The global pressure switch market is experiencing robust growth, driven by rising demand across industrial automation, HVAC, automotive, and oil & gas sectors. According to a report by Mordor Intelligence, the pressure switch market was valued at USD 6.8 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This expansion is fueled by increasing industrialization, the need for precision control systems, and the integration of smart sensing technologies in manufacturing processes. As reliability and performance become critical in high-pressure environments, manufacturers are investing in advanced materials, digital calibration, and IoT-enabled monitoring capabilities. In this evolving landscape, a select group of companies has emerged as leaders in innovation, product range, and global market reach—setting new benchmarks in pressure switch design and functionality. The following overview highlights the top nine manufacturers shaping the industry’s future.

Top 9 Pressure Switch Setting Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pressure Switch Manufacturers

Domain Est. 2002

Website: pressure-switches.net

Key Highlights: We offer an extensive line of high pressure switches, and our customer service representatives will help you find the perfect model for your application….

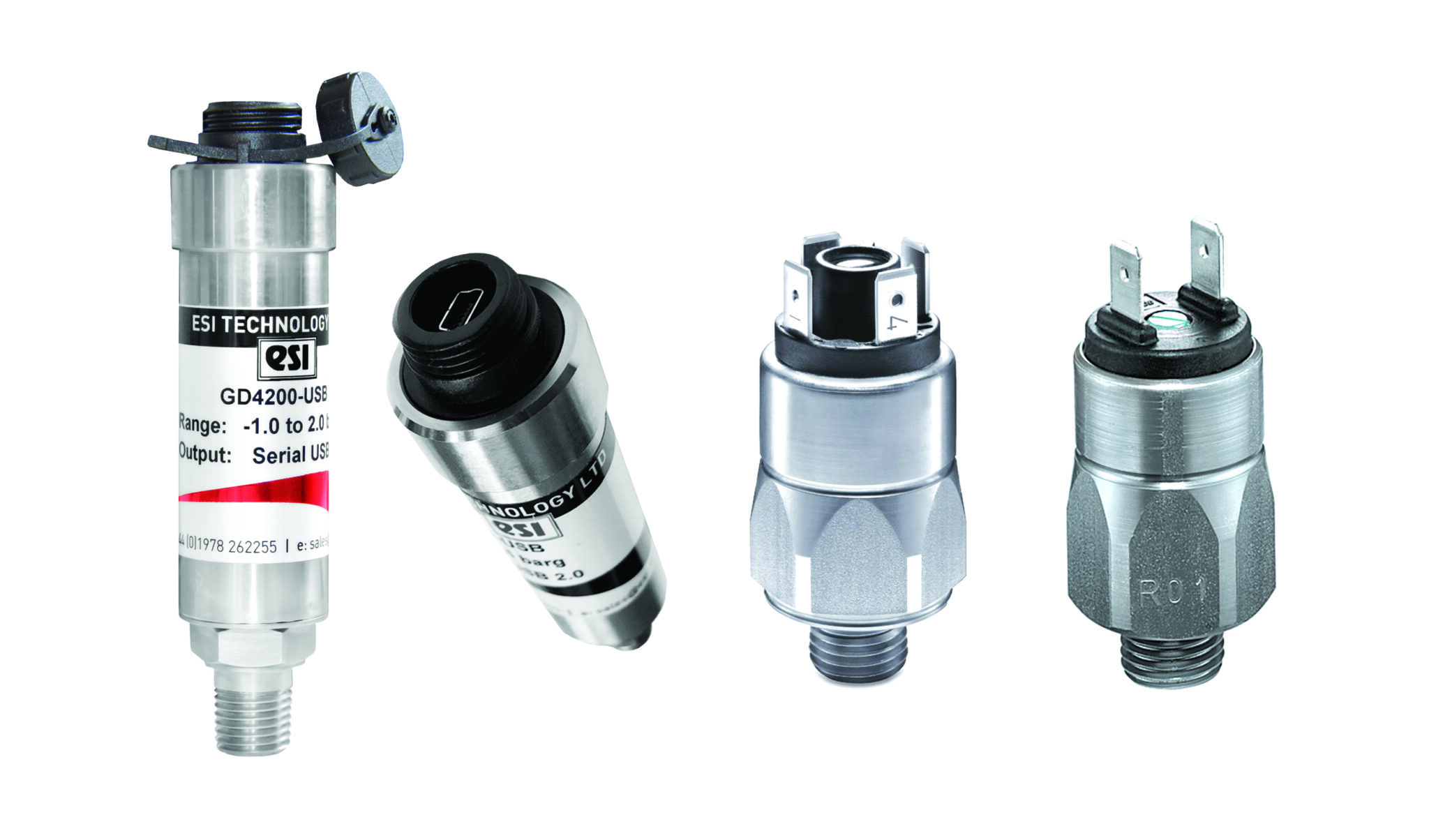

#2 SUCO ESI North America Pressure Switches & Transducers

Domain Est. 2021

Website: sucoesi.com

Key Highlights: SUCO ESI North America delivers high-performance pressure switches, sensors, and clutches engineered for reliability in demanding industrial, mobile, ……

#3 Aerospace Pressure Switches Designed To Reliably …

Domain Est. 1996

Website: hydraelectric.com

Key Highlights: Our pressure switches are designed to reliably perform over the long term, even in the harshest environments and under high vibration and shock conditions….

#4 United Electric Controls

Domain Est. 1997

Website: ueonline.com

Key Highlights: United Electric Controls proven solutions: Wireless gas detectors, Pressure and Temperature switches and transmitters, Thermocouples and RTDs….

#5 100 Series Mechanical Compact SPST Pressure Switches

Domain Est. 1997

Website: noshok.com

Key Highlights: Switch adjustment ranges from vacuum through 6,000 psi depending on model; 100V: Standard Brass with NBR diaphragm wetted parts…

#6 Whitman Controls

Domain Est. 1998

Website: whitmancontrols.com

