The global precast septic tank market is experiencing steady growth, driven by increasing urbanization, stricter environmental regulations, and a rising demand for rapid, sustainable construction solutions. According to Grand View Research, the global septic tank market size was valued at USD 7.2 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030, with precast concrete systems gaining preference due to their durability, factory-controlled quality, and quick on-site installation. As infrastructure development accelerates across emerging economies and developed regions alike, precast septic tanks are becoming a go-to solution for decentralized wastewater treatment. This growth trajectory has catalyzed strong competition among manufacturers, fostering innovation in design, hygiene, and environmental performance. In this context, identifying the top precast septic tank manufacturers offers valuable insights for contractors, municipalities, and developers seeking reliable, scalable, and compliant wastewater systems.

Top 9 Precast Septic Tank Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

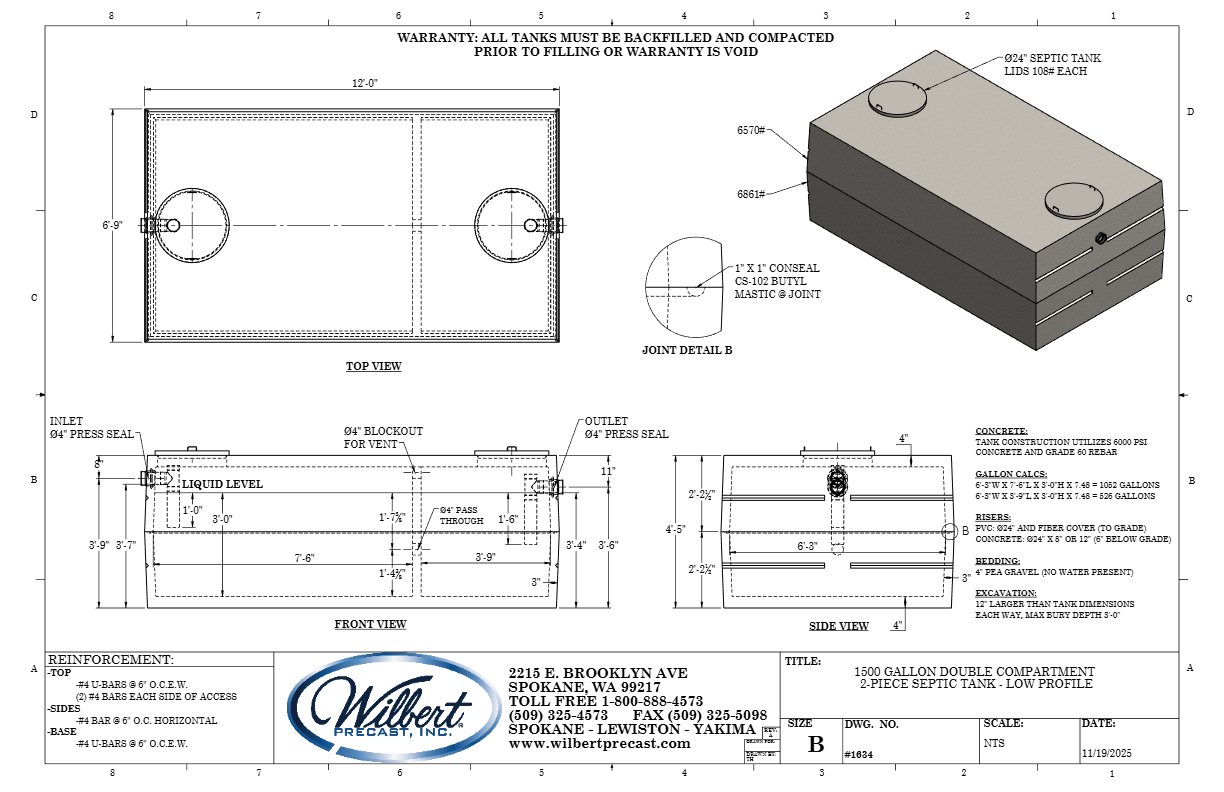

#1 Wilbert Precast Inc.

