The global trench drain market is experiencing steady growth, driven by increasing urbanization, infrastructure development, and demand for efficient water management solutions in commercial, industrial, and residential sectors. According to Mordor Intelligence, the trench drain market was valued at USD 4.2 billion in 2023 and is projected to grow at a CAGR of 5.8% from 2024 to 2029. A significant portion of this growth is attributed to the rising preference for precast concrete trench drains, which offer faster installation, superior durability, and consistent quality compared to cast-in-place alternatives. As cities expand and climate resilience becomes a priority, manufacturers specializing in precast trench systems are well-positioned to meet evolving industry demands. In this landscape, seven manufacturers have emerged as leaders, combining innovation, scalability, and global reach to set the standard for performance and reliability in precast trench drain solutions.

Top 7 Precast Trench Drain Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

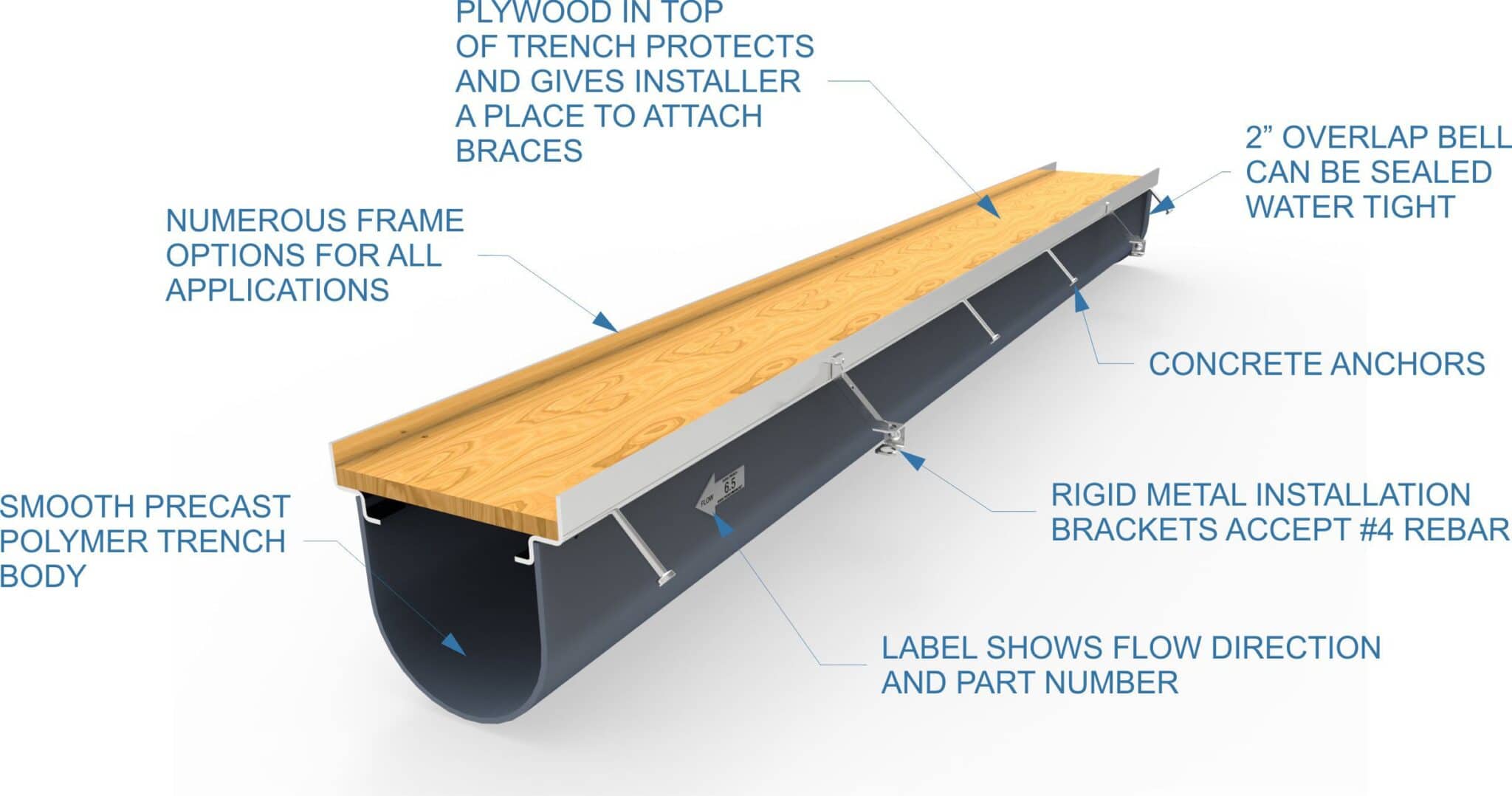

#1 Trenwa Precast Trench Products

Domain Est. 1996

Website: trenwa.com

Key Highlights: Home page for Trenwa, Inc. manufacturer of precast trench solutions for cable and piping….

#2 Trench Drain Systems Solutions

Domain Est. 1995

Website: hubbell.com

Key Highlights: Our POLYCAST® brand produces trench drain systems that ensure efficient removal of excess water and prevent pooling and overflowing….

#3 Trench Drain Systems

Domain Est. 1995

Website: zurn.com

Key Highlights: A complete line of trench drainage products engineered for easy layout and installation providing ideal solution to your unique needs….

#4 CXT Precast Concrete Trench Drains

Domain Est. 1996

Website: lbfoster.com

Key Highlights: Precast concrete trench drains are easy to maintain and can be installed in a variety of different environments. for 12′ wide grating. 9′ -10½” L x 1′-6⅛” W ……

#5 Spee

Domain Est. 1996

Website: ndspro.com

Key Highlights: This lightweight alternative to traditional concrete channel drains features the patented flying buttress design for load-bearing support….

#6 Presloped & Modular Concrete Trench Drain Channels

Domain Est. 1997

Website: abtdrains.com

Key Highlights: The ABT PolyDrain precast trench drain system provides modular design flexibility, facilitates construction accuracy, requires less installation labor and skill ……

#7 Trench Drains

Domain Est. 2000

Website: precastmfgco.com

