Imagine turning your wildest designs into wearable art—without the hassle of inventory, printing equipment, or shipping logistics. That’s the magic behind custom t-shirts in today’s creative economy, where self-expression meets smart business. Fueled by the explosive rise of Print on Demand (POD) platforms, anyone with a laptop and a bold idea can launch a t-shirt brand in hours, not months. From quirky indie artists to savvy online entrepreneurs, POD is democratizing fashion, one custom tee at a time. In this post, we’ll dive into how the POD revolution is reshaping the apparel landscape—and how you can ride the wave to print your passion, on demand.

Top 8 Best Print Custom T-Shirts Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

Custom Printed T-Shirts, Apparel and Much More. We’re a total apparel and merchandise company specializing in design and production, including screen printing …

#2 Custom No Minimum T-Shirts

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsUnderground Printing is your source for custom t shirts, custom sweatshirts and more. We specialize in screen printing and embroidery orders of all sizes.

#3 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#4 Custom Print Shop

Online Since 2003

#5 – Screen Printing & T-Shirt Design

Online Since 2004

Website: uprinting.com

1–5 day deliveryPromote your brand with affordable custom t-shirts. Choose from various colors, fits, and decoration options like printing, screen-printing, or embroidery.

#6 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#7 Custom T-Shirt Printing

Online Since 1997

Website: instantimprints.com

We can create the perfect custom t shirt of your design – or let one of our Image Experts design it for you! We have a variety of printing methods to suit your …

#8 ooShirts: Cheap Custom T

Online Since 2007

Website: ooshirts.com

Custom t-shirts for less! ooShirts is the leader in affordable t-shirt printing. Free shipping & setup. Design your own t-shirts at awesomely low prices!

Expert Guide: Ordering print custom t-shirts

Comparison Table: Screen Printing, DTG, and Heat Transfer for Custom T-Shirts

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs with limited colors, high-volume production | High – withstands many washes; may crack over time if low-quality ink | Low per unit for bulk; high setup cost for initial screens |

| DTG (Direct-to-Garment) | Small orders, detailed or full-color designs, photos, on-demand printing | Good – soft feel, fades gradually with washes; less durable on dark fabrics | Higher per unit; no setup fees; cost-effective for small runs |

| Heat Transfer | Very small orders, one-offs, complex designs, or time-sensitive projects | Low to Moderate – can peel, crack, or fade after repeated washing | Low setup cost; higher per-unit cost; ideal for prototypes or samples |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: A Fabric Guide for Custom T-Shirts

Choosing the right fabric for your custom t-shirts is crucial for comfort, durability, and print quality. Each material—100% cotton, 50/50 blend, and tri-blend—offers unique benefits. Here’s a breakdown to help you decide which is best for your needs.

100% Cotton

Pros:

– Soft and Breathable: Naturally soft against the skin and highly breathable, making it ideal for warm weather and everyday wear.

– Eco-Friendly: Biodegradable and often sourced from sustainable farming practices.

– Print-Friendly: Holds vibrant screen prints and DTG (direct-to-garment) designs well, especially on lighter fabrics.

– Classic Feel: Offers a traditional, heavyweight t-shirt feel that many customers love.

Cons:

– Prone to Shrinkage: Can shrink significantly after washing if not pre-shrunk.

– Less Durable: May wear out faster, especially with frequent washing.

– Wrinkles Easily: Requires ironing for a crisp look.

– Absorbs Moisture: Soaks up sweat, which can make it feel damp during intense activity.

Best For: Casual wear, promotional giveaways, eco-conscious brands, and designs with bold, colorful prints.

50/50 Blend (50% Cotton / 50% Polyester)

Pros:

– Durable and Resilient: Resists pilling and holds its shape better over time.

– Less Shrinkage: Polyester content reduces shrinking during washing.

– Affordable: Typically more budget-friendly than tri-blends and high-end cottons.

– Good Print Surface: Works well with screen printing and basic DTG; holds color decently.

Cons:

– Less Breathable: Polyester can trap heat, making it less ideal for hot climates.