Domain Est. 1999

Website: wilbertprecast.com

Key Highlights: [email protected] · (509) 325-4573 · Products · Septic Tanks & Water Tanks · Septic Tanks · Water Tanks · Grease Interceptors · Oil & Water Separators ……

#2 Precast Tanks

Domain Est. 2020

Website: precasttanks.com

Key Highlights: CTS is the top manufacturer of concrete septic tanks, grease interceptors, vaults, wash out pits, box culverts, lift stations, parking curbs, splash pads, and ……

#3 CXT Precast Concrete Septic Tanks Texas

Domain Est. 1996

Website: lbfoster.com

Key Highlights: Precast concrete septic tanks, pump tanks, and grease traps manufactured in Hillsboro, Texas, and distributed to the surrounding area….

#4 Pre

Domain Est. 1999

Website: donchapin.com

Key Highlights: The Don Chapin Company, Pre-Cast Division, manufactures concrete grease interceptors, clarifiers and septic tanks, which are listed by IAPMO….

#5 Precast Concrete Residential Septic Tanks

Domain Est. 1999

Website: sheaconcrete.com

Key Highlights: Precast concrete septic tanks from Shea are strong, watertight, environmentally friendly, and ideal for any residential waste management system….

#6 Septic Tanks

Domain Est. 2000

Website: precastmfgco.com

Key Highlights: CATALOG| Septic Tanks · Septic Tank – 750 Gallons · Septic Tank – 750 Gallons · Septic Tank – 1000 Gallons · Septic Tank – 1000 Gallons · Septic Tank – 1250 Gallons….

#7 Precast Concrete Septic Tanks

Domain Est. 2003

Website: gillespieprecast.com

Key Highlights: Gillespie Precast designs and manufactures tanks to withstand corrosive elements and integrate seamlessly with advanced wastewater treatment technologies. Our ……

#8 Precast Systems

Domain Est. 2004

Website: darwinconcrete.com

Key Highlights: We now produce septic tanks, feed bunks, wall panels, steps, retaining wall blocks, planters, signs, and various specialty products….

#9 Quality Precast Concrete Products

Domain Est. 2023

Website: poeppelmanmaterials.com

Key Highlights: Poeppelman Materials is a trusted provider of high-quality pre-cast concrete products, proudly serving Darke County, Miami County, ……

Expert Sourcing Insights for Precast Septic Tank

2026 Market Trends for Precast Septic Tanks

The global precast septic tank market is poised for significant evolution by 2026, driven by urbanization, environmental regulations, and technological advancements. Key trends shaping the industry include:

Sustainable Construction and Environmental Regulations

Stringent environmental regulations across North America, Europe, and parts of Asia are pushing municipalities and developers toward eco-friendly wastewater solutions. Precast concrete septic tanks, known for their durability and leak-proof design, are increasingly favored over traditional on-site poured or plastic alternatives. By 2026, compliance with green building standards such as LEED and BREEAM will likely accelerate adoption, especially in residential and commercial developments seeking sustainable certifications.

Urbanization and Infrastructure Development in Emerging Economies

Rapid urbanization in regions like Southeast Asia, Africa, and Latin America is fueling demand for efficient sanitation infrastructure. Governments are investing in decentralized wastewater treatment systems to support expanding peri-urban areas where centralized sewerage is impractical. Precast septic tanks offer a modular, quick-to-install solution ideal for such scenarios. Countries including India, Indonesia, and Nigeria are expected to see substantial market growth by 2026 due to public-private partnerships and rural sanitation programs.

Technological Advancements in Design and Manufacturing

By 2026, the integration of Building Information Modeling (BIM) and automated manufacturing processes will enhance precision and reduce production time for precast tanks. Innovations such as fiber-reinforced concrete, corrosion-resistant coatings, and internal baffling systems will improve tank longevity and treatment efficiency. Additionally, smart monitoring systems—featuring IoT-enabled sensors to track sludge levels and effluent quality—are beginning to emerge, offering predictive maintenance and regulatory compliance benefits.

Shift Toward Prefabricated and Modular Solutions

The construction industry’s broader shift toward off-site fabrication is benefiting the precast septic tank sector. Modular, factory-made tanks reduce on-site labor, minimize construction waste, and ensure consistent quality. As labor costs rise and project timelines tighten, developers are increasingly opting for prefabricated solutions. This trend will likely strengthen through 2026, especially in large-scale housing and industrial projects.