Key Highlights: CATALOG| Trench Drains · Accessories · Box Culverts & Holding Tanks · Catch Basins · Distribution Boxes · Drywells · Ductile Iron Pipe & Fittings · Filter Fabrics ……

Expert Sourcing Insights for Precast Trench Drain

H2: 2026 Market Trends for Precast Trench Drain

The global precast trench drain market is poised for significant evolution by 2026, driven by urbanization, infrastructure modernization, and technological advancements. Key trends shaping the market include:

1. Accelerated Adoption in Infrastructure & Smart Cities: Major government investments in resilient infrastructure—roads, airports, and urban drainage—are boosting demand. The rise of smart city projects emphasizes efficient water management, making precast trench drains a preferred choice due to their rapid installation, durability, and compatibility with integrated drainage systems. By 2026, public sector procurement is expected to remain a dominant market driver.

2. Emphasis on Sustainability and Green Construction: Environmental regulations and green building standards (e.g., LEED, BREEAM) are pushing demand for sustainable drainage solutions (SuDS). Precast trench drains align with these goals through recyclable materials, reduced on-site waste, and integration with permeable paving and rainwater harvesting. Manufacturers are increasingly offering eco-friendly variants with recycled aggregates or low-carbon cement.

3. Technological Innovation and Design Customization: Advances in mold technology and precast manufacturing enable greater design flexibility—custom shapes, integrated grates, and load-bearing capacities up to Class D4 or E6. In 2026, expect wider availability of modular, interlocking systems that simplify installation and reduce labor costs. Digital tools like BIM are streamlining planning and integration with larger construction workflows.

4. Growth in Commercial and Industrial Applications: Beyond municipal use, sectors such as logistics warehouses, data centers, and manufacturing facilities are adopting precast trench drains for efficient floor drainage and chemical resistance. The push for faster construction timelines in industrial developments favors precast over cast-in-place alternatives.

5. Regional Market Diversification: While North America and Europe remain mature markets, Asia-Pacific—led by China, India, and Southeast Asia—is expected to witness the highest growth due to rapid urbanization and infrastructure expansion. Latin America and the Middle East are also emerging as key regions, driven by large-scale construction and flood mitigation initiatives.

