The global power tools market, driven by increasing construction activity and demand for efficient renovation solutions, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. Within this expanding landscape, drywall finishing has emerged as a key application area fueling demand for specialized power sanders. With the rise in residential and commercial building projects—particularly in North America and Asia-Pacific—contractors are prioritizing tools that offer precision, dust control, and operator comfort. As the construction sector increasingly adopts time-saving and high-quality finishing techniques, the need for reliable, high-performance drywall sanders has intensified. This demand has catalyzed innovation among manufacturers, positioning a select group of brands at the forefront of engineering and market share. Based on production scale, technological advancement, and industry reputation, the following eight manufacturers represent the leading players in the power sander market specifically for drywall applications.

Top 8 Power Sander On Drywall Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sanders

Domain Est. 1996

Website: boschtools.com

Key Highlights: Bosch sanders are built tough for both professional and industrial use, including applications like auto body repair, furniture manufacturing, and metalworking….

#2 Abrasives

Domain Est. 1995

Website: rustoleum.com

Key Highlights: Find sandpaper, cutting and grinding tools, and abrasives for floors, drywall, vehicles and power sanders. Automotive Abrasives. Gator automotive sanding ……

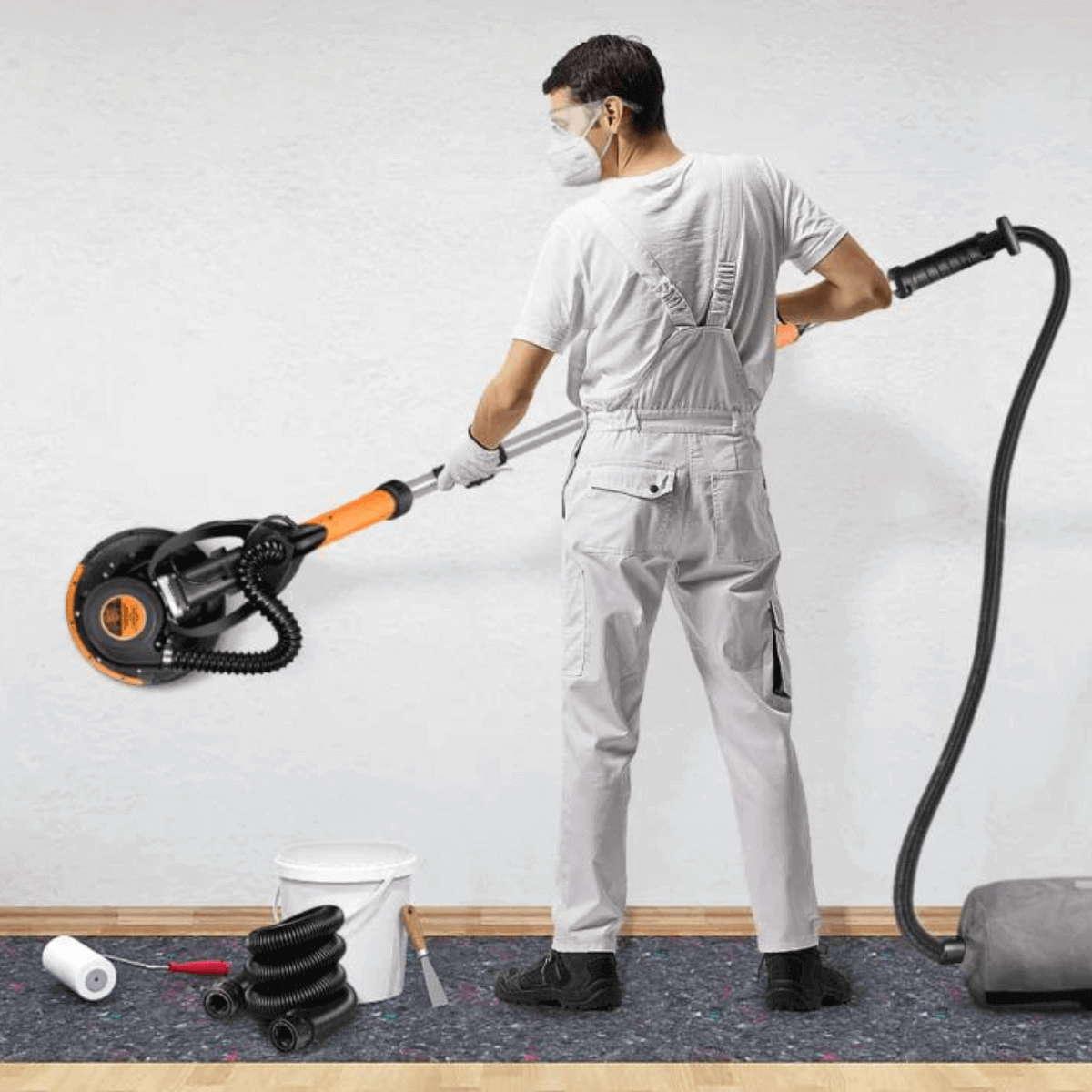

#3 Mirka® LEROS Wall & Ceiling and Drywall Sander

Domain Est. 1997

Website: mirka.com

Key Highlights: Mirka LEROS – the lightest and most advanced wall and ceiling sander. This unique brushless sander features innovative solutions, including a sanding head ……

