The global powder coating market is experiencing robust growth, driven by increasing demand for durable, eco-friendly surface finishing solutions across industries such as automotive, construction, and appliances. According to a report by Grand View Research, the global powder coatings market size was valued at USD 13.4 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 7.1% from 2023 to 2030. This expansion is fueled by stringent environmental regulations limiting volatile organic compound (VOC) emissions, making solvent-free powder coatings an attractive alternative to traditional liquid paints. Red powder coatings, in particular, have gained prominence due to their aesthetic appeal and corrosion resistance, especially in outdoor and industrial applications. As demand surges, a select group of manufacturers have emerged as leaders in formulating high-performance, consistent red powder coatings—combining advanced resin technologies, pigment stability, and rigorous quality control. The following analysis highlights the top seven manufacturers excelling in this niche, based on production scale, technological innovation, global reach, and customer reviews.

Top 7 Powder Coated Red Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Powder Coating Powder Manufacturer & Supplier in USA

Domain Est. 2022

Website: kromacoatings.com

Key Highlights: Leading manufacturer of Powder Coating powders in USA. High-performance powder coating colors for industrial, architectural & automotive parts applications….

#2 » Cardinal Paint

Domain Est. 1996

Website: cardinalpaint.com

Key Highlights: Cardinal Paint is a premier manufacturer of high quality liquid & powder coatings which include primers, top coats, aerosols, and various powder products….

#3 Powder Coatings Manufacturer

Domain Est. 2001

Website: ifscoatings.com

Key Highlights: IFS Coatings is a leading powder coatings manufacturer for all applications. Find the perfect color and powder chemistry for your project with IFS….

#4 Red Color Powder Coating

Domain Est. 1990

Website: powdercoatings.ppg.com

Key Highlights: Free delivery 30-day returnsFind the perfect powder by PPG. Select from a variety of RAL, pantone and AAMA red powder coating colors. Available for free standard shipping….