Competitive Landscape and Regional Dynamics

The market is becoming more competitive, with established players expanding production capacity and regional manufacturers enhancing product quality. North America and Europe will remain mature markets with steady growth, while Asia-Pacific is expected to lead in terms of CAGR due to urban expansion and government sanitation initiatives. Strategic collaborations between precast manufacturers and engineering firms are likely to increase, aiming to deliver integrated wastewater management solutions.

In summary, the precast septic tank market in 2026 will be defined by sustainability, innovation, and scalability, positioning it as a critical component of modern decentralized sanitation infrastructure worldwide.

Common Pitfalls Sourcing Precast Septic Tanks (Quality & Intellectual Property)

Sourcing precast septic tanks requires careful attention to avoid significant issues related to product quality and intellectual property (IP) rights. Overlooking these areas can lead to project delays, structural failures, legal disputes, and reputational damage. Below are key pitfalls to watch for:

Quality-Related Pitfalls

Inadequate Material Specifications and Testing

Procuring tanks without clearly defined material requirements (e.g., concrete strength, water-cement ratio, reinforcement grade) often results in substandard products. Suppliers may use lower-grade concrete or insufficient steel reinforcement to cut costs, compromising structural integrity and longevity.

Lack of Third-Party Certification or Compliance

Many suppliers claim compliance with ASTM, BS, or local standards without verifiable certification. Relying solely on supplier declarations without requesting third-party test reports or factory audits increases the risk of receiving non-compliant tanks prone to cracking, leakage, or failure under load.

Poor Manufacturing and Curing Processes

Inconsistent casting, improper vibration, and inadequate curing (e.g., insufficient moist curing time) can lead to honeycombing, weak spots, and reduced durability. Sourcing from facilities without quality control systems (e.g., ISO 9001) heightens this risk.

Inconsistent Dimensional Accuracy and Fit

Poor mold maintenance or lax tolerances can result in tanks with incorrect dimensions or misaligned inlet/outlet ports. This causes installation challenges, improper connections, and potential system inefficiencies.

Insufficient Structural Design Validation

Using tanks not engineered for local soil, groundwater, or traffic loading conditions can lead to collapse. A common pitfall is assuming generic designs are universally applicable without site-specific structural analysis.

Intellectual Property-Related Pitfalls

Use of Copycat or Counterfeit Designs

Some manufacturers replicate patented tank designs (e.g., proprietary baffle configurations, ribbing patterns, or modular connection systems) without authorization. Sourcing such products can expose the buyer or project owner to IP infringement claims, especially in regulated markets.

Unclear Ownership of Custom Tooling or Molds

When commissioning custom-designed tanks, failure to formalize IP ownership in contracts often means the supplier retains rights to the mold or design. This limits exclusivity and allows competitors to source identical products.

Lack of Licensing Agreements for Proprietary Technologies

Advanced precast tanks may incorporate patented filtration media, venting systems, or sealing mechanisms. Using these without proper licensing agreements not only violates IP law but may void performance warranties.

Inadequate Documentation and Traceability

Absence of design drawings, engineering stamps, or IP disclosures in procurement documents makes it difficult to verify originality or defend against infringement allegations later in the project lifecycle.

By proactively addressing these quality and IP pitfalls—through rigorous supplier vetting, clear contractual terms, and independent verification—buyers can ensure reliable performance and legal compliance in their septic tank procurement.

Logistics & Compliance Guide for Precast Septic Tanks

Overview

Precast septic tanks are essential components in decentralized wastewater treatment systems, commonly used in residential, commercial, and rural developments where centralized sewer systems are unavailable. Due to their size, weight, and regulatory implications, transporting, handling, and installing these units require careful planning and strict adherence to logistical and compliance standards.

Transportation & Handling

Weight and Dimensions

Precast septic tanks are typically manufactured from reinforced concrete and can weigh several tons, depending on size and design (e.g., 1,000–3,000 gallons). Accurate knowledge of the unit’s dimensions and weight is critical for selecting appropriate transport vehicles and ensuring road and bridge load compliance.

Equipment Requirements

- Flatbed Trucks or Lowboys: Required for safe over-the-road transport.

