The industrial automation sector is witnessing robust expansion, with the global Profibus cable market projected to grow at a CAGR of approximately 4.8% from 2024 to 2030, according to Grand View Research. As industries increasingly adopt advanced communication protocols to streamline manufacturing and process control systems, demand for reliable and high-performance Profibus cables continues to rise. Valued at over USD 3.2 billion in 2023, the market is driven by growing deployments in automotive, oil & gas, power, and chemical industries, where real-time data transmission and system integration are critical. Furthermore, Mordor Intelligence highlights the ongoing digital transformation in industrial infrastructure as a key catalyst for fieldbus technology adoption, including Profibus-enabled networks. With such momentum, selecting high-quality Profibus cables from reputable manufacturers has become essential for ensuring network reliability, minimizing downtime, and supporting Industry 4.0 initiatives. Below, we present the top 7 Profibus cable manufacturers shaping the industrial communication landscape through innovation, durability, and global reach.

Top 7 Profibus Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Profibus & RS485?

Domain Est. 1990

Website: control.com

Key Highlights: Profibus cable and connectors are available from a large selection of manufacturers (including Belden, see profibus.com)and at (relatively) ……

#2 Profibus cables for industrial automation

Domain Est. 1994

Website: ifm.com

Key Highlights: PROFIBUS cordsets and shielded connection cables from ifm are ideal for harsh industrial environments. Benefit from wide operating temperatures….

#3 PROFIBUS Cables

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB offers a wide range of cable for PROFIBUS PA and DP applications especially also blue DP cable for networks in Ex(Haz.) area….

#4 PROFIBUS RS 485 Festoon Cable

Domain Est. 1996

Website: profibus.com

Key Highlights: The PROFIBUS RS 485 Festoon Cable (stranded conductor) is designed for special festoon applications. It is a shielded and twisted conductor pair with circular ……

#5 PROFIBUS Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Belden’s PROFIBUS DP, PROFIBUS PA and PROFINET Cables ensure maximum reliability, uptime, and performance. Tested, certified and proven to ensure application ……

#6 Profibus, 2 wire substitute temporarily.??

Domain Est. 2002

Website: plctalk.net

Key Highlights: It’s just a shielded twisted pair cable for RS485 communication. Anything that is shielded and twisted pair would work….

#7 PROFIBUS Bus Cable

Domain Est. 2007

Website: lapptannehill.com

Key Highlights: 5-day deliveryLapp Tannehill is a distributor of PROFIBUS bus cable, including LAPP’s UNITRONIC PROFIBUS line. Contact us to order today….

Expert Sourcing Insights for Profibus Cable

H2: 2026 Market Trends for Profibus Cable

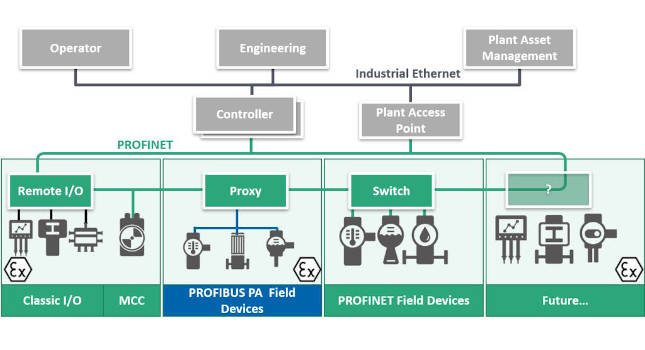

As industrial automation continues to evolve, the Profibus cable market is expected to undergo significant shifts by 2026, influenced by technological advancements, regional industrial growth, and the ongoing transition toward Industry 4.0. While facing competition from newer communication protocols such as Profinet, Profibus cables remain relevant in legacy systems and specific industrial applications. The following trends are projected to shape the Profibus cable market in 2026:

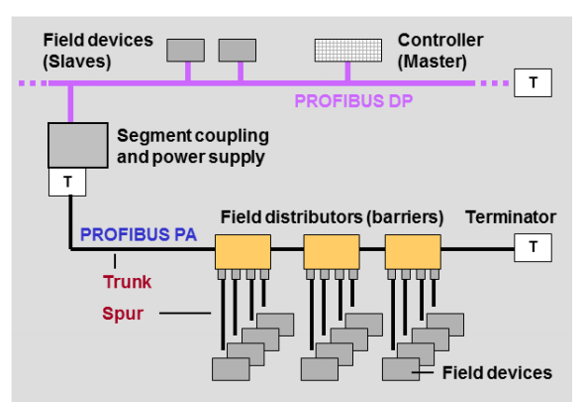

1. Sustained Demand in Legacy Industrial Installations

Despite the rise of Ethernet-based industrial networks, a substantial number of manufacturing, process, and utility sectors still rely on Profibus DP (Decentralized Peripherals) and Profibus PA (Process Automation) systems. These legacy infrastructures require maintenance, replacement, and retrofitting, ensuring continued demand for Profibus cables through 2026, particularly in regions with slower digital transformation rates such as parts of Eastern Europe, Latin America, and Southeast Asia.