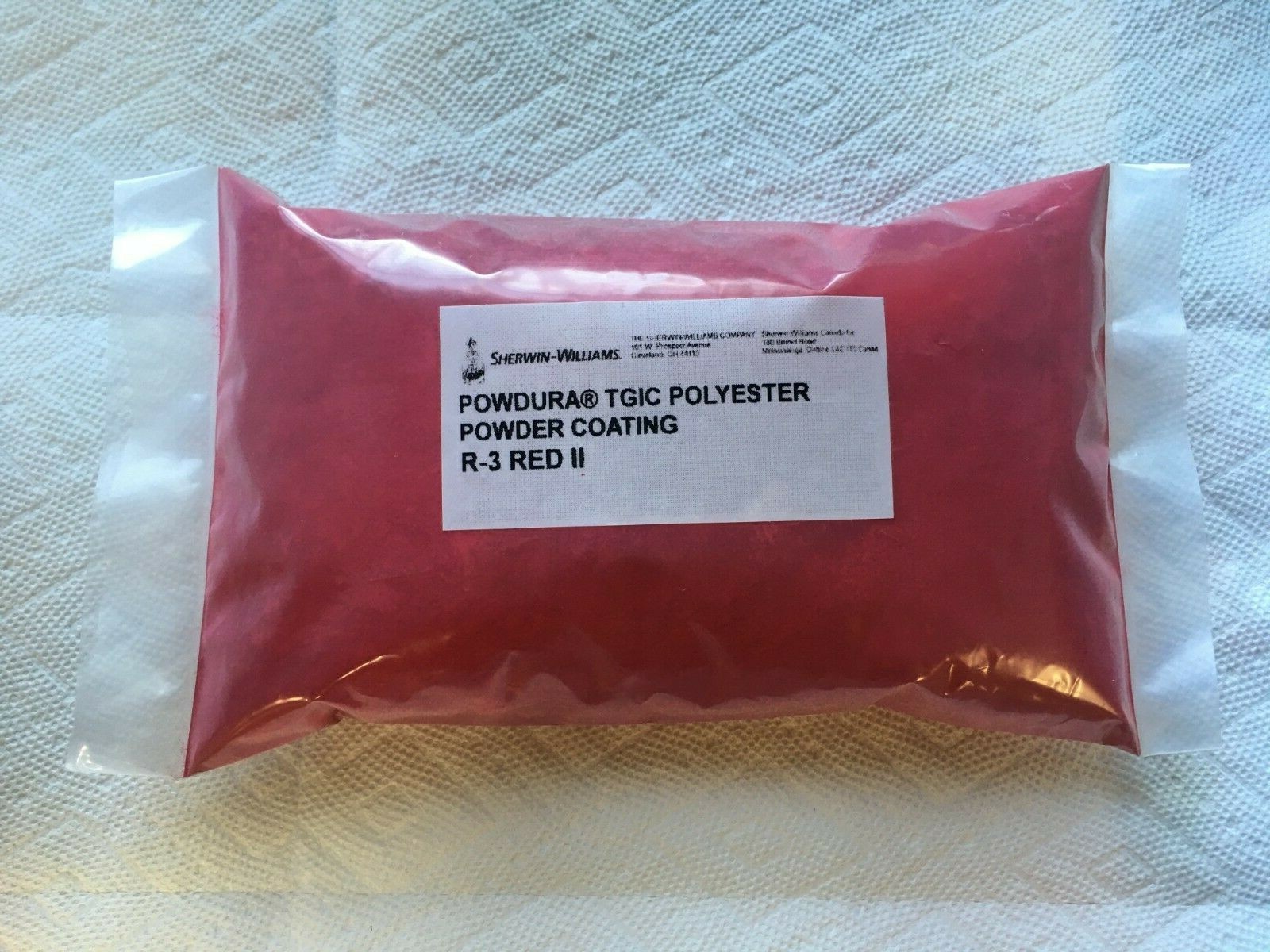

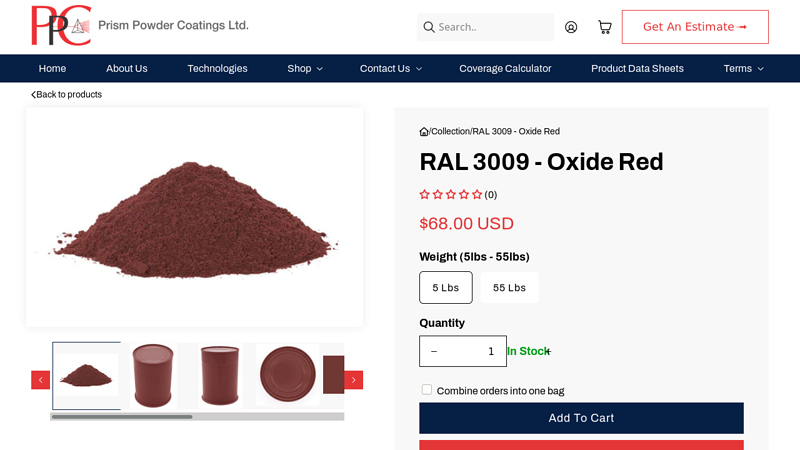

#5 RAL 3009

Domain Est. 1998

Website: prismpowder.com

Key Highlights: In stock $28.39 deliverySMOOTH: RAL 3009 “Oxide Red” High Gloss Powder Coating. · INTERIOR & EXTERIOR: Superior protection against corrosion in RAL 3009 “Oxide Red” PPC Code PR-048…

#6 Prismatic Powders

Domain Est. 2001

Website: prismaticpowders.com

Key Highlights: $13.95 delivery 30-day returnsWorld’s Largest Custom Powder Coating Color Selection. Prismatic Powders offers the world’s largest selection of powder coating colors and styles….

#7 Red

Domain Est. 2013

Website: thepowdercoatstore.com

Key Highlights: Free delivery over $125 30-day returns…

Expert Sourcing Insights for Powder Coated Red

H2: 2026 Market Trends for Powder Coated Red

The global market for powder coated finishes, including the vibrant Powder Coated Red, is projected to experience notable shifts by 2026, driven by evolving consumer preferences, sustainability mandates, and advancements in coating technologies. Powder Coated Red—a popular choice in architectural, automotive, and industrial applications due to its durability and aesthetic appeal—is expected to maintain strong demand, particularly in sectors prioritizing both performance and visual impact.

One of the key drivers shaping the 2026 outlook is the growing emphasis on eco-friendly manufacturing. Powder coating is inherently more sustainable than traditional liquid paints, producing minimal volatile organic compounds (VOCs) and allowing for overspray recovery. As regulatory frameworks tighten across North America, Europe, and parts of Asia-Pacific, industries are increasingly adopting powder coating solutions. Powder Coated Red pigments are being reformulated to meet environmental standards without compromising color consistency or weather resistance.

In the architectural sector, Powder Coated Red is gaining traction in façade systems, window frames, and structural elements, especially in urban redevelopment projects. Design trends favor bold, long-lasting colors that enhance building identity, and red offers high visibility and modern appeal. The rise of prefabricated and modular construction is further accelerating demand, as powder coating provides a durable, one-step finish suitable for off-site manufacturing.

