The global precast concrete pipes market is experiencing robust growth, driven by increasing infrastructure development, urbanization, and the need for efficient wastewater and stormwater management systems. According to Grand View Research, the global concrete pipes market size was valued at USD 108.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Complementing this outlook, Mordor Intelligence projects a CAGR of approximately 5.3% during the forecast period of 2024–2029, fueled by rising investments in water infrastructure and sustainable construction practices. With governments worldwide prioritizing resilient and cost-effective pipeline solutions, demand for high-quality precast pipes has surged. This growing market momentum has intensified competition among manufacturers, positioning innovation, production capacity, and compliance with international standards as key differentiators. In this landscape, the following nine companies have emerged as leading precast pipe manufacturers, setting benchmarks in quality, scalability, and technological advancement across regions.

Top 9 Precast Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

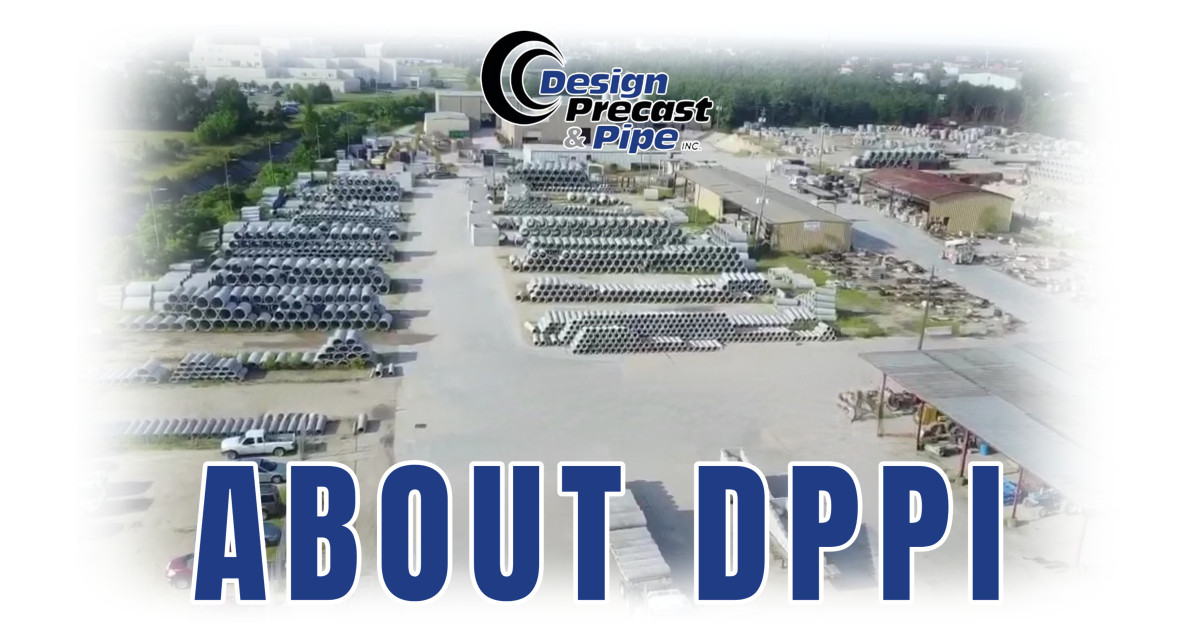

#1 Design Precast & Pipe, Inc.

Domain Est. 2006

Website: designprecast.com

Key Highlights: DPPI is a premiere family-owned concrete pipe and precast manufacturer with two southern locations ready to serve you in your next project….

#2 Serving the Precast Concrete Industry

Domain Est. 1996

Website: precast.org

Key Highlights: The National Precast Concrete Association serves precast concrete manufacturers and suppliers through education, opportunities and advocacy….

#3 Thompson Pipe Group US

Domain Est. 2013

Website: thompsonpipegroup.com

Key Highlights: The widest range of precast, pressure and trenchless pipe solutions in the US, plus industry-leading engineering and logistics….

#4 • Concrete Industries

Domain Est. 2000

Website: concreteindustries.com

Key Highlights: We are the #1 precast concrete supplier of high-quality structural concrete building precast products and bridge girder systems for the construction ……

#5 American Concrete Pipe Association

Domain Est. 2004

Website: concretepipe.org

Key Highlights: The American Concrete Pipe Association advocates on local, state, and national levels for legislation that drives investment into our nation’s infrastructure….

#6 Rinker Materials

Domain Est. 2008

Website: rinkerpipe.com

Key Highlights: Rinker Materials provides a range of infrastructure solutions, from stormwater, sanitary, bridge solutions, and specialty products that offer industry-leading ……

#7 Precast Concrete Products Supplier, Since 2012

Domain Est. 2012

Website: concretepandp.com

Key Highlights: Delivering a diverse range of high-quality precast concrete products & Structures tailored to meet the demands of any project….

