The global powdered whole eggs market is experiencing robust growth, driven by rising demand for convenient, shelf-stable protein sources across food manufacturing, bakery, and animal feed sectors. According to Grand View Research, the global egg products market size was valued at USD 20.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, fueled by increased industrialization of food processing and growing consumer preference for ready-to-eat and formulated foods. Powdered whole eggs, in particular, offer extended shelf life, reduced transportation costs, and consistent performance in production—making them a preferred choice for bulk procurement. As demand intensifies, especially in regions like North America and Asia-Pacific, sourcing from reliable, high-volume manufacturers becomes critical. This list highlights the top 10 powdered whole egg bulk manufacturers leading the industry in capacity, quality, and global supply chain reach.

Top 10 Powdered Whole Eggs Bulk Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Commercial / Wholesale Egg Products

Domain Est. 1999

Website: pacefarm.com

Key Highlights: We provide fresh, frozen and dried egg products to commercial kitchens and manufacturers. Our range includes egg white powder & frozen yolk….

#2 Whole Egg Powder

Domain Est. 1996

#3 Eggs & Egg Products — Rose Acre Farms

Domain Est. 1996

Website: goodegg.com

Key Highlights: Rose Acre Farms is a family-owned company dedicated to producing shell eggs and egg products of exceptional quality….

#4 Powdered Egg Products

Domain Est. 1998

Website: igreca.com

Key Highlights: Igreca, leader in egg products, offers a wide range of powdered eggs: quality, convenience and performance for food industry professionals….

