The global print head cleaner kit market is experiencing steady growth, driven by the increasing demand for reliable printing solutions across commercial, industrial, and consumer segments. According to a 2023 report by Mordor Intelligence, the global printer maintenance and consumables market—which includes cleaning solutions such as print head cleaner kits—is projected to grow at a CAGR of approximately 3.8% from 2023 to 2028. This expansion is fueled by rising printer usage in emerging economies, the proliferation of inkjet technology in manufacturing and packaging, and the need for cost-effective maintenance to extend equipment lifespan. As print heads are among the most sensitive and expensive components of inkjet systems, regular maintenance using specialized cleaning kits has become essential, creating strong demand for high-quality products. In this evolving landscape, a select group of manufacturers have emerged as leaders, combining technical innovation, product efficacy, and global distribution networks to support a wide range of printing platforms—from desktop printers to large-format industrial systems. Below, we explore the top 10 print head cleaner kit manufacturers shaping this niche yet critical segment of the printing ecosystem.

Top 10 Print Head Cleaner Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

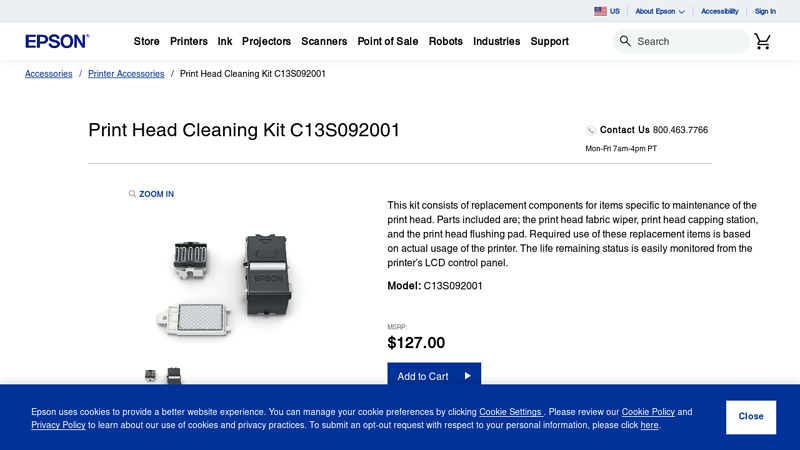

#1 Print Head Cleaning Kit C13S092001

Domain Est. 1991

#2 Printhead Cleaning Kit

Domain Est. 1996

Website: satoamerica.com

Key Highlights: Cleaning Kits include: 1 Printhead Cleaning Sheet; 12 Swabs; 12 Presaturated Cleaning Cards; 1 Glove ……

