The global power plug and connector market is experiencing steady growth, driven by rising demand across consumer electronics, automotive, industrial equipment, and renewable energy sectors. According to a 2023 report by Mordor Intelligence, the global electrical connectors market was valued at USD 75.6 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028. Increasing electrification, coupled with the expansion of electric vehicles and smart infrastructure, continues to fuel demand for reliable and standardized power plug connectors. In parallel, Grand View Research reports that the global plug and socket outlet market size reached USD 35.2 billion in 2022 and is expected to expand at a CAGR of 6.1% over the same period, underscoring the importance of innovation and compliance in connector design. With diverse regional standards and performance requirements, manufacturers must balance global scalability with local regulatory adherence. This evolving landscape positions leading players at the forefront of technological advancement and supply chain integration—shaping the future of safe, efficient power transmission. Below are the top 10 power plug connector type manufacturers leading this transformation.

Top 10 Power Plug Connector Types Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Meltric

Domain Est. 1997

Website: meltric.com

Key Highlights: MELTRIC offers a full line of industrial plugs and receptacles, including our signature brand of UL-listed Switch-Rated devices with DECONTACTOR™ ……

#2 Connectors

Domain Est. 1996

Website: phoenixcontact.com

Key Highlights: Wide variety of connectors: from versatile circular connectors (M5 to M58), data, energy storage, and photovoltaic connectors to heavy-duty industrial ……

#3 Types of Electrical Connectors and Wire Connectors

Domain Est. 1992

Website: te.com

Key Highlights: From USB connectors and RJ45 connectors to TE’s DEUTSCH connectors and AMP connectors, we design and manufacture the electrical connectors and wire connectors ……

#4 Connectors

Domain Est. 1994

Website: molex.com

Key Highlights: Molex offers a wide variety of Board-to-Board Connectors for microminiature, high-speed, high-density, and high-power applications….

#5 Connectors

Domain Est. 1996

Website: amphenol.com

Key Highlights: Our wide array of electrical and electronic connectors come in multiple form factors and are designed to meet the latest market needs….

#6 Electrical and Electronic Connectors

Domain Est. 1996

Website: hirose.com

Key Highlights: Connector Selector Categories, Applications, Customer Support, Partners, Locations, Contact Us, Privacy Policy | Terms of Use | Membership Agreement…

#7 Powerpole Connector Series

Domain Est. 1996

Website: andersonpower.com

Key Highlights: This versatile connector series invented by Anderson Power meets a wide range of power connection needs. The four housing sizes in the Powerpole product family ……

#8 Fischer Connectors

Domain Est. 1997

Website: fischerconnectors.com

Key Highlights: Fischer Connectors provide end-to-end interconnect solutions for ecosystems requiring local transfer and management of data, signals & power….

#9 Power Connector

Domain Est. 2003

Website: powerconnector.com

Key Highlights: Use parametric search tools to browse the entire line of PCI connectors in one place, including specialty connectors not found in our other product series….

#10 Winchester Interconnect

Domain Est. 2016

Website: winconn.com

Key Highlights: Let’s Build It Together. From concept to production, we design and manufacture tailored interconnect systems for demanding, high-performance applications….

Expert Sourcing Insights for Power Plug Connector Types

H2: 2026 Market Trends for Power Plug Connector Types

As the global demand for energy-efficient, safe, and standardized electrical systems continues to rise, the power plug connector market is undergoing significant transformation heading into 2026. Driven by technological advancements, regulatory changes, and shifting consumer preferences, several key trends are shaping the landscape of power plug and connector types.

-

Increased Adoption of Universal and Standardized Connectors

One of the most prominent trends in 2026 is the global push toward standardization. The European Union’s mandate for a common charging solution, primarily based on USB Type-C for portable devices, is extending influence into broader power connector applications. This standardization effort is reducing e-waste and improving consumer convenience, encouraging manufacturers to adopt universal connectors across multiple device categories. -

Growth in Smart and IoT-Enabled Connectors

The integration of smart technologies into power connectors is accelerating. By 2026, smart plugs and connectors with built-in energy monitoring, Wi-Fi/Bluetooth connectivity, and remote control capabilities are becoming mainstream, especially in residential and commercial smart building ecosystems. These intelligent connectors support energy management systems and align with global sustainability goals. -

Rise of High-Power and Fast-Charging Connectors

With the electric vehicle (EV) market expanding rapidly, high-power connectors such as the North American Charging Standard (NACS) and the Combined Charging System (CCS) are seeing widespread deployment. In 2026, NACS is expected to dominate the North American EV market, while CCS remains strong in Europe. Simultaneously, fast-charging connectors for consumer electronics—supporting protocols like USB PD (Power Delivery)—are becoming standard features in laptops, smartphones, and tablets. -