- Crane or Excavator with Lifting Gear: Necessary for offloading at the job site; use manufacturer-recommended lifting points only.

- Spreader Bars and Slings: Ensure even load distribution during lifting to prevent cracking.

Secure Loading and Transport

- Tanks must be secured with straps or chains during transit to prevent shifting.

- Avoid sharp turns and sudden stops to reduce stress on the tank structure.

- Confirm that transport routes accommodate oversized loads and comply with local Department of Transportation (DOT) regulations.

On-Site Handling

- Never drag or roll tanks on the ground.

- Use lifting eyes or embedded lifting loops; do not lift by manhole covers or inlets/outlets.

- Place tanks on a prepared, level bedding of granular material (e.g., sand or gravel) to avoid damage.

Regulatory Compliance

Environmental Regulations

- EPA and State Environmental Agencies: Ensure tanks meet effluent discharge standards and are installed in compliance with local wastewater codes.

- Groundwater Protection: Tanks must be sited at appropriate distances from wells, property lines, and water bodies as defined by local regulations.

Building and Plumbing Codes

- International Plumbing Code (IPC) and Uniform Plumbing Code (UPC): Govern tank sizing, materials, and installation practices.

- Local building departments often require permits and inspections at various stages (pre-installation, post-installation, and final).

Manufacturing Standards

- ASTM C913: Standard specification for precast concrete water and wastewater structures, including septic tanks.

- NSF/ANSI 46: Performance standard for onsite wastewater treatment systems—some jurisdictions require certification for tank models.

Installation Requirements

- Tanks must be level and backfilled in stages with compacted native soil or engineered fill.

- Inlet and outlet connections must be properly sealed and aligned to prevent leaks.

- Post-installation hydrostatic testing may be required to verify integrity.

Permitting and Documentation

Required Permits

- Site evaluation and soil percolation (perc) test approval.

- Septic system design approval from local health or environmental agency.

- Building and excavation permits.

Documentation

- Manufacturer’s installation instructions and product certifications.

- As-built drawings showing tank location, depth, and connection points.

- Inspection reports from third-party or municipal inspectors.

Safety Considerations

Worker Safety

- Use proper personal protective equipment (PPE): hard hats, gloves, steel-toed boots.

- Follow OSHA guidelines for trenching and excavation (e.g., shoring for deep installations).

- Never enter a septic tank—confined space entry is extremely hazardous due to risk of toxic gases.

Public and Environmental Safety

- Barricade the installation site to prevent unauthorized access.

- Prevent sediment runoff during excavation using silt fences or other erosion controls.

Best Practices Summary

- Verify all local, state, and federal requirements before transport and installation.

- Use certified equipment and trained personnel for handling and placement.

- Maintain clear communication between manufacturer, transporter, installer, and permitting authority.

- Conduct final inspection and secure sign-off before covering the tank.

Adhering to this logistics and compliance guide ensures the safe, legal, and effective deployment of precast septic tanks, protecting both public health and the environment.

Conclusion on Sourcing Precast Septic Tanks

Sourcing precast concrete septic tanks offers a reliable, durable, and cost-effective solution for efficient wastewater management in both residential and commercial applications. Their factory-controlled manufacturing ensures consistent quality, structural integrity, and compliance with industry standards, reducing the risk of on-site defects and long-term maintenance issues.

Prefabricated septic tanks significantly reduce installation time and labor costs due to their ready-to-install nature, making them ideal for projects with tight timelines. Additionally, their durability, resistance to corrosion, and low maintenance requirements contribute to a longer service life compared to alternative materials such as plastic or on-site constructed systems.

When sourcing precast septic tanks, it is essential to partner with certified and reputable manufacturers who adhere to relevant standards (e.g., ASTM, EN, or local regulations), provide proper technical support, and offer customization options to meet specific project requirements. Evaluating logistics, delivery timelines, and total lifecycle costs further ensures optimal performance and cost-efficiency.

In conclusion, precast septic tanks represent a sustainable, high-performance choice for modern sanitation infrastructure. With careful vendor selection and proper planning, they deliver long-term environmental, economic, and operational benefits, making them a preferred solution in a wide range of development projects.