2. Replacement and Maintenance-Driven Market Growth

The market will be increasingly driven by replacement needs rather than new installations. As existing Profibus cables degrade over time due to harsh industrial environments, there will be steady demand for high-quality, durable cables with enhanced shielding and resistance to EMI, temperature extremes, and mechanical stress. Manufacturers will focus on offering longer-lasting, low-maintenance cabling solutions to meet these needs.

3. Regional Disparities in Adoption and Demand

Europe and parts of Asia-Pacific will remain key markets. Germany, China, and India are expected to sustain demand due to their large industrial bases and extensive use of automation. In contrast, North America will see gradual decline in new Profibus deployments, favoring Profinet and other Industrial Ethernet solutions. However, retrofitting projects in oil & gas, chemicals, and water treatment will support regional demand.

4. Integration with Hybrid Automation Systems

By 2026, many industrial facilities will operate hybrid networks combining Profibus with modern protocols. This integration will necessitate compatible cabling solutions and gateways, supporting a niche but stable market for Profibus cables in transitional environments. Cable manufacturers may offer bundled solutions or hybrid connectivity kits to support interoperability.

5. Emphasis on Cable Quality and Certification

With increasing scrutiny on system reliability and safety—especially in hazardous environments such as chemical plants and refineries—there will be greater demand for certified Profibus cables compliant with standards like IEC 61158 and explosion-proof (Ex) certifications. Manufacturers investing in quality assurance and specialized variants (e.g., PUR jacketed, low-smoke zero-halogen) will gain competitive advantage.

6. Competitive Pressure from Industrial Ethernet

The continued expansion of Profinet and other Industrial Ethernet solutions poses a long-term challenge. By 2026, investment in new high-speed, real-time communication systems will likely reduce the share of Profibus in greenfield projects. However, Profibus cables will retain a foothold in cost-sensitive applications and sectors where bandwidth requirements remain modest.

7. Focus on Sustainability and Recycling

Environmental regulations and corporate sustainability goals will push cable manufacturers to develop eco-friendly Profibus cables—using recyclable materials and reducing hazardous substances. This trend will align with broader ESG (Environmental, Social, and Governance) initiatives within the industrial sector.

In conclusion, while the Profibus cable market is expected to experience moderate decline in terms of new installations, it will remain a resilient segment through 2026, supported by legacy infrastructure, maintenance cycles, and specific industrial requirements. Success in this market will depend on adaptability, quality differentiation, and strategic positioning in regions and sectors where Profibus remains entrenched.

Common Pitfalls When Sourcing Profibus Cable: Quality and IP Considerations

Sourcing Profibus cable may seem straightforward, but several pitfalls can compromise network performance, reliability, and longevity—especially when overlooking quality standards and Ingress Protection (IP) ratings. Being aware of these issues helps ensure a robust and compliant industrial communication system.

