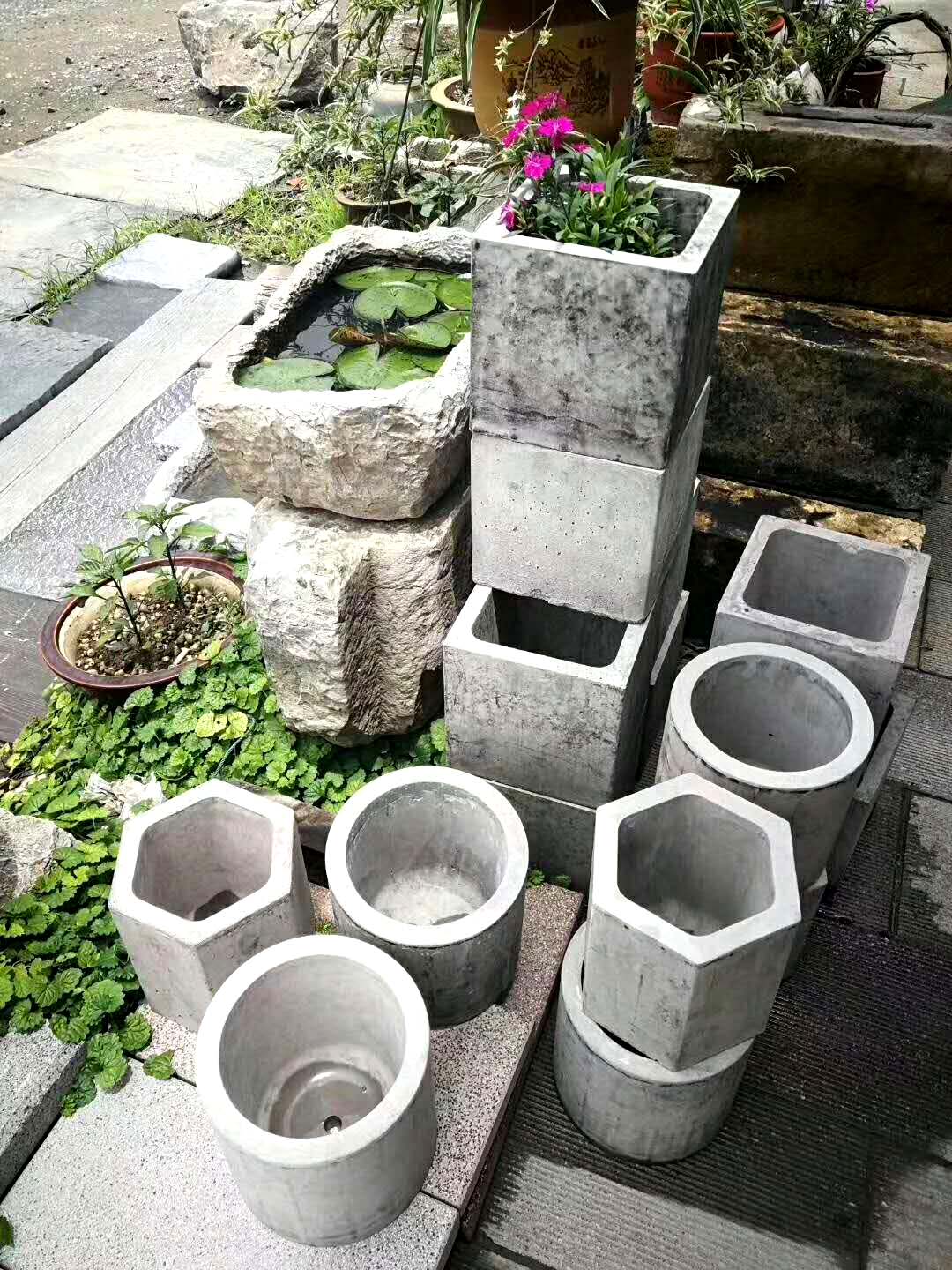

The global concrete products market is experiencing steady expansion, driven by rising infrastructure development, urbanization, and residential construction activities. According to a report by Mordor Intelligence, the global concrete products market was valued at USD 356.8 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. A key segment within this growth is precast concrete, including pot mould concrete products, which are increasingly favored for their durability, design flexibility, and efficiency in construction timelines. As demand for standardized, high-strength concrete forms rises—especially in landscaping, utility, and architectural applications—several manufacturers have emerged as leaders in pot mould technology and large-scale production. These companies leverage advanced moulding techniques, quality raw materials, and innovative R&D to meet stringent industry standards. Below are the top six pot mould concrete manufacturers shaping the future of precast infrastructure solutions.

