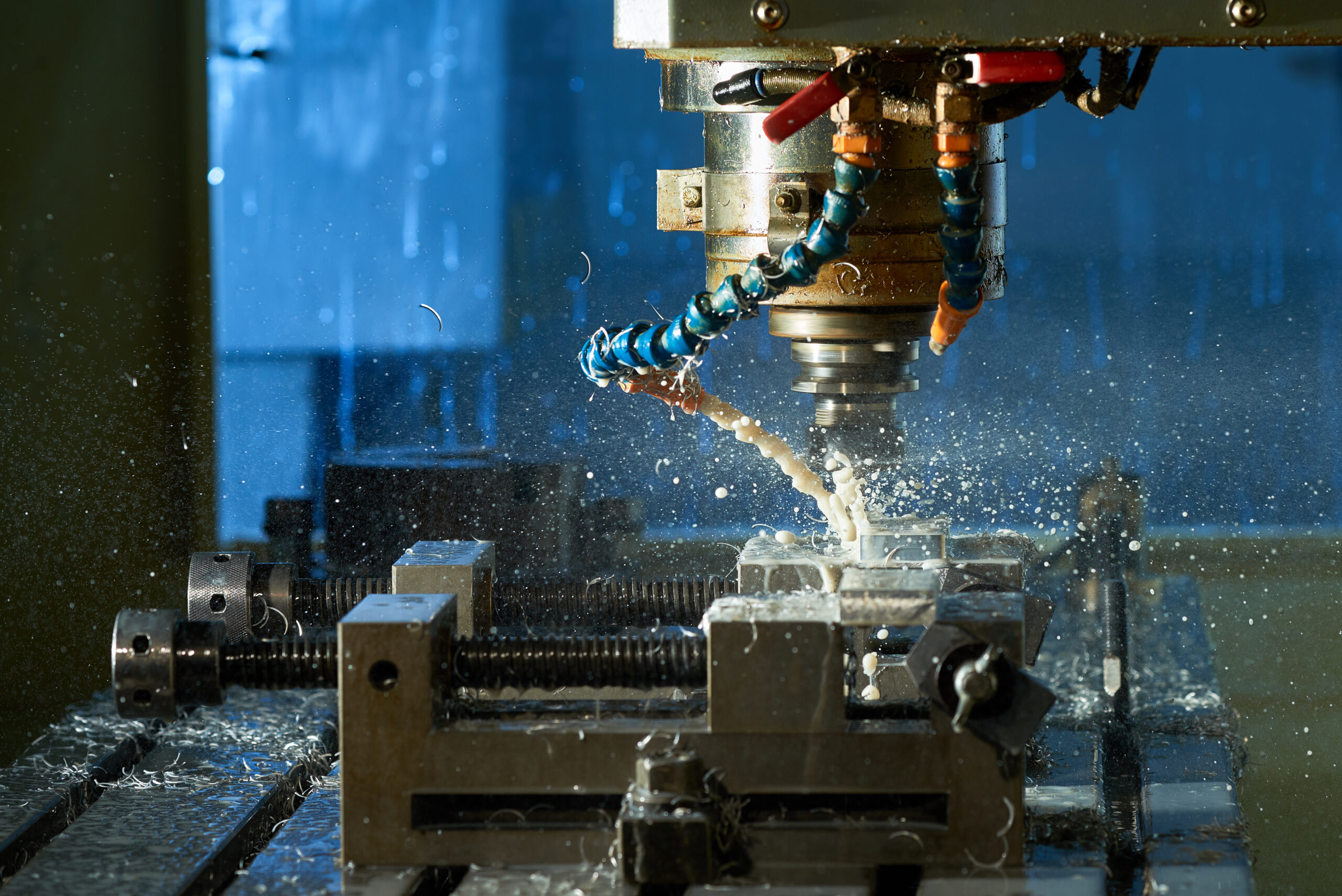

The global production machining industry is experiencing robust growth, driven by rising demand for precision components across aerospace, automotive, medical, and industrial sectors. According to Grand View Research, the global CNC machining market size was valued at USD 88.8 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2030. This expansion is fueled by advancements in automation, increasing adoption of smart manufacturing technologies, and the growing need for high-tolerance parts in complex applications. As manufacturers prioritize efficiency, scalability, and quality, leading production machining companies are investing heavily in multi-axis CNC systems, in-house tooling, and lean manufacturing practices to maintain competitive advantage. In this evolving landscape, the following ten manufacturers have emerged as industry leaders based on capacity, technological innovation, quality certifications, and global client footprint.

