The global product manufacturing sector has experienced robust growth over the past decade, driven by advancements in automation, increasing demand for customized goods, and the expansion of supply chain networks across emerging markets. According to a 2023 report by Mordor Intelligence, the global manufacturing market was valued at USD 14.3 trillion and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This expansion is further supported by rising investments in Industry 4.0 technologies, including IoT, AI-driven production systems, and smart logistics. As competition intensifies, a select group of leading product manufacturing companies have emerged as benchmarks for innovation, scalability, and operational excellence. These top-tier manufacturers not only dominate market share but also set industry standards in sustainability, quality, and on-time delivery. In this analysis, we spotlight the top 10 product manufacturing companies leading the charge in reshaping the global industrial landscape.

Top 10 Product Manufacturing Company Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Dow Inc.

Domain Est. 1992

Website: dow.com

Key Highlights: Dow is an industry leading chemical producer for the pulp and paper market, with solutions that enhance performance, global compliance and cost efficiency….

#2 DuPont

Domain Est. 1987

Website: dupont.com

Key Highlights: DuPont is a leading solutions provider for healthcare, water, and a broad range of industrial segments, powered by high-performance engineered products, ……

#3

Domain Est. 1994

Website: murata.com

Key Highlights: This is Murata Manufacturing’s products-related website. You can view electronic component information, product and event news, exhibition, campaign and ……

#4 Nehemiah Manufacturing

Domain Est. 2009

Website: nehemiahmfg.com

Key Highlights: Nehemiah’s purpose is to build brands, create jobs and change lives. … Nehemiah licenses/acquires brands, innovates new concepts and contract manufacturers ……

#5 PLZ Corp

Domain Est. 2021

Website: plzcorp.com

Key Highlights: PLZ Corp is the leading manufacturer of specialty brand and private label aerosol and liquid products in North America. Contact us to get started!…

#6

Domain Est. 1995

Website: richs.com

Key Highlights: Rich’s is a family-owned food company that offers innovative products and expert solutions to global food professionals….

#7 Rheem Manufacturing Company

Domain Est. 1995

Website: rheem.com

Key Highlights: Learn about Rheem’s innovative and efficient heating, cooling, and water heating solutions for homes and businesses….

#8 Manufactured

Domain Est. 1998

Website: manufactured.com

Key Highlights: Manufactured is an end-to-end manufacturing & inventory credit solution. With over $80 million in goods produced over the last 2 years, we’ll deliver the right ……

#9 Manufacturing.gov

Domain Est. 2003

Website: manufacturing.gov

Key Highlights: The manufacturing.gov website serves as the primary hub for information about federal manufacturing programs, funding opportunities, and other valuable ……

#10 Sheldon Manufacturing Inc

Domain Est. 2016

Website: sheldonmanufacturing.com

Key Highlights: Custom Solutions · Photo Gallery · Products · Accessories and Parts · Products Portfolio Promotions · Anaerobic Chambers · Incubators · Water Baths ……

Expert Sourcing Insights for Product Manufacturing Company

H2: 2026 Market Trends Forecast for Product Manufacturing Companies

As we approach 2026, product manufacturing companies are navigating a transformative landscape shaped by technological innovation, evolving consumer demands, regulatory changes, and global economic shifts. This analysis outlines key market trends expected to define the manufacturing sector in 2026, providing strategic insights for companies aiming to remain competitive and resilient.

