The global poplin textile market is experiencing steady growth, driven by rising demand for lightweight, durable fabrics in apparel and home textiles. According to Grand View Research, the global cotton fabric market—which includes poplin—was valued at USD 62.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. Poplin, known for its tightly woven, plain-weave structure and smooth finish, is particularly favored in premium shirting and formal wear, contributing to its increasing adoption across fashion and lifestyle segments. Additionally, Mordor Intelligence projects continued momentum in technical and blended poplin variants, fueled by innovation in sustainable textile production and rising consumer preference for breathable, low-maintenance fabrics. As the demand for high-quality poplin grows, a select group of manufacturers have emerged as industry leaders, combining scale, innovation, and supply chain efficiency to meet evolving global standards.

Top 9 Poplin Textile Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buy Cotton Poplin Fabric from Our Fabric Manufacturer & Factory

Domain Est. 2024

Website: fandafabrics.com

Key Highlights: We offer premium 100% cotton poplin fabric, known for its smooth, crisp texture and versatile applications. Our fabric is available in a wide range of colors ……

#2 Poplin – Cotton

Domain Est. 2000

Website: thefabricofourlives.com

Key Highlights: Poplin is a plain weave cotton fabric with very fine horizontal “ribs” that results in a strong, crisp fabric with a silky, lustrous surface….

#3 Buy poplin fabric online

Domain Est. 2003

#4 Poplin Fabric By The Yard

Domain Est. 2014

#5 Shop Woven Poplin Fabric

Domain Est. 2016

Website: fabricsyard.com

Key Highlights: A comfortable and stylish material for a range of clothing. We offer poplin fabric by the yard both solid colors and stripe patterns. Top your poplin fabric ……

#6 Poplin Laundry Service

Domain Est. 2021

Website: poplin.co

Key Highlights: Your clothes like you’ve never seen them. Your Laundry Pro will professionally wash, flawlessly dry, expertly fold, and deliver your laundry….

#7 Poplin Shirts Manufacturing

Domain Est. 2024

Website: thygesenapparel.com

Key Highlights: Thygesen Textile Vietnam specializes in manufacturing high-quality Poplin Shirts, providing production services tailored to the unique needs of brands….

#8 Poplin Fabric Collection

Domain Est. 2024

Website: prinstitch.com

Key Highlights: Free deliveryExplore hundreds of fabric bases—from cottons and polyesters to spandex blends—and a variety of products, all designed for quality, comfort, and versatility….

#9 Poplin & Co USA: Poplin & Co. USA

Domain Est. 2017

Expert Sourcing Insights for Poplin Textile

2026 Market Trends for Poplin Textile

1. Sustainability Driving Material Innovation and Sourcing

By 2026, environmental responsibility will be a dominant factor shaping the poplin textile market. Consumers and brands alike are demanding greater transparency and lower environmental impact. This trend is pushing manufacturers toward organic cotton poplin, recycled fiber blends (such as recycled polyester-cotton poplin), and low-impact dyeing processes. Certification standards like GOTS (Global Organic Textile Standard) and OEKO-TEX will become baseline requirements for premium poplin products. Additionally, traceability in the supply chain—from farm to fabric—will be increasingly expected, with blockchain and digital ID solutions gaining traction among leading producers.

2. Expansion into Technical and Performance Applications

While traditionally valued for its crisp handfeel and durability in apparel, poplin is evolving beyond fashion. In 2026, expect increased use of engineered poplin in technical textiles, including performance workwear, outdoor gear, and antimicrobial medical textiles. Innovations such as moisture-wicking finishes, UV protection, and wrinkle resistance are being integrated into poplin weaves, expanding its utility. This shift is fueled by demand for versatile, functional fabrics that combine comfort with durability, particularly in hybrid work environments and active lifestyles.