Top 10 Production Machining Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Metalworking CNC Machine Tools Supplier & Equipment Distributor …

Domain Est. 1991

Website: productivity.com

Key Highlights: We are a single source machine tool distributor of metalworking machines, tooling and industrial supplies, robots and related manufacturing products and ……

#2 Makino

Domain Est. 1996

Website: makino.com

Key Highlights: Achieve superior results with Makino’s CNC machining. Makino machines and engineering services provide precision and reliability across applications….

#3 National Tooling & Machining Association

Domain Est. 1996

Website: ntma.org

Key Highlights: NTMA has the know-how, resources and national presence to drive change and growth – and we’re committed to action….

#4 Okuma America

Domain Est. 1996

Website: okuma.com

Key Highlights: Okuma America Corporation helps users gain competitive advantage through the open possibilities of our CNC machine tools and advanced technologies….

#5 Production Machining

Domain Est. 1997

Website: productionmachining.com

Key Highlights: The online extension of Production Machining magazine and the most comprehensive Web site available for high volume precision machining professionals….

#6 to Mazak Corporation

Domain Est. 1998

Website: mazak.com

Key Highlights: Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various ……

#7 Production Machine

Domain Est. 1999

Website: production-machine.com

Key Highlights: We partner with companies to be a solution for their machining and manufacturing problems. We can machine parts as large as a truck and as small as a button….

#8 eMachineShop

Domain Est. 1999

Website: emachineshop.com

Key Highlights: eMachineShop manufactures low-cost prototype and production runs of custom parts. Get a fast quote or design and order your parts with our free CAD software ……

#9 Milling

Domain Est. 1999

Website: gfms.com

Key Highlights: The portfolio includes milling, EDM, laser texturing, laser micromachining, and additive manufacturing machines. Our advanced spindles, automation, tooling, and ……

#10 Aerostar Mfg

Domain Est. 2003

Website: aerostarmfg.com

Key Highlights: Learn about Aerostar’s manufacturing capabilities from casting to CNC production machining ensuring high standards for automotive, manufacturing & more….

Expert Sourcing Insights for Production Machining

2026 Market Trends in Production Machining

The production machining industry is poised for significant transformation by 2026, driven by technological innovation, evolving customer demands, and macroeconomic shifts. As manufacturers strive for greater efficiency, precision, and sustainability, several key trends are expected to define the market landscape.

Advanced Automation and Lights-Out Machining

By 2026, automation will move beyond simple robotic loading to fully integrated, smart production cells capable of lights-out machining. The convergence of collaborative robots (cobots), AI-driven process optimization, and machine monitoring systems will enable 24/7 operations with minimal human intervention. This shift is particularly critical in response to persistent labor shortages and rising labor costs, allowing shops to maintain competitiveness while improving throughput and consistency.

Integration of AI and Machine Learning

Artificial intelligence will play an increasingly central role in predictive maintenance, quality control, and process optimization. By analyzing real-time data from CNC machines, AI algorithms will anticipate tool wear, detect anomalies in machining processes, and dynamically adjust parameters to maintain precision. This results in reduced downtime, lower scrap rates, and extended tool life—key drivers of cost savings and operational excellence.

Growth in High-Mix, Low-Volume Manufacturing

As industries such as aerospace, medical devices, and electric vehicles (EVs) demand more customized and complex components, production machining shops are adapting to high-mix, low-volume environments. Flexible manufacturing systems (FMS) and modular tooling will become more prevalent, allowing rapid reconfiguration of production lines to accommodate diverse part families without sacrificing efficiency.

Sustainability and Green Machining Practices

Environmental regulations and corporate sustainability goals will accelerate the adoption of eco-friendly machining practices. This includes the use of biodegradable coolants, energy-efficient machine tools, and closed-loop recycling of metal chips. Additionally, shops will invest in digital twins and simulation tools to minimize material waste during programming and setup phases.

Supply Chain Resilience and Onshoring

Geopolitical uncertainties and supply chain disruptions have prompted a renewed focus on reshoring and nearshoring of precision components. North American and European manufacturers are increasingly investing in domestic production machining capabilities to reduce lead times and ensure supply continuity. This trend supports localized, agile supply chains that can respond quickly to market fluctuations.