Key Highlights: Whitman Controls manufactures pressure, vacuum, temperature, and liquid level switches and sensors-Trusted for 50+ years with high-quality solutions….

#7 Pressure Sensors

Domain Est. 2001

Website: sensata.com

Key Highlights: We produce millions of highly engineered pressure devices each year. Featuring three advanced sensing technologies, they can help make your products safer, ……

#8 Series DA/DS Bourdon Tube Pressure Switches

Domain Est. 2022

Website: dwyeromega.com

Key Highlights: In stock Rating 5.0 (1) Aug 21, 2025 · The Mercoid DA/DS Series is one of the world’s broadest lines of pressure switches. The DA/DS Series has extremely high sensitivity and gre…

#9 Mechanical pressure switches

Website: suco.de

Key Highlights: Mechanical pressure switches from SUCO monitor the pressure of liquid or gaseous media and close or open an electrical circuit on reaching a set threshold….

Expert Sourcing Insights for Pressure Switch Setting

H2: 2026 Market Trends for Pressure Switch Setting

The global market for pressure switch settings is poised for significant transformation by 2026, driven by technological innovation, expanding industrial automation, and rising demand across key sectors such as manufacturing, automotive, oil & gas, and HVAC. As industries increasingly prioritize precision, safety, and energy efficiency, the role of pressure switches—and their accurate calibration and setting—has become more critical. Below are the key market trends shaping the pressure switch setting landscape in 2026.

-

Increased Adoption of Smart Pressure Switches

Smart pressure switches equipped with digital interfaces, remote setting capabilities, and self-diagnostic features are gaining traction. These devices allow for real-time pressure monitoring and dynamic setting adjustments, reducing manual intervention and improving system reliability. The integration of IoT platforms enables predictive maintenance and cloud-based data analytics, positioning smart switches as a cornerstone in Industry 4.0 applications. -

Demand for High Precision and Customizable Settings

Industries are demanding pressure switches with tighter tolerances and customizable set points to meet stringent operational requirements. Applications in medical equipment, semiconductor manufacturing, and aerospace require pressure switches with highly accurate and repeatable settings. As a result, manufacturers are focusing on advanced calibration technologies and modular designs that allow for field-adjustable settings. -

