The global portable laser marking machine market is experiencing robust growth, driven by increasing demand for precision labeling across industries such as automotive, electronics, medical devices, and aerospace. According to a report by Mordor Intelligence, the global laser marking machines market was valued at USD 1.78 billion in 2023 and is projected to reach USD 2.65 billion by 2029, growing at a CAGR of approximately 6.8% during the forecast period. This expansion is fueled by advancements in fiber laser technology, rising adoption of automation, and the need for tamper-proof, permanent marking solutions in manufacturing environments. As industries prioritize portability, efficiency, and integration with smart factory systems, the demand for compact, high-performance laser markers has surged. In this evolving landscape, a select group of manufacturers has emerged as leaders in innovation, reliability, and application versatility—setting the benchmark for quality in portable laser marking solutions.

Top 9 Portable Laser Marker Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Industrial Laser Marking & Dot Peen Marking Solutions

Website: telesis.com

Key Highlights: At Telesis Technologies, we’re dedicated to creating the perfect laser marking system for you, with integrated software solutions and custom machines….

#2 Automator Marking Systems

Founded: 1940

Website: automator.com

Key Highlights: Since 1940, Automator Marking Systems has been a world leader in industrial marking solutions, with an unwavering commitment to customer-centric innovation….

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

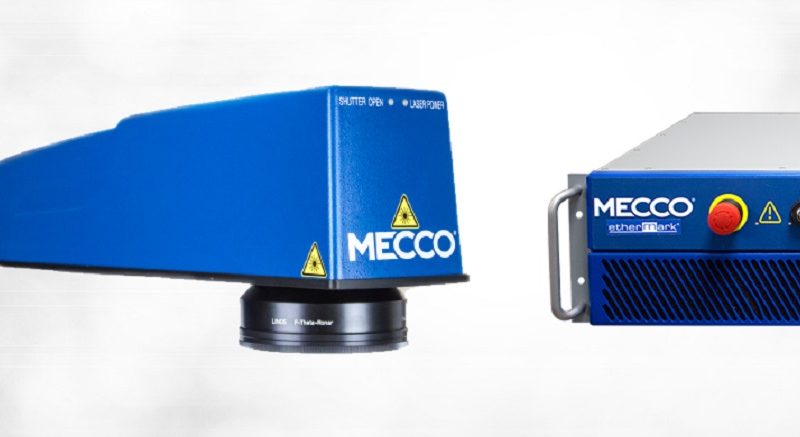

#5 MECCO

Website: mecco.com

Key Highlights: Our expertise in automated laser engraving and pin marking systems encompasses a comprehensive range of solutions for your industry, materials, and ……

#6 Handheld Laser Marking Systems

Website: laserphotonics.com

Key Highlights: The MarkStar Handheld Pro+ Marking Laser 1030 is our most powerful handheld tool for accelerated permanent marking. Delivering 30% more power than other ……

#7 Leader In Permanent Marking Solutions

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

#8 Lase

Website: permanentmarking.com

Key Highlights: The LaseNGo is a portable, handheld class 1 MOPA laser engraver on wheels, offering the flexibility for marking large objects like pipes, large containers, ……

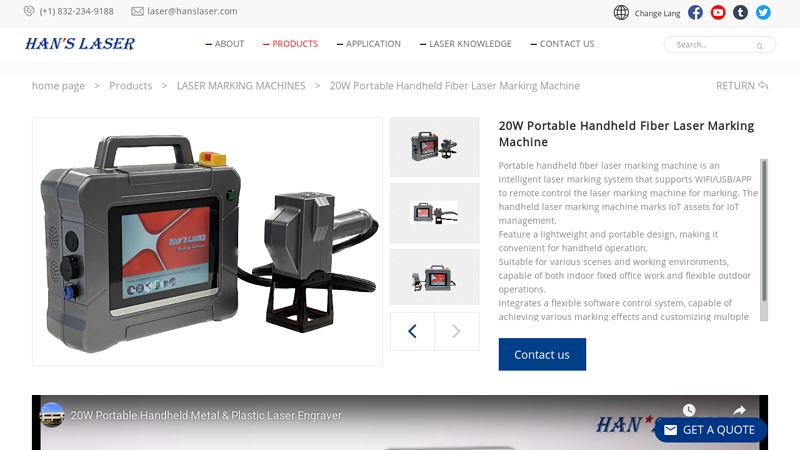

#9 20W Portable Handheld Fiber Laser Marker & Marking Machine

Website: us.hanslaser.net

Key Highlights: 20W portable laser marking machine is equipped with a high-precision 2D scanning head. With laser etching completed within 20s, it achieves fast marking….