Expansion of Industrial and Harsh Environment Connectors

In industrial sectors, demand is growing for ruggedized, waterproof, and dustproof power connectors (e.g., IP67 and IP68-rated) used in automation, renewable energy installations, and outdoor infrastructure. Connectors designed to withstand extreme temperatures and vibrations are gaining traction, especially in wind and solar power applications. -

Sustainability and Material Innovation

Environmental concerns are driving innovation in connector materials. By 2026, manufacturers are increasingly using recyclable plastics, bio-based polymers, and lead-free alloys to meet RoHS and REACH compliance standards. Additionally, modular and repairable connector designs are being introduced to extend product lifecycles and reduce electronic waste. -

Regional Divergence and Regulatory Compliance

Despite global trends toward standardization, regional differences in plug types (e.g., Type A/B in North America, Type C/E/F in Europe, Type G in the UK, and Type I in Australia) persist. However, dual-voltage and multi-plug travel adapters with enhanced safety features are becoming more sophisticated, catering to international travelers and global supply chains. -

Wireless Power and Contactless Connectivity

While still emerging, wireless power transfer technologies—such as magnetic induction and resonant charging—are influencing the design of next-gen connectors. By 2026, hybrid systems that combine traditional plug-in connectors with wireless backup options are being adopted in premium consumer electronics and medical devices.

In conclusion, the 2026 power plug connector market is characterized by a convergence of standardization, digitalization, and sustainability. As industries and consumers demand safer, smarter, and more efficient energy delivery solutions, connector manufacturers are innovating rapidly to meet evolving technical and regulatory requirements across diverse applications.

Common Pitfalls Sourcing Power Plug Connector Types (Quality, IP)

Sourcing power plug connectors involves more than just matching physical dimensions—overlooking key quality and Ingress Protection (IP) factors can lead to safety hazards, product failures, and compliance issues. Here are common pitfalls to avoid:

Inadequate IP Rating for the Application Environment

Selecting a connector without considering the required Ingress Protection (IP) rating is a frequent mistake. Using an IP20-rated connector in outdoor or industrial settings exposes equipment to dust and moisture, increasing the risk of short circuits or corrosion. Always match the IP rating (e.g., IP67 for dust-tight and water immersion) to the operational environment.

Prioritizing Cost Over Quality and Certification

Choosing the cheapest available connector often results in poor materials, inconsistent tolerances, and lack of safety certifications. Low-quality connectors may overheat, degrade quickly, or fail under load. Ensure connectors are certified by recognized bodies (e.g., UL, CE, VDE) and sourced from reputable manufacturers to guarantee reliability and compliance.

Ignoring Material and Build Quality

Substandard materials such as brittle plastics or low-grade metals compromise durability and electrical performance. Poorly molded housings, weak strain reliefs, or corroding contacts can lead to premature failure. Evaluate mechanical robustness, contact plating (e.g., gold or nickel), and housing temperature resistance during selection.

Assuming Interchangeability Without Verification

While some connectors appear physically compatible, differences in pin configuration, voltage/current ratings, or safety approvals can cause incompatibility. Assuming interchangeability without verifying electrical specs and certifications may result in unsafe installations or non-compliance with regional standards.

Overlooking Long-Term Supply and Obsolescence Risks

Sourcing from suppliers with limited production runs or unclear supply chains can lead to component obsolescence. This disrupts manufacturing and increases redesign costs. Always assess supplier stability, lifecycle commitments, and availability of long-term supply agreements.

Failing to Validate Environmental and Regulatory Compliance

Connectors used in specific markets (e.g., medical, marine, or hazardous locations) may require additional certifications (e.g., RoHS, REACH, ATEX). Overlooking these requirements can delay product launches or result in regulatory penalties. Confirm full compliance with applicable regional and industry standards before finalizing sourcing decisions.

Logistics & Compliance Guide for Power Plug Connector Types

Understanding power plug connector types is essential for global logistics, product compliance, and safe operation of electrical equipment across international markets. This guide outlines key considerations for sourcing, shipping, and ensuring regulatory compliance of devices with varying plug types.

