The global prefab awning market is experiencing steady expansion, driven by rising demand for energy-efficient building solutions, growing urbanization, and increased investments in commercial and residential infrastructure. According to Mordor Intelligence, the global retractable awnings market was valued at USD 1.78 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. This growth is further supported by architectural trends favoring sustainable design and outdoor living spaces, particularly across North America and Europe. As demand intensifies, manufacturers are focusing on innovation in materials, automation, and modular design to enhance durability, ease of installation, and aesthetic versatility. In this competitive landscape, a select group of prefab awning manufacturers have emerged as leaders, combining advanced manufacturing techniques with scalable supply chains to meet evolving customer needs. Based on market presence, product innovation, and growth trajectory, here are the top 10 prefab awning manufacturers shaping the industry’s future.

Top 10 Prefab Awning Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

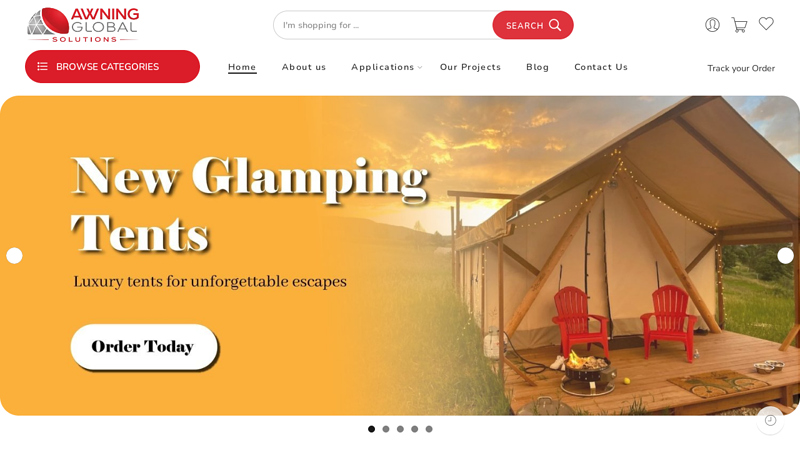

#1 Awning & Canopies Manufacturer

Domain Est. 2019

Website: awningglobal.com

Key Highlights: Awning Global provides the best awnings for residential and commercial properties. Buy Now High Quality Awning Canopies from Experienced Manufacturers in ……

#2 Anchor has you covered: American

Domain Est. 1995

Website: anchorinc.com

Key Highlights: Explore Anchor’s full line of American-made fabric & frame structures: tents, pool covers, shade, fire shelters, pergolas and awnings….

#3 AVAdek Walkway Cover Systems and Canopies

Domain Est. 1996

Website: avadek.com

Key Highlights: AVAdek has over 40 years of experience and specializes in prefabricated aluminum walkway and canopy combinations with options providing unique design…

#4 Prefabricated Canopies and Awnings

Domain Est. 1997

Website: madisonind.com

Key Highlights: Madison Industries designs and manufactures prefabricated canopies and awnings for commercial use — including gas stations, car washes, ……

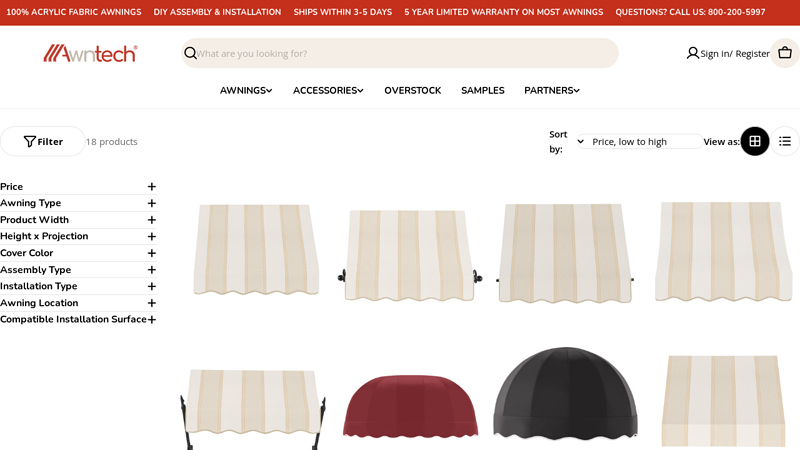

#5 Fixed Awnings

Domain Est. 1999

#6 Awning Components and Installation: products

Domain Est. 2003

Website: batgroup.com

Key Highlights: Bat Group specializes in artisanal manufacturing of components for all types of awning and outdoor covers. Browse our products and feel free to contact us….

#7 DAC Awnings

Domain Est. 2006

Website: dacawnings.com

Key Highlights: We are a family owned and operated business focused on delivering quality awnings for over 80 years in the Triangle area….