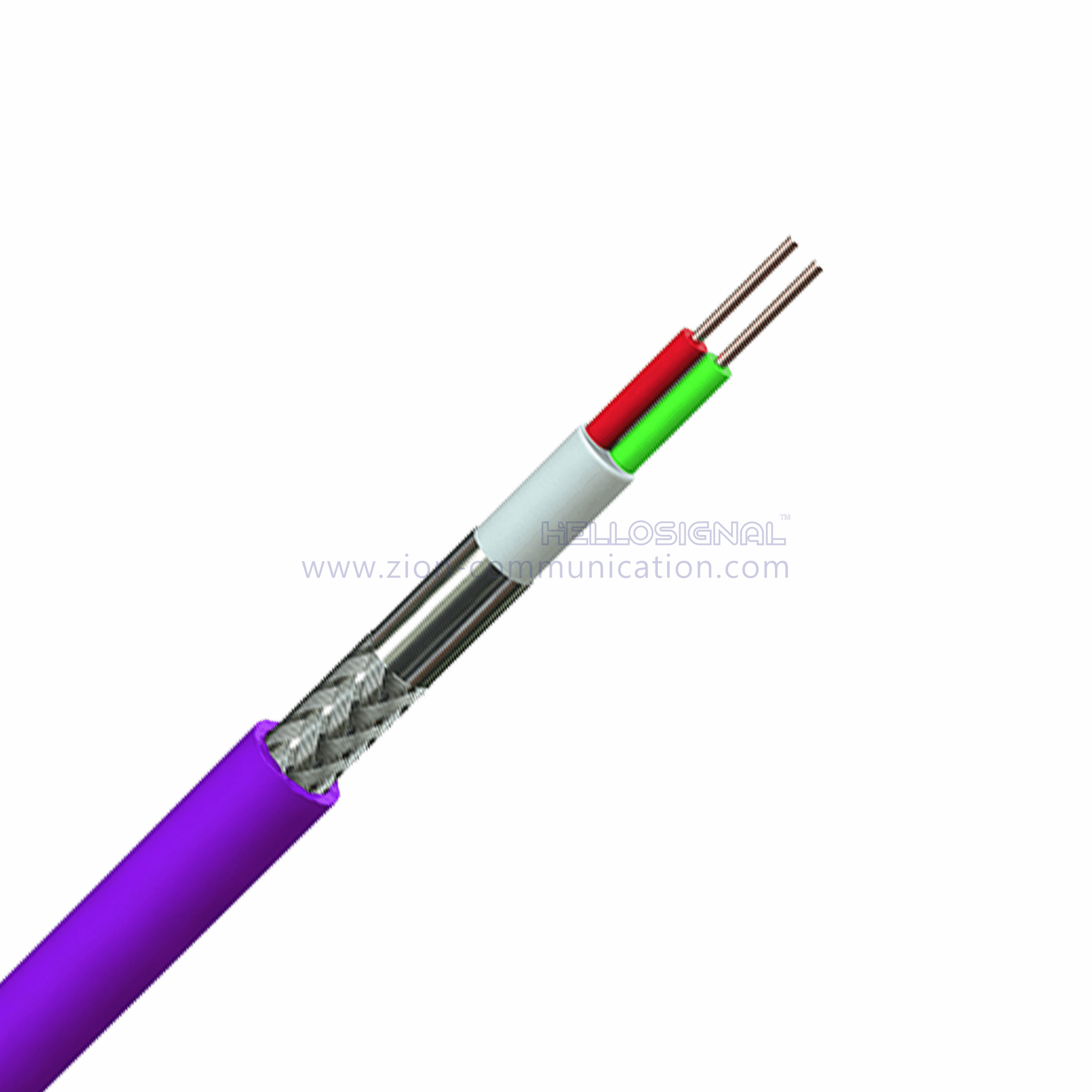

Poor Quality Cable Materials and Construction

One of the most frequent issues is selecting low-quality Profibus cables made with substandard materials. Cheap alternatives often use non-true impedance-matched conductors, inconsistent shielding, or inadequate insulation. These flaws lead to signal attenuation, electromagnetic interference (EMI), and increased bit error rates. Always verify that the cable meets the Siemens or PI (Profibus & Profinet International) specifications, such as using twin-core twisted pair with 38.5–40 Ω characteristic impedance and proper overall foil and braid shielding.

Incorrect or Missing Shielding

Profibus cables require robust shielding to operate reliably in electrically noisy industrial environments. Poorly shielded or unshielded cables are prone to interference, resulting in communication failures. Ensure the cable has both a foil shield (for high-frequency noise) and a tinned copper braid (for low-frequency grounding). Improper grounding of the shield at both ends (with one end grounded via a termination resistor) can also negate its effectiveness.

Ignoring Ingress Protection (IP) Ratings

The IP rating defines protection against solids and liquids—critical for cables used in harsh environments like factories, outdoor installations, or washdown areas. Using cables with insufficient IP ratings (e.g., IP20 instead of IP67 or IP68) risks moisture ingress, dust accumulation, and eventual cable or connector failure. Always match the cable’s IP rating to the environmental conditions of the installation site.

Using Non-Profibus-Specific Cable

Not all industrial communication cables are suitable for Profibus networks. Generic “fieldbus” cables may not meet the precise electrical characteristics required by Profibus DP or PA. Using incompatible cables can result in communication dropouts, timing errors, and difficult troubleshooting. Always confirm the cable is explicitly rated for Profibus applications.

Neglecting Installation and Flexibility Needs

Some Profibus cables are designed for fixed installations only and lack flexibility, making them prone to cracking when exposed to vibration or movement. For dynamic applications (e.g., robotics or moving machinery), use flexible, high-flex Profibus cables rated for repeated bending. Additionally, improper bending radius during installation can damage internal conductors and shielding.

Overlooking Certification and Compliance

Reputable suppliers provide certification from recognized bodies like UL, CE, or PI. Absence of such certifications may indicate non-compliance with safety and performance standards. Always request documentation proving compliance with relevant industrial standards to avoid liability and ensure long-term reliability.