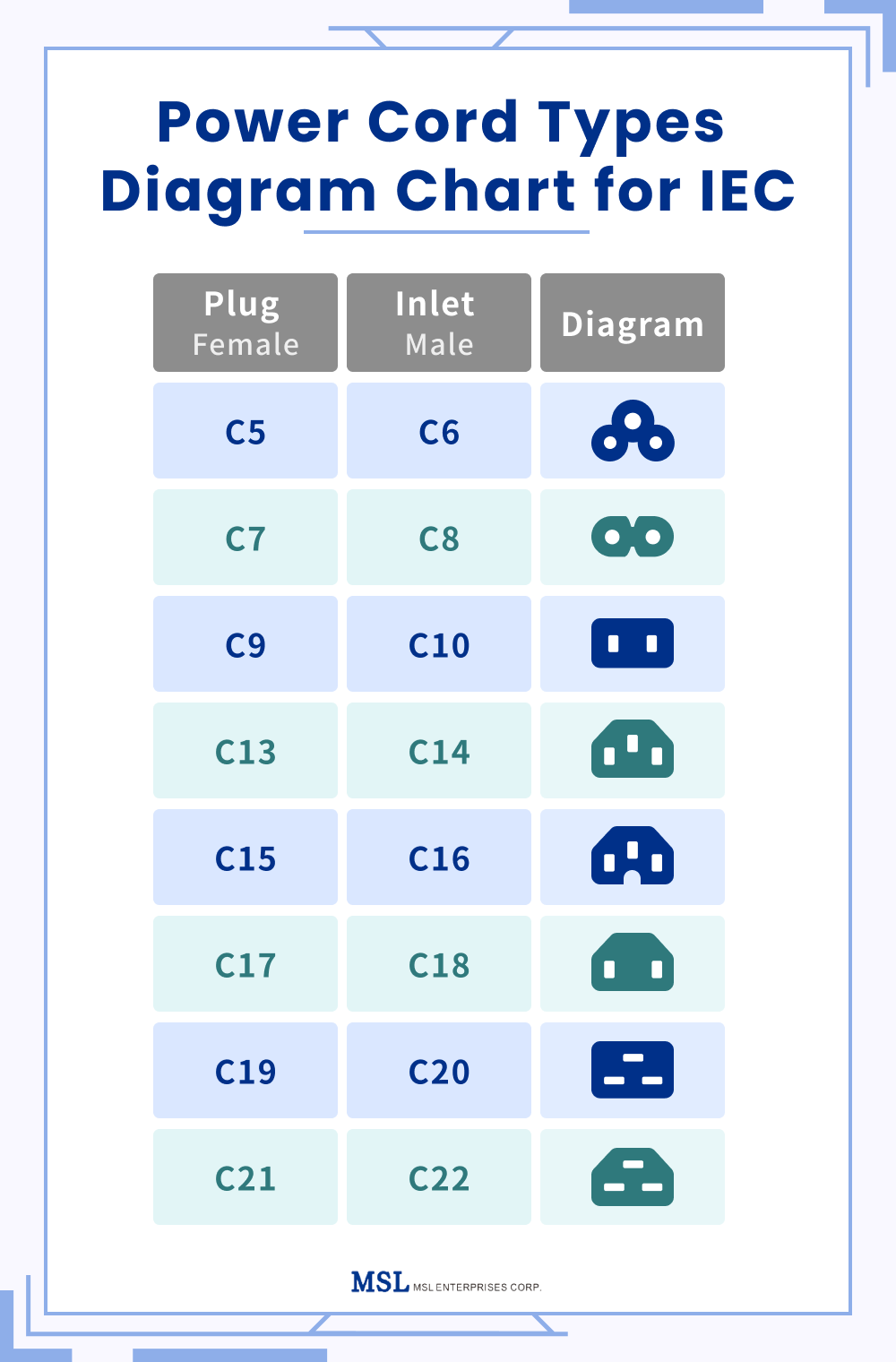

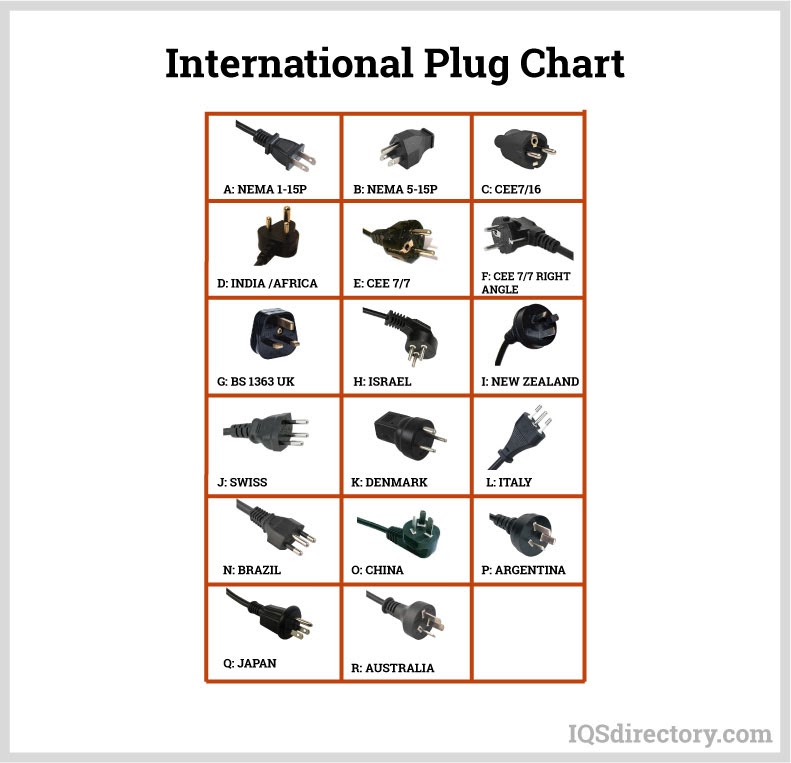

Overview of Power Plug Standards

Power plug and socket configurations vary significantly by region, governed by national and international standards. The International Electrotechnical Commission (IEC) classifies plug types from A to N, with each type differing in pin shape, size, voltage, and current rating. Common types include:

- Type A & B (North America, Japan): Flat parallel pins; Type B includes a grounding pin.

