The global pool plumbing fittings market is experiencing steady expansion, driven by rising residential and commercial construction, growing emphasis on water recreational infrastructure, and increasing demand for energy-efficient pool systems. According to Mordor Intelligence, the swimming pool market—from which plumbing fittings are a critical component—is projected to grow at a CAGR of over 4.5% from 2024 to 2029. Complementing this, Grand View Research estimated the global swimming pool market size at USD 13.4 billion in 2022, with continued growth expected due to urbanization and rising disposable incomes, particularly in emerging economies. As demand for durable, leak-proof, and corrosion-resistant plumbing components rises, manufacturers of pool plumbing fittings are scaling innovation in materials such as PVC, CPVC, and brass to meet evolving industry standards. In this competitive landscape, nine leading manufacturers have emerged as key suppliers, combining technical expertise, global distribution, and R&D investment to capture significant market share.

Top 9 Pool Plumbing Fittings Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: We are an American manufacturer. Sioux Chief believes in making our products right here in America. American manufacturing is important….

#2 Hajoca

Domain Est. 1997

Website: hajoca.com

Key Highlights: Hajoca is one of the country’s largest privately-held wholesale distributors of plumbing, heating & cooling, pool, and industrial supplies….

#3 Plumbing Products

Domain Est. 1995

Website: masco.com

Key Highlights: We offer an array of products, including faucets, plumbing fittings and valves, showerheads and handheld showers, bath hardware and accessories….

#4 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch….

#5 Westlake Pipe & Fittings (LASCO)

Domain Est. 1996

Website: hipco.com

Key Highlights: Westlake’s product range features a variety of pool/spa hose adapters, wyes, and venturi tees, highlighting its array of specialty components tailored to serve ……

#6 Pentair Products

Domain Est. 1996

Website: pentair.com

Key Highlights: Pentair offers a wide variety of products from pool and spa equipment, water filters, water pumps and spray nozzles. See how we can help you in your home or ……

#7 Plumbing Fittings

Domain Est. 2004

Website: c-m-p.com

Key Highlights: THE RIGHT POOL FITTINGS FOR YOUR PROJECT. In addition to all of the standard pieces you need, CMP also manufactures special “Pro Tools” options that give ……

#8 Pool & Spa PVC Systems

Domain Est. 2021

Website: westlakepipe.com

Key Highlights: Westlake Pipe & Fittings has a wide selection of PVC pipe & fittings designed for pool & spa systems. Explore our elbows, extenders, plugs and more today….

#9 Wholesale PVC Fittings for Pool Contractors

Domain Est. 2021

Website: mtpooldistributor.com

Key Highlights: Professional PVC fittings from Wool Plumbing, Dura Plastic & Lesso. Elbows, tees, couplings & caps in 1″-8″ sizes. Bulk pricing & fast shipping for ……

Expert Sourcing Insights for Pool Plumbing Fittings

2026 Market Trends for Pool Plumbing Fittings

The market for pool plumbing fittings is poised for significant evolution by 2026, driven by technological advancements, sustainability demands, and shifting consumer preferences in the residential and commercial pool sectors. Key trends shaping the landscape include:

Increased Demand for Sustainable and Eco-Friendly Materials

Environmental consciousness is pushing manufacturers and consumers toward recyclable, UV-resistant, and low-carbon footprint materials. By 2026, fittings made from recycled PVC, bio-based polymers, or advanced composites are expected to gain market share. Regulatory pressures and green building certifications (like LEED) will further incentivize the adoption of sustainable plumbing components that reduce environmental impact during production and disposal.

Growth in Smart Pool Systems Integration

As smart home technology expands, pool plumbing systems are becoming more intelligent. Plumbing fittings designed to integrate seamlessly with automated monitoring systems—such as flow sensors, leak detectors, or pressure-regulating valves—will see rising demand. These smart fittings enable real-time diagnostics, water conservation, and remote maintenance, appealing to tech-savvy homeowners and commercial operators seeking efficiency and cost savings.

Rise in Prefabricated and Modular Plumbing Solutions

To reduce installation time and labor costs, prefabricated plumbing manifolds and modular fitting kits are gaining popularity. By 2026, standardized, plug-and-play systems will be increasingly adopted by pool builders, especially in regions experiencing labor shortages. These systems improve consistency, reduce on-site errors, and support faster project completions, aligning with the construction industry’s push for efficiency.

