The global pressure regulating unit market is experiencing steady expansion, driven by increasing demand across oil & gas, water & wastewater, power generation, and industrial sectors. According to a report by Mordor Intelligence, the pressure regulator market was valued at USD 10.3 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This growth is fueled by rising infrastructure investments, stricter safety regulations, and the need for energy efficiency in fluid control systems. Additionally, expanding urbanization and industrial automation are amplifying the need for reliable pressure regulation solutions. As the market evolves, innovation in materials, smart monitoring integration, and leakage reduction are becoming key differentiators among manufacturers. In this competitive landscape, nine leading companies have emerged as dominant players, combining technological expertise, global reach, and comprehensive product portfolios to meet diverse industrial requirements.

Top 9 Pressure Regulating Unit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pressure Tech

Domain Est. 2003

Website: pressure-tech.com

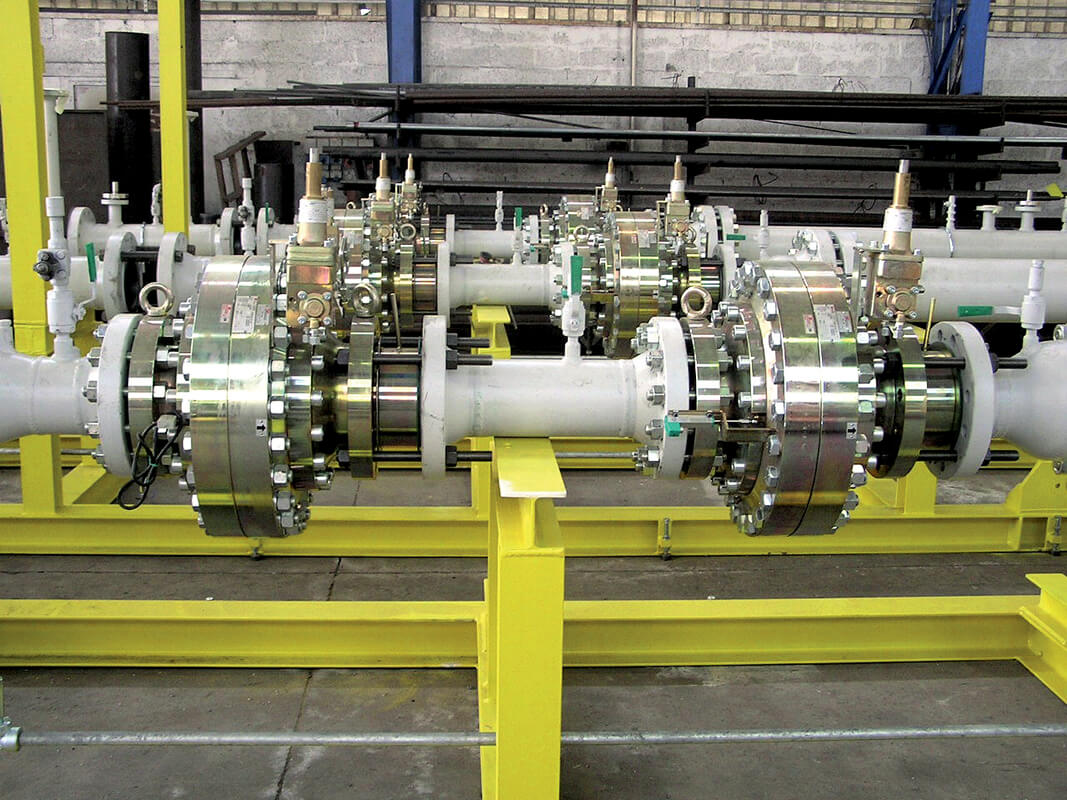

Key Highlights: Pressure Tech manufacturers high-quality ISO-9001 pressure regulators for use on critical high-pressure control systems up to 1380 bar (20000 psi)….

#2 Pressure control

Domain Est. 2016

Website: technipfmc.com

Key Highlights: TechnipFMC sets the benchmark for pressure control and flowline products and is the original equipment manufacturer of Chiksan®, Weco® and Coflexip™ products….

