The global pressure washer market is experiencing robust growth, driven by increasing demand for efficient and eco-friendly cleaning solutions across automotive and industrial sectors. According to Mordor Intelligence, the market was valued at USD 4.2 billion in 2023 and is projected to grow at a CAGR of over 6.8% through 2029. A critical component influencing cleaning performance and water efficiency in this space is the nozzle tip design. In the automotive manufacturing and detailing segments, precision, surface safety, and cleaning speed are paramount—factors heavily dependent on nozzle selection. With manufacturers increasingly adopting high-pressure cleaning systems for pre-treatment, paint车间 cleaning, and final inspections, the demand for specialized nozzles—particularly those tailored for sensitive automotive finishes—has surged. This list highlights the top 10 pressure washer nozzles engineered to meet the exacting standards of car manufacturers, balancing optimal spray patterns, durability, and minimal surface impact backed by performance metrics and industry adoption trends.

Top 10 Pressure Washer Nozzle For Car Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

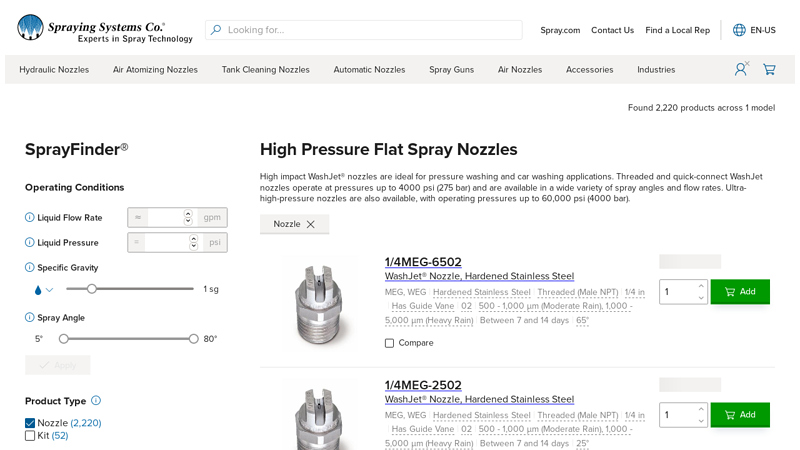

#1 High Pressure Flat Spray Nozzles

Domain Est. 1995

Website: portal.spray.com

Key Highlights: 9-day deliveryThreaded and quick-connect WashJet nozzles operate at pressures up to 4000 psi (275 bar) and are available in a wide variety of spray angles and flow rates….

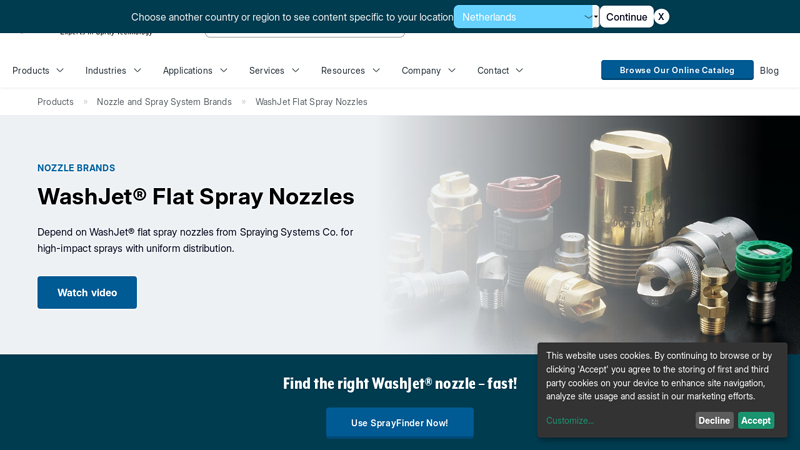

#2 WashJet Flat Spray Nozzles

Domain Est. 1995

Website: spray.com

Key Highlights: WashJet flat spray nozzles are ideal for pressure washing, cleaning and car wash applications. Hardened stainless steel construction provides long wear life….

#3 BOSS™ Pressure Washer Nozzle

Domain Est. 1996

Website: griotsgarage.com

Key Highlights: In stock $12.99 deliveryPrecision-machined, stainless-steel pressure washer nozzles featuring a protective shroud ensuring vehicle safety and a supreme cleaning….