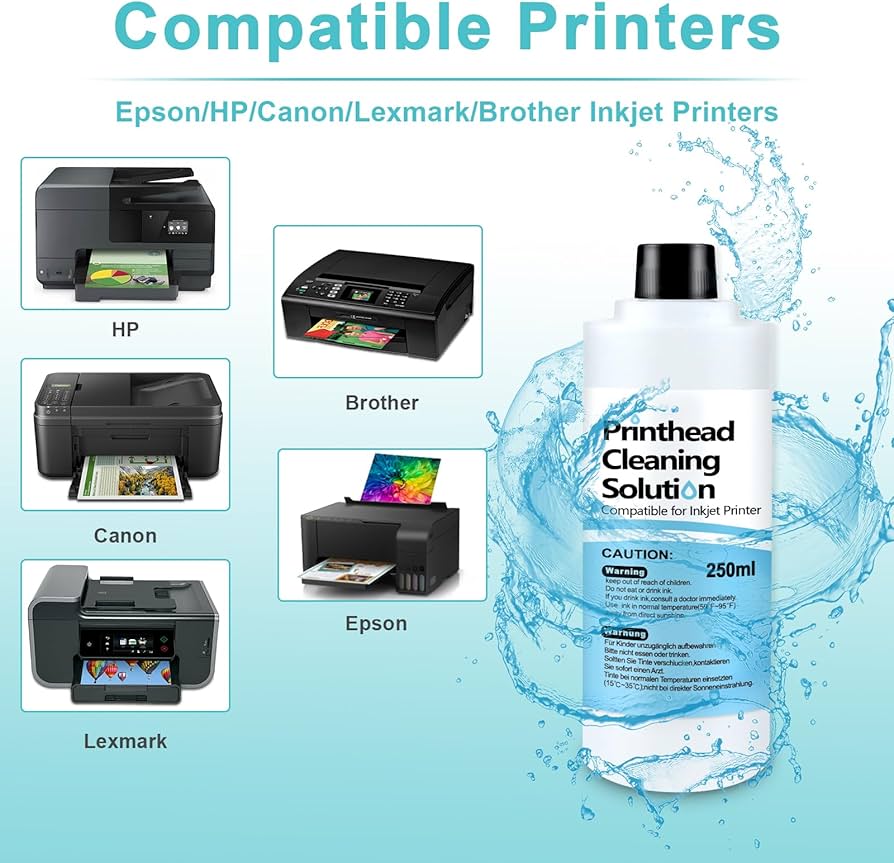

#3 Printhead cleaner

Domain Est. 1999

Website: bizerba.com

Key Highlights: Easy-to-use pump spray or cleaning pen; Available as a set with cleaning swabs for cleaning hard to reach areas; Leaves dry, residue-free surfaces ……

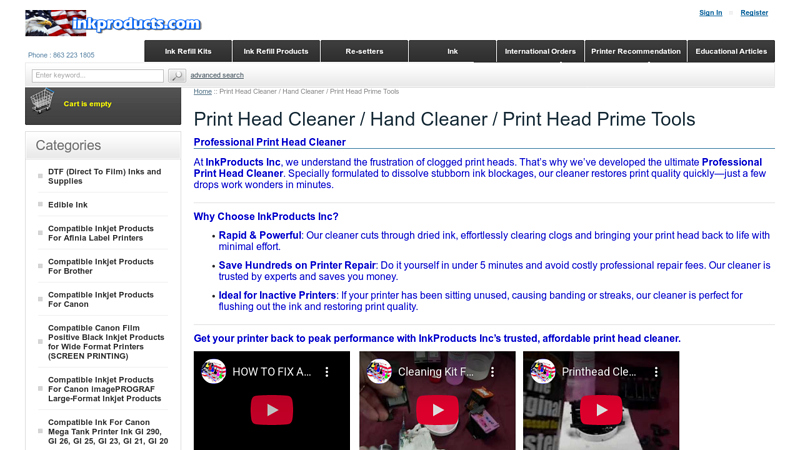

#4 Print Head Cleaner / Hand Cleaner / Print Head Prime Tools

Domain Est. 1999

Website: inkproducts.com

Key Highlights: Clean and maintain your printers with inkproducts print head cleaner, hand cleaner, and priming tools. Safe and effective for HP, Canon, Epson, Sawgrass,……

#5 Cleaning Kits

Domain Est. 2007

Website: webermarking.ie

Key Highlights: Weber provides three pre-saturated products to clean thermal printheads. These cost effective cleaning supplies are pre-saturated….

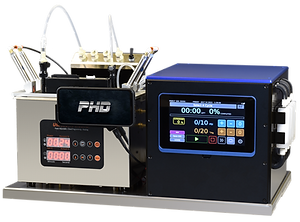

#6 Print Head Doctor

Domain Est. 2010

Website: printheaddoctor.com

Key Highlights: The Print Head Doctor is an AI-enabled print head cleaning machine that maintains and rejuvenates print heads. It recovers all types of inkjet print heads ……

#7 Printhead Hospital

Domain Est. 2010

Website: printheadhospital.com

Key Highlights: We have a range of cleaning kits compatible with Epson, Brother HP and Canon printers. The cleaning solution is suitable for unblocking dye, pigment, ……

#8 ID Card Printer Cleaning Kits & Maintenance Tools

Domain Est. 2017

Website: bodno.com

Key Highlights: Free delivery 30-day returnsKeep your ID card printer running like new with our high-quality cleaning kits. Designed to remove dust, debris, and residue for flawless prints and ext…

#9 Koala Printhead Cleaning Kit

Domain Est. 2017

Website: koalagp.com

Key Highlights: 【Great Cleaning Ability】Koala Print head cleaning kits can powerfully dissolve and clean dry ink, while moisturizing and protecting the printhead….

#10 Print Head Cleaning Kit for DTF Printer

Domain Est. 2024

Expert Sourcing Insights for Print Head Cleaner Kit

2026 Market Trends for Print Head Cleaner Kit

As the printing industry evolves with technological advancements and shifting consumer demands, the market for Print Head Cleaner Kits is poised for notable changes by 2026. These kits, essential for maintaining printer performance and extending equipment lifespan, are influenced by developments in printing technology, sustainability initiatives, and regional market dynamics. Below is an analysis of key trends expected to shape the Print Head Cleaner Kit market in 2026.