3. Regional Shifts in Production and Demand

Asia, particularly India and China, will remain central to poplin textile production due to established cotton infrastructure and manufacturing capabilities. However, rising labor costs and sustainability regulations may encourage some brands to diversify sourcing to Southeast Asia (e.g., Vietnam, Bangladesh) or nearshore production in Eastern Europe and North Africa. Simultaneously, demand for premium poplin is growing in North America and Western Europe, driven by the resurgence of tailored casual wear and minimalist fashion aesthetics. Emerging markets in Latin America and Africa will also contribute to rising mid-tier demand.

4. Digitalization and Customization in Supply Chains

The poplin market in 2026 will see greater integration of digital tools across design, production, and distribution. On-demand manufacturing, enabled by digital printing and agile supply chains, will allow brands to offer customized poplin fabrics with reduced waste. AI-driven forecasting will help mills optimize inventory and respond faster to micro-trends. Furthermore, virtual sampling and 3D fabric simulation will reduce lead times and support faster product development cycles, particularly in fast fashion and sustainable slow fashion segments alike.

5. Resilience in Fashion and Home Textiles

Poplin’s clean aesthetic and versatility will ensure its continued relevance in both apparel and home textiles. In fashion, it will remain a staple for shirts, dresses, and lightweight outerwear, especially in capsule wardrobes emphasizing quality over quantity. In home décor, poplin will gain favor for upholstery, curtains, and bedding due to its durability and ability to hold vibrant prints. The trend toward “quiet luxury” and timeless design will further boost demand for high-quality, long-lasting poplin fabrics across both sectors.

Conclusion

The 2026 poplin textile market will be defined by sustainability, technological integration, and functional versatility. Success will depend on manufacturers’ ability to innovate responsibly, adapt to shifting consumer values, and leverage digital transformation. As both a classic and evolving fabric, poplin is poised to maintain strong market presence by balancing tradition with forward-looking applications.

Common Pitfalls When Sourcing Poplin Textile (Quality and Intellectual Property)

Sourcing poplin textile can be cost-effective and efficient, but buyers often encounter critical challenges related to quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate potential supply chain disruptions, legal issues, and reputational damage.

Inconsistent Fabric Quality

One of the most frequent issues in poplin sourcing is inconsistent quality across production batches. Poplin, a tightly woven plain-weave fabric, should have a crisp hand feel, uniform weave density, and consistent color. However, suppliers—especially lower-tier manufacturers—may cut corners by using inferior cotton blends, uneven yarn counts, or inconsistent dyeing processes. This results in variations in weight, shrinkage, color fastness, or pilling resistance, which can compromise the final product’s performance and aesthetics.

Mitigation Tip: Always request physical swatches and lab test reports (e.g., for colorfastness, shrinkage, and tensile strength) before bulk production. Implement third-party quality inspections during and post-manufacturing.

Lack of Transparency in Fiber Content

Mislabeling or vague specifications regarding fiber composition is another common issue. Some suppliers may advertise “100% cotton poplin” but deliver fabrics blended with polyester or lower-grade cotton to reduce costs. This not only affects garment quality but can also mislead consumers and violate textile labeling regulations in markets like the EU or the US.

Mitigation Tip: Require certified fiber test results (e.g., via SGS or Intertek) and include precise fiber content clauses in procurement contracts.

Poor Dyeing and Color Matching

Poplin is often used in apparel requiring precise color matching (e.g., uniforms, shirts). Sourcing from facilities without advanced dyeing capabilities can lead to batch-to-batch color variations or poor colorfastness (e.g., fading after wash). This is especially problematic when coordinating with other components like trims or linings.

Mitigation Tip: Use standardized color systems (e.g., Pantone) and conduct pre-production strike-offs. Specify acceptable tolerance levels (ΔE values) for color deviation.

Intellectual Property Infringement Risks

When sourcing custom-designed or branded poplin fabrics, there’s a risk of IP infringement—either unintentional or deliberate. Some suppliers may replicate patented weaves, registered patterns, or proprietary finishes without authorization. If these fabrics are imported, they can be seized at customs, leading to legal liability and lost investments.

