The global welding equipment market is experiencing robust growth, driven by rising industrial automation, increased infrastructure development, and demand from key sectors such as automotive, construction, and energy. According to Mordor Intelligence, the market was valued at USD 28.3 billion in 2023 and is projected to reach USD 38.7 billion by 2029, growing at a CAGR of approximately 5.2% during the forecast period. This expansion is further supported by advancements in welding technologies, including the adoption of automation and robotic welding systems, especially in high-precision manufacturing environments. As demand for reliable and cost-effective welding solutions grows, the pricing of welding machines has become a critical factor for businesses evaluating capital expenditures. With manufacturers offering a wide range of products—from entry-level models to high-end industrial systems—understanding the price landscape across leading suppliers is essential for informed procurement decisions. Below is a data-driven look at the top 10 welding machine manufacturers and their respective pricing tiers, reflecting current market dynamics and technological positioning.

Top 10 Price Of A Welding Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 HobartWelders

Website: hobartwelders.com

Key Highlights: Hobart Welders is a leading welding manufacturer in the U.S. Browse a variety of welders, welding equipment, gear and projects to find the best match for ……

#2 Everlast Inverter Welders Equipment

Website: everlastgenerators.com

Key Highlights: Everlast Power Equipment, manufacturers of MIG, TIG & Stick welders. For reliable welding machines and supplies shop Everlast Power Equipment….

#3 MIG Welders

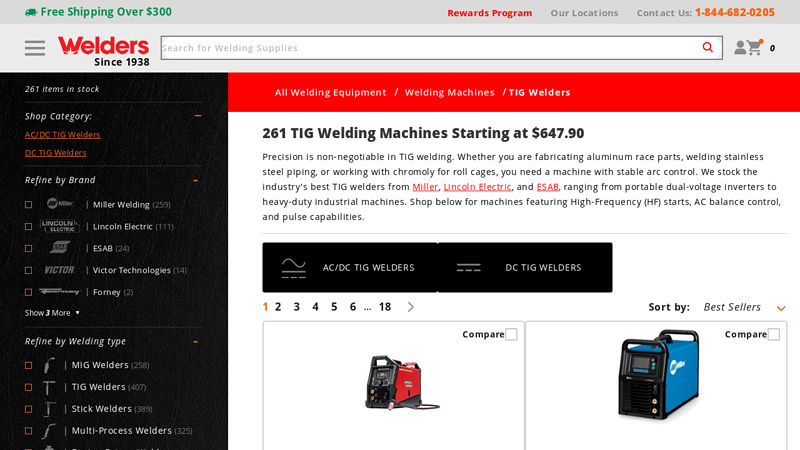

#4 261 TIG Welding Machines for sale from $647.90

Website: weldersupply.com

Key Highlights: Free delivery over $300Welder Supply has the best prices on TIG welders for sale online, with free shipping over $300. Shop quality machines & accessories from trusted top brands….

#5 Welding Equipment – Machines and Gear

Website: millerwelds.com

Key Highlights: Shop our complete selection of welding equipment, including welders, plasma cutters, oxy-fuel outfits, training solutions and welding automation systems….

#6 MIG Welding Equipment

Website: lincolnelectric.com

Key Highlights: Lincoln Electric MIG welders for your wire welding applications include Power MIG welders for home, farm, auto body, maintenance or fabrication….

#7 Fronius welding machines and welding equipment

Website: fronius.com

Key Highlights: Optimally equipped: with Fronius welding machines for MIG/MAG, TIG, and MMA welding as well as welding torches, welding accessories, and much more….

#8 Welding Machine Prices

Website: weldmaster.com

Key Highlights: Starting at $30,000. Our standard full-size machines are recommended for customers who are looking to gain speed, versatility, or require a variety of weld ……

#9 Welding Equipment

Website: esab.com

Key Highlights: Explore ESAB welding equipment including cordless, engine driven, MIG, TIG and multi process welders for shop or field use….

