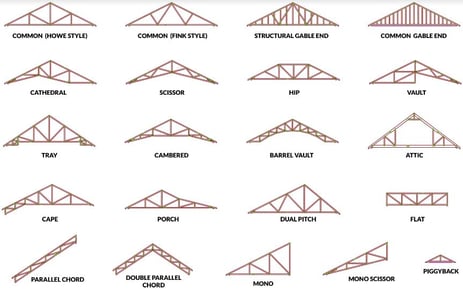

The global engineered wood truss market is experiencing robust growth, driven by rising demand for cost-effective, sustainable, and rapidly installable structural solutions in residential and commercial construction. According to a report by Mordor Intelligence, the global engineered wood market was valued at USD 95.7 billion in 2022 and is projected to grow at a CAGR of over 6.8% from 2023 to 2028. This expansion is fueled by increasing adoption of prefabricated construction methods, stricter energy efficiency standards, and growing environmental awareness favoring renewable building materials. Engineered wood trusses—known for their precision, design flexibility, and material efficiency—are a key contributor to this trend. As urbanization accelerates and labor costs rise, manufacturers specializing in pre-engineered wood trusses are well-positioned to meet evolving industry demands. In this competitive landscape, the following ten companies have emerged as leaders, combining innovation, scale, and quality to dominate the market.

Top 10 Pre Engineered Wood Trusses Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Truss Company

Domain Est. 1998

Website: thetrussco.com

Key Highlights: The Truss Company is a leading manufacturer of engineered wood roof and floor trusses, selling to the residential, commercial, and agricultural construction ……

#2 Stark Truss is a leading manufacturer and supplier of roof and floor …

Domain Est. 1998

Website: starktruss.com

Key Highlights: Our construction product line includes Roof and Floor Trusses, Wall Panels, Laminated Veneer Lumber (LVL), I-Joists, Glulam posts, pre-built stairs, StarkLam ……

#3 Engineered Wood, Beams & Trusses

Domain Est. 1996

Website: hammondlumber.com

Key Highlights: Hammond Lumber Company offers premium engineered wood beams, trusses, and I-joists designed for durability, strength, and efficiency….

#4 Roof & Floor Trusses

Domain Est. 1998

Website: bldr.com

Key Highlights: We can produce roof trusses to accommodate almost any roof design, using less lumber, reducing labor costs on the jobsite, and offering a far more flexible ……

#5 Trusses

Domain Est. 2000

Website: midwestmanufacturing.com

Key Highlights: Save design time by searching hundreds of thousands of predesigned trusses by entering your truss requirements. Save design time by searching hundreds of ……

#6 Floor Trusses

Domain Est. 2002

Website: mitek-us.com

Key Highlights: Choosing floor trusses over dimensional lumber or I-joists saves time on site, reduces material needs and costs, and enhances design opportunities….

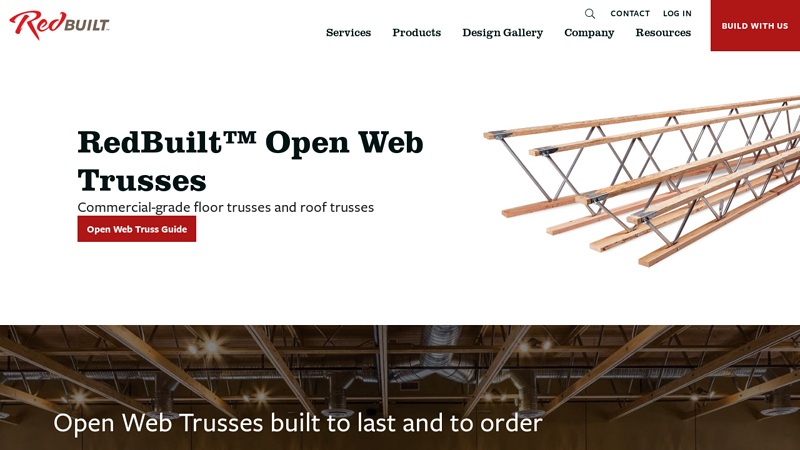

#7 RedBuilt™ Open

Domain Est. 2009

Website: redbuilt.com

Key Highlights: Open web trusses that support floor areas and roof spaces up to and over 100 feet. Crafted by hand to your precise specifications, these strong and light ……