#8 General Awnings

Domain Est. 2009

#9 MASA Architectural Canopies

Domain Est. 2010

Website: architecturalcanopies.com

Key Highlights: Leader in Architectural Canopies for Storefronts. Offering Extruded Aluminum Canopy, Aluminum Frame Awnings, Custom Canopy Systems, Fabricated Canopy, ……

#10 Prefabricated Commercial Awnings & Canopies

Domain Est. 2016

Website: skyscapecanopies.com

Key Highlights: Prefabricated awnings are crafted off-site and easily assembled on location and can create functional and stylish outdoor spaces buildings….

Expert Sourcing Insights for Prefab Awning

2026 Market Trends for Prefab Awning

The prefabricated awning market is poised for significant transformation by 2026, driven by technological advancements, shifting consumer preferences, and growing emphasis on sustainable living. As urbanization accelerates and outdoor living spaces become extensions of homes and commercial establishments, prefab awnings are gaining traction as cost-effective, customizable, and eco-friendly solutions. This analysis explores key trends shaping the prefab awning industry in 2026.

Rising Demand for Outdoor Living Spaces

One of the most influential drivers of the prefab awning market is the increasing popularity of outdoor living. Consumers are investing in patios, decks, and backyard entertainment areas, and awnings play a pivotal role in enhancing comfort and usability. The global shift toward work-from-home and hybrid lifestyles has further amplified the desire for functional outdoor spaces. By 2026, prefab awnings will be marketed not just as shade providers, but as integral architectural elements that extend interior design into exterior environments.

Technological Integration and Smart Features

By 2026, smart technology integration will become standard in the prefab awning industry. Motorized retractable awnings with remote control, smartphone app compatibility, and weather sensors will dominate the market. Some advanced models may include solar-powered motors, integrated LED lighting, and voice control via smart home assistants (e.g., Alexa, Google Home). These features enhance convenience, energy efficiency, and user experience, appealing especially to tech-savvy homeowners and commercial property managers.

Sustainability and Eco-Friendly Materials

Sustainability will be a central theme in the 2026 market. Consumers and regulators alike are demanding environmentally responsible products. Manufacturers are responding by using recyclable aluminum frames, eco-conscious fabric options (such as solution-dyed acrylics with low environmental impact), and solar-reflective coatings that reduce building cooling loads. Additionally, modular and reusable prefab designs minimize construction waste, aligning with circular economy principles.

Customization and Aesthetic Appeal

Personalization will be a major selling point. Advances in digital design tools and manufacturing allow for greater customization in color, size, shape, and functionality. In 2026, consumers can expect to use online configurators to design their ideal awning, previewing 3D renderings before purchase. Commercial spaces, in particular, will leverage branding opportunities through custom logos and colors on retractable awnings, enhancing both function and visual identity.

Growth in Commercial and Retail Applications

Beyond residential use, the commercial sector—including cafes, restaurants, hotels, and retail stores—will increasingly adopt prefab awnings to create inviting outdoor seating and protect storefronts. Urban planning initiatives promoting pedestrian-friendly zones and al fresco dining will further fuel demand. Prefab systems offer quick installation with minimal disruption, making them ideal for time-sensitive commercial projects.

Expansion in Emerging Markets

While North America and Europe remain strong markets, Asia-Pacific, Latin America, and the Middle East will see accelerated growth by 2026. Rapid urbanization, rising disposable incomes, and increasing awareness of energy-efficient building solutions are expanding the customer base. Localized manufacturing and distribution hubs will emerge to reduce lead times and transportation costs.

Competitive Pricing and Accessibility

Thanks to economies of scale and streamlined production methods, prefab awnings will become more affordable and accessible. DIY installation kits and flat-pack designs will lower labor costs, appealing to budget-conscious consumers. At the same time, premium models with advanced features will maintain strong margins, creating a tiered market structure.

Conclusion

By 2026, the prefab awning market will be characterized by innovation, sustainability, and increasing integration into smart living ecosystems. As consumer expectations evolve and climate-aware design becomes standard, prefab awnings will transition from simple sunshades to sophisticated, multifunctional outdoor solutions. Companies that embrace customization, technology, and environmental responsibility will lead the industry in this dynamic new era.

Common Pitfalls When Sourcing Prefab Awning (Quality and Intellectual Property)

Sourcing prefabricated awnings, especially from overseas manufacturers, can offer cost and time advantages. However, buyers often encounter significant challenges related to quality control and intellectual property (IP) protection. Being aware of these pitfalls is essential for a successful procurement process.

Quality Inconsistencies and Substandard Materials

One of the most prevalent issues when sourcing prefab awnings is inconsistent quality. Suppliers may promise high-grade materials such as powder-coated aluminum frames or UV-resistant acrylic fabrics but deliver substandard alternatives. Thin-gauge metals, inferior coatings, and non-weatherproof fabrics can lead to premature rust, fading, warping, or structural failure. Without rigorous on-site inspections or third-party quality audits, these defects may only become apparent after installation, resulting in costly replacements and reputational damage.

Lack of Standardized Manufacturing Processes

Many prefab awning manufacturers, particularly smaller or less experienced ones, lack standardized production protocols. This variability can result in dimensional inaccuracies, misaligned components, or poor weld integrity. Inconsistent manufacturing not only affects the aesthetic and functionality of the awning but also compromises safety, especially in high-wind or heavy-snow regions. Buyers should verify that suppliers adhere to recognized quality management systems (e.g., ISO 9001) and request production samples before full-scale orders.