-

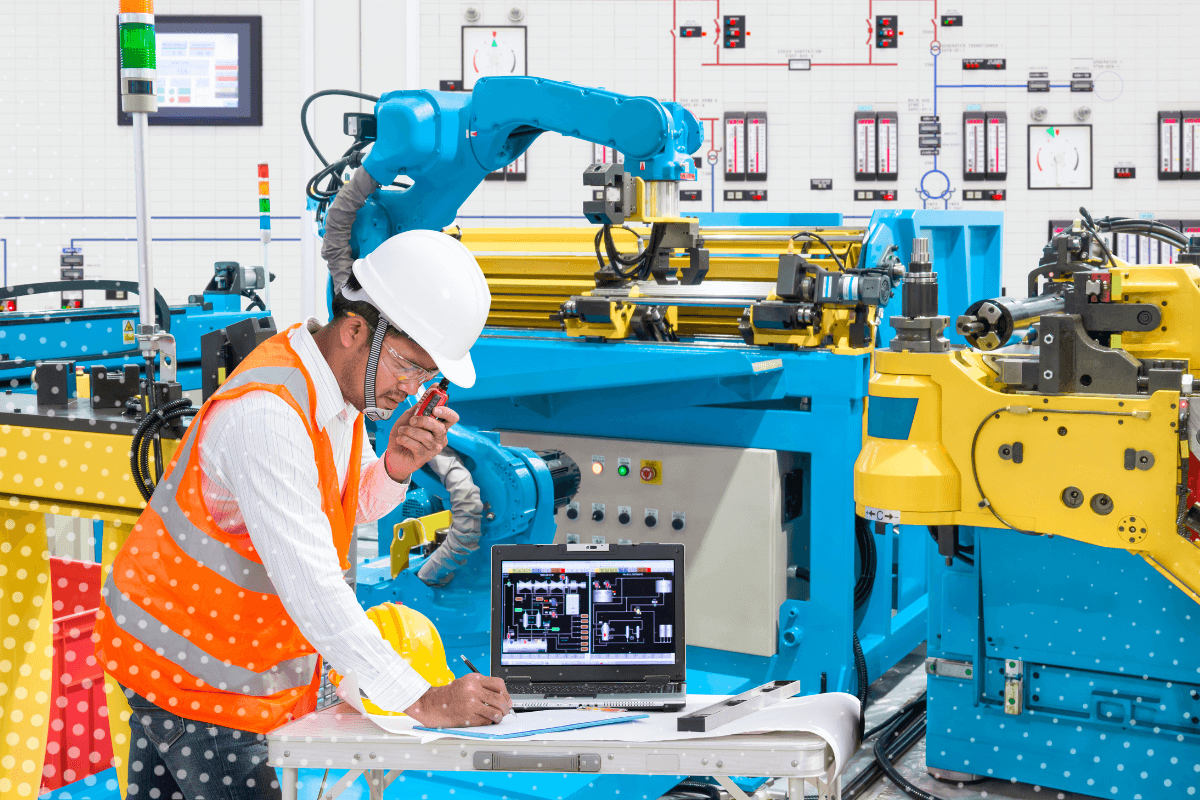

Accelerated Adoption of Industry 4.0 and Smart Manufacturing

By 2026, smart manufacturing technologies such as the Industrial Internet of Things (IIoT), artificial intelligence (AI), and machine learning will become standard across production lines. Real-time data analytics, predictive maintenance, and autonomous robotics will enhance operational efficiency, reduce downtime, and lower production costs. Manufacturers investing in digital twins—virtual replicas of physical systems—will gain a competitive edge through simulation-driven optimization and rapid prototyping. -

Sustainability and Circular Economy Integration

Environmental, social, and governance (ESG) imperatives will drive manufacturers to adopt circular economy models. In 2026, companies will prioritize recyclable materials, energy-efficient processes, and product life extension strategies. Regulatory pressures, consumer preferences, and carbon pricing mechanisms will push manufacturers to achieve net-zero goals. Adoption of green manufacturing practices and transparent supply chains will be critical for brand credibility and compliance. -

Reshoring and Supply Chain Resilience

Geopolitical instability, trade tensions, and lessons learned from recent global disruptions will continue to fuel the reshoring trend. By 2026, more manufacturers will localize production or regionalize supply chains to mitigate risks and reduce dependency on single-source suppliers. Nearshoring to regions like North America or Eastern Europe will gain traction, supported by government incentives and advancements in automation that reduce labor cost disadvantages. -

