues to rise—particularly across North America and Europe—the need for efficient, safe propane transfer tools like bottle splitters has gained prominence. Mordor Intelligence further highlights expanding outdoor recreation trends and do-it-yourself (DIY) culture as key demand drivers for propane-related accessories through 2028. In this evolving landscape, a select group of manufacturers have emerged as leaders in designing and producing high-performance propane bottle splitters, combining engineering precision with safety compliance to meet growing market needs.

Top 10 Propane Bottle Splitter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Propane Tank Y

Domain Est. 2002

Website: primelinetools.com

Key Highlights: Out of stockEasy to use splitter adaptor that allows two propane appliances or tools to run from one tank.Missing: bottle manufacturer…

#2 Y-Splitter w/ Propane Level Gauge

Domain Est. 2000

#3 3 Way Propane Splitter Valve

Domain Est. 2000

#4 Mr Heater F271715 Propane Y Adapter Splitter

Domain Est. 2002

Website: gas-space-heater.com

Key Highlights: In stock Free deliveryMale POL Threads Into Tank Valve to Allow Connection of Two Disposable Fitting Appliances. For Use with 5# up to 100# Cylinders….

#5 Propane Accessories

Domain Est. 2005

Website: flameking.com

Key Highlights: Flame King® T-Racks™ 5LB Propane Tank Mounting Bracket Strap for RVs, Trailers, Campervans, Jeeps, and Overland Vehicles ……

#6 Fittings

Domain Est. 2005

Website: propanewarehouse.com

Key Highlights: Propane Regulators, Propane Cylinders, Propane Fittings, Propane Hoses, Propane Valves. ² Navigation. Cylinders · Camping Cylinders · Portable Cylinders ……

#7 Propane supply splitter for multiple appliance connections (MPN

Domain Est. 2006

Website: sprinterpartsdepot.com

Key Highlights: In stock $15.47 delivery 30-day returnsThis propane supply splitter allows for the connection of additional appliances to a single propane tank, enabling the operation of two devic…

#8 Propane Adapter Hose with Regulator

Domain Est. 2006

Website: blackstoneproducts.com

Key Highlights: In stock Rating 4.7 707 The Propane Adapter Hose allows you to conveniently switch from a 1 lb. propane bottle to a bulk (20 lb.) propane tank….