– Slightly Stiffer Feel: Not as soft as 100% cotton or tri-blends.

– Static and Pilling: May develop static electricity or small fabric pills over time.

Best For: Workwear, events, budget-conscious bulk orders, and environments where durability is key.

Tri-Blend (Typically 50% Polyester / 25% Cotton / 25% Rayon)

Pros:

– Ultra-Soft and Lightweight: Offers a silky, vintage-inspired feel that feels broken-in from day one.

– Excellent Drape: Flatters the body with a smooth, slightly fitted look.

– Fade-Resistant: Blended fibers help preserve print colors over time.

– Moisture-Wicking: Polyester and rayon help manage moisture better than cotton alone.

Cons:

– Higher Price: More expensive due to the blend composition and specialty feel.

– Delicate Care: Requires gentle washing and may be less durable under heavy use.

– Not Ideal for Heavy Prints: Lightweight nature may not support thick plastisol inks as well.

Best For: Premium apparel, fashion-forward brands, boutique merchandise, and soft-hand prints like water-based inks.

Final Tips for Choosing

- Consider the Purpose: Is it for daily wear, athletic use, or promotional events? Match fabric to function.

- Think About Your Audience: Younger audiences may prefer tri-blends for style, while corporate clients may value durability in 50/50 blends.

- Test First: Order samples to feel the fabric and test print quality before bulk production.

- Check Care Instructions: Communicate washing guidelines to preserve the shirt’s look and feel.

By understanding the strengths of 100% cotton, 50/50 blends, and tri-blends, you can choose the perfect fabric to elevate your custom t-shirt project.

How to Get the Best Price for Custom T-Shirts (Bulk Quantity Breaks & Artwork Tips)

Ordering custom t-shirts in bulk can be a cost-effective way to promote your brand, support a cause, or outfit a team. Maximizing savings requires understanding quantity breaks and optimizing your design. Here’s how to get the best possible price.

Understand Bulk Quantity Breaks

One of the most significant factors in lowering your per-unit cost is ordering in larger quantities. Most printers offer tiered pricing, known as quantity breaks.

- Know the Common Break Points: Typical breaks occur at 25, 50, 75, 100, 250, 500, and 1,000 units. Prices per shirt drop significantly at each threshold.

- Order Just Above the Break: If you need 45 shirts, ordering 50 could save you money per shirt and might even be cheaper overall than ordering 45 at a higher per-unit rate.

- Forecast Demand Accurately: While bigger orders lower the price, overordering can lead to wasted inventory. Estimate carefully or consider future needs.

- Consolidate Orders: Combine upcoming events or team needs into one large order to reach higher quantity tiers.

Simplify Your Design to Reduce Costs

Complex artwork increases printing time and materials, which raises your price.

- Limit Print Colors: Each additional color requires a separate screen and pass through the press. Stick to 1–3 colors for the biggest savings.

- Choose Simpler Designs: Avoid gradients, fine details, and halftones—they require special techniques that cost more. Bold, solid graphics are cheaper to print.

- Minimize Print Area: Smaller prints use less ink and are faster to apply. Consider a small chest logo instead of a large back design.

- Avoid Expensive Techniques: Specialty inks (metallic, glow-in-the-dark), foil stamping, or embroidery add cost. Use them sparingly or eliminate them.

Select the Right T-Shirt Style and Brand

Not all blanks are created equal—and they vary widely in price.

- Opt for Budget-Friendly Blanks: Basic cotton or cotton/polyester blends are typically the most affordable. Premium brands (e.g., Bella+Canvas, Next Level) cost more.

- Stick to One Style: Mixing styles or colors adds complexity and setup fees. Standardizing reduces costs and streamlines fulfillment.

- Consider Weight and Fabric: Lightweight shirts (e.g., 4.5 oz) are usually cheaper than heavy 6+ oz options. Choose based on use case, not just preference.

Prepare Artwork Correctly to Avoid Extra Charges

Poor artwork can lead to delays, reprints, or extra fees for file corrections.