#4 Drywall construction

Domain Est. 1997

Website: metabo.com

Key Highlights: Light and practical with innovative dust extraction. Adjusts to three working lengths to suit various room heights and sizes. More details on long-neck sanders ……

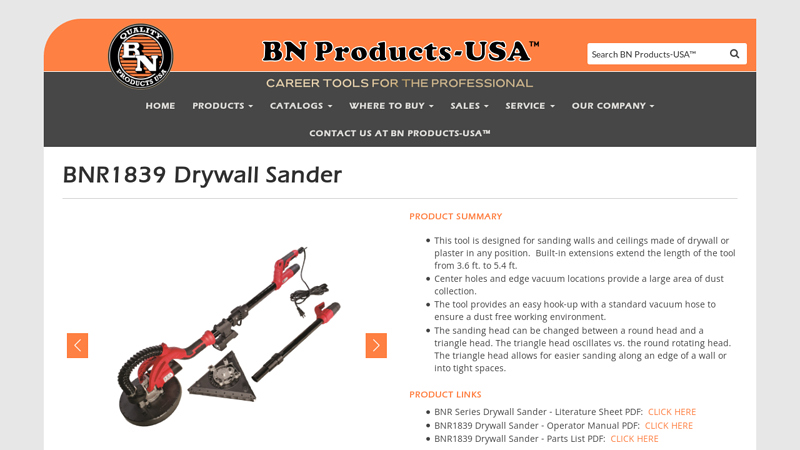

#5 BNR1839 Drywall Sander

Domain Est. 1999

Website: bnproducts.com

Key Highlights: This tool is designed for sanding walls and ceilings made of drywall or plaster in any position. · Center holes and edge vacuum locations provide a large area of ……

#6 Search

Domain Est. 2000

Website: milwaukeetool.com

Key Highlights: Drywall Setters · SHOCKWAVE™ Bit Holders/Extensions · SHOCKWAVE™ Nut Drivers … Power ToolsMX FUEL™ EquipmentBatteries and ChargersSite LightingOutdoor ……

#7 Sheetrock Tools Drywall Pole Sander

Domain Est. 2001

Website: alstapingtools.com

Key Highlights: In stock Free deliverySheetrock Tools Drywall Pole Sander The drywall industries premium brand brings you an exceptionally engineered pole sander built to perform….

#8 Drywall sanders

Domain Est. 2004

Website: festoolusa.com

Key Highlights: Festool professional drywall sanders make wall and ceiling sanding fast, clean, and effortless with powerful brushless motors and nearly dust-free operation. ……

Expert Sourcing Insights for Power Sander On Drywall

H2: 2026 Market Trends for Power Sanders on Drywall

The global market for power sanders used in drywall applications is poised for notable transformation by 2026, driven by advancements in technology, sustainability demands, and shifts in construction practices. This analysis explores key trends shaping the sector, focusing on innovation, market dynamics, regional developments, and consumer behavior.

Technological Advancements and Product Innovation

By 2026, manufacturers are expected to prioritize smart integration and automation in drywall power sanders. Features such as IoT connectivity, dust monitoring sensors, and real-time performance feedback will become standard in premium models. Cordless, battery-powered sanders with extended runtimes and faster charging—enabled by lithium-ion and emerging solid-state battery technologies—will dominate the market, offering contractors greater mobility and reduced downtime. Additionally, improved ergonomic designs, including vibration dampening and lightweight composites, will enhance user comfort during prolonged use, addressing occupational health concerns.

Emphasis on Dust Control and Environmental Compliance

Regulatory pressure and growing awareness of indoor air quality are accelerating demand for dust-containment systems. Power sanders with integrated HEPA filtration and vacuum-sealed systems will see increased adoption, especially in residential renovations where health and cleanliness are paramount. By 2026, compliance with EPA RRP (Renovation, Repair, and Painting) rules and similar international standards will be a key selling point, pushing manufacturers to innovate in zero-emission sanding solutions.