Top 6 Pot Mould Concrete Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Concrete Pot Molds Manufacturer

Domain Est. 2021

Website: siliconeconcretemolds.com

Key Highlights: We are the one-stop destination for all your cast shaping requirements. You will surely find unique and uncommon patterns of concrete pottery molds while ……

#2 Besser Company

Domain Est. 1996 | Founded: 1904

Website: besser.com

Key Highlights: Besser Company is a global leader in concrete production equipment, molds, and training. Serving the concrete industry with proven solutions since 1904….

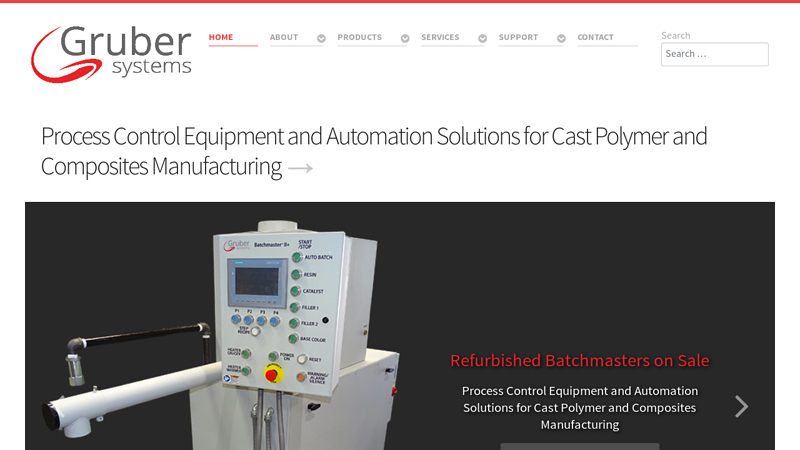

#3 Cast polymer and composites manufacturing equipment …

Domain Est. 1997

Website: grubersystems.com

Key Highlights: We supply the equipment, molds, materials and supplies needed. We can install your plant, then provide on-site introductory training to your employees….

#4 Silicone Molds For Concrete

Domain Est. 2018

Website: deparhome.com

Key Highlights: Concrete Flower Pot Mold – M1B. 51.00 $ ; Silicone Mold for Concrete Planters- M1K. 32.00 $ ; Silicone Mold for Concrete Planters – M9B. 51.00 $ ; Silicone Mold ……

#5 All Concrete and Jesmonite Molds

Domain Est. 2021

Website: boowannicole.com

Key Highlights: $5.99 delivery 15-day returnsLooking for unique concrete/Jesmonite/gypsum silicone molds? Check out our collection! Discover original designs released weekly. Create stunning concr…

#6 Concrete Molds

Website: lcmolds.com

Key Highlights: Supply any kinds of concrete molds, looking for DIY paver molds, silicone molds for concrete, planter molds, animal statue molds or garden decor molds….

Expert Sourcing Insights for Pot Mould Concrete

H2: Market Trends for Pot Mould Concrete in 2026

The global Pot Mould Concrete (PMC) market is poised for significant transformation by 2026, driven by advancements in construction technology, rising demand for prefabricated building components, and increasing urbanization. PMC, a specialized form of precast concrete used primarily in column and structural element fabrication, is gaining traction due to its precision, durability, and efficiency in construction timelines. Below are the key market trends shaping the Pot Mould Concrete industry in 2026:

1. Growth in Prefabricated and Modular Construction

The shift toward modular and off-site construction methods is accelerating PMC adoption. With developers seeking faster project completion and reduced labor costs, PMC offers standardized, reusable moulds that enhance consistency and reduce on-site casting errors. This trend is particularly strong in emerging economies and high-density urban developments.

2. Technological Integration and Automation

By 2026, automation in PMC production lines is becoming standard. Advanced robotics, IoT-enabled monitoring systems, and AI-driven quality control are being integrated into pot mould concrete plants. These technologies improve precision, reduce material waste, and ensure compliance with structural standards, making PMC more attractive for large-scale infrastructure projects.

3. Sustainability and Green Building Standards

Environmental regulations and green building certifications (such as LEED and BREEAM) are influencing PMC demand. Manufacturers are focusing on low-carbon cement alternatives, recycled aggregates, and energy-efficient curing processes. Pot mould systems support sustainable practices by minimizing formwork waste and enabling high reuse rates of steel moulds.