Mitigation Tip: Conduct IP due diligence on both the supplier and the fabric design. Use confidentiality agreements (NDAs) and ensure contracts include IP indemnification clauses. Register designs in key markets when applicable.

Unauthorized Subcontracting

Suppliers may outsource production to unapproved subcontractors to meet deadlines or reduce costs. These secondary mills often lack the same quality controls or ethical standards, increasing the risk of quality defects and IP leaks. Subcontracting also makes traceability and compliance audits more difficult.

Mitigation Tip: Include anti-subcontracting clauses in contracts and conduct unannounced factory audits. Require full supply chain transparency.

Sustainability and Compliance Gaps

Buyers increasingly demand eco-friendly textiles, but some poplin suppliers may falsely claim certifications like OEKO-TEX® or GOTS. Using fabrics with harmful chemicals or unsustainable practices can result in compliance failures and consumer backlash.

Mitigation Tip: Verify certifications through official databases and request up-to-date test certificates. Prioritize suppliers with audited, sustainable production practices.

By proactively addressing these common pitfalls—through due diligence, clear contracts, and quality control protocols—sourcing professionals can ensure reliable, compliant, and high-quality poplin textile procurement.

Logistics & Compliance Guide for Poplin Textile

This guide outlines key logistics and compliance considerations for businesses involved in the sourcing, manufacturing, shipping, and sale of poplin textile. Adhering to these practices ensures smooth operations, legal adherence, and supply chain sustainability.

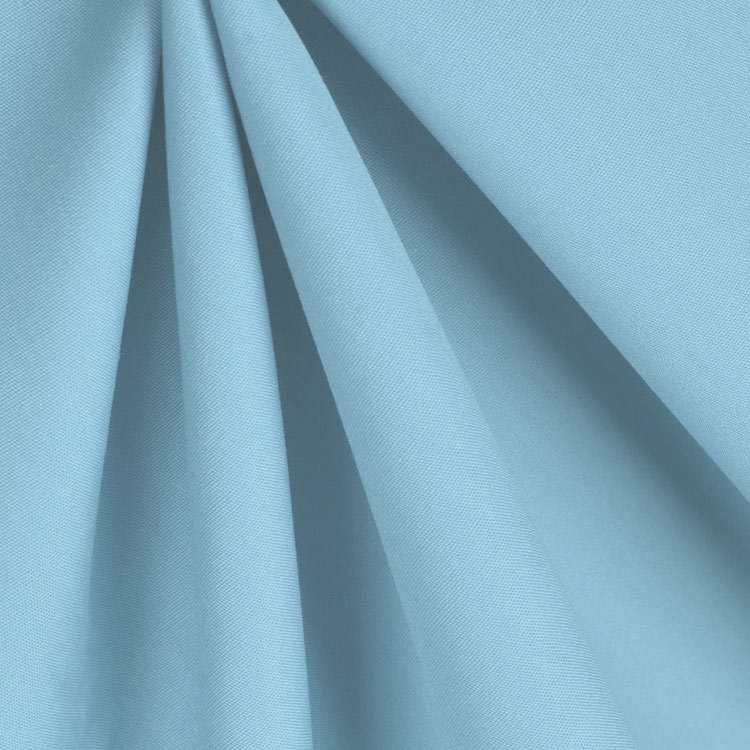

Understanding Poplin Textile Characteristics

Poplin is a tightly woven fabric typically made from cotton, silk, or synthetic fibers, known for its durability, smooth finish, and crisp hand feel. Its weight, composition, and finishing treatments impact packaging, storage, and shipping requirements. For example, cotton poplin may be more prone to wrinkling, while synthetic blends may require anti-static packaging.

Sourcing and Supplier Compliance

Ensure all suppliers adhere to ethical and legal standards. Conduct due diligence on mills and manufacturers, verifying compliance with labor laws (e.g., ILO standards), environmental regulations (e.g., wastewater treatment), and certifications such as OEKO-TEX® Standard 100 or GOTS (Global Organic Textile Standard) if applicable. Maintain documented supplier agreements that include quality benchmarks and compliance clauses.