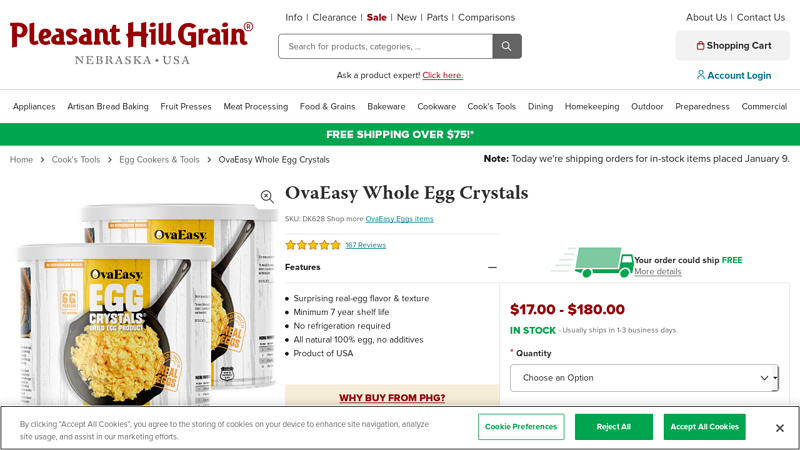

#5 OvaEasy Whole Egg Crystals

Domain Est. 1999

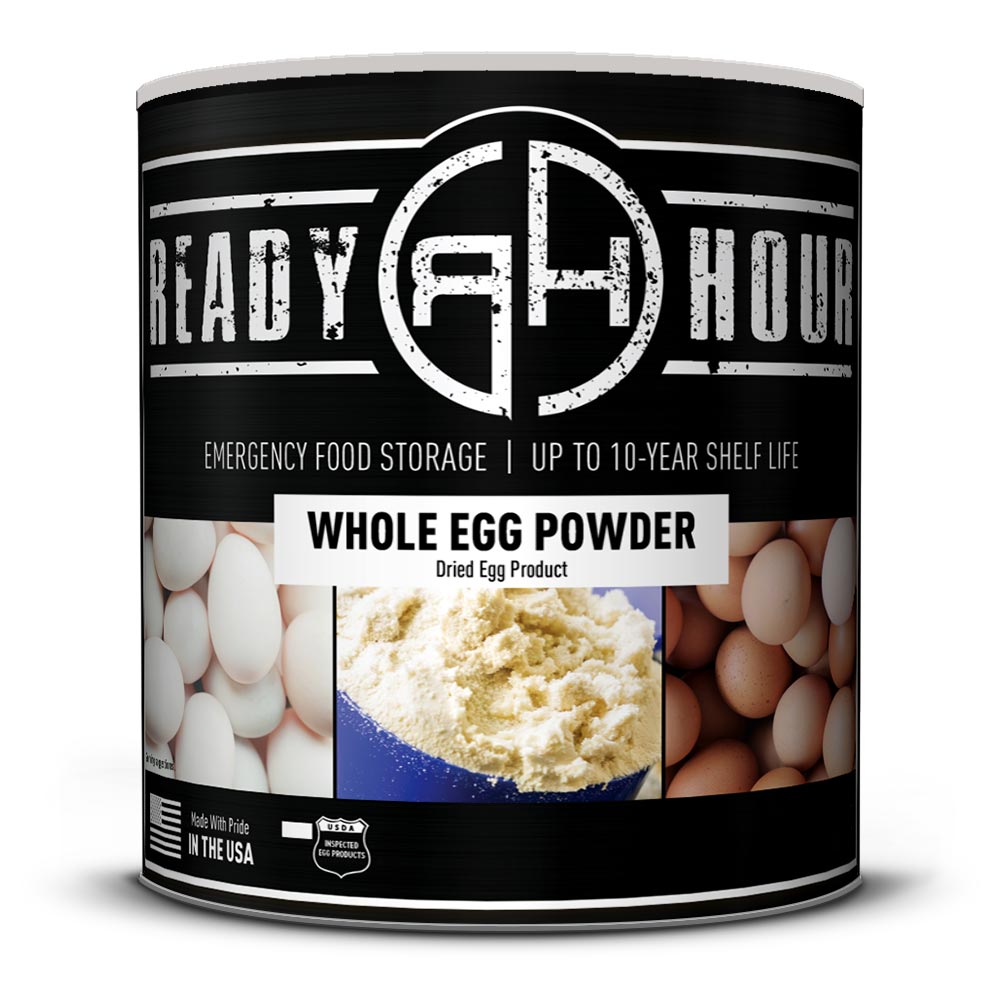

#6 Dried Whole Egg Powder Can

Domain Est. 2009

Website: augasonfarms.com

Key Highlights: Out of stock Rating 5.0 (3,000) Pasteurized Dried Whole Egg Powder Can, 85 Servings · Real eggs with no additives or preservatives · Ideal for baking, cooking, and breakfast dish…

#7 Bulk Whole Egg Powder

Domain Est. 2011

Website: legacyfoodstorage.com

Key Highlights: In stock Free deliveryLegacy bulk powdered eggs have a long shelf life and are made from US chickens, dried and pasteurized in the United States for safety and quality….

#8 Powdered Whole Eggs by Honeyville

Domain Est. 2017

#9 Powdered Dried Eggs

Domain Est. 2019

Website: eggsunlimited.com

Key Highlights: Buy wholesale Powdered Dried Eggs now. Find out how easy it is to keep a consistent supply of any egg product that customers love with Eggs Unlimited….

#10 Wabash Valley

Domain Est. 2020

Website: wabashvalleyeggs.com

Key Highlights: Wabash Valley Eggs is a leading United States egg processor and supplier of liquid, frozen, and dried egg products….

Expert Sourcing Insights for Powdered Whole Eggs Bulk

H2: 2026 Market Trends for Powdered Whole Eggs in Bulk

The global market for bulk powdered whole eggs is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements in food processing, and shifting supply chain dynamics. This analysis explores key trends expected to shape the powdered whole egg bulk market in the coming years.