Expert Sourcing Insights for Portable Laser Marker

H2: Market Trends for Portable Laser Markers in 2026

The global market for portable laser markers is projected to experience significant growth and transformation by 2026, driven by technological advancements, increasing demand for precision marking across industries, and the rising need for flexible, on-site solutions. Key trends shaping the 2026 landscape include:

1. Rising Demand in Industrial and Field Applications

By 2026, industries such as aerospace, automotive, oil & gas, and construction are increasingly adopting portable laser markers for on-site part identification, traceability, and maintenance documentation. The ability to mark serial numbers, barcodes, and logos directly on large or immobile components eliminates the need for part removal, reducing downtime and labor costs.

2. Advancements in Battery Technology and Portability

Ongoing improvements in lithium-ion and solid-state battery technologies are enabling longer operational runtimes and lighter, more compact designs. By 2026, many portable laser markers will feature extended battery life (up to 8+ hours), enhanced durability, and ergonomic designs, making them ideal for field technicians and mobile operations.

3. Integration with Industry 4.0 and IoT

Portable laser markers are increasingly being integrated into smart manufacturing ecosystems. By 2026, many models will support wireless connectivity (Wi-Fi, Bluetooth), cloud-based job management, and compatibility with enterprise resource planning (ERP) and manufacturing execution systems (MES). This enables real-time data capture, digital work instructions, and seamless traceability across supply chains.

4. Growth in Fiber and Green Laser Technologies

Fiber lasers remain dominant due to their reliability and effectiveness on metals, but green and UV lasers are gaining traction for use on sensitive or heat-sensitive materials (e.g., plastics, medical devices). By 2026, manufacturers are expected to offer more hybrid or multi-wavelength portable systems to broaden application versatility.

5. Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, is expected to be a high-growth region for portable laser markers due to expanding manufacturing bases and government initiatives promoting industrial automation. Local production and competitive pricing will further accelerate market penetration.

6. Focus on User-Friendly Software and Automation

By 2026, intuitive software with touchscreen interfaces, pre-programmed templates, and AI-assisted alignment systems will become standard. These features reduce operator training time and improve marking accuracy, especially in complex or variable environments.

7. Regulatory and Sustainability Pressures

Environmental regulations and sustainability goals are pushing industries toward non-contact, chemical-free marking solutions. Portable laser markers offer a clean, permanent alternative to ink-based systems, aligning with green manufacturing trends and reducing consumable waste.

Conclusion

By 2026, the portable laser marker market will be characterized by smarter, more connected, and energy-efficient systems tailored for diverse industrial needs. As demand for mobility, precision, and digital integration grows, portable laser markers are poised to become indispensable tools in asset management, quality control, and industrial traceability.

Common Pitfalls When Sourcing a Portable Laser Marker (Quality, IP)

Sourcing a portable laser marker involves navigating several potential challenges, particularly concerning product quality and intellectual property (IP) protection. Overlooking these aspects can lead to performance issues, legal risks, and financial loss. Below are key pitfalls to avoid:

Inadequate Quality Control and Performance Verification

Many suppliers, especially those from low-cost manufacturing regions, may offer portable laser markers that lack rigorous quality assurance. Buyers often encounter units with inconsistent marking depth, poor beam focus, or premature component failure due to substandard materials and assembly processes. Without third-party testing or performance validation, the laser may fail to meet required specifications in real-world applications.

Misrepresentation of IP Protection and Authenticity

A significant risk is sourcing laser markers that infringe on existing patents or incorporate counterfeit components. Some suppliers may falsely claim compliance with IP regulations or use unlicensed laser diode technology. This exposes the buyer to legal liability, import seizures, and reputational damage. Always verify the supplier’s IP compliance documentation and ensure the laser source and control systems are from reputable, licensed manufacturers.

Overlooking Ingress Protection (IP) Rating Accuracy

Portable laser markers are often marketed with high IP ratings (e.g., IP54 or IP65) suggesting dust and water resistance. However, these claims may not be independently verified. Units may lack proper sealing or use inferior gaskets, leading to internal damage in harsh environments. Request certified test reports from recognized laboratories to confirm the stated IP rating.

Lack of After-Sales Support and Spare Parts Availability

Low-cost suppliers may disappear after the sale or fail to provide technical support, firmware updates, or replacement parts. This is particularly problematic for portable units used in field operations, where downtime can be costly. Ensure the supplier offers a clear warranty, accessible support channels, and a documented supply chain for critical components.