#8 Alcrete

Domain Est. 2022

Website: alcrete.com

Key Highlights: Alcrete delivers reliable precast concrete products that perform flawlessly the first time. Partner with us for responsive service, strong relationships, ……

#9 Infinite Precast

Domain Est. 2024

Website: infiniteprecast.com

Key Highlights: Infinite Precast offers high-quality precast concrete products, including tanks, culverts, pipes, and utility structures, trusted for performance and ……

Expert Sourcing Insights for Precast Pipe

H2: 2026 Market Trends for Precast Concrete Pipe

The global precast concrete pipe market is poised for steady growth and transformation by 2026, driven by urbanization, infrastructure investment, and evolving sustainability demands. Key trends shaping the market include:

-

Accelerated Infrastructure Investment: Government initiatives (like the U.S. Infrastructure Investment and Jobs Act and similar global programs) targeting water, wastewater, and stormwater systems will be a primary growth driver. Aging infrastructure replacement, particularly in North America and Europe, will create sustained demand for durable precast solutions.

-

Heightened Focus on Sustainability & Resilience: Climate change adaptation is paramount. Precast pipe’s durability, leak resistance (reducing infiltration/inflow), and long lifespan (50-100+ years) align with sustainability goals. Demand will increase for pipes designed for extreme weather events (larger stormwater capacity) and materials incorporating recycled content (fly ash, slag) to lower carbon footprint.

-

Technological Advancements in Manufacturing: Automation, robotics, and digitalization (BIM integration, IoT in production) will enhance efficiency, precision, and quality control. This reduces costs and lead times while improving consistency, making precast more competitive against alternatives like HDPE.

-

Shift Towards Larger & Specialized Diameters: Growing urbanization and larger-scale projects drive demand for large-diameter pipes (120+ inches) for major trunk sewers and stormwater tunnels. Increased use of specialized products like jacking pipes for trenchless installation (microtunneling, pipe jacking) will continue, minimizing surface disruption.

-

Consolidation & Supply Chain Optimization: The market may see further consolidation among manufacturers to achieve economies of scale and broader geographic reach. Optimizing regional production facilities near major project hubs will be crucial for reducing transportation costs and lead times.

-

Competition from Thermoplastics (HDPE): While precast dominates large-diameter applications, HDPE remains a strong competitor, especially in smaller diameters and trenchless applications, due to lighter weight and flexibility. Precast manufacturers must emphasize their superior strength, longevity, and fire resistance to maintain market share.

-

Regulatory & Standards Evolution: Stricter environmental regulations (NPDES, water quality standards) and building codes will favor leak-proof, durable systems like precast concrete, reinforcing its role in sustainable infrastructure. Adoption of performance-based standards will validate long-term benefits.

In Summary: The 2026 precast concrete pipe market will be characterized by robust demand fueled by essential infrastructure renewal and climate resilience needs. Success will depend on embracing sustainability, leveraging technology for efficiency, focusing on large and specialized applications, and effectively communicating the long-term lifecycle value proposition against competing materials.

Common Pitfalls in Sourcing Precast Pipes (Quality and Intellectual Property)

Sourcing precast concrete pipes involves several critical considerations, particularly concerning quality assurance and intellectual property (IP) protection. Failing to address these aspects can lead to project delays, structural failures, legal disputes, and increased costs. Below are some common pitfalls to avoid.

1. Inadequate Quality Control and Certification

One of the most frequent issues in sourcing precast pipes is the lack of stringent quality control measures. Buyers may prioritize cost over compliance with international or national standards (e.g., ASTM, EN, or IS codes), leading to substandard products.

- Pitfall: Accepting pipes without proper test certifications (e.g., compressive strength, water tightness, and joint performance).

- Impact: Poor durability, leakage, and premature failure in infrastructure projects.

- Solution: Require third-party inspection reports and factory audits. Ensure suppliers comply with recognized standards and conduct regular batch testing.

2. Inconsistent Manufacturing Processes

Variability in production methods across suppliers—especially in regions with less regulatory oversight—can result in inconsistent product dimensions, reinforcement placement, and curing practices.

- Pitfall: Assuming uniformity in manufacturing without verifying production capabilities.

- Impact: Misalignment during installation, reduced load-bearing capacity, and increased maintenance.

- Solution: Evaluate the supplier’s manufacturing facility, automation level, and process documentation before procurement.

3. Poor Reinforcement and Concrete Mix Design

The structural integrity of precast pipes depends heavily on proper reinforcement (rebar) and concrete mix proportions.

- Pitfall: Suppliers cutting corners by using undersized rebar or suboptimal concrete mixes.

- Impact: Cracking, corrosion, and reduced service life.

- Solution: Specify detailed technical requirements in contracts and conduct random destructive testing on delivered units.

4. Lack of Intellectual Property Protection

Precast pipe designs, especially for specialized applications (e.g., jacking pipes, earthquake-resistant joints), may incorporate proprietary technology or patented manufacturing techniques.

- Pitfall: Sourcing from suppliers who replicate patented designs without authorization.

- Impact: Legal liabilities, project injunctions, and reputational damage.

- Solution: Verify that the supplier owns or is licensed to use the technology. Include IP indemnity clauses in procurement contracts.