-

Rising Demand in Food Manufacturing

By 2026, the demand for powdered whole eggs in bulk is projected to grow steadily, primarily fueled by their extensive use in bakery, confectionery, and processed food industries. With advantages such as extended shelf life, ease of transportation, and consistent quality, powdered eggs are becoming a preferred ingredient for large-scale food manufacturers. The expansion of ready-to-eat meals and convenience foods—especially in emerging markets—will further bolster this demand. -

Focus on Food Safety and Traceability

As food safety regulations become more stringent globally, producers of powdered whole eggs are investing heavily in quality control and traceability systems. By 2026, consumers and B2B buyers alike will increasingly demand transparency in sourcing and processing. This trend is pushing suppliers to adopt blockchain and digital tracking technologies to verify egg origin, feed quality, and processing conditions, enhancing trust and compliance. -

Growth in Plant-Based and Alternative Egg Markets (Indirect Pressure)

While powdered whole eggs remain a staple in traditional food applications, the rise of plant-based egg alternatives presents both competition and innovation opportunities. However, powdered whole eggs continue to benefit from their natural composition, protein density, and functional properties (e.g., emulsification, binding) that are difficult to replicate. As a result, the bulk powdered egg market is expected to coexist and even grow alongside plant-based alternatives, particularly in non-vegan commercial applications. -

Sustainability and Ethical Sourcing

Environmental and ethical concerns are reshaping procurement strategies. By 2026, bulk powdered egg suppliers will face increasing pressure to adopt sustainable practices—such as cage-free egg sourcing, reduced carbon footprint in drying processes, and energy-efficient manufacturing. Certifications like Non-GMO, organic, and animal welfare-approved will become standard differentiators in the bulk market, especially in North America and Europe. -

Regional Market Expansion

Asia-Pacific is expected to emerge as a high-growth region for bulk powdered whole eggs by 2026, driven by rising urbanization, expanding food processing industries, and increasing Western-style diet adoption. Countries like China, India, and Indonesia will see greater integration of powdered eggs in industrial baking and snack production. Meanwhile, North America and Europe will maintain stable demand, supported by strong regulatory frameworks and innovation in functional food applications. -

Technological Advancements in Drying and Preservation

Innovations in spray drying, vacuum freezing, and microencapsulation technologies are enhancing the nutritional retention and solubility of powdered whole eggs. By 2026, these improvements will enable manufacturers to offer higher-quality products with better reconstitution properties, appealing to premium food producers and health-conscious applications.

Conclusion

The 2026 outlook for bulk powdered whole eggs is characterized by resilience, innovation, and adaptation. While challenges such as competition from alternatives and sustainability pressures persist, the functional benefits and scalability of powdered eggs ensure their continued relevance in the global food supply chain. Stakeholders who prioritize quality, transparency, and sustainability are likely to gain a competitive edge in this evolving market landscape.

Common Pitfalls When Sourcing Powdered Whole Eggs in Bulk (Quality & Intellectual Property)

Sourcing powdered whole eggs in bulk presents significant advantages in cost, shelf life, and convenience, but it also comes with critical risks related to quality consistency and intellectual property (IP) protection. Avoiding these common pitfalls is essential for maintaining product integrity and safeguarding your brand.

Quality Inconsistencies and Adulteration Risks

One of the foremost challenges in bulk sourcing is ensuring consistent quality across batches. Variability in egg source, processing methods, and storage conditions can lead to differences in color, flavor, solubility, and functional properties (e.g., emulsification, foaming). Buyers may receive product that performs poorly in their formulations, leading to production delays or subpar end products. Additionally, there’s a risk of adulteration—such as the addition of fillers, lower-grade egg components, or even non-egg proteins—to reduce costs. Without rigorous third-party testing and transparent supplier audits, these issues can go undetected until after integration into the supply chain.

Inadequate Microbiological and Allergen Controls

Powdered eggs are susceptible to microbial contamination, including Salmonella and Enterobacteriaceae, especially if pasteurization and sanitation protocols are not strictly followed. Sourcing from suppliers without verifiable food safety certifications (e.g., SQF, BRCGS, or FDA compliance) increases the risk of contamination, potentially leading to recalls or regulatory action. Furthermore, allergen cross-contamination is a serious concern in multi-product facilities. Failure to ensure dedicated production lines or proper allergen management can compromise food safety and violate labeling regulations, exposing the buyer to legal and reputational risks.