Hidden Costs from Non-Compliant Safety Features

Some portable lasers may lack essential safety certifications (e.g., FDA, CE, or IEC 60825) or include insufficient safety interlocks and labeling. Non-compliant units can be rejected at customs or pose operator hazards. Always confirm that the device meets regional regulatory standards and includes proper safety mechanisms.

Avoiding these pitfalls requires due diligence: vet suppliers thoroughly, request product samples, verify certifications, and consult legal experts when assessing IP risks.

Logistics & Compliance Guide for Portable Laser Marker

This guide outlines essential logistics considerations and compliance requirements for the safe and legal transportation, handling, and operation of a portable laser marker. Adherence to these guidelines ensures regulatory compliance, operational safety, and efficient supply chain management.

Regulatory Classification and Documentation

Identify and classify the portable laser marker according to international and local regulations. The device typically falls under laser product safety standards (e.g., IEC 60825-1) and may be subject to export controls depending on power output and technical specifications. Ensure all technical documentation, including the Declaration of Conformity (DoC), laser classification label (e.g., Class 4), user manual, and safety data sheet (if applicable), are complete and available. For international shipments, prepare commercial invoices, packing lists, and certificates of origin. Verify if the product requires an export license (e.g., under EAR or ITAR in the U.S.) based on its laser power and destination country.

Packaging and Handling Requirements

Use robust, shock-resistant packaging designed to protect the laser marker and its components during transit. Include internal cushioning (e.g., foam inserts) to prevent movement and damage. Clearly label packaging with hazard warnings such as “Fragile,” “This Side Up,” and “Laser Radiation – Avoid Direct Exposure.” Do not power on or operate the device during transportation. Ensure batteries (if removable) are either removed or properly secured and protected against short circuits in accordance with IATA/IMDG regulations for lithium batteries.

Transportation and Shipping Compliance

Comply with applicable transport regulations for ground, air, and sea freight. For air transport, follow IATA Dangerous Goods Regulations if the device contains lithium batteries or meets criteria for hazardous materials. Shipments containing Class 3B or Class 4 lasers may require specific labeling and handling instructions. Confirm carrier-specific policies regarding laser devices. Maintain a chain of custody and tracking for high-value units. Avoid extreme environmental conditions (e.g., temperature, humidity) during storage and transit to prevent damage.

Import/Export Controls and Customs Clearance

Verify import restrictions or licensing requirements in the destination country. Some jurisdictions regulate high-power lasers due to safety or dual-use concerns. Provide accurate Harmonized System (HS) codes (e.g., 8515.21 or 9013.20) and product descriptions to customs authorities. Retain records of all compliance documentation for a minimum of five years. Engage licensed customs brokers when necessary to facilitate smooth clearance and avoid delays.

On-Site Safety and Operational Compliance

Upon delivery, ensure end-users comply with local occupational health and safety regulations. Operators must be trained in laser safety (e.g., ANSI Z136.1 in the U.S. or EN 60825 in Europe). Use appropriate personal protective equipment (PPE), including laser safety goggles rated for the emission wavelength. Install warning signs in operation areas and implement controlled access zones when using Class 4 lasers. Perform regular equipment maintenance and safety checks as specified by the manufacturer.

Disposal and End-of-Life Management

Dispose of the portable laser marker and its components in accordance with local environmental and electronic waste (WEEE) regulations. Do not discard batteries in regular trash. Coordinate with certified e-waste recyclers to ensure proper handling of optical components, electronics, and hazardous materials. Maintain records of disposal for compliance and audit purposes.

Conclusion for Sourcing a Portable Laser Marker

After a thorough evaluation of market options, technical requirements, and cost considerations, sourcing a portable laser marker presents a strategic opportunity to enhance operational flexibility, improve marking accuracy, and increase efficiency across various work environments. Portable laser markers offer distinct advantages such as ease of use, mobility, and the ability to mark materials on-site without the need for large, fixed installations.

Key factors such as laser type (fiber, CO2, or UV), marking speed, precision, compatibility with different materials (metal, plastic, etc.), battery life, software integration, and durability in industrial conditions must be carefully assessed to ensure the selected unit meets both current and future needs. Additionally, choosing a reputable supplier with adequate technical support, training, and warranty coverage is critical for long-term reliability and performance.

In conclusion, investing in a high-quality portable laser marker aligns with modern demands for agility and precision in manufacturing, maintenance, and production traceability. With proper due diligence in selection and supplier evaluation, the integration of a portable laser marking solution will deliver significant value through improved workflow efficiency, product traceability, and reduced downtime.