4. Rising Infrastructure Investments in Developing Regions

Countries in Asia-Pacific, Latin America, and Africa are investing heavily in transportation, housing, and smart city projects. PMC is well-suited for rapid construction of bridges, high-rise buildings, and industrial facilities, positioning it as a preferred solution in these regions. China, India, and Southeast Asian nations are expected to lead PMC market growth.

5. Customization and Design Flexibility

Advancements in mould design software allow for greater customization of PMC elements. Architects and engineers can now specify unique column shapes, textures, and integrated features (e.g., embedded conduits or reinforcement), expanding PMC applications beyond standard cylindrical columns to complex architectural elements.

6. Consolidation and Supply Chain Optimization

The PMC market is witnessing increased consolidation among precast concrete manufacturers. Larger players are acquiring niche producers to expand their product portfolios and geographic reach. Simultaneously, supply chain digitization is improving raw material sourcing, logistics, and delivery coordination, enhancing overall project efficiency.

7. Regulatory Support and Standardization

By 2026, many governments are expected to introduce or update construction codes to support prefabricated systems, including PMC. Standardization of PMC dimensions, strength classifications, and quality testing protocols will boost investor confidence and facilitate cross-border trade in precast components.

Conclusion

The Pot Mould Concrete market in 2026 is characterized by innovation, sustainability, and scalability. As construction industries worldwide prioritize speed, quality, and environmental responsibility, PMC is emerging as a critical enabler of modern infrastructure development. Companies that invest in automation, eco-friendly materials, and global compliance standards are likely to dominate this evolving market landscape.

Common Pitfalls When Sourcing Pot Mould Concrete (Quality and Intellectual Property)

Sourcing Pot Mould Concrete—a specialized precast concrete product often used for architectural features, landscaping, or bespoke construction elements—requires careful attention to both quality assurance and intellectual property (IP) considerations. Overlooking these aspects can lead to project delays, cost overruns, legal disputes, and compromised outcomes. Below are key pitfalls to avoid:

Quality-Related Pitfalls

1. Insufficient Specification Clarity

Failing to provide detailed technical specifications (e.g., concrete mix design, strength class, curing methods, surface finish, dimensional tolerances) can result in inconsistent or substandard products. Suppliers may interpret vague requirements differently, leading to non-compliance.

2. Inadequate Quality Control Processes

Relying solely on supplier claims without verifying their quality management systems (e.g., ISO 9001 certification) or conducting factory audits increases the risk of defects. Lack of on-site inspections or third-party testing may allow flawed units to be delivered.

3. Poor Material Sourcing and Consistency

Variations in aggregates, pigments, or cement from batch to batch can cause color inconsistencies or reduced durability. Suppliers using low-grade or non-compliant materials compromise long-term performance, especially in exposed environments.

4. Inconsistent Mould Maintenance and Reuse

Pot moulds degrade over time. If suppliers reuse worn or damaged moulds without proper maintenance, the resulting concrete units may have surface blemishes, dimensional inaccuracies, or weak structural integrity.

5. Inadequate Curing and Handling Practices

Improper curing (e.g., insufficient time, incorrect temperature/humidity) weakens concrete strength and increases susceptibility to cracking. Poor handling and transportation can cause chipping or breakage, particularly with intricate designs.

Intellectual Property-Related Pitfalls

1. Assumption of Design Ownership

Assuming that paying for a custom Pot Mould Concrete design automatically transfers IP rights is a common mistake. Without a clear contractual agreement, the designer or manufacturer may retain copyright or design rights, limiting your ability to reproduce or modify the product.

2. Lack of IP Clauses in Contracts

Failing to include explicit IP clauses in procurement contracts can lead to disputes. Ensure contracts specify who owns the design, moulds, and any derivative works, and whether usage rights are exclusive or non-exclusive.

3. Use of Proprietary Moulds Without Licensing

Some suppliers use patented or trademarked mould designs. Sourcing products made with such moulds without proper licensing exposes you to infringement claims, especially if the product is used commercially or replicated.

4. Reverse Engineering Risks

Attempting to replicate a competitor’s Pot Mould Concrete design without authorization—even if inspired by publicly available products—can lead to IP litigation if the original design is protected.

5. Inadequate Documentation of Original Designs

Failing to document the design creation process (e.g., sketches, CAD files, approvals) weakens your position in asserting ownership or defending against infringement claims. Proper records are essential for IP protection.

Best Practices to Avoid Pitfalls

- Define clear technical and aesthetic specifications upfront.

- Audit suppliers for quality certifications and production capabilities.

- Require sample approvals and conduct batch testing.

- Include comprehensive IP clauses in contracts, specifying ownership and usage rights.

- Conduct IP due diligence when using third-party designs or moulds.