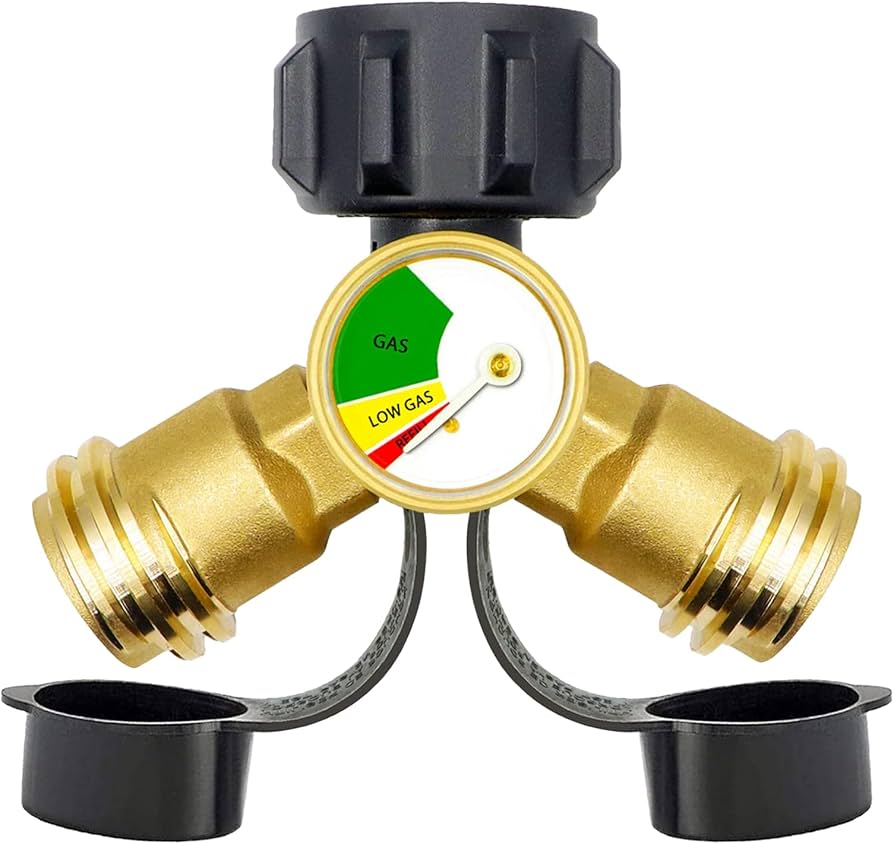

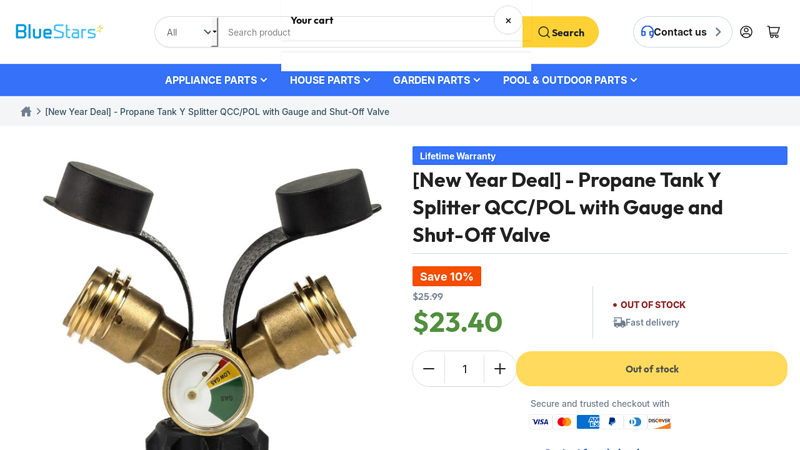

#9 Propane Tank Y Splitter QCC/POL with Gauge and Shut

Domain Est. 2017

Website: bluestarsparts.com

Key Highlights: Out of stock Rating 3.5 (13) The BlueStars Propane Tank Y Splitter allows you to safely connect two propane appliances to a single propane tank. Designed with a built-in fuel gau…

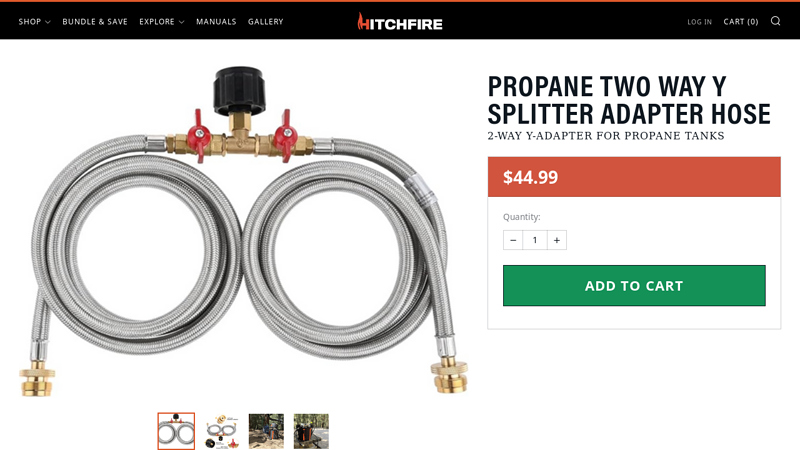

#10 Propane Two Way Y Splitter Adapter Hose

Domain Est. 2019

Expert Sourcing Insights for Propane Bottle Splitter

H2: 2026 Market Trends for Propane Bottle Splitter

The propane bottle splitter market is poised for notable shifts by 2026, driven by evolving safety regulations, rising demand for propane cylinder recycling, and advancements in metal fabrication tools. A propane bottle splitter is a specialized tool designed to safely cut used or expired propane cylinders (e.g., 20 lb BBQ tanks) for disposal or recycling, ensuring residual pressure is released and the cylinder is rendered inoperable. Below is an analysis of key market trends expected in 2026 under the H2 category.