Inadequate Testing and Certification

Reputable awnings should meet regional building codes and performance standards (e.g., ASTM, EN, or AS/NZS for wind load, fire resistance, and durability). However, some suppliers provide falsified or generic test reports that don’t reflect the actual product. Sourcing without verified, product-specific certifications increases liability and may lead to non-compliance issues during inspections or insurance claims. Always require up-to-date, accredited test reports relevant to your market.

Intellectual Property Infringement Risks

When sourcing awnings, especially from regions with weak IP enforcement, there’s a risk of inadvertently purchasing counterfeit or plagiarized designs. Many suppliers replicate patented structural designs, unique fabric patterns, or proprietary hardware without authorization. Buyers who import such products may face legal action, customs seizures, or forced recalls. Conduct due diligence by verifying the originality of designs, requesting IP ownership documentation, and including IP indemnity clauses in supply contracts.

Poor Documentation and Lack of Traceability

Suppliers may fail to provide detailed technical documentation, including material specifications, assembly instructions, or maintenance guidelines. This lack of traceability complicates quality assurance, post-installation support, and warranty claims. Ensure that contracts require comprehensive documentation and that each batch is traceable to its production run for accountability.

Overreliance on Samples

While sample evaluation is important, relying solely on a single sample can be misleading. Some manufacturers improve the quality of sample units while downgrading mass production to cut costs. Implement a robust quality assurance plan that includes random batch inspections during and after production to ensure consistency.

Conclusion

To mitigate these risks, buyers should partner with vetted suppliers, conduct factory audits, enforce clear quality specifications in contracts, and protect IP through legal agreements. Proactive due diligence significantly reduces the likelihood of encountering quality failures or IP disputes when sourcing prefab awnings.

Logistics & Compliance Guide for Prefab Awning

Overview

Prefabricated (Prefab) awnings are manufactured off-site and transported to project locations for installation. Efficient logistics and strict compliance with regulations are essential to ensure timely delivery, safety, and adherence to building codes and standards.

Transportation Planning

Plan transportation routes carefully to accommodate the size and weight of prefab awning units. Use flatbed trucks or enclosed trailers depending on weather conditions and fragility. Secure awnings with straps, braces, and protective padding to prevent shifting or damage during transit. Coordinate delivery schedules with installation timelines to avoid on-site storage delays.

Packaging & Handling

Package awnings in weather-resistant materials to protect against moisture, dust, and impact. Clearly label each unit with handling instructions, orientation indicators (e.g., “This Side Up”), and project-specific identifiers. Use forklifts or cranes with soft slings for unloading—avoid dragging or dropping components. Designate a clean, level staging area on-site for temporary storage.

Import/Export Compliance (if applicable)

For international shipments, ensure awnings comply with destination country regulations. Verify Harmonized System (HS) codes for accurate tariff classification—common codes may fall under 9405 (lamps and lighting fittings) or 7308 (structures of iron or steel). Prepare required documentation, including commercial invoices, packing lists, and certificates of origin. Confirm adherence to local electrical or fire safety standards if integrated lighting or motors are included.

Safety & Regulatory Standards

Ensure awning designs comply with local building codes, wind load requirements, and fire safety regulations (e.g., flame-retardant fabric certifications like NFPA 701). Structural components must meet material standards such as ASTM or EN for aluminum or steel. If applicable, comply with accessibility standards (e.g., ADA in the U.S.) regarding overhang height and clearance.

Environmental & Sustainability Compliance

Use materials with low environmental impact and ensure compliance with regulations such as REACH (EU) or TSCA (U.S.) for chemical content. Recycle packaging materials and minimize waste during transport and installation. Document the use of sustainable materials or processes for LEED or BREEAM certification eligibility.

Installation & Final Inspection

Only trained personnel should install prefabricated awnings following manufacturer guidelines. Conduct a post-installation inspection to verify structural integrity, alignment, and operational functionality (e.g., retractable mechanisms). Retain compliance documentation, including engineering certifications, material test reports, and inspection records, for client handover and audits.

Documentation & Record-Keeping

Maintain complete records of logistics schedules, shipping manifests, compliance certificates, inspection reports, and installation sign-offs. Digital tracking systems are recommended for real-time visibility and audit readiness.

In conclusion, sourcing a prefab awning offers a cost-effective, time-efficient, and reliable solution for enhancing outdoor spaces with protection from sun and rain. With standardized designs and quick installation processes, prefab awnings provide a practical option for both residential and commercial applications. Careful consideration of materials, size, climate suitability, and supplier reputation ensures durability and aesthetic appeal. By evaluating suppliers based on quality, warranty, customization options, and customer service, buyers can make informed decisions that balance budget and performance. Overall, prefab awnings represent a smart investment for immediate shade and improved comfort with minimal hassle.