Customization and Mass Personalization

Consumer demand for personalized products will push manufacturers toward flexible production systems. Advances in additive manufacturing (3D printing) and modular assembly lines will enable cost-effective small-batch production. In 2026, mass customization will no longer be a niche strategy but a core capability, particularly in industries such as consumer electronics, automotive, and apparel. -

Workforce Transformation and Talent Development

As automation reshapes job functions, the manufacturing workforce will increasingly require digital literacy, data analytics skills, and AI collaboration capabilities. By 2026, companies will invest heavily in upskilling programs and partnerships with educational institutions. Human-machine collaboration, supported by augmented reality (AR) and wearable tech, will redefine shop floor operations and maintenance protocols. -

Expansion of Servitization and Product-as-a-Service Models

Manufacturers will increasingly shift from selling products to offering integrated services. The “Product-as-a-Service” (PaaS) model—where customers pay for usage rather than ownership—will gain momentum in sectors like industrial equipment, HVAC, and heavy machinery. This transition will require new business models, IoT-enabled monitoring, and long-term customer relationship management. -

Regulatory and Trade Dynamics

In 2026, manufacturing companies will face evolving regulatory landscapes, including stricter emissions standards, digital product passports (e.g., EU’s Ecodesign for Sustainable Products Regulation), and cybersecurity requirements for connected devices. Trade policies influenced by national security concerns and green industrial strategies (e.g., U.S. Inflation Reduction Act, EU Green Deal) will shape investment decisions and market access.

Conclusion

The 2026 manufacturing environment will reward agility, innovation, and sustainability. Product manufacturing companies that embrace digital transformation, strengthen supply chain resilience, and align with evolving societal expectations will be best positioned for growth. Strategic foresight and proactive adaptation will be essential to thrive in this dynamic and increasingly complex marketplace.

Common Pitfalls When Sourcing a Product Manufacturing Company (Quality, IP)

Sourcing a manufacturing partner is a critical step in bringing a product to market, but it comes with significant risks—especially concerning product quality and intellectual property (IP) protection. Overlooking these areas can lead to costly delays, legal disputes, and damage to brand reputation. Below are key pitfalls to avoid:

Overlooking Quality Control Processes

Many companies assume that a manufacturer’s certifications or past experience guarantee consistent quality. However, failing to audit actual production processes, test samples rigorously, or implement clear quality benchmarks often results in defective batches, product recalls, or customer dissatisfaction. It’s essential to establish defined quality standards, conduct regular on-site inspections, and require third-party testing when necessary.

Inadequate Intellectual Property Protection

Sharing designs, prototypes, or technical specifications with a manufacturer without proper legal safeguards exposes your IP to theft or unauthorized use. A common mistake is relying solely on verbal agreements or assuming that non-disclosure agreements (NDAs) are sufficient. In reality, manufacturers in some regions may replicate and sell your product independently. Always formalize IP ownership in contracts, register patents or trademarks where possible, and consider working with legal counsel familiar with international IP law.

Choosing the Lowest-Cost Option Without Due Diligence

While cost is a major factor, prioritizing the cheapest manufacturer often leads to compromised quality, hidden fees, or production delays. Low-cost suppliers may cut corners on materials or labor, increasing the risk of defects. Conduct thorough due diligence—including factory audits, reference checks, and sample evaluations—before committing to a partner.

Lack of Clear Communication and Documentation

Misunderstandings about product specifications, timelines, or responsibilities can derail production. Poor communication, language barriers, or vague contracts create room for errors. Ensure all agreements, including technical drawings, quality standards, and delivery schedules, are documented in writing and mutually understood.

Ignoring Supply Chain Transparency

Relying on a manufacturer without visibility into their sub-suppliers or raw material sources can lead to ethical, legal, or logistical issues. For example, using materials sourced unethically or subject to export controls can result in reputational harm or compliance violations. Demand transparency and traceability throughout the supply chain.