Growth in Residential Renovation and DIY Markets

The continued surge in home improvement projects—fueled by remote work trends and aging housing stock—will expand the consumer segment for drywall sanders. Entry-level and mid-tier power sanders tailored for DIY users, featuring simplified controls, safety mechanisms, and compact designs, will gain market share. Online retail platforms and subscription-based tool services may further boost accessibility, especially in North America and Western Europe.

Regional Market Dynamics

North America will remain a leading market due to high construction activity and stringent safety regulations. Meanwhile, the Asia-Pacific region—particularly China and India—will experience rapid growth, driven by urbanization and infrastructure development. Local manufacturing and affordable product variants will be critical for success in emerging markets. Europe will emphasize eco-design and energy efficiency, aligning with EU Green Deal objectives.

Competitive Landscape and Strategic Moves

By 2026, consolidation among tool manufacturers and strategic partnerships with drywall material suppliers could emerge. Brands like DeWalt, Makita, and Bosch are likely to expand their specialized drywall sander lines, while new entrants may focus on niche innovations such as robotic sanding arms or AI-assisted surface analysis. Rental platforms and tool-as-a-service (TaaS) models may also disrupt traditional ownership patterns, especially among small contractors.

Conclusion

The 2026 market for power sanders on drywall will be defined by smarter, cleaner, and more user-centric tools. As sustainability and efficiency take center stage, manufacturers that invest in innovation, regulatory compliance, and market-specific solutions will lead the industry. The convergence of professional needs and DIY accessibility will create a diverse and dynamic marketplace, positioning power sanders as essential tools in modern construction and renovation.

Common Pitfalls Sourcing a Power Sander for Drywall (Quality and IP)

When sourcing a power sander for drywall applications, overlooking key quality and Ingress Protection (IP) factors can lead to poor performance, safety hazards, and reduced equipment lifespan. Here are the most common pitfalls to avoid:

Choosing Low-Quality Materials and Construction

Many budget-friendly drywall sanders are built with subpar materials and lack durability. Users often encounter plastic housings that crack under stress, poorly balanced motors that cause excessive vibration, and sanding pads that wear out quickly or fail to maintain flat contact with the wall. These quality issues not only reduce finish quality but also increase maintenance costs and downtime.

Ignoring Ingress Protection (IP) Ratings

A frequent oversight is selecting a sander without appropriate IP protection. Drywall sanding generates fine dust that can infiltrate motor components and electrical systems. Tools with low or no IP rating (e.g., IP20) are vulnerable to dust ingress, leading to overheating, motor failure, or electrical hazards. For drywall work, a minimum of IP5X (dust protected) is advisable, with IP54 or higher being ideal to guard against both dust and incidental water exposure from cleaning.

Overlooking Dust Extraction Compatibility

Even with a high IP rating, a sander that isn’t designed for effective dust extraction compromises both air quality and tool longevity. Some models lack proper seals or dust ports compatible with standard vacuum systems, rendering integrated dust control ineffective. This pitfall increases health risks from airborne silica and reduces visibility during operation.

Assuming All Sanders Are Suitable for Drywall

Not all power sanders are designed for drywall’s specific demands. Orbital or random orbit sanders meant for woodwork may be too aggressive, damaging paper-faced drywall. Selecting a tool without a variable speed control or a dedicated drywall sanding head (e.g., pole sander with a flat platen) results in uneven finishes and unnecessary surface damage.

Failing to Verify Motor Longevity and Cooling

Low-quality motors in poorly ventilated housings tend to overheat during extended drywall jobs. Lack of thermal protection or inadequate cooling—exacerbated by dust accumulation due to poor IP ratings—leads to premature motor burnout. Always verify motor specifications and cooling mechanisms, especially for continuous use.

By addressing these pitfalls—prioritizing robust build quality, adequate IP protection, and drywall-specific design features—you ensure a safer, more efficient, and longer-lasting sanding solution.

Logistics & Compliance Guide for Power Sander on Drywall

Product Overview

A power sander used for drywall applications is a handheld electric or pneumatic tool designed to smooth joint compound, feather drywall seams, and prepare surfaces for painting. Common types include pole sanders, orbital sanders, and detail sanders equipped with dust collection systems.

Regulatory Compliance Requirements

Occupational Safety and Health Administration (OSHA)

- Respiratory Protection (29 CFR 1910.134): Operators must wear NIOSH-approved respirators when engineering controls (e.g., dust extractors) do not reduce airborne silica and drywall dust below permissible exposure limits (PELs).

- Hazard Communication (29 CFR 1910.1200): Employers must provide training on hazards associated with drywall dust, including crystalline silica and gypsum particulates.

- General Duty Clause: Employers must ensure a workplace free from recognized hazards, including excessive dust exposure during sanding operations.