Growth in Energy Efficiency Regulations

Global regulatory standards promoting energy efficiency—particularly in HVAC and refrigeration systems—are influencing the design and deployment of pressure switches. By 2026, pressure switches with optimized setting ranges that prevent compressor overload and improve system efficiency are expected to dominate. Regulatory compliance is pushing manufacturers toward eco-friendly designs with reduced leakage and enhanced durability. -

Expansion in Emerging Markets

Rapid industrialization in Asia-Pacific, Latin America, and Africa is fueling demand for pressure switch solutions. Infrastructure development, urbanization, and investments in water treatment and power generation are increasing the need for reliable pressure control systems. Localized production and cost-effective setting solutions are enabling wider adoption across small and medium enterprises. -

Rise of Wireless and Remote Configuration

Wireless pressure switches with Bluetooth or Wi-Fi connectivity are emerging as a key trend. These allow technicians to remotely configure pressure settings via mobile apps or control panels, enhancing safety in hazardous environments and reducing downtime. By 2026, remote setting capabilities are expected to become standard in industrial and process applications. -

Focus on Safety and Compliance

Stringent safety standards in oil & gas, chemical processing, and food & beverage industries are driving demand for pressure switches with fail-safe setting mechanisms. Devices compliant with ATEX, IECEx, and UL certifications are preferred, with emphasis on tamper-proof settings and secure calibration records to meet audit requirements. -

Integration with Advanced Control Systems

Pressure switches are increasingly being integrated into larger control ecosystems, including SCADA and PLC systems. This integration requires seamless communication protocols (such as Modbus, HART, or IO-Link) and standardized setting procedures that align with broader automation strategies.

In conclusion, the 2026 market for pressure switch setting is being reshaped by digitalization, regulatory demands, and industrial modernization. Companies that invest in smart, accurate, and compliant pressure switch technologies—backed by robust setting and calibration services—are likely to lead the market evolution.

Common Pitfalls Sourcing Pressure Switch Settings (Quality, IP)

When sourcing pressure switches—especially for critical applications—overlooking key quality and Ingress Protection (IP) rating factors can lead to premature failure, safety hazards, and costly downtime. Below are common pitfalls to avoid:

Inadequate IP Rating for Environmental Conditions

One of the most frequent mistakes is selecting a pressure switch with an IP rating that doesn’t match the operating environment. For example, using an IP65-rated switch in a washdown or outdoor setting where water jets or dust ingress are common may result in internal contamination and failure. Always verify that the IP rating (e.g., IP67 for temporary immersion, IP69K for high-pressure washdown) aligns with the specific exposure risks.

Overlooking Material Quality and Construction

Low-quality materials—such as inferior diaphragms, housings, or electrical contacts—can compromise reliability and longevity. Sourcing switches made with substandard metals or plastics may lead to corrosion, mechanical fatigue, or poor sealing. Ensure housings are constructed from durable materials like stainless steel or high-grade polymers and that internal components are compatible with the media being measured.

Assuming All Switches Meet Minimum Standards

Not all pressure switches labeled with a certain IP rating or quality claim undergo rigorous third-party testing. Some suppliers may exaggerate or self-certify ratings without independent verification. Always request certification documentation (e.g., IEC 60529 for IP ratings) and prefer suppliers with recognized quality management systems (e.g., ISO 9001).

Neglecting Application-Specific Requirements

Pressure switch settings (e.g., set points, differential, hysteresis) must be precisely matched to system demands. Sourcing switches without verifying calibration accuracy or repeatability under real operating conditions can result in inconsistent performance. Additionally, temperature fluctuations and vibration can affect switch behavior—ensure the selected model is rated for the full range of expected service conditions.

Failing to Verify Supplier Reliability and Traceability

Sourcing from unknown or non-reputable suppliers increases the risk of counterfeit or non-compliant components. Lack of traceability makes it difficult to address quality issues or perform root cause analysis after a failure. Partner with trusted suppliers who provide full product traceability, datasheets, and technical support.