Misrepresentation of Specifications and Shelf Life

Suppliers may overstate key product specifications such as fat content, moisture levels, or solubility index. Discrepancies can affect the performance of powdered eggs in food manufacturing, particularly in sensitive applications like baked goods or sauces. Equally problematic is misrepresentation of shelf life—either through inaccurate dating or failure to disclose storage conditions required to maintain quality. Buyers assuming standard shelf life without verifying real-world stability data may face spoilage or degraded functionality upon use.

Intellectual Property Exposure in Custom Formulations

When working with suppliers to develop proprietary blends or value-added powdered egg products, companies risk IP leakage if proper legal safeguards are not in place. This includes the absence of robust Non-Disclosure Agreements (NDAs), clear ownership clauses in contracts, or inadequate control over process know-how. Unscrupulous suppliers may replicate or resell custom formulations to competitors, eroding competitive advantage. Additionally, using generic or uncertified sources may inadvertently infringe on patented processing technologies or ingredient systems, leading to legal disputes.

Lack of Supply Chain Transparency and Traceability

Bulk sourcing often involves complex, multi-tiered supply chains with limited visibility into farm origins, animal welfare practices, or feed sources. This lack of traceability not only undermines claims of sustainability or ethical sourcing but also complicates recall management in case of contamination. Without blockchain-enabled tracking or supplier certification programs (e.g., cage-free, non-GMO feed), buyers cannot confidently validate the integrity of their supply, exposing them to consumer backlash and regulatory scrutiny.

Insufficient Contractual Protections and Audit Rights

Many sourcing agreements fail to include enforceable quality benchmarks, penalties for non-compliance, or rights to conduct on-site audits. Without these provisions, buyers have limited recourse when quality issues arise. Suppliers may also resist third-party inspections or delay corrective actions, prolonging disruptions. A robust contract should define acceptance criteria, testing protocols, and remedies for breach, ensuring accountability throughout the partnership.

Logistics & Compliance Guide for Powdered Whole Eggs (Bulk)

This guide outlines the key logistics and compliance considerations for handling, transporting, and storing bulk powdered whole eggs. Adherence to these guidelines is critical for maintaining product safety, quality, and regulatory compliance throughout the supply chain.

Regulatory Compliance

Compliance with local, national, and international food safety regulations is mandatory when handling powdered whole eggs in bulk. Key regulatory frameworks include:

- FDA Food Safety Modernization Act (FSMA): Requires facilities to implement preventive controls for human food, including hazard analysis, allergen controls, and supplier verification. Bulk powder handling facilities must have a written Food Safety Plan.

- USDA/FDA Jurisdiction: In the U.S., egg products (including dried whole eggs) are regulated by the USDA Food Safety and Inspection Service (FSIS) under the Egg Products Inspection Act (EPIA). Facilities must be federally inspected and approved.

- Codex Alimentarius Standards: Internationally, compliance with Codex STAN 290-2008 (Standard for Egg Products) ensures quality and safety benchmarks are met for global trade.

- Allergen Labeling: Powdered whole eggs are a major allergen. Proper labeling and segregation protocols are required under FALCPA (U.S.) and similar regulations (e.g., EU Directive 1169/2011).

- Export Requirements: For international shipments, compliance with destination country regulations (e.g., EU Novel Foods, China GACC registration, Canadian CFIA standards) is essential. Pre-shipment inspections and documentation may be required.

Storage Conditions

Proper storage is crucial to prevent spoilage, microbial growth, and quality degradation:

- Temperature: Store in a cool, dry environment. Ideal storage temperature is between 10°C and 21°C (50°F to 70°F). Avoid temperature fluctuations.

- Humidity: Maintain relative humidity below 65% to prevent caking, clumping, and microbial activity. Excess moisture can lead to Salmonella proliferation.