#8 Carolina Structural Systems

Domain Est. 2016

Website: carolinastructuralsystems.com

Key Highlights: Our roof trusses are specifically designed for your project using industry-leading software. Trusses are carefully assembled to your specifications and shipped ……

#9 Engineered Timber Trusses

Domain Est. 2021

Website: ufpsitebuilt.com

Key Highlights: We design & manufacture timber trusses. From residential to commercial projects, we are your source, servicing multiple regions across the country….

#10 Engineered Truss Systems

Domain Est. 2022

Website: engineeredtruss.com

Key Highlights: Engineered Truss Systems specializes in manufacturing wood roof trusses, wood floor trusses and wall panels for residential, commercial and agricultural ……

Expert Sourcing Insights for Pre Engineered Wood Trusses

H2: 2026 Market Trends for Pre-Engineered Wood Trusses

The global pre-engineered wood trusses market is poised for steady growth through 2026, driven by evolving construction methodologies, sustainable building practices, and technological advancements. Several key trends are expected to shape the industry landscape over the next few years.

1. Rising Demand in Residential Construction

The residential construction sector remains the primary driver for pre-engineered wood trusses. With ongoing housing shortages in North America, Europe, and parts of Asia-Pacific, there is increasing reliance on efficient and cost-effective building solutions. Pre-engineered wood trusses offer faster installation, design flexibility, and reduced labor costs—making them ideal for single-family homes, multi-family housing, and affordable housing projects. This demand is expected to grow consistently through 2026.

2. Focus on Sustainability and Green Building

As environmental regulations tighten and green building certifications (such as LEED, BREEAM, and WELL) gain traction, wood trusses are benefiting from their renewable and low-carbon profile. Wood is increasingly seen as a sustainable alternative to steel and concrete. Manufacturers are responding by sourcing FSC- or PEFC-certified lumber and investing in low-emission production processes, aligning with global net-zero goals.

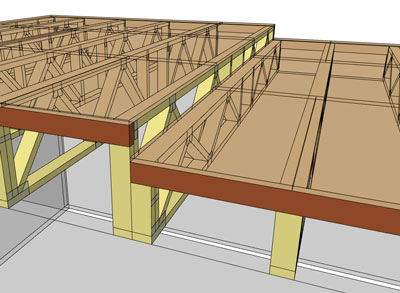

3. Advancements in Design and Engineering Software

The integration of Building Information Modeling (BIM), 3D modeling, and automated design software is transforming truss manufacturing. These tools enable precise customization, reduce material waste, and improve coordination between architects, engineers, and contractors. By 2026, cloud-based truss design platforms are expected to become standard, enhancing collaboration and speeding up project timelines.

4. Growth in Off-Site and Modular Construction

The shift toward off-site and modular construction methods is accelerating demand for pre-engineered components, including wood trusses. Factory-built trusses ensure higher quality control and reduce on-site construction time. This trend is particularly strong in urban areas where labor shortages and tight schedules make prefabrication highly attractive.

5. Regional Market Expansion

While North America remains the largest market due to established wood construction traditions and strong DIY culture, growth in the Asia-Pacific region—especially in countries like India, Vietnam, and the Philippines—is expected to accelerate. Government initiatives promoting affordable housing and infrastructure development are creating new opportunities for wood truss adoption, especially as supply chains for engineered wood products expand.

6. Supply Chain Resilience and Material Innovation

After disruptions caused by the pandemic and fluctuating lumber prices, manufacturers are focusing on supply chain diversification and inventory optimization. Additionally, research into engineered wood products such as laminated veneer lumber (LVL) and cross-laminated timber (CLT) is opening doors for hybrid truss systems that offer greater strength and span capabilities, potentially expanding applications into commercial and low-rise commercial buildings.