#3 Regulators & Safety Accessories

Domain Est. 1988

Website: process.honeywell.com

Key Highlights: Honeywell offers a variety of gas pressure regulating devices, safety equipment, and accessories for the natural gas industry, transmission, ……

#4 Pressure Reducing Valves

Domain Est. 1995

Website: zurn.com

Key Highlights: Zurn’s water pressure regulator valve is ideal for residential & commercial applications. Check out our complete line of pressure ……

#5 TESCOM

Domain Est. 1995

Website: discreteautomation.emerson.com

Key Highlights: TESCOM designs and manufactures a wide range of standard and custom engineered pressure control regulator and valve solutions for a diverse, global market….

#6 Pressure Regulators

Domain Est. 1995

Website: smcusa.com

Key Highlights: An air pressure regulator controls and maintains a constant output pressure from a compressed air system, even when the input pressure or air demand changes….

#7 Pressure Reducing Regulators

Domain Est. 1995

Website: emerson.com

Key Highlights: Robust and reliable self-contained pressure-reducing regulators, setting industry standards & driving operational excellence. Explore more here….

#8 Rotarex Valves Regulators Systems

Domain Est. 1997

Website: rotarex.com

Key Highlights: Rotarex is a global company that designs and manufactures premium quality gas valves, pressure regulators and systems….

#9 Maxitrol

Domain Est. 1997

Website: maxitrol.com

Key Highlights: International leaders in the design and manufacture of gas pressure regulators, modulation systems and safety devices….

Expert Sourcing Insights for Pressure Regulating Unit

H2: Market Trends in Pressure Regulating Units (PRUs) for 2026

The global Pressure Regulating Unit (PRU) market is poised for significant transformation by 2026, driven by technological advancements, increased energy infrastructure investments, and stringent regulatory standards. Key trends shaping the PRU landscape include:

-

Growth in Natural Gas Infrastructure

The continued expansion of natural gas distribution networks—especially in emerging economies and as a transitional fuel in developed regions—will drive demand for reliable pressure regulation. Governments and energy companies are investing heavily in pipeline modernization and rural gas grid extensions, directly boosting PRU adoption. -

Smart and Digital PRUs on the Rise

The integration of IoT and smart monitoring technologies into PRUs is accelerating. By 2026, smart PRUs equipped with real-time pressure sensors, remote diagnostics, and predictive maintenance capabilities are expected to gain market share. These digital solutions enhance safety, reduce downtime, and improve operational efficiency, particularly in urban gas distribution and industrial applications. -

Focus on Energy Efficiency and Emissions Reduction

With increasing emphasis on reducing greenhouse gas emissions, especially methane leaks from gas networks, regulators are mandating higher performance standards for PRUs. This trend is pushing manufacturers to develop low-emission, high-efficiency models compliant with global standards such as ISO 10438 and API 614. -

Asia-Pacific as a High-Growth Region

Countries like China, India, and Southeast Asian nations are projected to lead PRU market growth due to rapid urbanization, industrialization, and government-led gas grid expansion projects. Infrastructure development under initiatives such as India’s City Gas Distribution (CGD) program will significantly increase PRU demand. -

Consolidation and Strategic Partnerships

Market consolidation is expected as major players acquire niche technology providers to enhance their digital PRU offerings. Strategic collaborations between PRU manufacturers, utility companies, and software firms will be critical in delivering integrated pressure management solutions. -

Regulatory and Safety Compliance as a Market Driver

Stringent safety regulations in Europe and North America, including updated directives from OSHA, ATEX, and DNV, are compelling utilities to upgrade aging PRU systems. Compliance requirements are accelerating the replacement cycle for legacy units, creating sustained replacement demand. -

Sustainability and Material Innovation

Manufacturers are increasingly adopting corrosion-resistant and recyclable materials to extend product lifecycles and reduce environmental impact. Lightweight composites and advanced coatings are being explored to improve durability in harsh environments.

In conclusion, the 2026 PRU market will be defined by digitalization, regulatory compliance, and sustainable innovation. Companies that invest in smart technologies and adapt to regional infrastructure needs will be best positioned to capture growth opportunities.