By addressing these pitfalls early in the sourcing process, you can ensure the pressure switches selected deliver reliable, safe, and long-term performance in your application.

Logistics & Compliance Guide for Pressure Switch Setting

This guide outlines the essential logistics and compliance considerations when setting or adjusting pressure switches across industrial, commercial, and process environments. Adhering to this guidance ensures operational safety, regulatory compliance, and system reliability.

Regulatory and Standards Compliance

Ensure all pressure switch settings comply with applicable local, national, and international standards. Key regulatory frameworks and standards include:

- ASME Boiler and Pressure Vessel Code (BPVC): Mandates safe operation of pressure systems; pressure switch settings must align with design pressure and safety relief thresholds.

- OSHA 29 CFR 1910: Requires controls to prevent over-pressurization; pressure switches must be set and documented to protect personnel and equipment.

- ATEX / IECEx (for hazardous areas): In explosive atmospheres, pressure switches must be set within certified operational ranges and installed per zone classification.

- API Standards (e.g., API 554): Applicable in oil and gas; defines requirements for process instrumentation, including setpoint accuracy and calibration.

- ISO 13849 & IEC 62061: For safety-related control systems; pressure switches used in safety circuits must meet performance level (PL) or safety integrity level (SIL) requirements.

Document all settings and calibrations to demonstrate compliance during audits or inspections.

Pressure Switch Setting Procedures

Follow a standardized procedure to ensure accuracy and safety:

- Isolate the System: Depressurize and lockout/tagout (LOTO) the system before adjustment.

- Verify Equipment Specifications: Confirm the switch’s pressure range, electrical rating, and process compatibility.

- Use Calibrated Test Equipment: Employ a certified pressure gauge or digital calibrator to monitor system pressure during setting.

- Adjust Setpoint: Gradually adjust the pressure switch (cut-in/cut-out or high/low trip point) while increasing or decreasing system pressure.

- Verify Operation: Confirm activation and deactivation at the desired setpoints; repeat for accuracy.

- Seal and Label: Once set, seal adjustment points (e.g., with tamper-evident seal) and label with setpoint values and date.

Documentation and Traceability

Maintain comprehensive records for compliance and troubleshooting:

- Record setpoint values, date, technician name, and equipment ID.

- Include calibration certificate numbers and next due date.

- Store logs in a centralized system (e.g., CMMS) for audit readiness.

- Update P&IDs (Piping and Instrumentation Diagrams) if setpoints are modified.

Logistics and Inventory Management

Efficient logistics support consistent pressure switch management:

- Spare Parts Inventory: Maintain critical spares based on mean time between failures (MTBF) and lead times.

- Calibration Scheduling: Integrate pressure switch calibration into preventive maintenance (PM) schedules.

- Training: Ensure technicians are trained on proper setting procedures and safety protocols.

- Traceable Tools: Use only calibrated hand tools and test instruments; log their calibration status.

Safety and Risk Mitigation

- Never bypass or disable a pressure switch unless authorized under a formal work permit.

- Conduct a risk assessment before adjusting switches in safety-critical systems.

- Implement redundancy where required (e.g., dual switches for high-integrity protection systems).

By adhering to this guide, organizations ensure safe, compliant, and reliable operation of pressure-controlled systems.

Conclusion for Sourcing Pressure Switch Setting:

When sourcing a pressure switch, accurately determining the correct pressure switch setting is crucial to ensure the safe, efficient, and reliable operation of the system. The set point must align with the operational requirements of the application, taking into account factors such as system pressure ranges, safety margins, environmental conditions, and compliance with industry standards. Additionally, selecting a pressure switch with appropriate differential (deadband), accuracy, material compatibility, and electrical ratings ensures long-term performance and minimizes maintenance issues. Proper documentation and verification during installation and commissioning further support optimal functionality. Ultimately, careful evaluation and precise specification of the pressure switch setting contribute significantly to system integrity, energy efficiency, and operational safety.