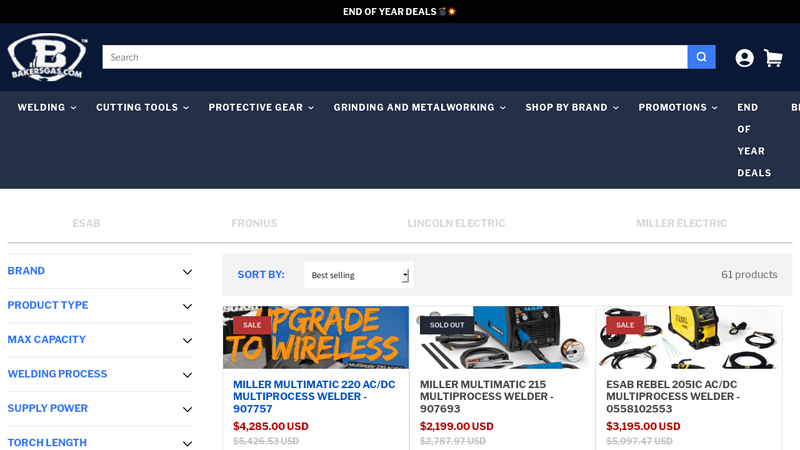

#10 Best

Website: bakersgas.com

Key Highlights: Free delivery over $15061 products ; Miller Multimatic 220 AC/DC Multiprocess Welder – 907757 · $4,285.00 USD · $5,426.53 USD ; Miller Multimatic 215 Multiprocess Welder – 907693….

Expert Sourcing Insights for Price Of A Welding Machine

2026 Market Trends for the Price of a Welding Machine

As the global manufacturing, construction, and automotive sectors continue to evolve, so too does the demand and pricing dynamics for industrial tools such as welding machines. Looking ahead to 2026, several macroeconomic, technological, and industry-specific factors are expected to influence the price of welding machines. This analysis explores key trends shaping the market and their potential impact on pricing across different segments.

Global Demand and Industrial Growth

One of the primary drivers affecting welding machine prices in 2026 will be the continued expansion of industrial activity in emerging economies. Countries in Southeast Asia, India, and parts of Africa are investing heavily in infrastructure and manufacturing, increasing demand for welding equipment. This rising demand is likely to exert upward pressure on prices, especially for mid- to high-end models used in precision fabrication and automated production lines.

Additionally, the global push toward renewable energy—including offshore wind farms and solar infrastructure—requires extensive metal fabrication, further boosting the need for advanced welding solutions. As demand grows, manufacturers may increase prices to balance supply constraints and capitalize on favorable market conditions.

Technological Advancements and Automation

Welding machine technology is rapidly advancing, with increased integration of automation, robotics, and digital controls. By 2026, smart welding systems featuring IoT connectivity, real-time monitoring, and AI-assisted weld optimization are expected to dominate the premium market segment. These high-tech models command higher price points due to their enhanced efficiency, reduced error rates, and improved safety.

As a result, the price gap between traditional manual welding machines and automated systems is expected to widen. While basic welding units may see moderate price increases, advanced models could experience steeper rises due to R&D costs and specialized components.

Supply Chain and Raw Material Costs

The cost of raw materials—particularly copper, steel, and rare earth metals used in welding transformers and inverters—will continue to influence pricing. Geopolitical tensions, trade policies, and fluctuations in mining output may lead to volatility in material costs through 2026. For instance, disruptions in copper supply chains could directly increase production costs for inverter-based welding machines, which rely heavily on copper windings.

Manufacturers may pass these increased costs onto consumers, leading to higher retail prices. However, companies that have invested in localized production or alternative materials may be better positioned to maintain competitive pricing.

Shift Toward Energy Efficiency and Sustainability

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop more energy-efficient welding machines. In 2026, models with higher energy efficiency ratings and lower emissions are likely to gain market share, particularly in regions with strict environmental standards such as the European Union and North America.

These eco-friendly models often come with a premium price tag due to advanced engineering and compliance certifications. However, long-term cost savings from reduced energy consumption may justify higher upfront costs for industrial buyers, supporting sustained demand despite elevated prices.

Competitive Landscape and Market Consolidation

The welding equipment market is seeing increased consolidation, with major players acquiring smaller innovators to expand their technology portfolios. Companies like Lincoln Electric, Miller Electric, and Panasonic are investing in digital welding platforms and automated solutions, positioning themselves as integrated system providers rather than just hardware vendors.

This shift could lead to premium pricing strategies, especially for bundled offerings that include software, training, and maintenance. At the same time, competition from Chinese and Indian manufacturers offering cost-effective alternatives may cap price increases in the entry-level and mid-range segments.

Conclusion

By 2026, the price of a welding machine is expected to reflect a combination of rising demand, technological innovation, and material cost pressures. While basic models may see modest price increases, advanced and automated systems are likely to become significantly more expensive. Buyers should anticipate a more segmented market, where price reflects not just functionality but also connectivity, efficiency, and integration capabilities. Strategic sourcing, early adoption of new technologies, and partnerships with reliable suppliers will be key to managing costs in the evolving welding equipment landscape.

Common Pitfalls When Sourcing the Price of a Welding Machine (Quality, IP)

When evaluating the price of a welding machine, especially concerning quality and IP (Ingress Protection) rating, buyers often fall into several traps that can lead to poor value or operational issues. Being aware of these pitfalls helps ensure a smarter, more cost-effective purchase.