Cost-Cutting at the Expense of Performance

While upfront cost savings may be tempting, investing in high-quality, properly rated Profibus cable prevents costly downtime, maintenance, and system failures. Low-cost cables often fail prematurely under industrial conditions, negating any initial savings.

By avoiding these common pitfalls—prioritizing certified quality, proper shielding, correct IP ratings, and application-specific design—engineers and procurement teams can ensure reliable, high-performance Profibus communication networks.

Logistics & Compliance Guide for Profibus Cable

Overview

Profibus (Process Field Bus) cables are essential for industrial automation networks, enabling reliable communication between controllers, drives, sensors, and other field devices. Ensuring proper logistics handling and regulatory compliance is critical to maintain performance, safety, and legal adherence across global supply chains.

Packaging and Labeling Requirements

Profibus cables must be packaged to prevent physical damage during transport. Use spools or reels made from durable materials, with protective end caps and sealed wrapping to guard against moisture and contaminants. Labels must include:

– Product name and model number

– Length and gauge specifications

– Manufacturer details and batch/lot number

– Compliance markings (e.g., CE, UL, RoHS)

– Storage conditions (e.g., temperature, humidity)

– Direction of winding (for reels)

Storage Conditions

Store Profibus cables in a dry, climate-controlled environment with temperatures between 5°C and 40°C and relative humidity below 70%. Avoid direct sunlight, corrosive atmospheres, and mechanical stress. Reels should be stored vertically on pallets to prevent deformation. Shelf life should not exceed 5 years under proper conditions.

Transportation Guidelines

Transport cables in enclosed, weather-protected vehicles. Protect spools from impact and compression; never drop or roll reels. Maintain stable temperatures during transit—avoid freezing or extreme heat. Use appropriate lifting equipment when handling heavy reels. For international shipments, ensure compliance with IATA, IMDG (if applicable), and regional freight regulations.

Regulatory Compliance

Profibus cables must meet key international and regional standards:

– IEC 61158/61784: Specifies fieldbus communication standards, including Profibus.

– EN 50170: European standard for Profibus installation and performance.

– CE Marking: Required for sale in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

– UL/CSA Listing: Mandatory for use in North America; cables should be rated for industrial applications (e.g., UL AWM, CSA LL80043).

– RoHS & REACH: Ensure cables are free from restricted hazardous substances (e.g., lead, cadmium, phthalates).

– Low Smoke Zero Halogen (LSZH): Required in confined or public spaces (e.g., tunnels, buildings) to reduce toxic emissions during fire. Verify with certifications like CPR (EU Construction Products Regulation) for such installations.

Environmental and Safety Compliance

Dispose of defective or excess Profibus cables in accordance with local e-waste regulations. Recycle copper and jacket materials through certified electronic waste handlers. During installation, ensure cables comply with local electrical codes (e.g., NEC in the U.S., IEC 60364 internationally) to prevent fire or shock hazards.

Documentation and Traceability

Maintain complete documentation for each batch, including:

– Certificate of Conformity (CoC)

– Test reports (e.g., impedance, attenuation, crosstalk)

– Material Declarations (RoHS, REACH)

– Safety Data Sheets (SDS) for jacketing materials

Ensure full traceability from manufacturer to end-user through batch numbers and digital logs.

Import/Export Considerations

For cross-border shipments, verify:

– HS Code classification (typically 8544.42 or 8544.49 for insulated copper wires)

– Country-specific certifications (e.g., CCC in China, KC in South Korea)

– Customs documentation (commercial invoice, packing list, CoO)

– Import duties and VAT requirements

Use authorized distributors familiar with local compliance frameworks to streamline market entry.

Conclusion

Proper logistics and compliance management for Profibus cables ensures uninterrupted supply, regulatory approval, and long-term operational reliability. Adhering to packaging, storage, transportation, and certification standards minimizes risk and supports global deployment in industrial automation systems.

Conclusion for Sourcing Profibus Cable:

Sourcing the appropriate Profibus cable is a critical step in ensuring reliable, high-performance communication within industrial automation systems. After evaluating technical specifications, environmental conditions, supplier reliability, and cost considerations, it is evident that selecting a high-quality, shielded, impedance-matched Profibus cable compliant with IEC 61158-2 standards is essential for minimizing signal interference and ensuring long-term network stability.

Priority should be given to cables from reputable manufacturers that offer proven compatibility with existing Profibus DP or PA networks, along with appropriate certifications for use in hazardous or demanding environments (e.g., ATEX, UL). Additionally, considering future scalability, availability of technical support, and total cost of ownership—not just initial price—will contribute to a more sustainable and efficient automation infrastructure.

In conclusion, a well-informed sourcing decision based on technical fit, supplier credibility, and lifecycle value will ensure optimal network performance, reduce downtime, and support the overall efficiency of industrial operations.