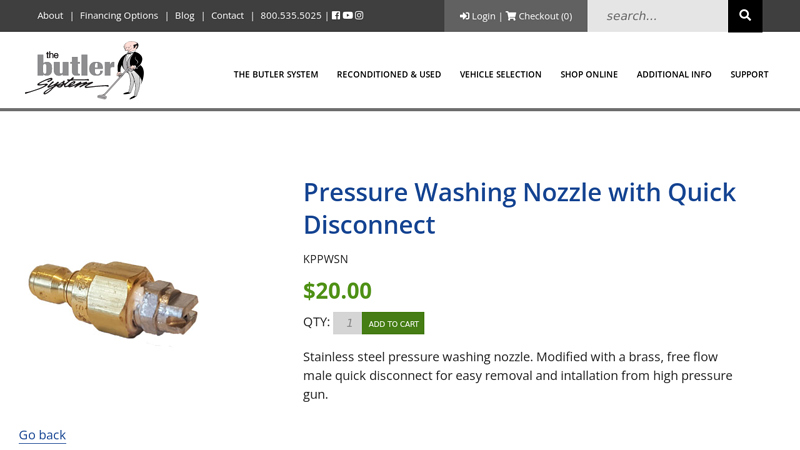

#4 Pressure Washing Nozzle with Quick Disconnect

Domain Est. 1996

Website: butlersystem.com

Key Highlights: Stainless steel pressure washing nozzle. Modified with a brass, free flow male quick disconnect for easy removal and intallation from high pressure gun….

#5 Active Products

Domain Est. 2001

Website: activeproducts.com

Key Highlights: Active pressure washers come with all the accessories you need out of the box. This includes: Garden Hose Adapter; Pressure Hose; Pressure Gun; Lance; Nozzles ……

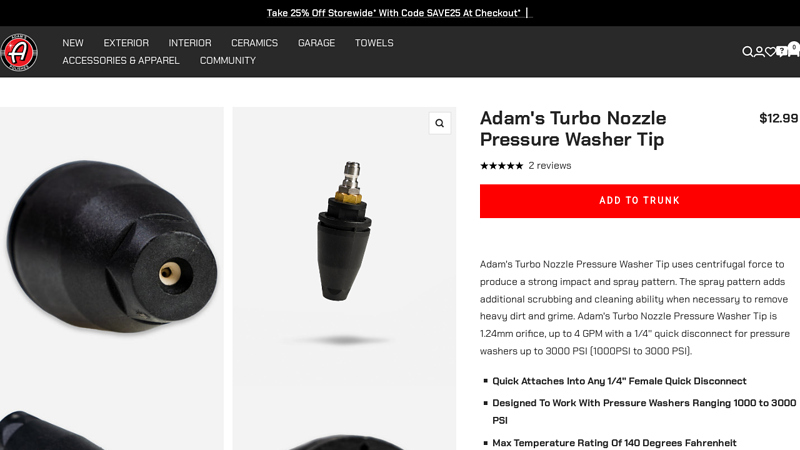

#6 Adam’s Turbo Nozzle Pressure Washer Tip

Domain Est. 2002

#7 Pressure Washer Spray Nozzles

Domain Est. 2006

#8 Pressure Washer Nozzles

Domain Est. 2006

Website: simpsoncleaning.com

Key Highlights: SIMPSON offers a complete assortment of pressure washer nozzles for multiple applications. Click here to browse our selection….

#9 Hi

Domain Est. 2018

#10 Pressure Washer Nozzle Set

Domain Est. 2023

Website: thecarcarebn.com

Key Highlights: Nozzle Tips set includes: Choose different angles nozzle according to the actual need. Pressure up to 4000 PSI (2.5 GPM) Material: Stainless steel and Cooper…

Expert Sourcing Insights for Pressure Washer Nozzle For Car

H2: 2026 Market Trends for Pressure Washer Nozzle for Car

The global market for pressure washer nozzles designed specifically for car cleaning is poised for significant transformation by 2026, driven by technological advancements, rising consumer demand for vehicle maintenance, and a growing emphasis on water efficiency and eco-friendly cleaning practices. This section explores key market trends shaping the industry.