The automotive and transportation industries are also significant adopters. By 2026, increasing use of powder coatings on electric vehicle (EV) components—such as battery enclosures, chassis parts, and wheels—will boost demand for corrosion-resistant, heat-stable finishes like Powder Coated Red. OEMs are exploring colored coatings to differentiate EV models, with red symbolizing performance and innovation.

Technological advancements are improving the performance of red pigments, which have historically faced challenges with UV stability and chalking. New hybrid and polyester-based powders offer enhanced fade resistance, expanding the outdoor applicability of Powder Coated Red. Additionally, digital color matching and batch consistency tools are enabling manufacturers to deliver precise, repeatable red finishes across large-scale projects.

Geographically, Asia-Pacific is expected to lead growth due to rapid industrialization and infrastructure development, particularly in China, India, and Southeast Asia. Meanwhile, North America and Western Europe will see steady demand fueled by renovation activities and green building certifications like LEED and BREEAM, which favor low-emission finishes.

In summary, the 2026 market for Powder Coated Red is poised for growth, underpinned by sustainability trends, aesthetic demand, and technical innovation. Stakeholders in manufacturing, design, and construction should anticipate increased competition, higher quality expectations, and opportunities in emerging applications such as smart infrastructure and sustainable mobility.

Common Pitfalls When Sourcing Powder Coated Red

Sourcing high-quality powder coated red finishes presents unique challenges due to the inherent properties of red pigments and the demands of the powder coating process. Overlooking these pitfalls can lead to inconsistent color, poor durability, and costly rework.

Inconsistent Color Quality and Batch Variation

Red pigments, especially organic types like quinacridones, are highly sensitive to processing conditions. Minor variations in curing temperature, time, or oven dwell can cause significant shifts in hue, leading to batch-to-batch inconsistency. Suppliers may use different pigment sources or formulations, resulting in mismatched shades across production runs. Additionally, achieving the desired opacity can be difficult with reds, often requiring multiple coats or higher pigment loads, which increases cost and risk of defects.

Poor Lightfastness and UV Degradation

Many red pigments exhibit poor resistance to ultraviolet (UV) radiation, leading to fading, chalking, and color shift over time—particularly problematic for outdoor applications. Low-quality or non-weatherable pigments degrade quickly when exposed to sunlight, compromising both appearance and protective performance. Sourcing without verifying the pigment’s lightfastness rating (e.g., ASTM D4799 or ISO 11341) increases the risk of premature failure in exterior environments.

Thermal Instability During Curing

Red pigments can degrade at standard powder coating cure temperatures (typically 180–200°C). This thermal instability may cause darkening, blooming, or color distortion. Suppliers using substandard pigments or improper formulations may not disclose this risk, resulting in finished parts that do not meet color specifications after curing. Ensuring the pigment is thermally stable at the intended cure profile is critical.

Intellectual Property and Pigment Sourcing Risks

High-performance, light-stable red pigments (e.g., certain perylene or diketopyrrolopyrrole types) are often patented. Unauthorized use or sourcing from non-licensed suppliers can expose buyers to intellectual property (IP) infringement claims. Additionally, reliance on single-source pigments with limited supply chains can lead to material shortages or price volatility, disrupting production.

Inadequate Performance Testing and Certification

Suppliers may provide limited or falsified test data for weathering, corrosion resistance, or chemical resistance. Without independent verification—such as QUV testing, salt spray (ASTM B117), or color stability reports—there’s a risk of receiving a coating that fails prematurely in real-world conditions. Insufficient batch traceability also complicates quality control and accountability.

Conclusion

To mitigate these risks, buyers should specify pigment chemistry, require third-party test reports, conduct pre-qualification audits, and establish clear color tolerances (e.g., ΔE values). Prioritizing suppliers with proven experience in stable red formulations and transparent IP practices ensures long-term quality and compliance.

Logistics & Compliance Guide for Powder Coated Red (H2)

Version 1.0 – For Industrial Use Only

1. Product Overview

Product Name: Powder Coated Red (H2)

Type: Thermosetting powder coating

Color Code: H2 (Pantone equivalent: 18-1663 TCX “Fire Brick”)

Chemistry: Epoxy-Polyester Hybrid

Intended Use: Protective and decorative coating for metal substrates (e.g., automotive parts, architectural components, industrial equipment)

2. Regulatory Classification (GHS)

Hazard Statement (H2):

H228: Flammable solid.

Note: “H2” in this context refers to the hazard statement code H228. Ensure all labeling and documentation reflect this classification.