Rising Demand from Industrial and Commercial Printing Sectors

Industrial inkjet printing is expanding rapidly in applications such as packaging, textiles, and label printing. As businesses adopt high-speed, high-volume inkjet systems, the need for consistent maintenance grows. Print Head Cleaner Kits will see increased demand from commercial and industrial users seeking to minimize downtime and ensure print quality. By 2026, companies will prioritize preventive maintenance solutions, boosting the market for advanced, compatible cleaner kits tailored to industrial-grade printers.

Integration with Smart Maintenance Systems

The Internet of Things (IoT) and predictive maintenance technologies are making their way into printing ecosystems. In 2026, Print Head Cleaner Kits may be integrated with smart monitoring systems that detect clogs or performance degradation and recommend or automatically trigger cleaning cycles. Some kits could come with companion apps or QR-based diagnostics, enabling users to follow step-by-step cleaning procedures. This trend will enhance usability and reduce human error, particularly in enterprise environments.

Growth in Compatible and Eco-Friendly Formulations

Environmental regulations and consumer preference for sustainable products are pushing manufacturers to develop biodegradable, non-toxic cleaning solutions. By 2026, the market will likely see a surge in eco-conscious Print Head Cleaner Kits made from renewable resources and packaged in recyclable materials. Additionally, third-party suppliers will expand their offerings of compatible kits that work across multiple printer brands, providing cost-effective alternatives to OEM (Original Equipment Manufacturer) products and appealing to budget-conscious consumers and SMEs.

Regional Market Expansion in Asia-Pacific and Latin America

Emerging economies in Asia-Pacific and Latin America are experiencing increased adoption of digital printing for both personal and business use. Countries like India, Vietnam, Brazil, and Mexico are witnessing growth in small-to-medium enterprises that rely on affordable printing solutions. As printer ownership rises, so does the need for maintenance products. By 2026, these regions will represent significant growth opportunities for Print Head Cleaner Kit manufacturers, especially those offering localized pricing and distribution networks.

Impact of 3D and Specialty Printing Technologies

While traditional 2D inkjet printers dominate the market, the rise of 3D printing and specialty applications (e.g., UV, solvent, and dye-sublimation printers) introduces new challenges for print head maintenance. These printers often use viscous or chemically reactive inks that are more prone to clogging. In response, specialized cleaner kits designed for niche printing technologies will gain traction by 2026. Manufacturers will focus on developing formulations that are safe and effective for sensitive print heads used in high-end and industrial applications.

Conclusion

The 2026 Print Head Cleaner Kit market will be shaped by technological innovation, sustainability, and expanding global demand. As printers become more sophisticated and widely used across industries, the role of maintenance products like cleaner kits will grow in importance. Companies that invest in eco-friendly formulations, smart integration, and region-specific strategies will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing a Print Head Cleaner Kit (Quality and Intellectual Property)

Sourcing a Print Head Cleaner Kit, especially from overseas suppliers, involves several risks related to product quality and intellectual property (IP) protection. Being aware of these pitfalls can help avoid costly mistakes and ensure a reliable, legally compliant supply chain.

Poor Product Quality and Inconsistent Formulations

One of the most frequent issues is receiving kits with substandard cleaning solutions. Low-quality solvents may lack the necessary chemical composition to effectively dissolve dried ink, leading to incomplete cleaning or even increased clogging. Inconsistent batch-to-batch formulations can result in variable performance, damaging print heads over time. Additionally, poorly manufactured syringes, tubing, or connectors can leak or fail during use, reducing the kit’s effectiveness and creating safety hazards.

Use of Counterfeit or Non-Branded Chemicals

Some suppliers may advertise compatibility with major printer brands (e.g., Epson, HP, Canon) but use generic or unlicensed chemical formulations. While marketed as “compatible,” these cleaners may not meet OEM specifications and could void printer warranties. Worse, counterfeit labeling may falsely claim compliance with safety or environmental standards, exposing buyers to regulatory and reputational risks.

Intellectual Property Infringement Risks

Sourcing kits that mimic branded packaging or include logos, trademarks, or design elements of OEMs can lead to IP violations. Even if the product is functionally similar, unauthorized use of protected branding constitutes trademark infringement. Additionally, copying proprietary kit designs—such as unique syringe mechanisms or nozzle caps—may infringe design patents. Buyers risk legal action, shipment seizures, or forced product recalls when IP rights are violated.

Lack of Technical Documentation and Safety Compliance

Many low-cost suppliers fail to provide essential documentation such as Material Safety Data Sheets (MSDS), Certificates of Conformity, or regulatory certifications (e.g., REACH, RoHS). Without these, businesses cannot ensure the product is safe for handling or compliant with regional regulations. This lack of transparency also makes it difficult to verify the actual ingredients or performance claims of the cleaner.