Environmental Protection Agency (EPA) – Renovation, Repair, and Painting (RRP) Rule

- Applicability: If working in pre-1978 housing or child-occupied facilities, lead-based paint may be present beneath drywall patches. The EPA RRP rule requires certified renovators and lead-safe work practices.

- Containment & Cleanup: Use plastic sheeting, HEPA vacuuming, and wet methods to minimize dust spread. Prohibit dry sweeping.

- Certification: Contractors must be EPA RRP-certified, and firms must be registered.

National Emission Standards for Hazardous Air Pollutants (NESHAP) – Subpart TTT

- Asbestos Awareness: While modern drywall does not contain asbestos, older buildings may have asbestos-containing materials (ACMs) near walls or joints. If ACMs are disturbed during sanding, EPA NESHAP and OSHA asbestos standards (29 CFR 1910.1001) apply.

- Pre-Renovation Inspection: Required before drywall work in structures built before 1981.

Equipment Standards and Certification

Electrical Safety (UL & CSA)

- Power sanders must be certified by Underwriters Laboratories (UL) or Canadian Standards Association (CSA) for electrical safety.

- Tools used in damp locations must meet UL 60745 standards for portable motor-operated tools.

Dust Extraction and Air Quality

- HEPA Filtration: Dust extractors used with sanders must have HEPA filters (99.97% efficient at 0.3 microns) to capture fine particulates.

- California Air Resources Board (CARB): Cordless sanders with lithium-ion batteries must comply with CARB battery regulations if sold or used in California.

Transportation and Shipping

Domestic Shipping (US)

- Power sanders may be shipped via ground or air freight depending on battery type.

- Lithium-Ion Batteries: Must comply with DOT 49 CFR Part 173 for hazardous materials when shipped in quantity. Labels, packaging, and documentation required.

- Class 9 Hazardous Materials: Lithium batteries are classified as Class 9; limited quantities may be exempt with proper packaging.

International Shipping (IMDG, IATA)

- For air transport, adhere to IATA Dangerous Goods Regulations (DGR).

- For sea transport, comply with IMDG Code.

- Ensure batteries are installed in tools or packed separately per PI 965/PI 966/PI 967.

Workplace Use and Handling Procedures

Personal Protective Equipment (PPE)

- Respirator (N95 or P100)

- Safety goggles or face shield

- Hearing protection (if noise exceeds 85 dB)

- Gloves and long-sleeve clothing

Dust Control Best Practices

- Always use a sander with an integrated dust collection system.

- Connect to a HEPA-rated vacuum.

- Perform wet sanding when feasible to suppress dust.

- Clean work area with HEPA vacuum post-sanding.

Tool Maintenance & Inspection

- Inspect cords, switches, and dust ports before each use.

- Replace worn sanding pads and filters regularly.

- Store in dry, secure location to prevent damage.

Disposal and Environmental Responsibility

Used Sanding Discs and Filters

- Dispose of used sanding discs and filters as construction debris unless contaminated with lead or asbestos.

- If hazardous materials are present, dispose as hazardous waste per RCRA regulations.

End-of-Life Equipment

- Recycle power sanders through certified e-waste programs.

- Remove and recycle lithium-ion batteries separately at approved facilities (e.g., Call2Recycle).

Training and Documentation

Required Training

- OSHA 10-Hour Construction Safety Certification.

- EPA RRP Certification (if applicable).

- In-house training on tool operation, dust hazards, and emergency procedures.

Recordkeeping

- Maintain logs of equipment maintenance, worker training, and air monitoring (if required).

- Keep copies of safety data sheets (SDS) for drywall compounds and related materials.

Summary

Compliance when using a power sander on drywall involves adherence to OSHA, EPA, and transportation regulations focusing on dust control, hazardous materials, and worker safety. Proper logistics—from shipping with lithium batteries to end-of-life disposal—ensure legal and environmental responsibility. Regular training and documentation are essential components of a compliant drywall sanding operation.

In conclusion, sourcing a power sander for drywall work is a crucial step in achieving a smooth, professional finish efficiently. Selecting the right type of sander—such as a pole sander, orbital sander, or drywall vacuum sander—depends on the scale of the project, accessibility, and desired dust control. Key factors to consider include dust extraction capabilities, ease of use, adjustable speed settings, and compatibility with different sandpaper grits. Additionally, investing in a high-quality, durable model with strong user reviews can enhance productivity and reduce long-term costs. Whether purchasing or renting, it’s important to evaluate reliability, brand reputation, and after-sales support. Proper sourcing ensures not only improved workmanship but also safer working conditions through reduced dust exposure, ultimately contributing to a faster, cleaner, and more effective drywall finishing process.