Common Pitfalls in Sourcing Pressure Regulating Units (Quality and IP)

Sourcing Pressure Regulating Units (PRUs) is a critical task in engineering and infrastructure projects, particularly in oil and gas, water supply, and industrial applications. Poor sourcing decisions can lead to operational inefficiencies, safety hazards, and costly downtime. Two major areas where pitfalls commonly occur are quality assurance and intellectual property (IP) concerns. Below are key challenges in these areas:

Quality-Related Pitfalls

-

Inadequate Supplier Qualification

Selecting vendors without thorough vetting of their manufacturing standards, certifications (e.g., ISO 9001, API 6D), and track record can result in substandard PRUs. Inferior materials or poor workmanship may lead to premature failure under pressure. -

Non-Compliance with Industry Standards

PRUs must meet specific codes (e.g., ASME B16.34, API 526, PED). Sourcing units that do not comply with applicable standards compromises safety and may invalidate insurance or regulatory approvals. -

Insufficient Testing and Documentation

Skipping factory acceptance tests (FAT) or accepting PRUs without valid test reports (e.g., hydrostatic testing, set pressure verification) increases the risk of in-field failures. Lack of traceability in materials (e.g., mill test certificates) is another red flag. -

Mismatched Technical Specifications

Using generic specifications without accounting for site-specific conditions (e.g., fluid type, temperature, pressure range) can lead to improper PRU selection, reducing efficiency and lifespan. -

Counterfeit or Substandard Components

In global supply chains, counterfeit pressure regulators may be sold with fake certifications. These units often fail under operational stress, creating safety risks.

Intellectual Property (IP) Pitfalls

-

Unauthorized Use of Patented Designs

Sourcing PRUs from manufacturers that replicate patented technologies without licensing exposes the buyer to legal liability, especially in regulated markets. -

Lack of IP Clarity in Custom Solutions

When ordering custom-designed PRUs, failure to define IP ownership in contracts may result in disputes. The buyer may not retain rights to modifications or designs developed during the project. -

Reverse-Engineered Products

Some low-cost suppliers offer PRUs that closely mimic branded models. These may infringe on design patents or trademarks, leading to shipment seizures or legal action, especially in international procurement. -

OEM vs. Aftermarket Confusion

Aftermarket or “compatible” PRUs may lack proper IP licensing. While cheaper, they can void warranties on original systems and may not perform to OEM specifications. -

Inadequate Due Diligence on Supplier IP Practices

Not verifying whether a supplier holds proper IP rights or has a history of infringement claims can expose the buyer to reputational and legal risks.

Mitigation Strategies

- Conduct thorough supplier audits and request proof of certifications.

- Specify compliance with relevant standards in procurement documents.

- Include mandatory FAT and full documentation requirements in contracts.

- Perform technical reviews with engineering teams before finalizing purchases.

- Engage legal counsel to review IP clauses in procurement agreements.

- Source from reputable manufacturers with transparent IP policies.

Avoiding these pitfalls ensures reliable performance, regulatory compliance, and protection against legal and operational risks when sourcing Pressure Regulating Units.

H2: Logistics & Compliance Guide for Pressure Regulating Units (PRUs)

Proper logistics and compliance management are critical for the safe, legal, and efficient deployment of Pressure Regulating Units (PRUs). This guide outlines key considerations across the lifecycle of PRUs, from procurement to installation and operation.

H2: 1. Regulatory Standards and Certifications

Ensure all PRUs meet applicable international, national, and regional regulatory requirements:

- ASME B31.8 / B31.3: Governs design, fabrication, and installation for gas transmission/distribution and process piping systems.

- API 520/521: Recommended practices for sizing and selection of pressure-relieving devices used in conjunction with PRUs.

- PED (Pressure Equipment Directive 2014/68/EU): Mandatory for PRUs placed on the EU market; requires CE marking and involvement of a Notified Body for certain categories.

- CRN (Canadian Registration Number): Required for pressurized components in Canada; registration varies by province.

- DOT 49 CFR Parts 192/195: Regulates transportation of natural gas and hazardous liquids in the U.S., including PRU requirements for gas distribution systems.

- ISO 15848 / API 622/641: Standards for fugitive emissions testing—critical for environmental compliance.

Action: Verify that each PRU has valid certification documentation (e.g., CE, CRN, ASME stamp) and test reports prior to shipment.