Expansion in Emerging Markets and Residential Construction

Rising disposable incomes and urbanization in regions like Asia-Pacific, Latin America, and the Middle East are fueling new pool construction. This growth will directly increase demand for reliable and corrosion-resistant plumbing fittings. Manufacturers targeting these markets will need to offer cost-effective, durable solutions suited to diverse climatic conditions and water chemistries.

Emphasis on Durability and Corrosion Resistance

With longer product lifecycles expected, fittings engineered for enhanced durability—particularly in saltwater and chlorinated environments—will dominate. Innovations in material coatings, UV stabilization, and chemical resistance will differentiate premium products. Brands investing in R&D for long-lasting fittings will capture market share as consumers prioritize low maintenance and longevity.

Consolidation and Brand Differentiation

The competitive landscape will likely see consolidation among mid-tier suppliers, while leading brands focus on innovation and certification (e.g., NSF/ANSI 61 compliance). By 2026, trust in product performance, warranty offerings, and technical support will become critical purchasing factors, pushing companies to strengthen customer engagement and after-sales service.

In summary, the 2026 pool plumbing fittings market will be defined by sustainability, smart integration, and efficiency. Companies that anticipate these shifts and innovate accordingly will be best positioned to thrive in an increasingly sophisticated and environmentally aware industry.

Common Pitfalls When Sourcing Pool Plumbing Fittings (Quality, IP)

Sourcing pool plumbing fittings involves more than just matching size and material. Overlooking key quality and Intellectual Property (IP) considerations can lead to system failures, safety hazards, and legal risks. Here are common pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is selecting fittings made from substandard materials. Low-quality PVC, CPVC, or stainless steel may degrade quickly when exposed to chlorinated water, UV radiation, and temperature fluctuations. This can result in cracking, leaks, or structural failure, leading to costly repairs and downtime.

Inadequate Pressure and Temperature Ratings

Not all fittings are rated for the operational demands of pool systems. Using fittings with insufficient pressure (PSI) or temperature ratings can cause blowouts or deformation, especially in heated pools or high-flow circuits. Always verify that the fittings meet or exceed the maximum expected operating conditions.

Non-Compliance with Industry Standards

Fittings that don’t comply with standards such as ASTM, NSF-61, or ISO may pose health and safety risks. Non-compliant products can leach harmful substances into pool water or fail under stress. Always request certification documentation to ensure regulatory compliance.

Counterfeit or IP-Infringing Products

Sourcing from unreliable suppliers increases the risk of receiving counterfeit fittings that mimic reputable brands. These products often violate intellectual property rights and lack the engineering integrity of genuine parts. Using them can expose your business to legal liability and void equipment warranties.

Lack of Traceability and Documentation

Reputable suppliers provide batch traceability, material certifications, and test reports. Without these, it’s difficult to verify product authenticity or troubleshoot issues. Poor documentation also complicates compliance audits and recall management.

Ignoring UV and Chemical Resistance

Pool environments are chemically aggressive and often exposed to sunlight. Fittings not specifically designed for UV and chemical resistance can become brittle or corrode prematurely. Ensure materials are formulated for outdoor and chlorinated water applications.

Inconsistent Dimensional Tolerances

Low-cost fittings may have poor dimensional accuracy, leading to improper seals, joint failures, or difficulty during installation. This increases labor costs and the risk of leaks. Insist on fittings that adhere to strict manufacturing tolerances.

Overlooking IP Protection in Supplier Agreements

When developing custom fittings or using proprietary designs, failing to secure IP rights in contracts can result in design theft or unauthorized replication. Always include clear IP clauses in sourcing agreements to protect innovations and branding.

Logistics & Compliance Guide for Pool Plumbing Fittings

This guide outlines key logistics and compliance considerations for the import, distribution, and sale of pool plumbing fittings to ensure regulatory adherence and efficient supply chain operations.

Product Classification and Harmonized System (HS) Codes

Accurate product classification is essential for customs clearance and duty assessment. Pool plumbing fittings typically fall under Chapter 84 (Nuclear reactors, boilers, machinery and mechanical appliances) or Chapter 74 (Copper and articles thereof), depending on material and function. Common HS codes include:

– 7412.20: Fittings for pipes, tubes, or hoses, of copper

– 8484.10: Gaskets and similar jointing materials, of metal and other materials

– 3917.33: Plastic tubes, pipes, and hoses, with fittings, of polymers of ethylene

Verify the correct HS code based on material composition (PVC, CPVC, brass, stainless steel), design, and intended use to avoid customs delays and incorrect tariffs.

