The global power sockets market is experiencing robust growth, driven by rising electricity demand, rapid urbanization, and increased investments in residential, commercial, and industrial infrastructure. According to a report by Mordor Intelligence, the global electrical sockets and switches market was valued at approximately USD 33.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. Similarly, Grand View Research estimates the market to expand at a CAGR of 6.4% during the 2023–2030 period, fueled by the adoption of smart building technologies and energy-efficient electrical components. With Asia-Pacific leading in both production and consumption due to extensive construction activities and government-led electrification initiatives, the competitive landscape features a mix of established multinational manufacturers and regional players innovating in smart, modular, and sustainable socket solutions. In this evolving market, identifying the top power sockets manufacturers becomes essential for professionals seeking reliability, compliance, and technological advancement.

Top 10 Power Sockets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High Performance Products for Industrial Applications

Domain Est. 1996

Website: mennekes.com

Key Highlights: MENNEKES is a world-leading manufacturer of pin and sleeve wiring devices, switched and interlocked receptacles, disconnect switches and power distribution ……

#2 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#3 MEAN WELL Switching Power Supply Manufacturer

Domain Est. 1997

Website: meanwell.com

Key Highlights: MEAN WELL is one of the world’s few standard power supply mainly professional manufacturers, covering 0.5 to 25600W products are widely used in industrial ……

#4 Leviton

Domain Est. 1995

Website: leviton.com

Key Highlights: Leviton offers a wide range of lighting controls, wiring devices and networking to meet the needs of today’s residential, commercial and industrial ……

#5 Eaton: Electrical and Industrial

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton is an intelligent power management company dedicated to improving the quality of life and protecting the environment for people everywhere. We are ……

#6 Wall Industries

Domain Est. 1998 | Founded: 1961

Website: wallindustries.com

Key Highlights: Leading Manufacturer of Power Supplies and Converters. Wall Industries has been designing and manufacturing power supplies in the US since 1961….

#7 Plugs and sockets

Domain Est. 1997

Website: catalogue.bals.com

Key Highlights: A large selection of Bals connectors. We manufacture plugs and sockets in different variants and thus cover all your needs for different connection solutions ……

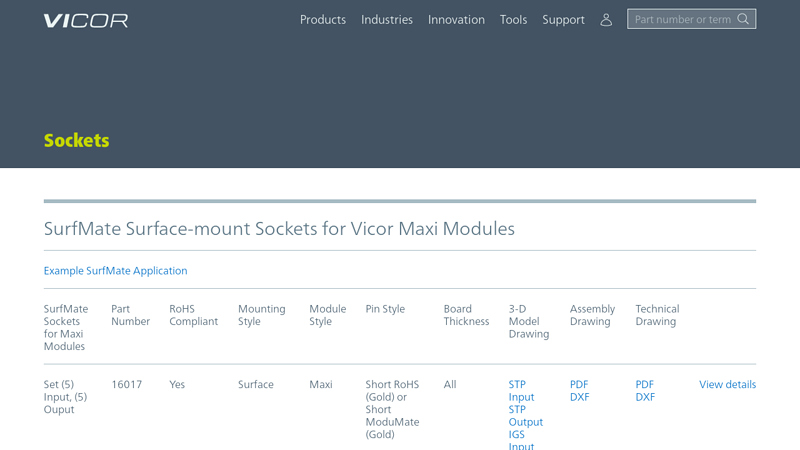

#8 Sockets for Power Modules

Domain Est. 2001

Website: vicorpower.com

Key Highlights: Surface mount and through-hole sockets for Vicor power modules and components. Surfmate Sockets for Maxi modules:16017, 22101 Surfmate Sockets for Mini ……

#9 Milbank

Domain Est. 2012 | Founded: 1927

Website: milbankworks.com

Key Highlights: Founded in 1927 by Charlie Milbank, Milbank Manufacturing sets the standard for quality metering equipment and enclosures….

#10 World plugs

Website: iec.ch

Key Highlights: Select a location, electric potential or frequency to discover what plug type(s), voltage and frequency are used there….

Expert Sourcing Insights for Power Sockets

2026 Market Trends for Power Sockets

The global power sockets market is poised for significant evolution by 2026, driven by technological advancements, shifting consumer demands, and a growing emphasis on sustainability and energy efficiency. Key trends shaping the landscape include the rapid adoption of smart sockets, integration with renewable energy systems, heightened focus on safety standards, and the expansion of USB-C charging capabilities.

Smart and Connected Sockets Leading Innovation

Smart power sockets are expected to dominate market growth by 2026, fueled by the expansion of smart home ecosystems and the Internet of Things (IoT). Consumers and businesses alike are increasingly adopting Wi-Fi and Bluetooth-enabled sockets that allow remote control, energy monitoring, and automation via smartphone apps or voice assistants like Alexa and Google Assistant. Advanced features such as usage analytics, scheduling, and integration with home energy management systems will enhance user convenience and support energy-saving goals.