- Packaging Integrity: Bulk containers (e.g., multi-wall paper bags with poly liners, bulk totes, or intermediate bulk containers – IBCs) must be sealed to prevent moisture absorption and contamination.

- Shelf Life: Typically 12–24 months when stored properly. Rotate stock using FIFO (First In, First Out) principles.

- Segregation: Store away from strong-smelling products, chemicals, and allergens to avoid cross-contamination.

Transportation Requirements

Transportation must maintain the cold chain and sanitary conditions throughout transit:

- Vehicle Sanitation: Trailers or containers must be food-grade, clean, dry, and odor-free. Provide documentation of pre-trip sanitation (e.g., cleaning certificates).

- Temperature Control: While powdered eggs are shelf-stable, avoid exposure to high temperatures (>38°C / 100°F) or direct sunlight. Use temperature-monitored trailers when possible, especially in extreme climates.

- Moisture Protection: Ensure trailers are watertight and use protective tarps if necessary. Avoid transport during heavy rain unless the cargo is fully protected.

- Pest Infestation Prevention: Vehicles must be inspected for signs of pests before loading. Use sealed containers and avoid stops in high-risk areas.

- Documentation: Include Certificates of Analysis (CoA), Certificates of Free Sale (for export), allergen statements, and shipping manifests with proper commodity descriptions (e.g., “Powdered Whole Eggs, Pasteurized, Bulk”).

Handling and Hygiene Practices

Safe handling minimizes contamination risks during loading, unloading, and processing:

- Personal Hygiene: Personnel must follow strict hygiene protocols: handwashing, protective clothing (hairnets, gloves), and health screening.

- Equipment Sanitation: Conveyors, hoppers, and bulk discharge systems must be cleaned and sanitized regularly according to a documented SSOP (Sanitation Standard Operating Procedure).

- Cross-Contamination Prevention: Dedicate equipment for egg powder where possible. If shared, implement thorough cleaning between product runs.

- Dust Control: Powdered eggs can generate dust, which poses respiratory and explosion hazards. Use dust collection systems and ensure facilities comply with NFPA 652 (Combustible Dust Standard).

Documentation and Traceability

Complete and accurate documentation ensures regulatory compliance and enables rapid traceability:

- Lot Tracking: Each batch must have a unique lot number traceable to raw material sources, processing date, and pasteurization parameters.

- Certificates of Analysis (CoA): Provide CoAs for each shipment, including microbiological results (e.g., absence of Salmonella), moisture content, and fat/protein levels.

- Supplier Verification: Maintain records of supplier audits, certifications (e.g., GMP, SQF, BRCGS), and incoming inspection results.

- Recall Readiness: Have a documented recall plan that includes procedures for identifying, locating, and removing affected product from the supply chain.

Emergency and Contingency Planning

Prepare for potential disruptions:

- Spill Response: In the event of a spill, clean using food-safe methods. Avoid water; use dry vacuuming to prevent clumping and microbial growth.

- Power Outages: Ensure backup systems for climate-controlled storage areas if applicable.

- Natural Disasters: Protect inventory from flooding or extreme temperature exposure through facility design and insurance coverage.

Adhering to this guide ensures the safe, compliant, and efficient logistics management of bulk powdered whole eggs from production to end-user. Regular audits and staff training are recommended to maintain standards.

In conclusion, sourcing powdered whole eggs in bulk offers numerous advantages for food manufacturers, bakeries, restaurants, and other large-scale operations. The extended shelf life, reduced storage and transportation costs, consistent quality, and ease of use make powdered whole eggs a practical and cost-effective alternative to fresh eggs. When selecting a supplier, it is essential to prioritize quality, food safety certifications (such as HACCP, GMP, and organic or non-GMO if required), and reliability in supply chain management. Conducting due diligence, requesting samples, and evaluating pricing structures can help secure a long-term partnership that ensures product consistency and operational efficiency. Overall, bulk powdered whole eggs present a sustainable and efficient solution for meeting high-volume ingredient demands in today’s food industry.