Overlooking Build Quality for Short-Term Savings

One of the most common mistakes is prioritizing a lower upfront price while ignoring the machine’s build quality. Cheaper models may use inferior components, such as thin metal casings, low-grade internal wiring, or substandard cooling systems. While the initial cost is attractive, these machines often fail prematurely under regular use, leading to higher long-term costs due to repairs, downtime, and replacement.

Misunderstanding IP Ratings and Their Real-World Impact

Many buyers assume that any IP rating offers sufficient protection, but not all IP ratings are created equal. For example, an IP21 rating only protects against large solid objects and vertically dripping water—insufficient for dusty workshops or outdoor use. Choosing a machine with an inadequate IP rating (e.g., IP21 instead of IP23 or higher) for the intended environment can lead to frequent malfunctions, safety hazards, and costly damage from dust or moisture ingress.

Assuming Higher Price Equals Better Quality

While premium brands often deliver reliable performance, a higher price tag doesn’t always guarantee superior quality or suitability. Some expensive models may include features irrelevant to your application, inflating the cost unnecessarily. It’s essential to assess whether advanced functions, brand prestige, or extended warranties justify the price difference compared to mid-range, well-reviewed alternatives.

Ignoring Total Cost of Ownership

Focusing solely on the purchase price neglects ongoing costs such as power consumption, maintenance, consumables, and repair frequency. A low-priced welding machine with poor energy efficiency or frequent part replacements can become more expensive over time than a higher-quality, energy-efficient model with lower maintenance needs.

Falling for Inflated IP Claims Without Verification

Some manufacturers may exaggerate or vaguely reference IP ratings without third-party certification. Always verify that the stated IP rating is officially tested and documented. Unverified claims can mislead buyers into thinking they’re getting rugged, weather-resistant equipment when, in reality, the unit may not meet basic protection standards.

Neglecting Duty Cycle and Performance Consistency

Price comparisons often overlook the duty cycle—the amount of welding a machine can perform within a 10-minute period. A cheaper machine with a low duty cycle may overheat quickly during sustained use, reducing productivity and increasing downtime. This hidden limitation undermines quality and efficiency, making the low initial price misleading.

Skipping Brand and After-Sales Support Evaluation

A low-cost machine from an unknown or unsupported brand may save money upfront but could become a liability if spare parts are hard to find or technical support is unavailable. Reliable after-sales service, warranty terms, and access to trained technicians significantly impact long-term usability and should be factored into the purchasing decision.

By avoiding these common pitfalls, buyers can make informed choices that balance price, quality, and IP protection—ensuring a welding machine that delivers value, durability, and performance over its lifespan.

Logistics & Compliance Guide for Price of a Welding Machine

When sourcing or selling welding machines, understanding the logistics and compliance factors is critical to ensuring timely delivery, avoiding legal issues, and accurately determining the final landed cost. While the base price of a welding machine is important, hidden logistics and regulatory costs can significantly affect total expenses. This guide outlines key considerations to help stakeholders manage the end-to-end process efficiently.

Import and Export Regulations

Welding machines are classified under specific Harmonized System (HS) codes, typically falling under 8515.21 or similar categories depending on the type (e.g., arc, resistance, or laser welding equipment). Accurate classification is essential for:

- Determining applicable import/export duties and taxes

- Complying with country-specific trade regulations

- Avoiding customs delays or penalties

Exporters must ensure compliance with export control laws (e.g., U.S. Export Administration Regulations or EU Dual-Use Regulations) if the equipment contains advanced technology or could have military applications.

Shipping and Transportation

Welding machines vary in size and weight, from compact portable units to large industrial systems. Proper shipping considerations include:

- Packaging: Use durable, moisture-resistant packaging with adequate cushioning to protect sensitive electrical components.

- Freight Mode: Choose between air, sea, or ground transport based on urgency, cost, and destination. Heavy industrial models are typically shipped via sea freight (FCL or LCL).

- Handling Requirements: Clearly label units with “Fragile,” “This Side Up,” and “Keep Dry” to prevent damage. Some models may require crating or skidding for forklift handling.

Customs Clearance and Duties

Customs clearance can affect delivery timelines and final pricing:

- Provide complete documentation: commercial invoice, packing list, bill of lading/airway bill, certificate of origin, and any required import permits.

- Anticipate duties and VAT/GST based on the destination country. For example, import duties on welding machines in the U.S. may range from 0% to 4%, depending on the HS code and country of origin.