Rise of USB-C and Multi-Port Integration

As mobile and portable electronics standardize around USB-C, power sockets are evolving to incorporate multiple USB-C ports alongside traditional AC outlets. By 2026, hybrid sockets featuring high-wattage USB-C PD (Power Delivery) capable of charging laptops, tablets, and smartphones quickly will become commonplace in homes, offices, and public spaces. This trend reduces reliance on bulky adapters and streamlines charging solutions.

Sustainability and Energy Efficiency Driving Design

Environmental concerns are pushing manufacturers toward eco-friendly materials and energy-efficient designs. Power sockets with built-in power-saving modes—such as auto-shutoff when devices are fully charged or motion sensing to cut power in unoccupied rooms—are gaining traction. Additionally, demand for sockets compatible with solar power systems and energy storage units is rising, especially in regions with strong renewable energy adoption.

Enhanced Safety Standards and Global Harmonization

Safety remains a critical focus, with stricter regulations being implemented worldwide. Sockets featuring child safety shutters, surge protection, overload prevention, and fire-resistant materials are becoming standard. There is also a push toward greater international harmonization of plug and voltage standards, particularly in multinational corporations and travel-related infrastructure, although regional differences will persist.

Growth in Commercial and Industrial Applications

Beyond residential use, the commercial and industrial sectors are driving demand for advanced power socket solutions. Data centers, EV charging stations, and smart buildings require high-capacity, intelligent power distribution units (PDUs) with remote monitoring and load balancing capabilities. The rollout of electric vehicle (EV) charging infrastructure also contributes to specialized socket development, including vehicle-to-grid (V2G) enabled outlets.

In conclusion, the 2026 power sockets market will be defined by intelligence, connectivity, sustainability, and user-centric design. Companies that innovate in smart integration, energy management, and safety will be best positioned to capture market share in this dynamic and increasingly competitive landscape.

Common Pitfalls When Sourcing Power Sockets (Quality and IP Ratings)

Sourcing power sockets—especially for industrial, commercial, or outdoor applications—requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking key factors can lead to safety hazards, product failures, compliance issues, and costly replacements. Below are common pitfalls to avoid:

Overlooking IP Rating Requirements for the Environment

One of the most frequent mistakes is selecting a power socket without matching its IP rating to the intended environment. For example, using an IP44-rated socket outdoors in heavy rain (which typically requires IP66 or higher) can lead to water ingress, short circuits, or electric shock. Always assess the exposure to dust, moisture, and physical contact to determine the correct IP rating.

Assuming Higher IP Always Means Better Quality

While a higher IP rating offers greater protection, it doesn’t automatically mean the product is of higher overall quality. Some manufacturers may boost IP ratings through design (e.g., gaskets and seals) while using substandard internal components. Always evaluate build materials, contact quality, and certifications—not just the IP number.

Ignoring Certification and Compliance Standards

Many sourced power sockets—especially from low-cost suppliers—lack proper certifications such as CE, UL, or IEC. A socket may claim an IP67 rating but fail independent testing. Always request test reports or certification documents from accredited bodies to verify compliance.

Prioritizing Cost Over Long-Term Reliability

Opting for the cheapest option often results in poor-quality materials (e.g., brittle plastics, low-grade metal contacts) that degrade quickly under thermal or mechanical stress. These sockets may work initially but fail prematurely, increasing maintenance and safety risks. Consider lifecycle cost rather than upfront price.

Inadequate Protection Against Environmental Stress

Even with a suitable IP rating, sockets may not be designed for extreme temperatures, UV exposure, or chemical environments. For example, a socket rated IP66 may resist water jets but degrade in sunlight if not UV-stabilized. Ensure the housing material (e.g., polycarbonate, thermoset) is appropriate for the operating conditions.

Poor Sealing Design and Gasket Quality

A high IP rating depends heavily on effective sealing. Low-quality gaskets or poorly designed enclosures can compress unevenly or degrade over time, compromising protection. Inspect samples for consistent gasket thickness, proper compression fit, and material resistance to aging.

Misunderstanding IP Rating Limitations

IP ratings don’t cover all risks—such as impact resistance (IK rating), voltage rating, or fire resistance. A socket with IP68 may still be vulnerable to physical damage or fire if not rated accordingly. Always cross-check with mechanical and electrical specifications.

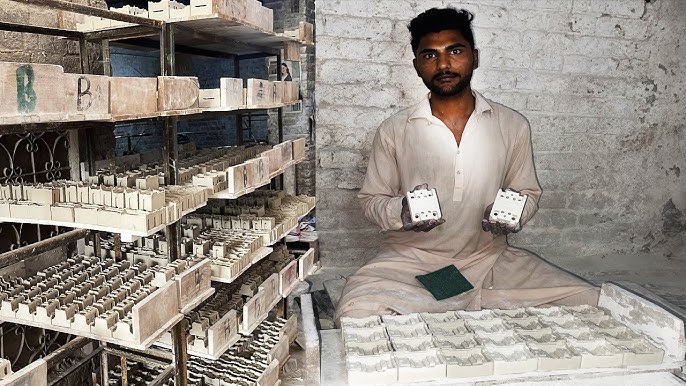

Sourcing from Unverified Suppliers

Purchasing from unknown or unverified manufacturers increases the risk of counterfeit or misrepresented products. Conduct supplier audits, request samples, and verify factory certifications to ensure authenticity and consistent quality.