7. Labor Shortages Driving Mechanization

With persistent labor shortages in the construction sector, contractors are turning to prefabricated solutions that require less on-site skilled labor. Pre-engineered trusses reduce dependency on highly specialized carpenters and can be installed more quickly, making them a strategic choice for builders facing workforce constraints.

In summary, the 2026 outlook for pre-engineered wood trusses is positive, underpinned by technological innovation, sustainability trends, and structural shifts in construction practices. Stakeholders who invest in digital integration, sustainable sourcing, and regional market development are likely to capture significant growth opportunities.

Common Pitfalls When Sourcing Pre-Engineered Wood Trusses (Quality & Intellectual Property)

Sourcing pre-engineered wood trusses offers efficiency and cost savings, but overlooking critical quality and intellectual property (IP) aspects can lead to structural failures, legal disputes, and project delays. Here are key pitfalls to avoid:

Inadequate Verification of Design and Engineering Credentials

Relying on truss designs without confirming the legitimacy and qualifications of the engineering firm behind them is a major risk. Some suppliers may use unlicensed engineers or replicate designs without proper oversight, compromising structural integrity and violating building codes. Always verify that the engineering is performed by a licensed professional registered in your jurisdiction and that sealed drawings are provided.

Use of Substandard or Non-Compliant Materials

Suppliers may cut costs by using lower-grade lumber, undersized members, or connectors (like metal plates) that don’t meet ASTM or ICC-ES standards. This directly impacts truss strength and longevity. Ensure materials comply with specified grading rules (e.g., SP/SYP, DF/LF) and that connector plates meet requirements for thickness, coating, and embedment depth.

Lack of Traceability and Documentation

Failing to obtain complete documentation—including sealed engineering drawings, material certifications, and load calculations—creates liability issues. Without proper records, proving compliance during inspections or in case of failure becomes difficult. Demand full traceability from the supplier, including batch numbers and third-party testing reports where applicable.

Intellectual Property Infringement

Some manufacturers or fabricators reproduce truss designs protected by copyright or proprietary software without authorization. Using such designs exposes the builder or developer to legal action from the original design owner. Always confirm that the supplier holds the rights to the designs or has appropriate licensing agreements in place.

Poor Manufacturing Quality Control

Inconsistent welding of connector plates, improper joint alignment, or inaccurate cutting can significantly weaken trusses. Facilities without rigorous quality assurance programs (e.g., SBCA QCP certification) may deliver trusses that look adequate but fail under load. Audit the manufacturer’s quality control processes and certifications before awarding contracts.

Incomplete or Miscommunicated Design Assumptions

Truss designs are based on specific load conditions, support configurations, and environmental factors. If site-specific conditions (e.g., snow load, wind uplift, or point loads from equipment) are not clearly communicated or incorporated, the trusses may be inadequately engineered. Ensure a collaborative design review process involving architects, engineers, and truss fabricators.

Failure to Protect Custom or Proprietary Designs

If your project involves custom truss configurations developed in-house or by a design consultant, failing to assert IP ownership or use licensing agreements can allow suppliers to reuse or resell the design. Clearly define IP rights in contracts and require confidentiality and non-disclosure from suppliers.

Logistics & Compliance Guide for Pre-Engineered Wood Trusses

This guide outlines the key logistics considerations and compliance requirements for the successful procurement, transportation, handling, storage, and installation of pre-engineered wood trusses.

Material Specifications and Compliance

Pre-engineered wood trusses must conform to recognized industry standards and project specifications. Key compliance benchmarks include:

– Design Standards: Trusses must be designed in accordance with the latest editions of the International Building Code (IBC) and referenced standards such as ANSI/TPI 1 (National Design Standard for Metal Plate Connected Wood Trusses).

– Engineered Sealed Plans: Each truss design must be certified by a licensed professional engineer and include a stamped engineering drawing specifying load capacities, deflection criteria, and connection details.

– Material Quality: Lumber used in trusses must meet established grading rules (e.g., from ALSC, NHLA, or DOC) and be properly identified with grade stamps. Metal connector plates must comply with ASTM A153 or ASTM A653 standards.