Regulatory Requirements by Region

Different markets impose specific import and safety regulations. For instance:

– United States: Comply with FTC labeling rules (fiber content, country of origin, care instructions) and CPSC regulations if used in children’s apparel.

– European Union: Adhere to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and the EU Textile Regulation (EU) No 1007/2011 for labeling. CE marking may be required for certain end products.

– Canada: Follow the Textile Labelling Act and Care Labelling Regulations administered by the Competition Bureau.

Packaging and Labeling Standards

Use moisture-resistant, durable packaging to protect poplin rolls or cut fabric during transit. Labels must include:

– Fiber content (e.g., 100% Cotton Poplin)

– Country of origin

– Care instructions (washing, drying, ironing)

– Manufacturer or distributor information

Ensure labels are securely attached and legible to meet consumer protection laws.

Shipping and Transportation Logistics

Choose transportation methods (air, sea, or ground) based on volume, urgency, and cost. For international shipments:

– Prepare accurate commercial invoices, packing lists, and certificates of origin.

– Classify goods under the correct HS (Harmonized System) code—typically 5208.xx for cotton poplin or 5516.xx for synthetic variants.

– Account for Incoterms® (e.g., FOB, CIF) to define responsibilities between buyer and seller.

Customs Clearance and Duties

Ensure all documentation is complete to avoid delays at customs. Work with licensed customs brokers to calculate applicable tariffs, import quotas, and taxes. Be aware of trade agreements (e.g., USMCA, RCEP) that may reduce or eliminate duties for qualifying goods.

Inventory and Warehousing

Store poplin textile in dry, temperature-controlled environments to prevent mildew, shrinkage, or discoloration. Implement FIFO (First In, First Out) inventory practices to minimize aging and quality degradation. Use warehouse management systems (WMS) for tracking batch numbers and shelf life, especially for treated or specialty finishes.

Sustainability and Environmental Compliance

Minimize environmental impact by:

– Sourcing from mills with water and energy efficiency programs.

– Using recyclable or biodegradable packaging materials.

– Complying with local waste disposal regulations for textile offcuts and packaging.

Consider third-party certifications (e.g., bluesign®, ISO 14001) to demonstrate environmental responsibility.

Quality Assurance and Testing

Conduct regular quality inspections at pre-shipment and upon receipt. Test for:

– Fabric weight (GSM)

– Shrinkage rate

– Colorfastness (to washing, light, and rubbing)

– Pilling resistance

Maintain records of test reports to support compliance claims and customer inquiries.

Risk Management and Documentation

Develop contingency plans for supply chain disruptions (e.g., port delays, raw material shortages). Keep comprehensive records of contracts, compliance certificates, shipping documents, and communications for at least seven years to support audits and legal requirements.

Conclusion

Effective logistics and compliance management for poplin textile requires attention to detail, adherence to international standards, and proactive supplier engagement. By integrating these practices, businesses can ensure timely delivery, regulatory compliance, and sustained market access.

Conclusion for Sourcing Poplin Textile

Sourcing poplin textile requires a strategic approach that balances quality, cost, sustainability, and supply chain reliability. Poplin, known for its durability, smooth finish, and versatility, is widely used in apparel, uniforms, and home textiles, making it essential to partner with reputable suppliers who adhere to international quality standards. Factors such as fiber composition (cotton, polyester, or blends), fabric weight, weave tightness, and finishing treatments should be carefully evaluated to meet specific end-use requirements.

Sustainable and ethical sourcing is increasingly important, with many brands prioritizing eco-friendly production methods, organic certifications, and compliance with labor and environmental regulations. Developing long-term relationships with suppliers, conducting regular audits, and leveraging technology for supply chain transparency can enhance efficiency and mitigate risks.

Ultimately, successful sourcing of poplin fabric hinges on thorough market research, clear communication with suppliers, and a commitment to quality and sustainability—ensuring that the final product meets both performance expectations and corporate responsibility goals.