Failing to Test Samples Under Real Conditions

Even with documentation, real-world performance can differ. Always test prototype units under simulated operating conditions—such as temperature cycling, water spray, or dust exposure—to validate performance before bulk procurement.

Neglecting Maintenance and Serviceability

High-IP-rated sockets often have sealed designs that make inspection or repair difficult. Consider whether the socket allows for periodic maintenance or replacement of seals without compromising integrity—especially in critical or hard-to-access installations.

Logistics & Compliance Guide for Power Sockets

Power sockets, whether sold as standalone components or integrated into electrical products, are subject to stringent logistics and compliance requirements due to safety, regulatory, and international trade considerations. This guide outlines key aspects to ensure safe handling, transportation, import/export, and regulatory adherence.

Regulatory Compliance

Power sockets must meet electrical safety, performance, and environmental standards depending on the target market. Key regulations include:

- IEC 60884 Series (International): Defines general requirements for plugs and socket-outlets for household and similar purposes.

- UL 498 (USA): Standard for attachment plugs and receptacles; products typically require UL listing.

- BS 1363 (UK): Specifies requirements for 13A fused plugs and associated socket outlets.

- AS/NZS 3112 (Australia/New Zealand): Covers plug and socket-outlet systems used in these regions.

- GB 2099 & GB 1002 (China): Chinese national standards for plugs and sockets.

- RoHS & REACH (EU): Restricts hazardous substances in electrical equipment; compliance is mandatory for CE marking.

- Energy Efficiency & Labeling: Some regions require energy efficiency compliance if the socket includes smart or power management features.

Ensure all products have necessary certifications (e.g., CE, UKCA, CCC, KC, INMETRO) before entering the market. Documentation such as test reports, declarations of conformity, and technical files must be maintained.

Product Labeling & Packaging

Proper labeling ensures traceability and compliance:

- Clearly display voltage, current, frequency, and model number on the product.

- Include certification marks (e.g., CE, UL, CCC) as required.

- Provide multilingual user instructions and safety warnings for international markets.

- Use packaging that prevents physical damage during transit and complies with environmental regulations (e.g., recyclable materials, no restricted substances).

Logistics & Transportation

Due to the electrical nature of power sockets, specific handling and shipping protocols apply:

- Classification: Most power sockets are non-hazardous but verify with UN/DOT classifications if containing batteries or electronic components.

- Packaging Requirements: Use anti-static and moisture-resistant materials to protect against environmental damage. Ensure secure packaging to prevent short circuits.

- Storage Conditions: Store in dry, temperature-controlled environments (typically 10°C–30°C, <75% RH) to prevent corrosion or material degradation.

- Shipping Documentation: Include commercial invoices, packing lists, and certificates of conformity. For regulated markets, provide test reports and import permits.

- Customs Clearance: Accurately classify goods using HS codes (e.g., 8536.69 for electrical apparatus for switching or protecting electrical circuits). Be prepared for inspections, especially in regulated markets like China, India, or the EU.

Import & Export Controls

- Tariff & Duties: Research applicable import duties and taxes; some countries offer reduced rates for components under free trade agreements.

- Product Restrictions: Certain plug types may be restricted or banned in specific countries due to safety concerns.

- Local Representation: In markets like the EU, appoint an Authorised Representative; in China, a local agent may be required for CCC certification.

- EPR Compliance: In the EU and other regions, comply with Extended Producer Responsibility schemes for WEEE (Waste Electrical and Electronic Equipment).

Quality Assurance & Traceability

- Implement lot tracking and serial numbering for recalls and warranty claims.

- Conduct periodic audits and product sampling to verify ongoing compliance.

- Maintain records of supplier qualifications, component sourcing, and quality inspections.

End-of-Life & Sustainability

- Design for recyclability and comply with local take-back schemes.

- Provide clear disassembly and disposal instructions.

- Report to relevant WEEE authorities where required.

Adhering to this logistics and compliance framework minimizes risks, avoids customs delays, and ensures market access for power socket products globally. Always consult local regulatory experts for market-specific requirements.

In conclusion, sourcing power sockets requires careful consideration of several key factors including safety standards and certifications, compatibility with regional electrical systems, quality of materials, cost-effectiveness, and supplier reliability. Ensuring compliance with local regulations such as UL, CE, or CCC is essential to guarantee user safety and legal adherence. Additionally, evaluating suppliers based on reputation, production capacity, and ability to meet volume and delivery requirements is crucial for long-term success. By balancing cost with quality and prioritizing safety and reliability, businesses can effectively source power sockets that meet technical, operational, and regulatory needs while minimizing risks and supporting sustainable procurement practices.