6. Competitive Landscape and Consolidation: The market is seeing increased competition and consolidation, with major players expanding production capacity and distribution networks. Differentiation is occurring through value-added services (design support, installation training) and product innovation focused on durability, corrosion resistance, and aesthetic appeal.

In summary, by 2026, the precast trench drain market will be characterized by smart, sustainable, and rapidly deployable solutions, underpinned by strong demand from both public and private sectors seeking cost-effective and resilient drainage infrastructure.

Common Pitfalls When Sourcing Precast Trench Drains (Quality and Intellectual Property)

Sourcing precast trench drains involves more than just price comparison. Overlooking quality standards and intellectual property (IP) rights can lead to performance failures, legal disputes, and project delays. Below are key pitfalls to avoid:

Poor Material and Manufacturing Quality

Low-quality precast trench drains often use substandard concrete mixes, inadequate reinforcement, or poor curing practices, leading to premature cracking, spalling, or structural failure. Suppliers may cut corners to reduce costs, resulting in inconsistent dimensions, weak load-bearing capacity, and reduced lifespan—especially in heavy-duty applications like industrial sites or roads.

Lack of Compliance with Industry Standards

Many suppliers fail to adhere to recognized standards such as ASTM C1709, ASME A112.6.3, or local building codes. Without certification or third-party testing, there’s no assurance that the product will perform under specified loads (e.g., A15, B125, D400 classifications). This increases liability risk and may result in non-compliant installations rejected during inspection.

Inadequate Load and Durability Testing

Some manufacturers provide unverified performance claims without comprehensive testing for compressive strength, freeze-thaw resistance, or chemical exposure. Without documented test reports, the trench drain may not withstand real-world conditions, especially in harsh environments like chemical plants or cold climates.

Misrepresentation of Intellectual Property (IP) and Design Rights

A significant but often overlooked pitfall is the unauthorized use of patented trench drain designs. Some suppliers replicate proprietary profiles, locking systems, or reinforcement methods without licensing. Purchasing such products can expose the buyer to legal liability, especially if the original IP holder takes enforcement action. Always verify that the design is either licensed, in the public domain, or independently developed.

Insufficient Documentation and Traceability

Reliable suppliers provide material test reports, quality control documentation, and batch traceability. Lack of proper documentation makes it difficult to verify quality or support warranty claims. In the event of a failure, absence of records complicates root cause analysis and accountability.

Poor Joint and Connection Design

Precast systems rely on proper interlocking mechanisms and sealants between sections. Poorly designed or executed joints can lead to water leakage, ground erosion, or structural misalignment. Some suppliers use generic connection methods not suited for dynamic loads or settlement, compromising long-term integrity.

Inadequate Support and Technical Expertise

Choosing a supplier without engineering support can lead to improper product selection or installation errors. Technical guidance on bedding, alignment, and integration with existing drainage systems is essential—especially for custom or complex applications.

Conclusion

To mitigate these risks, conduct thorough due diligence: verify certifications, request test data, confirm IP compliance, and choose reputable suppliers with proven track records. Investing time upfront ensures durability, legal safety, and long-term performance of your precast trench drain system.

Logistics & Compliance Guide for Precast Trench Drain

Product Overview

Precast trench drains are factory-manufactured drainage systems made from concrete or polymer concrete, designed for efficient surface water management in commercial, industrial, and infrastructure applications. Their precast nature ensures consistent quality, faster installation, and compliance with structural and environmental standards.

Material Specifications & Standards

Precast trench drains must conform to recognized industry standards to ensure durability and performance:

– ASTM C14: Standard Specification for Precast Concrete Sewage-Related Structures.

– ASTM C478: Standard Specification for Precast Reinforced Concrete Manholes.

– AASHTO M 242: For polymer concrete used in drainage elements.

– International Building Code (IBC): Compliance with load classifications (e.g., A15, B125, C250, D400) based on application (pedestrian, vehicular, heavy traffic).