-

Increased Regulatory Pressure and Safety Compliance

By 2026, stricter environmental and occupational safety regulations—especially in North America and Western Europe—are expected to drive demand for certified propane bottle splitters. Agencies such as OSHA (U.S.) and CSA (Canada) are likely to enforce mandatory decommissioning procedures for expired propane tanks. This will compel scrap yards, recycling centers, and propane retailers to adopt compliant tools like bottle splitters, boosting market growth. -

Growth in Propane Tank Recycling and Circular Economy Initiatives

With global emphasis on sustainability and circular economy models, the recycling rate of propane cylinders is expected to rise. Steel from decommissioned tanks is highly recyclable, and using propane bottle splitters ensures safe and efficient dismantling. Municipal waste programs and private recyclers are increasingly investing in these tools, projecting steady market expansion through 2026. -

Technological Advancements and Automation

By 2026, the propane bottle splitter market will likely see integration with semi-automated and electric-powered systems. Innovations such as hydraulic-assisted cutters, IoT-enabled safety interlocks, and modular designs are expected to enhance operational efficiency and worker safety. These upgrades will appeal to industrial users seeking faster throughput and reduced labor costs. -

Expansion in Emerging Markets

While North America currently dominates the propane bottle splitter market due to high propane usage in residential and recreational sectors, emerging economies in Latin America, Southeast Asia, and Africa are expected to increase propane consumption for cooking and heating. This will create new demand for cylinder decommissioning tools, presenting growth opportunities for manufacturers by 2026. -

Market Consolidation and Brand Differentiation

Anticipated market consolidation will lead to a few key players offering certified, high-durability splitters. Companies will differentiate through safety certifications (e.g., CE, ANSI), customer training programs, and bundling services (e.g., maintenance, compliance documentation). Online sales and direct-to-business distribution channels will grow, especially for SMEs and independent recyclers. -

Impact of Alternative Fuel Competition

While the rise of electric grills and renewable energy may slightly reduce long-term propane demand, the large existing base of propane tanks (estimated in the tens of millions in the U.S. alone) ensures continued need for decommissioning tools. The lifespan of propane tanks (typically 12–20 years) means a consistent stream of expired units will require safe disposal through 2026 and beyond.

Conclusion:

The 2026 market for propane bottle splitters will be shaped by regulatory compliance, sustainability goals, and technological innovation. Demand will remain strong in industrial recycling and hazardous waste management sectors, with opportunities expanding in both developed and emerging markets. Companies investing in safety-certified, user-friendly, and scalable splitter solutions are best positioned to capture market share in this niche but essential segment.

H2: Common Pitfalls When Sourcing a Propane Bottle Splitter – Quality and Intellectual Property Risks

Sourcing a propane bottle splitter—whether for commercial distribution, industrial use, or personal application—can expose buyers to several critical pitfalls, particularly concerning product quality and intellectual property (IP) infringement. Understanding these risks is essential to ensuring safety, regulatory compliance, and legal protection.

1. Substandard Quality and Safety Hazards

-

Poor Material Construction: Many low-cost propane bottle splitters are made from inferior materials (e.g., non-grade stainless steel or unsuitable alloys) that cannot withstand high pressure or prolonged exposure to propane. This increases the risk of leaks, ruptures, or catastrophic failure.

-

Lack of Certifications: Reputable propane handling equipment should meet recognized safety standards such as ASME, CGA (Compressed Gas Association), or UL. Sourced splitters lacking third-party testing or certification may not comply with local or international safety codes, creating liability and operational risks.

-

Inconsistent Manufacturing Tolerances: Poorly manufactured splitters may feature imprecise threading or sealing surfaces, leading to gas leaks. Even minor deviations can compromise the integrity of propane delivery systems.

