The global handheld laser cleaning machine market is experiencing robust growth, driven by increasing demand for eco-friendly, non-abrasive cleaning solutions across industries such as automotive, aerospace, electronics, and heritage conservation. According to a report by Mordor Intelligence, the global laser cleaning market was valued at USD 707.7 million in 2023 and is projected to grow at a CAGR of over 24.5% from 2024 to 2029. This surge is fueled by the rising adoption of Industry 4.0 technologies, stringent environmental regulations, and the need for precision maintenance in manufacturing processes.

Handheld and portable laser cleaning systems, in particular, are gaining traction due to their operational flexibility, minimal maintenance, and compatibility with robotic integration. Grand View Research further supports this trend, noting that advancements in fiber laser technology and decreasing costs of diode pumps are accelerating market penetration. As demand escalates, a competitive landscape has emerged, with several manufacturers leading innovation in power efficiency, ergonomics, and智能化 features. The following list highlights the top 8 manufacturers excelling in the portable handheld laser cleaning segment, recognized for their technological advancements, global footprint, and comprehensive product offerings.

Top 8 Portable Handheld Laser Cleaning Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 SFX Laser

Website: sfxlaser.com

Key Highlights: SFX Laser is a 20+ years professional laser equipment manufacturer including laser cleaning machine, laser welding machine, fiber laser engraver, ……

#2 Laser Cleaners (Handheld)

Website: laserstar.net

Key Highlights: Free deliveryLaserStar Technologies is a state-of-the-art modern laser system manufacturer located in Orlando, FL USA and provides quality welding, marking+engraving ……

#3 Laser Cleaning Machine Manufacturer

Website: hantencnc.com

Key Highlights: We offer a wide range of laser cleaners, from 100W to 3000W. Our lineup includes handheld, backpack, and trolley-type products to meet diverse cleaning needs….

#4 Laser Cleaning Machine Manufacturers

Website: fortunelaser.com

Key Highlights: FL-C1000 Pulse Laser Cleaning Machine · Fortunelaser FL-C6000 6000W Continuous Wave Laser Cleaning Machine · Mopa 3-in-1 Backpack Pulse Laser Cleaner · FL-C300N ……

#5 SHARK P CL Industrial Laser Cleaning Machines (100

Website: pulsar-laser.com

Key Highlights: The SHARK P CL 500A is an air-cooled laser cleaning machine with 500 W output, combining high laser power with a compact and portable system design. AIRKNIFE ……

#6 Handheld Laser Cleaning Machines

Website: ipgphotonics.com

Key Highlights: Handheld and portable laser cleaning machines designed for manual applications including rust removal, paint stripping, restoration, and more….

#7 Portable Laser Cleaning Machine

Website: laserphotonics.com

Key Highlights: The Marlin PF-1010 is an effective tool for speedy polishing, meticulous cleaning, top-layer coating removal, and other surface preparation needs for small- ……

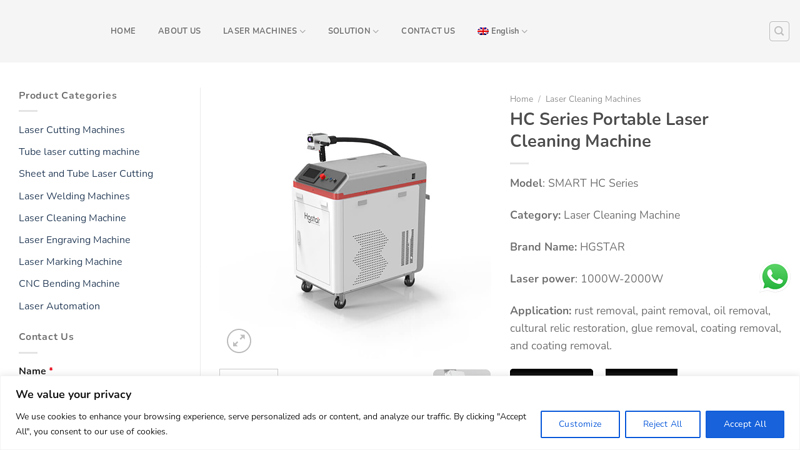

#8 HC series portable laser cleaning machine

Website: hg-star.com

Key Highlights: Laser cleaning machine can be used for metal rust removal, oil cleaning, local quenching, surface roughening, coating removal, weld cleaning….

Expert Sourcing Insights for Portable Handheld Laser Cleaning Machine

H2: 2026 Market Trends for Portable Handheld Laser Cleaning Machines

The global market for portable handheld laser cleaning machines is poised for significant growth and transformation by 2026, driven by technological advancements, rising environmental regulations, and expanding industrial applications. This section analyzes key market trends shaping the industry in 2026.

1. Rising Demand for Eco-Friendly Cleaning Solutions

One of the most influential trends in 2026 is the global shift toward sustainable and environmentally responsible manufacturing and maintenance practices. Portable handheld laser cleaning machines offer a chemical-free, non-abrasive alternative to traditional cleaning methods such as sandblasting and solvent washing. With tightening environmental regulations—especially in North America and Europe—industries are increasingly adopting laser cleaning to reduce hazardous waste and lower their carbon footprint, fueling market expansion.