– ADA Compliance: Grating design must meet Americans with Disabilities Act requirements for slip resistance and opening size when applicable.

Manufacturing & Quality Control

- Produced in certified precast plants under controlled conditions.

- Each unit undergoes quality inspection per plant’s Quality Management System (e.g., PCI Certification).

- Documentation includes batch test reports for compressive strength, reinforcement placement, and dimensional tolerances.

- Surface finish and joint integrity are verified prior to shipment.

Packaging & Handling

- Units are stacked on wooden skids or cradles with protective padding between layers.

- Grates and frames are packaged separately to prevent damage.

- Lifting points (e.g., embedded lifting inserts) must be used during handling; never lift by rebar or edges.

- Use slings or spreader bars to avoid cracking during crane operations.

Transportation Guidelines

- Load secured with straps and dunnage to prevent shifting.

- Maximum stack height adhered to (typically 3–4 layers depending on size and weight).

- Transport vehicles must have flat, stable beds; avoid rough roads to minimize vibration damage.

- Deliveries scheduled to minimize on-site storage; protect units from weather if stored outdoors.

Site Storage & Inventory Management

- Store on level, compacted ground with adequate support (e.g., timber bearers).

- Cover tops with waterproof tarpaulins if exposed to rain.

- Keep units off the ground to prevent moisture absorption and staining.

- Rotate stock using First-In, First-Out (FIFO) principle to prevent aging issues.

Installation & Site Compliance

- Verify alignment, slope (typically 1–2%), and elevation per project drawings.

- Bedding material (e.g., granular base or concrete haunching) must meet engineering specifications.

- Joints sealed with approved elastomeric sealants or gaskets to prevent infiltration.

- Backfill in controlled lifts with compaction to prevent settlement.

- All work must comply with local building codes, stormwater management regulations, and site safety protocols (OSHA standards).

Environmental & Regulatory Compliance

- Stormwater discharge must comply with NPDES (National Pollutant Discharge Elimination System) requirements.

- Concrete washout procedures must follow EPA guidelines to prevent contamination.

- Material Safety Data Sheets (MSDS) available for sealants, coatings, and cleaning agents.

- Recycling of packaging materials encouraged; follow local waste management regulations.

Documentation & Traceability

- Maintain records of:

- Material test reports (concrete strength, reinforcement).

- Certificates of compliance (ASTM, AASHTO, etc.).

- Delivery notes and inspection reports.

- As-built drawings and installation logs.

- Each batch traceable via unique casting or lot numbers.

Safety & Training

- Personnel must be trained in safe lifting, trenching, and equipment operation.

- Use PPE (hard hats, gloves, safety boots) during handling and installation.

- Follow confined space entry procedures if accessing connected drainage systems.

- Comply with OSHA 29 CFR 1926 Subpart P for excavation safety.

Inspection & Certification

- Final system inspected by qualified engineer or third-party reviewer.

- Acceptance tests may include water tightness (hydrostatic test) and flow verification.

- Obtain sign-off from local authority having jurisdiction (AHJ) where required.

Maintenance & Warranty

- Provide end-user with maintenance guidelines (debris removal, grate inspection).

- Typical warranty: 1–5 years against manufacturing defects, subject to proper installation.

- Report defects promptly with photographic and technical documentation for claims.

Conclusion for Sourcing Precast Trench Drain

In conclusion, sourcing precast trench drains offers numerous advantages including faster installation, consistent quality, durability, and long-term cost efficiency. Precast systems are manufactured under controlled conditions, ensuring high structural integrity and standardized performance, which minimizes on-site errors and delays. When selecting a supplier, it is essential to evaluate factors such as product specifications, material quality (e.g., polymer concrete or reinforced concrete), load ratings, customization options, lead times, and compliance with industry standards.

Partnering with reputable manufacturers or suppliers who offer technical support, reliable logistics, and warranty services further enhances project success. Additionally, considering lifecycle costs rather than just initial pricing leads to smarter investment decisions. Overall, precast trench drains represent a superior solution for effective and sustainable drainage in commercial, industrial, and infrastructure applications, making thoughtful sourcing a critical step in achieving optimal performance and project efficiency.