H2: 2. Transportation and Handling

PRUs are precision mechanical systems and must be transported with care to prevent damage:

- Packaging: Units must be crated with protective materials (foam, corner guards) and sealed against moisture and contaminants. Include desiccants if stored long-term.

- Lifting: Use proper lifting points; never lift by piping, instrumentation, or actuators. Refer to manufacturer’s lifting instructions.

- Orientation: Maintain specified orientation (e.g., upright) during transport. Mark units clearly with “This Side Up” indicators.

- Environmental Exposure: Avoid exposure to extreme temperatures, rain, snow, or corrosive atmospheres during transit.

- Documentation: Include shipping manifests, packing lists, and compliance certificates in external documentation pouch.

H2: 3. Import/Export Compliance

Cross-border movement of PRUs requires adherence to trade regulations:

- Customs Classification: Accurately classify PRUs under HS Codes (e.g., 8481.80 for valves and regulators).

- Export Controls: Verify if PRUs contain components subject to ITAR or EAR (e.g., specialized actuators or sensors).

- Documentation: Prepare commercial invoices, certificates of origin, packing lists, and conformity declarations.

- Sanctions: Confirm destination country is not under international trade sanctions.

Tip: Work with a licensed freight forwarder experienced in industrial equipment and pressure systems.

H2: 4. Storage and Inventory Management

Proper storage preserves PRU integrity before installation:

- Environment: Store indoors in a dry, temperature-controlled area (10–30°C / 50–86°F). Avoid high humidity and corrosive atmospheres.

- Positioning: Keep units on pallets or racks; never place directly on the floor. Support long assemblies to prevent sagging.

- Protection: Cap all ports and openings to prevent ingress of dust, moisture, or debris. Apply corrosion inhibitors if recommended.

- Inventory Tracking: Use barcodes or RFID tags to track PRUs, including model, serial number, certification status, and storage duration.

H2: 5. Installation and Commissioning

Ensure compliance during setup:

- Qualified Personnel: Installation must be performed by certified technicians familiar with piping codes and safety procedures.

- Alignment and Supports: Secure PRUs with proper pipe supports to avoid stress on connections.

- Leak Testing: Perform hydrostatic or pneumatic testing per ASME B31 or company procedures prior to operation.

- Documentation: Retain installation records, inspection reports, and as-built drawings for audit purposes.

H2: 6. Ongoing Compliance and Maintenance

Maintain regulatory adherence during service life:

- Inspection Schedules: Follow API 570 or company-mandated intervals for in-service inspection.

- Calibration: Regularly calibrate pressure sensors, relief valves, and control systems (annually or per OEM spec).

- Record Keeping: Maintain logs of maintenance, repairs, modifications, and compliance audits.

- Reporting: Report failures, leaks, or non-conformances to relevant authorities as required (e.g., PHMSA in the U.S.).

H2: 7. Decommissioning and Disposal

End-of-life handling must comply with environmental and safety regulations:

- Depressurization: Safely isolate and depressurize the unit before removal.

- Cleaning: Purge residual media; clean components if recycling.

- Recycling/Disposal: Follow local regulations for disposal of metals, elastomers, and hazardous materials (e.g., lead, mercury).

- Documentation: Archive final inspection reports and disposal certificates.

Conclusion: Adhering to logistics and compliance protocols ensures the safety, reliability, and legal operation of Pressure Regulating Units. Always consult manufacturer guidelines and applicable regulatory bodies to remain current with evolving standards.

Conclusion for Sourcing a Pressure Regulating Unit

In conclusion, sourcing a pressure regulating unit requires a comprehensive evaluation of technical specifications, operational requirements, quality standards, and supplier reliability. It is essential to select a unit that aligns with the system’s pressure and flow demands, environmental conditions, and safety regulations to ensure efficient and safe operation. Prioritizing reputable suppliers with proven experience, compliance certifications (such as ISO, API, or ASME), and strong after-sales support will contribute to long-term performance and reduced maintenance costs. Additionally, considering factors such as energy efficiency, material compatibility, and ease of installation enhances overall system reliability. By conducting thorough due diligence during the sourcing process, organizations can procure a pressure regulating unit that delivers optimal performance, durability, and value for their specific application.