2. Advancements in Laser Technology and Portability

By 2026, manufacturers have achieved notable improvements in laser efficiency, battery life, and device ergonomics. Fiber laser systems have become more compact and energy-efficient, enabling longer operational times on a single charge. Enhanced portability and user-friendly interfaces are making these machines accessible to a broader range of operators, even in remote or confined workspaces, thereby increasing adoption across sectors like automotive, aerospace, and heritage conservation.

3. Expansion into New Industrial Applications

While initially used primarily in heavy industries for rust and paint removal, the application scope of handheld laser cleaners has broadened significantly by 2026. They are now widely used in precision cleaning for electronics, mold maintenance in plastics manufacturing, surface preparation for welding, and even in the restoration of historical artifacts. This diversification is opening new revenue streams and attracting investment from both startups and established industrial equipment manufacturers.

4. Growth in Asia-Pacific Markets

The Asia-Pacific region, particularly China, India, and South Korea, is emerging as a major growth hub in 2026. Rapid industrialization, government support for advanced manufacturing technologies, and increasing awareness of laser cleaning benefits are accelerating adoption. Additionally, local production of laser components is reducing costs and improving supply chain resilience, making handheld systems more affordable and accessible.

5. Integration with Smart Manufacturing and IoT

In line with Industry 4.0 trends, portable laser cleaning devices in 2026 are increasingly equipped with smart features such as real-time monitoring, data logging, and remote diagnostics via IoT connectivity. These capabilities allow for predictive maintenance, performance optimization, and integration into digital workflow systems, enhancing productivity and justifying higher initial investments.

6. Competitive Landscape and Price Optimization

The market is witnessing intensified competition, with both established players (e.g., CleanLasers, Laser Photonics) and new entrants offering innovative, cost-effective models. By 2026, increased production scale and technological maturity have led to a downward trend in unit prices, making handheld laser cleaners more viable for small and medium-sized enterprises (SMEs).

7. Regulatory Support and Safety Standards

Governments and industry bodies have introduced clearer safety standards and operational guidelines for laser equipment by 2026, improving user confidence. Mandatory training and certification programs have also reduced workplace accidents, promoting wider acceptance across industries.

Conclusion

By 2026, the portable handheld laser cleaning machine market is characterized by strong growth, technological innovation, and expanding applications. Driven by sustainability goals, digital integration, and global industrial modernization, the market is expected to maintain a robust compound annual growth rate (CAGR) of over 15% through the mid-2020s. Companies that invest in R&D, scalability, and user-centric design will be best positioned to capitalize on these evolving trends.

H2: Common Pitfalls When Sourcing Portable Handheld Laser Cleaning Machines (Quality and Intellectual Property)

Sourcing portable handheld laser cleaning machines from global suppliers can offer cost advantages, but it also comes with significant risks—especially concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial for making informed procurement decisions.

1. Inconsistent Product Quality and Performance

A major challenge is the variability in build quality and laser performance across suppliers, particularly from regions with less stringent manufacturing standards. Some vendors may use substandard components such as low-grade laser diodes, inefficient cooling systems, or poor ergonomics, leading to reduced machine lifespan and unreliable cleaning results. Without independent verification or third-party testing, buyers may receive units that fail to meet advertised specifications.

2. Misleading Technical Specifications

Suppliers may exaggerate power ratings (e.g., labeling a 100W machine as equivalent to a 300W system) or omit critical details like pulse frequency, beam quality (M²), and duty cycle. This “spec sheet inflation” misleads buyers into believing they are purchasing high-performance equipment when the actual output may be inadequate for industrial applications.

3. Lack of Safety and Compliance Certification

Many low-cost suppliers fail to provide necessary safety certifications such as CE, FDA (for U.S. import), or IEC 60825 for laser safety. Non-compliant machines pose serious safety risks to operators and may be barred from use in regulated environments, leading to legal and financial liabilities.

4. Intellectual Property (IP) Infringement Risks

Some manufacturers produce clones or reverse-engineered versions of patented laser cleaning technologies. Purchasing such equipment—even unknowingly—can expose buyers to IP litigation, especially if the machines are imported into markets with strong IP enforcement (e.g., the U.S. or EU). Customs authorities may seize infringing products, and businesses may face reputational damage.

5. Poor After-Sales Support and Spare Parts Availability

Many overseas suppliers offer limited technical support, training, or warranty coverage. When machines break down, obtaining replacement parts or repairs can take weeks or months, resulting in costly downtime. Some vendors disappear altogether after the sale, leaving buyers without recourse.

6. Hidden Costs and Scalability Issues

While initial purchase prices may seem attractive, hidden costs—such as import duties, compliance testing, or retrofitting for local standards—can significantly increase total ownership cost. Additionally, machines that work for small-scale trials may not scale effectively for larger industrial operations.

7. Inadequate Documentation and Software Lock-in

Poorly documented user manuals, proprietary control software, or lack of API access can hinder integration into existing workflows. Some suppliers lock users into closed ecosystems, limiting customization and long-term flexibility.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct factory audits or use third-party inspection services.