Adoption of Hybrid Manufacturing and Additive Integration

While not replacing traditional subtractive methods, hybrid machining—combining CNC milling with directed energy deposition (DED) or laser cladding—will gain traction for high-value applications. By 2026, we can expect more shops to utilize additive techniques for near-net-shape preforms, followed by precision machining to final tolerances, reducing raw material waste and lead times.

Workforce Development and Digital Skills

As technology advances, the demand for skilled machinists with expertise in programming, data analytics, and machine maintenance will intensify. Companies will invest more in training programs, partnerships with technical schools, and upskilling initiatives to close the skills gap. The machinist of 2026 will be as proficient with software platforms as with cutting tools.

In conclusion, the 2026 production machining landscape will be shaped by intelligent automation, digital integration, and a strategic focus on agility and sustainability. Companies that embrace these trends will be best positioned to thrive in an increasingly competitive and technologically driven market.

Common Pitfalls in Sourcing Production Machining: Quality and Intellectual Property Risks

Sourcing production machining services is critical for manufacturing efficiency and product integrity, but organizations often encounter significant challenges related to quality control and intellectual property (IP) protection. Failing to address these pitfalls can result in costly rework, delays, legal disputes, or loss of competitive advantage.

Quality Control Inconsistencies

One of the most frequent issues in outsourced machining is inconsistent product quality. Suppliers may lack standardized processes, use outdated equipment, or have insufficient quality assurance protocols. This can lead to dimensional inaccuracies, surface finish defects, or non-compliance with engineering specifications. Without clear acceptance criteria, regular inspections, and documented process controls, companies risk receiving batches that require rework or rejection, disrupting supply chains and increasing costs.

Inadequate Supplier Qualification

Many organizations select machining partners based solely on cost or lead time without thoroughly vetting their capabilities. Skipping comprehensive supplier audits—covering certifications (e.g., ISO 9001), equipment calibration records, workforce training, and process validation—can expose buyers to unreliable production outputs. A supplier that performs well on prototypes may struggle to maintain quality at scale, especially if they lack statistical process control (SPC) or fail to implement proper first-article inspection (FAI) procedures.

Poor Communication of Tolerances and Specifications

Misunderstandings about technical drawings, geometric dimensioning and tolerancing (GD&T), or material requirements are common. Ambiguous documentation or lack of collaboration during the design-for-manufacturability (DFM) phase can result in parts that technically meet a drawing but fail in assembly or function. Ensuring clear, detailed, and mutually reviewed specifications helps prevent costly errors and rework.

Intellectual Property Exposure

Sharing design files, CAD models, and proprietary processes with external machining partners inherently risks IP theft or unauthorized use. This is especially concerning when sourcing internationally, where legal protections may be weaker or enforcement inconsistent. Without robust legal safeguards, companies may find their designs replicated, sold to competitors, or used in unauthorized products.

Insufficient Legal and Contractual Protections

Many sourcing agreements lack strong IP clauses, non-disclosure agreements (NDAs), or restrictions on subcontracting. Without explicit terms governing data ownership, usage rights, and confidentiality, suppliers may retain design data or share it with third parties. Additionally, vague or absent clauses on liability for IP infringement leave the buyer vulnerable to financial and reputational damage.

Lack of Traceability and Documentation

Effective production machining requires full traceability of materials, processes, and inspections. Suppliers that fail to maintain detailed records—including material certifications, inspection reports, and non-conformance logs—make it difficult to troubleshoot quality issues or respond to audits. This absence of documentation undermines quality assurance and regulatory compliance, particularly in regulated industries like aerospace or medical devices.

Failure to Monitor and Audit Ongoing Performance

Once a supplier is onboarded, ongoing oversight is often neglected. Without regular performance reviews, quality audits, or key performance indicator (KPI) tracking, small issues can escalate into systemic problems. Proactive monitoring helps maintain consistency, ensures continuous improvement, and strengthens the buyer-supplier relationship.

By addressing these common pitfalls through rigorous supplier selection, clear communication, strong contracts, and continuous quality management, organizations can mitigate risks and ensure reliable, secure production machining outcomes.

Logistics & Compliance Guide for Production Machining

This guide outlines key considerations and best practices for managing logistics and ensuring regulatory compliance within a production machining environment. Adherence to these standards helps maintain operational efficiency, product quality, and legal responsibility.