– Moisture Content: Lumber should be manufactured and shipped with moisture content between 12% and 19% to minimize warping and dimensional changes post-installation.

Transportation and Delivery Logistics

Proper planning for transport is essential to prevent damage and ensure timely installation:

– Load Securing: Trusses must be securely strapped and braced on delivery vehicles to prevent shifting, bending, or impact damage during transit. Use of edge protectors is recommended.

– Delivery Scheduling: Coordinate delivery with the construction schedule to minimize on-site storage time. Deliver trusses as close as possible to the installation date.

– Site Access: Ensure the delivery route and job site allow adequate clearance for large flatbed trucks and crane or forklift access for unloading.

– Documentation: Verify that delivery includes material test reports, engineered drawings, and a detailed truss layout plan for field verification.

On-Site Handling and Storage

Improper handling is a leading cause of truss damage. Follow these best practices:

– Unloading: Use lifting straps or spreader bars to lift entire bundles; never lift individual trusses by their ends. Avoid forklift tines directly contacting truss members.

– Storage Location: Store trusses on level, well-drained ground. Elevate bundles on sleepers (at least 6 inches off the ground) to prevent moisture absorption and pest infestation.

– Protection from Elements: Cover stored trusses with breathable construction fabric or tarps—avoid plastic sheeting that can trap moisture. Ensure ends are protected from rain.

– Stacking: Limit stack height to prevent crushing. Do not stack more than one bundle high unless specifically designed for multi-tier storage with adequate support.

Installation and Field Compliance

Correct installation ensures structural integrity and compliance with design intent:

– Temporary Bracing: Install permanent and temporary bracing per the truss manufacturer’s instructions and engineering drawings. Lateral stability during construction is critical.

– Alignment and Support: Verify wall plate alignment and bearing conditions before setting trusses. Ensure supports are level and properly spaced.

– Mechanical Fastening: Use specified connector plates, nails, and adhesives. Field modifications are strictly prohibited without written approval from the truss designer.

– Inspections: Schedule framing inspections by the Authority Having Jurisdiction (AHJ) prior to enclosing walls or applying roofing.

Regulatory and Safety Compliance

Adherence to safety and regulatory standards protects workers and ensures project legality:

– OSHA Requirements: Comply with fall protection, scaffolding, and material handling regulations during truss installation.

– Building Department Submittals: Submit approved truss drawings, calculations, and compliance statements as part of the building permit package.

– Traceability and Recordkeeping: Maintain copies of engineering stamps, material certifications, and delivery receipts for audit and warranty purposes.

Quality Assurance and Documentation

A documented quality process ensures accountability and long-term performance:

– Pre-Installation Review: Conduct a site meeting with the truss supplier, builder, and supervisor to review logistics, layout, and safety protocols.

– As-Built Verification: Confirm truss placement matches the layout plan and note any field deviations with engineer-approved solutions.

– Warranty and Support: Retain all manufacturer warranties and service contacts for post-installation support and potential claims.

By following this logistics and compliance guide, construction teams can ensure the safe, efficient, and code-compliant use of pre-engineered wood trusses in building projects.

Conclusion for Sourcing Pre-Engineered Wood Trusses:

Sourcing pre-engineered wood trusses offers a highly efficient, cost-effective, and reliable solution for modern construction projects. These trusses provide superior design precision, structural integrity, and consistency due to their factory-controlled manufacturing process. By leveraging advanced engineering software and standardized production techniques, pre-engineered trusses reduce on-site labor, minimize material waste, and accelerate project timelines.

Additionally, sourcing from reputable suppliers ensures compliance with building codes and industry standards, enhancing overall safety and performance. The ability to customize truss designs to meet specific architectural and load requirements further increases their versatility across residential, commercial, and industrial applications.

In conclusion, investing in pre-engineered wood trusses not only improves construction efficiency and quality but also contributes to sustainable building practices. Careful selection of suppliers based on experience, certification, and technical support is key to maximizing these benefits and ensuring long-term project success.