-

Absence of Pressure Relief Mechanisms: High-quality splitters often include built-in safety features like pressure relief valves. Counterfeit or poorly engineered products frequently omit these, increasing the risk of over-pressurization.

2. Intellectual Property (IP) Infringement

-

Unauthorized Replicas or Counterfeits: Many propane bottle splitters available through third-party suppliers or online marketplaces are unauthorized copies of patented designs. These replicas often mimic well-known branded products but lack proper licensing, exposing the buyer or distributor to legal liability.

-

Patent and Design Violations: Original propane splitter designs may be protected by utility patents (covering functional mechanisms) or design patents (covering aesthetic elements). Sourcing unlicensed copies—even unknowingly—can lead to cease-and-desist orders, seizures, or lawsuits, especially when importing across borders.

-

Trademark Infringement: Knockoff products often use branding or logos similar to established manufacturers (e.g., misleading labels or packaging), which can result in trademark violations and damage to your business reputation.

-

Limited Recourse in Disputes: Suppliers of infringing products typically operate in jurisdictions with weak IP enforcement, making it difficult to seek compensation or product recalls in case of failure or legal action.

Mitigation Strategies

- Verify Compliance and Certification: Demand documentation proving the splitter meets pressure safety standards (e.g., DOT, ASME, or ISO).

- Source from Reputable Manufacturers: Work directly with OEMs or authorized distributors who can provide proof of IP ownership or licensing.

- Conduct IP Due Diligence: Use patent databases (e.g., USPTO, WIPO) to check if a design is protected and whether your supplier has rights to produce or sell it.

- Include Warranty and Liability Clauses: Contracts should specify quality standards, indemnification for IP violations, and return policies for defective products.

In summary, sourcing propane bottle splitters requires careful vetting to avoid dangerous quality issues and legal exposure from IP infringement. Prioritizing certified, legally compliant products protects both end-users and business interests.

H2: Logistics & Compliance Guide for Propane Bottle Splitter

Handling and transporting propane bottle splitters—devices used to transfer propane from large tanks (such as 100-lb cylinders) into smaller portable bottles (e.g., 1-lb or 16.4-oz disposable cylinders)—involves strict logistics and compliance requirements due to the flammable nature of propane and regulatory oversight by agencies such as the U.S. Department of Transportation (DOT), Occupational Safety and Health Administration (OSHA), and the National Fire Protection Association (NFPA).

This guide outlines key logistics and compliance considerations for the safe and legal use, storage, transportation, and maintenance of propane bottle splitters.

H2.1 Regulatory Compliance

Compliance with federal, state, and local regulations is mandatory when using propane bottle splitters.

- DOT Regulations (49 CFR): Propane is classified as a hazardous material (UN1075, Propane, compressed). The transfer of propane using bottle splitters may be restricted or prohibited under DOT regulations unless performed under an authorized exemption or by a licensed entity.

- Refilling of disposable propane cylinders (e.g., 1-lb “camp stove” bottles) is generally prohibited by DOT 49 CFR § 173.302d, unless the cylinder is specifically designed and marked for requalification and reuse.

-

Use of unauthorized refill adapters or splitters on disposable cylinders violates federal safety standards and voids insurance coverage.

-

NFPA 58 – Liquefied Petroleum Gas Code: NFPA 58 governs the storage, handling, and use of LP-Gas. Any propane transfer operation must comply with equipment design, ventilation, and safety requirements.

- Only DOT-approved containers and fittings may be used.

-

Transfer operations must occur in well-ventilated, non-enclosed areas away from ignition sources.

-

OSHA Standards (29 CFR 1910.110): Workplaces using propane must follow OSHA’s requirements for handling flammable gases, including proper training, ventilation, fire protection, and emergency procedures.

⚠️ Important: Refilling disposable propane cylinders using splitters is not compliant with most U.S. regulations and poses serious safety and liability risks.

H2.2 Equipment Standards & Safety

To ensure safe operation, all propane bottle splitter systems must meet specific technical and safety standards.

- Approved Components Only:

- Use only DOT- and ASME-certified propane cylinders.