Supply Chain & Material Management

Effective logistics in production machining begins with the reliable sourcing and handling of raw materials and components.

- Vendor Qualification: Establish and maintain a list of approved suppliers meeting quality, delivery, and compliance standards. Conduct regular audits and performance evaluations.

- Material Traceability: Implement systems (e.g., barcoding, ERP integration) to track raw materials from receipt through final product. Maintain lot and heat number documentation for metals.

- Inventory Control: Utilize Just-In-Time (JIT) or Kanban systems where feasible to minimize excess inventory while ensuring uninterrupted production. Conduct regular cycle counts.

- Receiving Procedures: Inspect incoming materials for conformance to specifications, including material certifications (e.g., Mill Test Reports), dimensions, and surface quality.

In-Process Logistics

Streamlining the movement of parts through the machining workflow is essential for maintaining throughput and reducing lead times.

- Work-in-Progress (WIP) Tracking: Use digital or physical tracking methods to monitor part status across work centers. Minimize WIP to reduce bottlenecks.

- Tool and Fixture Management: Maintain organized storage and calibration records for cutting tools, gauges, and fixtures. Use tool presetters and manage tool life cycles.

- Internal Material Handling: Employ standardized containers, carts, and labeling to reduce handling damage and errors. Define clear routing paths on the shop floor.

- Lean Manufacturing Practices: Apply 5S (Sort, Set in Order, Shine, Standardize, Sustain) and value stream mapping to eliminate waste and optimize flow.

Regulatory Compliance

Production machining operations must comply with various local, national, and international regulations.

- Quality Standards: Adhere to relevant quality management systems such as ISO 9001 or IATF 16949. Document processes, conduct internal audits, and maintain corrective action records.

- Environmental Regulations: Comply with EPA and local rules for coolant disposal, metal shavings (swarf), and hazardous waste (e.g., oils, solvents). Secure permits and maintain disposal logs.

- Workplace Safety: Follow OSHA guidelines for machine guarding, lockout/tagout (LOTO), personal protective equipment (PPE), and chemical handling. Conduct regular safety training.

- Export Controls: For international shipments, comply with regulations like ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations) where applicable, especially in aerospace and defense sectors.

Shipping & Distribution

Final logistics steps ensure machined parts are delivered correctly and on time.

- Packaging Standards: Use protective packaging to prevent damage during transit. Clearly label containers with part numbers, quantities, PO numbers, and handling instructions.

- Documentation Accuracy: Generate accurate packing slips, certificates of conformance (CoC), and shipping manifests. Include required compliance documentation (e.g., RoHS, REACH declarations).

- Carrier Coordination: Partner with reliable freight carriers and track shipments. Use freight management software for visibility and cost control.

- Customer-Specific Requirements: Adhere to customer-specific logistics protocols (e.g., ASN – Advanced Shipping Notices, EDI integration, barcoding formats).

Continuous Improvement & Audits

Sustained compliance and logistical efficiency require ongoing evaluation and improvement.

- Internal Audits: Conduct regular audits of logistics processes and compliance records to identify gaps and drive corrective actions.

- Key Performance Indicators (KPIs): Monitor metrics such as on-time delivery rate, inventory turnover, scrap rate, and compliance incident frequency.

- Root Cause Analysis: Use tools like 8D or 5 Whys to investigate logistics failures or compliance deviations.

- Training Programs: Provide ongoing training for staff on updated regulations, safety procedures, and logistical best practices.

By integrating robust logistics planning with strict compliance protocols, production machining operations can achieve high reliability, customer satisfaction, and regulatory adherence.

Conclusion for Sourcing Production Machining

In conclusion, sourcing production machining requires a strategic balance between quality, cost, lead time, and supplier reliability. By carefully evaluating potential suppliers based on technical capabilities, quality certifications, production capacity, and past performance, companies can establish strong partnerships that support consistent product quality and on-time delivery. Leveraging both domestic and global suppliers offers opportunities for cost optimization and scalability, but must be weighed against logistical complexity and communication challenges.

Implementing a robust supplier selection process, ongoing performance monitoring, and clear communication of specifications are critical to mitigating risks and ensuring alignment with production goals. Ultimately, effective sourcing of production machining not only enhances manufacturing efficiency but also contributes significantly to overall product competitiveness and customer satisfaction in the market.