3. Safety & Handling (H228 Compliance)

Due to its flammable solid classification, the following precautions must be observed:

Storage Guidelines

- Store in a cool, dry, well-ventilated area away from heat, sparks, open flames, and direct sunlight.

- Keep container tightly closed when not in use.

- Store separately from oxidizers and strong acids.

- Maximum storage temperature: 30°C (86°F).

- Use non-combustible flooring and explosion-proof electrical fixtures in storage areas.

Handling Precautions

- Use only in areas with adequate ventilation (local exhaust recommended).

- Avoid creating dust. Use grounding and bonding procedures to prevent static discharge.

- Do not eat, drink, or smoke while handling.

- Use non-sparking tools.

- Clean up spills immediately using approved methods (see Section 6).

4. Personal Protective Equipment (PPE)

Mandatory PPE when handling Powder Coated Red (H2):

– Respiratory Protection: NIOSH-approved N95 respirator (or equivalent) when dust is generated.

– Eye Protection: Safety goggles or face shield.

– Skin Protection: Wear nitrile gloves and long-sleeved clothing.

– Footwear: Closed-toe, static-dissipative shoes.

5. Transportation (H228 – Flammable Solid)

UN Number: UN 1355

Proper Shipping Name: FLAMMABLE SOLID, ORGANIC, N.O.S. (Powder Coating Material)

Hazard Class: 4.1 (Flammable Solids)

Packing Group: III (Low danger)

Label Required: Flammable Solid (Class 4.1) diamond label

Packaging: Sealed, non-combustible containers (e.g., lined fiber drums, HDPE pails) meeting UN certification.

Air & Sea Transport (IATA/IMDG Compliance)

- Mark packages with proper UN number, hazard class, and orientation arrows.

- Include Shipper’s Declaration for Dangerous Goods when required.

- Avoid temperature extremes during transit (>40°C or <0°C).

6. Spill & Emergency Response

In Case of Spill:

– Eliminate ignition sources immediately.

– Use non-sparking tools to collect material.

– Place in a sealed, labeled metal container.

– Use a vacuum with HEPA filtration (not dry sweeping).

– Do not allow powder to enter drains or waterways.

Fire Response:

– Extinguishing Media: Dry chemical, CO₂, or sand. Do not use water jet (may disperse dust and worsen fire).

– Evacuate area and use full firefighting gear (SCBA).

– Combustion may emit toxic fumes (e.g., CO, NOx, organic vapors).

7. Disposal & Environmental Compliance

- Dispose of as hazardous waste in accordance with local, state, and federal regulations (e.g., EPA, REACH, RoHS).

- Waste code (EU): 16 05 05* (hazardous organic powder waste).

- Never dispose of in household trash or via incineration without proper air pollution controls.

8. Documentation & Labeling

Ensure compliance with:

– SDS Requirements: Maintain Safety Data Sheet (SDS) per OSHA HazCom 2012 / CLP Regulation (EC) No 1272/2008.

– Labeling: All containers must display:

– Product name: Powder Coated Red (H2)

– H228 pictogram (flame symbol)

– Signal word: Danger

– Precautionary statements (P210, P240, P370+P378, etc.)

9. Training & Compliance Verification

- All personnel must complete GHS hazard communication and fire safety training.

- Conduct annual audits of storage, handling, and transport procedures.

- Maintain records of SDS, training, and incident reports for minimum 5 years.

10. Supplier & Regulatory Contacts

For SDS or compliance questions, contact:

Technical Support: [email protected] | +1 (800) 555-1234

Regulatory Affairs: [email protected]

Always consult the latest Safety Data Sheet (SDS) before use. Regulations vary by region—confirm compliance with local authorities.

Disclaimer: This guide is for informational purposes only and does not replace legal or regulatory advice. The user assumes all responsibility for safe and compliant use.

© 2024 Coating Solutions Inc. All rights reserved.

Conclusion for Sourcing Powder Coated Red:

Sourcing powder coated red components requires a strategic approach that balances color consistency, quality, durability, and cost-effectiveness. It is essential to partner with reliable suppliers who use high-quality pigments and adhere to industry standards for powder coating application and curing processes. Ensuring batch-to-batch color matching, proper surface preparation, and resistance to environmental factors such as UV exposure and corrosion is critical—especially for outdoor or high-visibility applications.

Additionally, verifying certifications, requesting samples, and conducting performance testing can mitigate risks related to color deviation or coating failure. By prioritizing suppliers with proven expertise in powder coating and robust quality control measures, businesses can achieve a durable, aesthetically pleasing red finish that meets both functional and design requirements. Overall, a well-managed sourcing process ensures long-term satisfaction, reduced maintenance costs, and enhanced product value.