- Type C (Europlug, Europe, parts of Asia/Africa): Two round pins; ungrounded.

- Type D (India, Nepal, South Africa): Three round pins in a triangular pattern.

- Type G (UK, Ireland, UAE, Hong Kong): Three rectangular pins in a triangular configuration; includes built-in fuse.

- Type I (Australia, New Zealand, China): Slanted flat pins; grounding pin varies by country.

- Type F (Schuko, Germany, most of EU): Two round pins with side grounding clips.

Regulatory and Compliance Requirements

Electrical products must meet the safety and regulatory standards of the destination country. Key compliance frameworks include:

- CE Marking (European Union): Required for products sold in the EU; includes compliance with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive. Plug type must conform to regional standards (e.g., Type C, E, or F).

- UKCA Marking (United Kingdom): Replaces CE for goods placed on the UK market; requires adherence to UK safety standards (e.g., Type G plugs).

- UL/CSA Certification (USA/Canada): Devices must be listed by Underwriters Laboratories (UL) or Canadian Standards Association (CSA). Type A/B plugs are standard.

- PSE Mark (Japan): Mandatory for electrical appliances; Type A/B plugs used, but may require specific voltage compatibility (100V).

- BIS Certification (India): Required for electrical goods; Type D or C plugs must meet Bureau of Indian Standards.

- SAA/RCM (Australia and New Zealand): Devices must comply with AS/NZS standards; Type I plugs are mandatory.

Manufacturers must ensure that both the plug and the complete electrical device meet local safety, labeling, and testing requirements.

Logistics and Packaging Considerations

Shipping electrical products internationally requires careful attention to plug compatibility and packaging:

- Plug Variants: Offer region-specific plug versions or include interchangeable plug adapters to reduce returns and improve customer satisfaction.

- Voltage Compatibility: Clearly label input voltage range (e.g., 100–240V) to prevent device damage. Transformers or converters may be needed for non-universal power supplies.

- Packaging Labels: Include multilingual instructions, safety warnings, and compliance marks (e.g., CE, UKCA, UL). Clearly indicate plug type on packaging.

- Inventory Management: Maintain separate SKUs for different plug types to avoid distribution errors. Use barcode or RFID tagging for traceability.

- Returns and Warranty: Define policies for regions with incompatible plugs. Consider local service centers or authorized repair networks.

Safety and Environmental Compliance

Ensure all power connectors meet safety standards to prevent fire, electric shock, or equipment failure:

- RoHS (EU): Restricts hazardous substances (e.g., lead, mercury) in electrical components.

- REACH (EU): Regulates chemical substances used in manufacturing.

- WEEE Directive (EU): Requires proper recycling and disposal of electrical equipment; includes labeling and take-back obligations.

- Energy Efficiency Standards (e.g., Energy Star, MEPS): May influence power supply design and plug compatibility.

Best Practices for Global Distribution

- Conduct Market Research: Identify required plug types and certifications for each target country.

- Partner with Local Experts: Work with compliance consultants or certification bodies to navigate regulations.

- Use Universal Power Supplies: Design products with auto-switching power supplies (100–240V, 50/60Hz) to reduce regional variants.

- Document Compliance: Maintain technical files, test reports, and conformity declarations for audits.

- Train Logistics Teams: Ensure warehouse and shipping staff can identify plug types and compliance labels.

By aligning plug connector specifications with regional regulations and logistical strategies, businesses can ensure safe, compliant, and efficient global distribution of electrical products.

In conclusion, sourcing the appropriate power plug connector type requires careful consideration of regional electrical standards, device compatibility, safety certifications, and intended use. With numerous plug types in use globally—such as Type A, B, C, G, and I—selecting the correct connector ensures not only efficient power delivery but also compliance with local regulations and enhanced user safety. When sourcing, prioritize connectors that meet international standards (e.g., IEC, UL, CE), are made from durable and insulating materials, and are supplied by reputable manufacturers. Additionally, for products distributed across multiple regions, adopting interchangeable or multi-standard connectors can improve versatility and customer satisfaction. Proper due diligence in sourcing power plug connectors ultimately supports reliability, safety, and market success.