1. Increased Demand for Specialized Automotive Nozzles

As car owners prioritize exterior care and appearance, there is a growing preference for pressure washer nozzles engineered specifically for automotive use. Nozzles with fan spray patterns (e.g., 25° and 40° angles) are gaining popularity for their ability to deliver gentle yet effective cleaning without damaging paint or trim. By 2026, the market is expected to see a surge in demand for smart nozzles that automatically adjust spray intensity based on vehicle surface type.

2. Integration of Smart Technology and IoT Features

Innovations in smart home and automotive care devices are influencing pressure washer nozzle design. By 2026, expect to see nozzles embedded with sensors and connectivity features that sync with smartphone apps, offering real-time feedback on water pressure, spray angle, and cleaning efficiency. These intelligent nozzles may also include auto-shutoff functions to prevent surface damage, enhancing user safety and convenience.

3. Emphasis on Water and Energy Efficiency

Environmental regulations and consumer awareness are pushing manufacturers to develop nozzles that optimize water usage. High-efficiency nozzles with precision flow control will become standard, reducing water consumption by up to 30% without compromising cleaning performance. This trend aligns with global sustainability goals and is expected to be a key differentiator in the 2026 market.

4. Growth in E-Commerce and Direct-to-Consumer Sales

Online retail platforms are becoming primary channels for purchasing automotive cleaning accessories. By 2026, brands are likely to focus on digital marketing, subscription models for nozzle replacements, and bundled kits with pressure washers. Enhanced product visualization, such as 3D nozzle spray simulations, will improve customer decision-making and drive online sales.

5. Expansion of Aftermarket and DIY Car Care Segments

The rising popularity of DIY car detailing, especially in emerging economies, is fueling demand for affordable, high-quality pressure washer nozzles. Manufacturers are responding with durable, interchangeable nozzle sets tailored for various vehicle cleaning tasks—from wheels to windows. This trend supports market growth in regions like Asia-Pacific and Latin America.

6. Material Innovation and Durability Enhancements

To withstand frequent use and exposure to cleaning chemicals, next-generation nozzles are being developed using advanced composite materials and ceramic tips. These materials offer superior resistance to wear and corrosion, extending nozzle lifespan. By 2026, eco-conscious materials such as recycled polymers may also enter mainstream production.

7. Competitive Landscape and Brand Differentiation

The market will see intensified competition among established brands (e.g., Kärcher, Sun Joe, Greenworks) and new entrants focusing on niche innovations. Differentiation will come through patented spray technologies, ergonomic designs, and compatibility with cordless or battery-powered pressure washers, which are gaining traction in the consumer segment.

In summary, the 2026 market for pressure washer nozzles for cars will be shaped by innovation, sustainability, and consumer-centric design. Companies that invest in smart features, water efficiency, and specialized automotive performance will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Pressure Washer Nozzles for Cars (Quality and Intellectual Property)

Logistics & Compliance Guide for Pressure Washer Nozzle For Car

Product Overview

A pressure washer nozzle for car is a specialized attachment designed to connect to a high-pressure hose to direct and control the water stream during vehicle cleaning. These nozzles vary in spray angle (e.g., 0°, 15°, 25°, 40°) and function (e.g., turbo, soap applicator), influencing cleaning efficiency and safety. Ensuring proper logistics handling and regulatory compliance is critical for safe distribution and market acceptance.

Regulatory Compliance Requirements

International and Regional Standards

- CE Marking (European Union): Required if the nozzle is sold in the EU. Compliance with the Pressure Equipment Directive (PED 2014/68/EU) may apply if the nozzle is part of a system exceeding certain pressure thresholds. Even as a component, adherence to general product safety directives (GPSD 2001/95/EC) is mandatory.

- UKCA Marking (United Kingdom): Post-Brexit equivalent of CE marking. Applicable for products placed on the UK market. Compliance with UK Supply of Machinery (Safety) Regulations 2008 is required.

- UL/CSA Certification (North America): While not always mandatory for individual nozzles, compliance with safety standards such as UL 60335-2-79 (for electric motor-compressors) may be expected when sold with pressure washer systems. CSA B149.1 may apply in Canada for gas-powered units.