Failing to Plan for Contingencies

Unexpected events like production delays, equipment breakdowns, or geopolitical disruptions can halt manufacturing. Not having backup suppliers, clear escalation procedures, or force majeure clauses in contracts leaves your product launch vulnerable. Build resilience into your sourcing strategy by diversifying suppliers and planning for risks.

By proactively addressing these pitfalls, businesses can build stronger, more secure partnerships with manufacturers and ensure both product quality and IP protection are maintained throughout the production lifecycle.

Logistics & Compliance Guide for Product Manufacturing Companies

This guide outlines key logistics and compliance considerations essential for product manufacturing companies to ensure efficient operations, regulatory adherence, and successful product delivery.

Supply Chain Management

Establish a resilient and transparent supply chain by mapping all suppliers, identifying single points of failure, and maintaining strategic inventory levels. Implement supplier qualification processes and conduct regular performance evaluations to ensure reliability and quality consistency.

Transportation & Distribution

Select appropriate transportation modes (air, sea, road, rail) based on product type, lead time requirements, and cost efficiency. Optimize routing and consolidate shipments to reduce costs and environmental impact. Ensure all logistics partners comply with safety and handling requirements for your products.

Warehousing & Inventory Control

Maintain organized and secure storage facilities with clear labeling, proper environmental controls (e.g., temperature, humidity), and robust inventory tracking systems (e.g., barcode/RFID). Conduct regular cycle counts and audits to ensure inventory accuracy and minimize shrinkage.

Regulatory Compliance

Adhere to all local, national, and international regulations relevant to your industry and product type. This includes product safety standards (e.g., FDA, CE marking, FCC), labeling requirements, and documentation such as certificates of conformity and safety data sheets (SDS).

Import/Export Regulations

For international operations, comply with customs regulations, tariff classifications, and import/export controls. Obtain necessary permits and licenses, and ensure accurate preparation of shipping documents including commercial invoices, packing lists, and bills of lading.

Product Labeling & Packaging Compliance

Ensure all product packaging and labeling meet legal requirements for content, language, warnings, and traceability (e.g., batch/lot numbers, expiry dates). Follow industry-specific standards such as FDA food labeling or EU’s CE marking directives.

Environmental & Sustainability Standards

Comply with environmental regulations related to waste management, emissions, and hazardous materials handling. Implement sustainable practices such as reducing packaging waste, using recyclable materials, and adhering to regulations like RoHS or REACH (for electronics and chemicals).

Quality Management Systems

Maintain a certified Quality Management System (e.g., ISO 9001) to standardize processes, ensure product consistency, and support continuous improvement. Document procedures for production, inspection, and non-conformance handling.

Health, Safety & Workplace Compliance

Ensure workplace safety by complying with OSHA (or equivalent) standards. Provide employee training, conduct risk assessments, and maintain proper documentation for hazardous materials and equipment use.

Recordkeeping & Audit Readiness

Keep accurate, up-to-date records for all logistics and compliance activities, including supplier agreements, shipping logs, inspection reports, and compliance certifications. Maintain readiness for internal and external audits.

Continuous Monitoring & Improvement

Regularly review logistics performance and compliance status through KPIs and audits. Stay informed about regulatory changes and leverage technology (e.g., ERP, supply chain visibility tools) to enhance efficiency and compliance.

In conclusion, selecting the right product manufacturing company is a critical step in ensuring the success, quality, and scalability of your product. A thorough evaluation of potential partners—considering factors such as production capabilities, industry experience, quality control processes, cost-efficiency, communication, and ethical practices—helps mitigate risks and aligns your vision with a reliable manufacturer. By conducting due diligence, visiting facilities when possible, and establishing clear contractual agreements, you can build a strong, long-term partnership that supports innovation, timely delivery, and customer satisfaction. Ultimately, the right manufacturing partner doesn’t just produce your product—they become an extension of your brand and a key contributor to your business growth.