Inadequate Supplier Vetting and Hidden Costs

Relying solely on price and online listings without verifying supplier credentials increases the risk of dealing with intermediaries or fly-by-night manufacturers. Hidden costs—such as poor packaging leading to damage in transit, or the need for rework due to non-compliant products—can outweigh initial savings. Furthermore, weak contractual terms may leave buyers with little recourse in case of quality disputes or IP issues.

To mitigate these risks, conduct thorough due diligence: request samples, audit suppliers, verify IP rights, and ensure all documentation is in order before scaling procurement.

Logistics & Compliance Guide for Print Head Cleaner Kit

Product Overview

The Print Head Cleaner Kit is designed to maintain and restore optimal performance of inkjet print heads. It typically includes cleaning solution, syringes, lint-free wipes, and protective gloves. Proper logistics handling and regulatory compliance are essential for safe distribution and use.

Regulatory Classification

- HS Code: 3808.94 (Preparations as fillers, anti-foaming agents, or cleaning solutions for printing machinery)

- UN Number: Not classified as hazardous (for standard aqueous-based formulations)

- GHS Classification: May vary by formulation; typically non-hazardous. Confirm with Safety Data Sheet (SDS). If containing alcohol or solvents, may be classified as flammable (Category 4) or irritant (Skin/Eye Irritation 2).

Safety Data Sheet (SDS) Requirements

- Maintain updated SDS compliant with GHS (Globally Harmonized System) and regional regulations (e.g., OSHA HazCom in the U.S., CLP in EU).

- SDS must include:

- Product identifier and composition

- Hazard identification

- First-aid and firefighting measures

- Handling and storage instructions

- Exposure controls and PPE recommendations

- Disposal considerations

Packaging & Labeling

- Primary Packaging: Leak-proof containers (e.g., HDPE bottles) sealed with child-resistant caps where applicable.

- Secondary Packaging: Corrugated cardboard boxes with internal cushioning to prevent breakage.

- Labeling Requirements:

- Product name and batch/lot number

- Net quantity

- Manufacturer and distributor details

- GHS pictograms (if applicable)

- Precautionary and hazard statements (if classified)

- “Keep out of reach of children” warning

- Recyclability symbols (e.g., ♻️)

Transportation Guidelines

- Domestic (U.S.): Compliant with 49 CFR; non-hazardous when SDS confirms no hazardous classification.

- International:

- Air (IATA): Verify non-regulated status; if flammable, must comply with Packing Instruction 355 (limited quantity).

- Sea (IMDG): Classify under proper shipping name if applicable; otherwise, non-regulated.

- EU (ADR/RID): Follow CLP and transport regulations; non-hazardous kits require no special documentation.

- Use “Fragile” and “This Way Up” labels on outer packaging.

Storage Conditions

- Store in a cool, dry place (15–25°C / 59–77°F).

- Avoid direct sunlight and heat sources.

- Keep containers tightly closed.

- Shelf life: Typically 24 months; indicate expiry date on packaging.

Import & Export Compliance

- Export Documentation:

- Commercial Invoice

- Packing List

- Certificate of Origin (if required)

- SDS (mandatory for international shipments)

- Import Requirements:

- Verify destination country regulations (e.g., REACH in EU, TSCA in U.S.).

- Some countries may require product registration or labeling in local language.

Environmental & Disposal Compliance

- Do not pour residual solution down drains.

- Dispose of contents and containers in accordance with local waste regulations.

- If classified as hazardous waste, follow EPA (U.S.) or equivalent national guidelines.

- Encourage recycling of packaging materials.

Quality Assurance & Traceability

- Implement batch tracking system for full traceability.

- Conduct periodic audits of supplier compliance and packaging integrity.

- Retain SDS and compliance documentation for minimum of 10 years.

Customer & End-User Compliance

- Include user instructions and safety guidelines in multilingual inserts (as needed).

- Advise users to wear gloves and eye protection during use.

- Prohibit use in poorly ventilated areas if solvents are present.

Notes

Always verify formulation-specific compliance with a qualified regulatory consultant. Reformulations may require reclassification and updated documentation.

Conclusion:

Sourcing a print head cleaner kit is a cost-effective and efficient solution for maintaining optimal printer performance and extending the lifespan of print heads. By selecting a high-quality, compatible cleaner kit from a reliable supplier, businesses and individuals can reduce downtime, minimize print quality issues, and avoid costly replacements. Considerations such as chemical compatibility, ease of use, environmental impact, and supplier reputation are key to making an informed sourcing decision. Ultimately, investing in a trusted print head cleaning solution ensures consistent print output and supports long-term operational efficiency.