Regulatory Compliance Standards

Pool plumbing fittings must comply with regional and international safety and performance standards. Key regulations include:

– United States: Conform to NSF/ANSI 61 (Drinking Water System Components – Health Effects) and NSF/ANSI 14 (Plastic Piping System Components and Related Materials). Fittings used in potable water systems must be certified by an accredited body such as NSF International or IAPMO.

– European Union: Must comply with the Construction Products Regulation (CPR) and bear the CE marking. Materials in contact with water should meet the requirements of the EU Drinking Water Directive (Council Directive 98/83/EC), often demonstrated via WRAS (UK) or KIWA (NL) certifications.

– Australia & New Zealand: Comply with AS/NZS 2638 (Plastics piping systems for pressure applications) and require WaterMark certification for use in plumbing systems.

Material and Environmental Regulations

Ensure materials used in fittings meet environmental and health safety regulations:

– Lead Content Restrictions: In the U.S., fittings must comply with the Reduction of Lead in Drinking Water Act (lead content ≤ 0.25% weighted average). The EU enforces similar limits under REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals).

– REACH & RoHS Compliance: Confirm fittings do not contain restricted substances such as lead, cadmium, or phthalates above allowable thresholds. Documentation (e.g., SVHC declarations) may be required.

– California Proposition 65: Label products containing chemicals known to the State of California to cause cancer or reproductive harm.

Packaging and Labeling Requirements

Proper packaging and labeling facilitate compliance and logistics:

– Include manufacturer information, material type, size, pressure rating, temperature limits, and compliance markings (e.g., NSF, WRAS, CE).

– Use multilingual labeling where required for international distribution.

– Packaging must protect products during transit and comply with ISPM 15 for wooden pallets (if used).

Import and Customs Documentation

Prepare accurate documentation to streamline customs processing:

– Commercial invoice with detailed product descriptions, HS codes, and values

– Packing list

– Certificate of Origin

– Test reports and product compliance certificates (e.g., NSF, CE, WRAS)

– Bill of Lading or Air Waybill

Transportation and Storage

- Use appropriate transport methods (e.g., containerized freight) to protect fittings from moisture, UV exposure, and physical damage.

- Store fittings in dry, temperature-controlled environments to prevent warping, cracking, or degradation, especially for plastic components.

- Segregate materials by type and certification to avoid cross-contamination or mislabeling.

Recordkeeping and Traceability

Maintain comprehensive records for at least five years, including:

– Supplier certifications and test reports

– Batch/lot tracking information

– Import documentation

– Customer compliance disclosures

Traceability enables rapid response to recalls or regulatory inquiries.

Conclusion

Adhering to logistics and compliance standards for pool plumbing fittings ensures market access, customer safety, and supply chain efficiency. Regular audits, supplier verification, and staying updated on regulatory changes are essential for ongoing compliance.

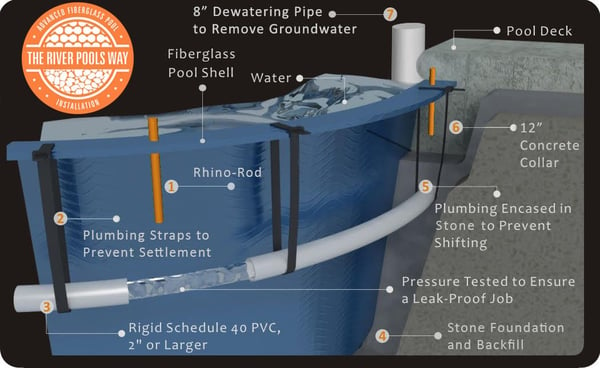

In conclusion, sourcing pool plumbing fittings requires careful consideration of material quality, compatibility with existing systems, durability, and compliance with industry standards. Selecting the right fittings—such as PVC, CPVC, or stainless steel—ensures efficient water flow, reduces the risk of leaks, and enhances the overall longevity of the pool’s plumbing system. It is essential to partner with reputable suppliers, compare pricing and availability, and prioritize corrosion-resistant, UV-stable materials suited for outdoor environments. Proper sourcing not only supports optimal pool performance but also minimizes maintenance costs and downtime over time. A well-planned procurement strategy ultimately contributes to a safer, more reliable, and energy-efficient swimming pool installation or renovation.