5. Inadequate Documentation and Traceability

Traceability of materials and manufacturing records is crucial for quality assurance and compliance audits.

- Pitfall: Receiving pipes without batch-specific documentation or unique identification markings.

- Impact: Inability to trace defects or respond to warranty claims.

- Solution: Mandate lot numbering, material test reports, and digital traceability systems.

6. Overlooking Long-Term Supplier Reliability

Short-term cost savings can be offset by long-term risks if the supplier lacks reliability or technical support.

- Pitfall: Choosing suppliers based solely on the lowest bid without evaluating track record.

- Impact: Supply chain disruption, inconsistent quality, and poor after-sales service.

- Solution: Conduct due diligence on supplier history, client references, and financial stability.

By addressing these pitfalls proactively, stakeholders can ensure the procurement of high-quality, compliant precast pipes while mitigating legal and operational risks related to intellectual property.

Logistics & Compliance Guide for Precast Concrete Pipe

Overview

Precast concrete pipe is a critical component in infrastructure projects such as stormwater drainage, wastewater systems, and culverts. Due to its size, weight, and fragility, transporting and handling precast pipe requires careful planning and adherence to regulatory standards. This guide outlines key logistics and compliance considerations to ensure safe, efficient, and lawful delivery and installation.

Transportation & Handling

Load Securement

Precast pipes must be securely fastened during transit to prevent shifting, rolling, or damage. Use cradles, blocking, and tiedowns in accordance with the U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) guidelines under 49 CFR Part 393, Subpart I. Pipes should be stacked with appropriate dunnage and separated by wood spacers to prevent chipping.

Weight Distribution & Vehicle Selection

Due to the high weight of precast concrete (typically 150 lbs/ft³), ensure that transport vehicles are properly rated for the load. Use lowboy trailers or flatbeds with adequate axle distribution to meet state weight limits and bridge formulas. Verify Gross Vehicle Weight (GVW) compliance and obtain necessary oversize/overweight permits when required.

Route Planning

Plan transport routes to avoid low-clearance bridges, weak roadways, and tight urban corridors. Coordinate with local authorities for route approvals, especially when transporting large-diameter pipes (e.g., 72” and above). Consider road conditions, weather, and construction zones.

Site Handling & Storage

Unloading Procedures

Use cranes or forklifts with appropriate lifting capacity and rigging. Lift pipes by their designated lifting points or with spreader bars to prevent cracking. Never drag or roll pipes off trailers. Maintain a safe work zone during unloading.

On-Site Storage

Store pipes on level, well-drained ground. Use support blocks at each end and under the middle of longer sections to prevent deflection or cracking. Stack no more than two layers high, with dunnage between layers. Protect from excessive moisture and freezing conditions that could compromise integrity.

Regulatory Compliance

DOT & State Regulations

Adhere to federal and state transportation regulations for heavy haul. This includes securing proper permits for oversize/overweight loads, displaying required signage (e.g., “Oversize Load”), and following designated travel times and routes. Each state has specific requirements; verify with the relevant Department of Transportation.

OSHA Safety Standards

Ensure all handling operations comply with OSHA regulations (29 CFR 1926), particularly Subpart Q (Cranes and Rigging) and Subpart N (Materials Handling). Workers must be trained in safe lifting practices, use of PPE, and hazard communication.

Environmental & Stormwater Compliance

During installation, comply with EPA and local stormwater regulations under the National Pollutant Discharge Elimination System (NPDES). Implement erosion and sediment controls to prevent runoff contamination, especially near waterways.

Quality Assurance & Documentation

Material Certification

Ensure all precast pipe meets ASTM standards such as ASTM C76 (for reinforced concrete sewer pipe) or ASTM C14 (for non-reinforced concrete pipe). Request and retain mill test reports and quality certifications from the manufacturer.

Inspection & Verification

Inspect pipes upon delivery for cracks, spalls, or dimensional inaccuracies. Document any damage and notify the supplier immediately. Conduct compliance checks during installation to ensure alignment, bedding, and joint sealing meet project specifications and industry standards (e.g., AASHTO, ACI).

Conclusion

Effective logistics and compliance for precast concrete pipe involve coordination across transportation, site operations, and regulatory domains. By following industry best practices and legal requirements, stakeholders can ensure project safety, structural integrity, and timely completion. Always consult project specifications, local authorities, and engineering guidelines to tailor procedures to your specific project needs.

Conclusion for Sourcing Precast Pipes:

Sourcing precast concrete pipes is a critical component in infrastructure development, particularly for drainage, sewerage, and culvert systems. A successful procurement strategy requires careful evaluation of supplier capabilities, product quality, compliance with relevant standards (such as ASTM, BS, or local regulations), and cost-effectiveness. Emphasis should be placed on partnering with reputable manufacturers that demonstrate consistent quality control, timely delivery, and technical expertise. Additionally, considering logistics, lead times, and lifecycle costs ensures long-term project efficiency and durability. By adopting a structured and due diligence-driven approach to sourcing, project stakeholders can ensure the reliability, sustainability, and performance of precast pipe systems within their infrastructure projects.