- RoHS Compliance (EU, UK, China, etc.): Restricts the use of hazardous substances (e.g., lead, cadmium, mercury) in electrical and electronic components. If the nozzle contains electronic components (e.g., adjustable smart nozzles), RoHS compliance is required.

Material and Environmental Regulations

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals. Ensure all materials (e.g., brass, stainless steel, plastics) are registered and do not contain substances of very high concern (SVHCs) above threshold limits.

- Proposition 65 (California, USA): Requires warning labels if the product contains chemicals known to cause cancer or reproductive harm (e.g., lead in brass alloys). Conduct material testing and provide appropriate labeling if applicable.

Product Labeling and Documentation

- Labeling Requirements: Include:

- Manufacturer/importer name and address

- Model number and batch/lot code

- CE/UKCA/other applicable marks

- Maximum pressure rating (e.g., “Max 4000 PSI”)

- Spray angle indication (e.g., 15°, 40°)

- Safety warnings (e.g., “Wear eye protection”)

- Country of origin

- User Instructions: Provide multilingual safety and usage instructions, especially for export markets. Include warnings about high-pressure hazards and proper handling.

Packaging and Shipping Considerations

Packaging Standards

- Use durable, shock-resistant packaging to prevent deformation or damage during transit.

- Include individual blister packs or clamshells for retail display and theft deterrence.

- Use recyclable or eco-friendly materials to comply with environmental directives (e.g., EU Packaging Waste Directive).

- Clearly mark packages with handling symbols: “Fragile,” “Do Not Stack,” “Keep Dry.”

Shipping and Trade Logistics

- HS Code Classification: Use Harmonized System code 8424.90 (parts for mechanical appliances for projecting, dispersing liquids or powders) for customs declaration. Confirm local tariff codes (e.g., 8424.90.50 for the US).

- Import Duties and Taxes: Research duty rates and VAT/GST requirements in destination countries. Utilize trade agreements (e.g., USMCA, RCEP) where applicable to reduce tariffs.

- Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, certificate of origin, and any required conformity certificates (e.g., CE, RoHS).

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP) in sales contracts.

Safety and Handling in Transit

- Pressure Safety: Ensure nozzles are shipped empty and dry. Residual moisture may lead to corrosion or microbial growth.

- Temperature Control: Avoid extreme temperatures during transit that may degrade plastic components.

- Hazardous Materials: Confirm that materials used do not classify the product as hazardous for air or sea freight (e.g., no reactive metals or flammable coatings).

End-of-Life and Sustainability

- Comply with WEEE Directive (EU) if the nozzle contains electronic components.

- Design for disassembly and recyclability; label plastic parts with resin codes (e.g., ABS, PP).

- Provide information on proper disposal or recycling options in user manuals.

Summary Checklist for Compliance

- [ ] CE, UKCA, or other regional certifications obtained

- [ ] RoHS and REACH compliance confirmed via material declarations

- [ ] Proposition 65 compliance assessed (if sold in California)

- [ ] Accurate product labeling with safety warnings

- [ ] Correct HS code used in shipping documentation

- [ ] Packaging meets durability and environmental standards

- [ ] Safety data and user instructions available in required languages

- [ ] Appropriate Incoterms and export documentation prepared

Adhering to this guide ensures safe, legal, and efficient distribution of pressure washer nozzles for car use across global markets. Regularly review regulatory updates and consult with compliance experts for high-risk jurisdictions.

In conclusion, sourcing the right pressure washer nozzle for car cleaning is essential to ensure effective, safe, and efficient results. The ideal nozzle type—typically a 15-degree (yellow) or 25-degree (green) tip—balances cleaning power with surface safety, minimizing the risk of paint or finish damage. When sourcing, consider factors such as nozzle material (preferably brass or stainless steel for durability), compatibility with your pressure washer model, quality from reputable suppliers, and customer reviews. Additionally, having a nozzle set that includes multiple angles offers versatility for different cleaning tasks beyond just the car’s body, such as wheels, tires, and undercarriage. Investing time in selecting the correct nozzle not only enhances cleaning performance but also protects your vehicle and extends the life of your equipment.