- Use Vector Files (EPS, AI, SVG): These scale infinitely and are ideal for screen printing. High-resolution PNG or PDFs (300 DPI) can work but aren’t as flexible.

- Outline Fonts: Convert text to outlines to prevent font issues during printing.

- Use CMYK or Spot Colors: For screen printing, specify Pantone (PMS) colors. Avoid RGB, which doesn’t translate accurately.

- Submit Print-Ready Art: Include proper bleed, trim lines, and color separation if needed. Clear, organized files reduce setup time and errors.

Get Multiple Quotes and Negotiate

Don’t settle for the first quote.

- Compare at Least 3–5 Printers: Prices and quality vary widely. Look for reputable vendors with good reviews.

- Ask About Hidden Fees: Clarify costs for setup, screens, shipping, and taxes. Some vendors hide fees until checkout.

- Negotiate for Large Orders: If ordering 500+, ask for a custom quote or discount. Long-term clients often get better rates.

- Look for Promotions: Many printers offer seasonal discounts, first-time customer deals, or free shipping on bulk orders.

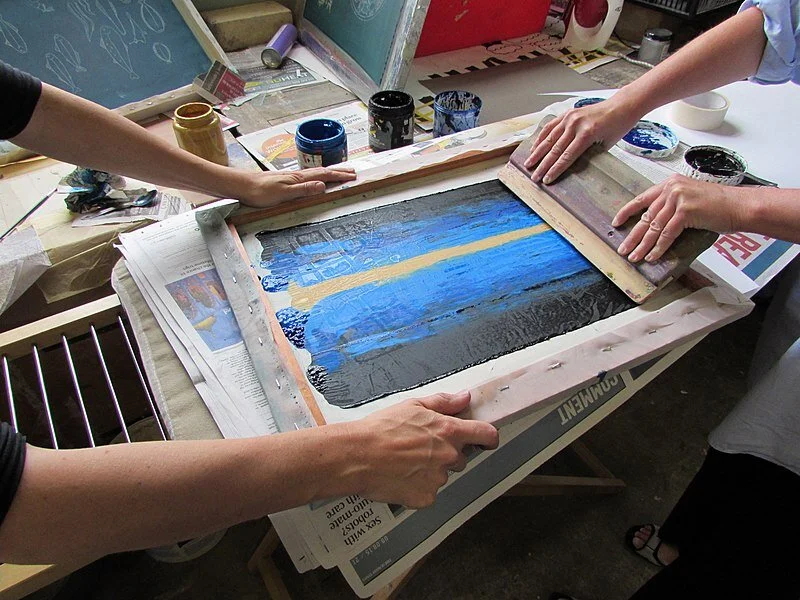

Consider Printing Method

The technique impacts cost, durability, and design flexibility.

- Screen Printing: Best for large quantities and simple designs. Lower per-unit cost at scale.

- DTG (Direct-to-Garment): Good for small runs or complex, full-color designs. Higher per-shirt cost, no setup fees.

- Heat Transfer: Cost-effective for very small batches or prototypes, but less durable than screen printing.

By leveraging bulk quantity breaks, simplifying your artwork, and choosing the right materials and methods, you can significantly reduce your custom t-shirt costs—without sacrificing quality.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, value, and customer satisfaction. Start by defining your needs—such as quantity, design complexity, fabric type, and intended use—so you can narrow down providers that specialize in your requirements. Evaluate the quality of materials and printing techniques by ordering samples, as this gives you a firsthand look at durability and appearance.

Customer reviews and testimonials are invaluable for assessing reliability and service quality. Pay attention to turnaround times and shipping options, especially if you’re working with a tight deadline. Transparent pricing with no hidden fees is another essential factor; compare quotes from multiple vendors to ensure you’re getting a fair deal.

Additionally, prioritize providers with strong customer support and easy-to-use design tools, which can streamline the ordering process. A provider that offers design assistance or file-checking services can prevent costly mistakes.

Ultimately, the best custom t-shirt provider balances quality, affordability, and excellent service. By doing thorough research and considering your specific needs, you can find a partner who delivers professional, durable, and visually appealing t-shirts that meet your expectations.