- Splitters must include overfill prevention devices (OPD), pressure relief valves, and check valves.

-

Hoses and fittings must be rated for propane service and regularly inspected for wear or leaks.

-

Leak Testing:

- Perform a soap-and-water leak test on all connections before and after each use.

-

Never use open flames to detect leaks.

-

Ventilation & Location:

- All transfer operations must be conducted outdoors or in well-ventilated areas.

-

Keep equipment at least 10 feet away from ignition sources (e.g., pilot lights, electrical equipment).

-

Static Electricity Control:

- Ground both the source and receiving cylinders to prevent static discharge.

- Use conductive hoses and bonding straps where applicable.

H2.3 Transportation & Storage

Transporting propane and associated equipment requires adherence to hazardous materials transportation rules.

- Cylinder Transport:

- Secure all cylinders in an upright position.

- Transport only in well-ventilated vehicles; never inside passenger compartments.

-

Limit total propane quantity in vehicles per DOT regulations (e.g., ≤ 90 kg or ~200 lbs may qualify for limited quantity exceptions under 49 CFR 173.150).

-

Storage Requirements:

- Store propane cylinders outdoors in a dry, well-ventilated area away from direct sunlight and heat sources.

- Keep away from exits, stairways, and building openings.

-

Follow quantity-distance rules per NFPA 58 (e.g., separation from buildings, property lines).

-

Labeling & Documentation:

- Clearly label all equipment and containers.

- Maintain records of cylinder inspections, maintenance, and training.

H2.4 Training & Operational Procedures

All personnel involved in propane handling must be properly trained.

- Required Training:

- Hazard communication (HazCom)

- Fire safety and emergency response

- Proper use of personal protective equipment (PPE)

-

Leak detection and shutdown procedures

-

Standard Operating Procedures (SOPs):

- Develop written procedures for setup, transfer, shutdown, and emergency response.

-

Prohibit unauthorized or unsupervised use of bottle splitters.

-

Incident Reporting:

- Document any leaks, spills, or near misses.

- Report incidents involving injuries or significant propane release to OSHA or local authorities if required.

H2.5 Legal and Liability Considerations

Using propane bottle splitters—especially to refill disposable cylinders—can create serious legal and insurance liabilities.

- Voided Warranties & Insurance:

- Most propane cylinder manufacturers void warranties if disposable cylinders are refilled.

-

General liability and property insurance may not cover incidents arising from non-compliant propane transfers.

-

Criminal & Civil Penalties:

-

Violations of DOT or NFPA regulations can result in fines, operational shutdowns, or criminal charges in case of injury or death.

-

Recommended Alternatives:

- Use refillable, DOT-approved portable tanks (e.g., ASME tanks with OPD valves).

- Purchase pre-filled propane bottles from licensed suppliers.

H2.6 Conclusion

While propane bottle splitters may appear to offer cost savings or convenience, their use—particularly for refilling disposable cylinders—is largely non-compliant with U.S. safety regulations. Organizations and individuals must prioritize compliance, safety, and legal risk mitigation over convenience.

Always consult with a qualified safety officer, legal counsel, or certified hazardous materials specialist before implementing any propane transfer system. When in doubt, use only manufacturer-approved, refillable containers and certified propane service providers.

✅ Best Practice: Avoid using propane bottle splitters on disposable cylinders. Opt for DOT-compliant refillable systems and professional refilling services to ensure safety and regulatory compliance.

In conclusion, sourcing a propane bottle splitter requires careful consideration of safety, quality, and compliance with local regulations. It is essential to purchase from reputable suppliers who provide certified, durable, and properly tested equipment to minimize risks associated with propane handling. While cost and availability are important factors, they should not compromise safety standards. Whether sourcing from industrial gas equipment suppliers, online marketplaces, or specialty retailers, verifying product specifications, material quality, and customer reviews is crucial. Additionally, ensuring that users are properly trained in the safe operation of the splitter is vital to prevent accidents. Ultimately, a well-sourced propane bottle splitter can offer efficient, economical, and safe fuel transfer when acquired responsibly and used correctly.