– Request sample testing under real-world conditions.

– Verify compliance with international safety and laser standards.

– Perform IP due diligence, including patent searches.

– Negotiate service agreements and secure access to spare parts.

– Work with legal counsel to include IP indemnification clauses in procurement contracts.

By proactively addressing quality and IP concerns, businesses can reduce risk and ensure reliable, compliant, and legally safe deployment of portable handheld laser cleaning technology.

Logistics & Compliance Guide for Portable Handheld Laser Cleaning Machine

Product Classification and Regulatory Overview

The Portable Handheld Laser Cleaning Machine is classified as a Class 4 laser product under international laser safety standards (IEC 60825-1). Due to its high-intensity laser emission, it is subject to strict regulations regarding transportation, import/export, safety, and usage. Compliance with local, national, and international regulations is mandatory for legal distribution and operation.

International Shipping and Transportation

When shipping internationally, ensure the machine is packaged in shock-resistant, electrostatic-discharge (ESD)-protected packaging. Label all shipments clearly with “Fragile,” “This Side Up,” and “Class 4 Laser Product – Do Not Stare Into Beam or View Directly with Optical Instruments.” Use UN-certified packaging if required. Air transport must comply with IATA Dangerous Goods Regulations (DGR), specifically under Category UN3490 (Laser devices, Class 9). Ground and sea freight must adhere to IMDG (for sea) and ADR (for road in Europe) guidelines as applicable.

Export Control and Documentation

Portable handheld laser cleaning machines may be subject to export control regulations such as the U.S. Export Administration Regulations (EAR) under ECCN 6A003.b.4 or similar controls in other jurisdictions. A valid export license or license exception may be required depending on destination country, end-user, and end-use. Required documentation includes a commercial invoice, packing list, bill of lading/air waybill, and a laser product compliance statement. For shipments to certain countries, additional authorization (e.g., from BIS in the U.S.) may be necessary.

Import Regulations and Duties

Import regulations vary by country. Common requirements include customs declarations, payment of import duties and VAT, and conformity assessment. In the European Union, the machine must comply with the CE marking directives, including the Machinery Directive (2006/42/EC), Electromagnetic Compatibility (EMC) Directive (2014/30/EU), and the Low Voltage Directive (2014/35/EU). In the U.S., compliance with FDA/CDRH regulations for laser products (21 CFR 1040.10 and 1040.11) is required, including product reporting and certification. Be prepared to provide technical files, test reports, and user manuals in the local language.

Laser Safety and User Compliance

End-users must comply with laser safety standards such as ANSI Z136.1 (U.S.) or IEC 60825 (international). The device must be operated in a controlled environment with appropriate laser safety interlocks, warning signs, and protective barriers. Operators must wear certified laser safety goggles with the correct optical density (OD) for the laser wavelength (commonly 1064 nm for fiber lasers). Training on safe operation, emergency procedures, and maintenance is required. A Laser Safety Officer (LSO) should be designated in workplaces using Class 4 lasers.

Environmental and Disposal Considerations

The machine contains electronic components and batteries (if applicable) that may be subject to WEEE (Waste Electrical and Electronic Equipment) regulations in the EU and similar e-waste laws elsewhere. Do not dispose of in regular trash. Return to the manufacturer or an authorized recycling facility. Laser cleaning may generate hazardous fumes or particulates; use with local exhaust ventilation and follow OSHA or equivalent workplace safety standards for air quality monitoring.

Warranty and Maintenance Compliance

To maintain compliance and warranty validity, only authorized service personnel should perform repairs or maintenance. Use only OEM replacement parts. Regular maintenance logs must be kept, including laser output calibration and safety system checks. Non-compliant modifications may void certifications and create safety hazards.

Summary and Best Practices

Ensure all logistics and compliance steps are documented. Verify destination country requirements before shipping. Provide end-users with multilingual safety manuals and compliance certificates. Maintain records of export licenses, safety certifications, and training logs. Regularly review regulatory updates to remain compliant with evolving standards.

In conclusion, sourcing a portable handheld laser cleaning machine offers a highly efficient, eco-friendly, and cost-effective solution for a wide range of industrial cleaning applications. These machines provide precise, non-abrasive cleaning without the use of chemicals or media, reducing environmental impact and minimizing substrate damage. Their portability and ease of operation make them ideal for on-site maintenance, restoration, and manufacturing processes across various sectors—including automotive, aerospace, mold maintenance, and heritage conservation.

When sourcing such equipment, it is essential to consider factors such as laser power, pulse frequency, beam quality, built-in safety features, ease of maintenance, and after-sales support. Choosing a reputable supplier with proven technology and customer service ensures long-term reliability and optimal performance.

Ultimately, investing in a high-quality portable handheld laser cleaning machine not only enhances operational efficiency and cleaning precision but also supports sustainability goals. As industries continue to adopt advanced cleaning technologies, laser cleaning stands out as a forward-thinking solution that aligns with modern demands for performance, safety, and environmental responsibility.