- Register original designs where applicable to strengthen IP protection.

By proactively addressing these quality and IP pitfalls, stakeholders can ensure reliable supply, legal compliance, and successful project outcomes when sourcing Pot Mould Concrete.

Logistics & Compliance Guide for Pot Mould Concrete

Product Overview and Handling Requirements

Pot Mould Concrete is a precast concrete product typically used in architectural and landscaping applications. It is manufactured using reusable pot-shaped moulds to create consistent cylindrical or decorative forms. Due to its weight and fragility, proper handling, packaging, and transportation are critical to ensure product integrity and safety.

Packaging and Unit Load Configuration

Pot Mould Concrete units must be securely packaged to prevent chipping, cracking, or breakage during transit. Recommended packaging includes:

– Wooden skids or pallets sized appropriately to the unit diameter.

– Corner protectors and edge guards for exposed edges.

– Shrink-wrapping or stretch-wrapping to stabilize units on the pallet.

– Interlayer cardboard or foam padding between stacked units (if allowed by design and weight limits).

– Clearly labeled top and side markings indicating “Fragile,” “This Side Up,” and weight per unit.

Stacking height should not exceed manufacturer specifications or structural limits of the packaging to prevent bottom-unit damage.

Transportation and Carrier Specifications

Transport of Pot Mould Concrete requires specialized freight handling due to product weight (typically 200–800 kg per unit, depending on size). Key logistics considerations:

– Use of flatbed trucks, low-bed trailers, or enclosed freight vans with forklift or crane access.

– Securement using ratchet straps, load bars, or custom cradles to prevent shifting.

– Avoid open transport in inclement weather unless units are fully covered or waterproofed.

– Coordinate with carriers experienced in heavy, non-standard building materials.

Ensure delivery schedules account for potential delays due to route restrictions (e.g., bridge weight limits, urban access).

Site Delivery and Unloading Procedures

On-site logistics must prioritize safety and product protection:

– Confirm site accessibility (road width, ground bearing capacity, overhead clearance).

– Require trained personnel and appropriate equipment (e.g., forklift, crane, telehandler) for unloading.

– Designate a safe, level staging area free of debris and water accumulation.

– Conduct a visual inspection upon delivery; document any damage before signing delivery receipt.

Avoid dragging or rolling units, which may cause edge damage.

Regulatory Compliance and Documentation

Ensure compliance with all applicable regional and international regulations:

– Building Codes: Confirm product meets local structural and fire safety standards (e.g., ASTM C39 for compressive strength, if applicable).

– Environmental Regulations: Verify concrete mix complies with environmental standards (e.g., low chloride content, use of supplementary cementitious materials).

– Transportation Regulations: Adhere to weight and dimension limits under national freight laws (e.g., FMCSA in the U.S., ADR in Europe).

– Customs Documentation (if international): Provide commercial invoice, packing list, certificate of origin, and product conformity certification (e.g., CE marking, if exported to EU).

Quality Assurance and Traceability

Maintain batch traceability for compliance and quality control:

– Label each batch with production date, mix design, and batch number.

– Retain compressive strength test reports and material certifications.

– Implement a quality checklist for pre-shipment inspection.

Safety and Training Requirements

Personnel involved in handling Pot Mould Concrete must be trained in:

– Safe lifting techniques and use of mechanical aids.

– Hazard identification (e.g., pinch points, falling objects).

– Emergency procedures for load shifts or product breakage.

Provide Material Safety Data Sheets (MSDS) for any chemical additives used in the concrete mix.

Sustainability and End-of-Life Considerations

Promote sustainable logistics practices:

– Optimize load planning to reduce transport emissions.

– Reuse or recycle packaging materials where possible.

– Advise clients on proper disposal or recycling options for damaged units (concrete can often be crushed and reused as aggregate).

Adherence to these logistics and compliance guidelines ensures safe, efficient delivery and regulatory alignment for Pot Mould Concrete products.

In conclusion, sourcing pot mould concrete requires careful consideration of material quality, supplier reliability, cost-efficiency, and project-specific requirements. Pot mould concrete, often used for precast elements such as pots, planters, and decorative structures, demands a mix design that ensures durability, aesthetic finish, and resistance to weathering. It is essential to source materials from reputable suppliers who adhere to industry standards and provide consistent product quality. Additionally, evaluating transportation logistics, lead times, and environmental impact contributes to a sustainable and efficient procurement process. By establishing clear specifications and maintaining strong supplier relationships, stakeholders can ensure the successful integration of high-quality pot mould concrete into their projects, ultimately achieving both structural and aesthetic objectives.