- Use Incoterms (e.g., FOB, CIF, DDP) clearly in contracts to define responsibility for shipping, insurance, and customs costs.

Product Certification and Safety Compliance

Welding machines must meet safety and electromagnetic compatibility (EMC) standards in the destination market:

- North America: Look for UL, CSA, or ETL certification. Machines must comply with OSHA and NFPA safety standards.

- European Union: CE marking is mandatory, demonstrating conformity with the Low Voltage Directive (LVD) and EMC Directive.

- Other Markets: Check local requirements (e.g., RCM in Australia, CCC in China, PSE in Japan).

Non-compliant machines may be seized at customs or recalled, leading to financial losses and reputational damage.

Environmental and Disposal Regulations

Welding machines may contain components subject to environmental regulations:

- RoHS Compliance: Restriction of Hazardous Substances (RoHS) applies in the EU and other regions, limiting lead, cadmium, and other harmful materials.

- WEEE Directive: In the EU, suppliers may be responsible for recycling end-of-life equipment.

- Ensure proper documentation is available to demonstrate compliance with environmental standards.

Insurance and Risk Management

Shipping high-value welding equipment involves risks. Consider:

- Marine cargo insurance to cover loss or damage during transit.

- All-risk policies that include theft, accidents, and natural disasters.

- Clarifying liability under Incoterms to avoid disputes.

Final Landed Cost Calculation

The price of a welding machine should include more than just the purchase cost. Calculate the total landed cost by adding:

- Purchase price

- Shipping and handling fees

- Import duties and taxes

- Insurance

- Customs brokerage fees

- Compliance certification costs (if applicable)

Understanding these elements ensures accurate pricing, better negotiation power, and improved profitability.

Conclusion

Successfully managing the logistics and compliance aspects of welding machine transactions requires attention to detail and proactive planning. By addressing export controls, shipping methods, customs procedures, safety certifications, and environmental regulations, businesses can avoid delays, reduce costs, and ensure smooth operations across international borders. Always consult with logistics experts and compliance officers to stay updated on evolving regulations.

Conclusion on Sourcing Price of a Welding Machine:

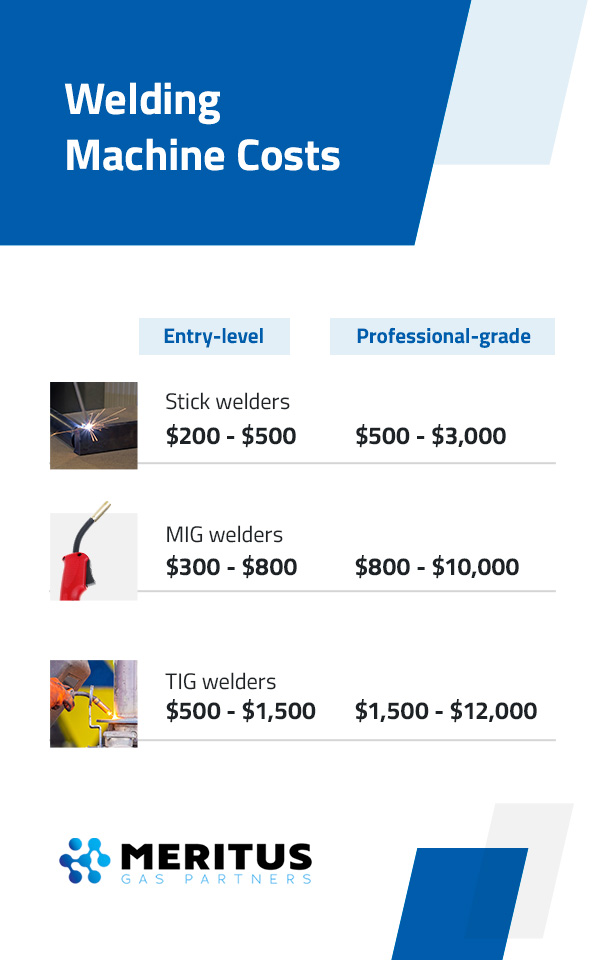

After evaluating various suppliers, brands, and market options, it is evident that the sourcing price of a welding machine depends on several key factors including machine type (e.g., MIG, TIG, Stick), power output, brand reputation, build quality, and additional features. Prices can vary significantly between local suppliers and international vendors, with potential cost savings from overseas manufacturers—though these must be weighed against shipping costs, import duties, and lead times. Bulk purchasing and long-term supplier agreements may offer further price advantages. Ultimately, the most cost-effective solution balances initial procurement cost with durability, after-sales support, and total cost of ownership. A thorough comparative analysis ensures the selected welding machine meets both technical requirements and budgetary constraints.