The global pool table accessories market, driven by rising recreational spending and increased adoption in commercial venues such as bars, clubs, and leisure centers, is witnessing steady expansion. According to Mordor Intelligence, the global billiards market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 4.5% through 2028. A key component within this ecosystem—pool ball cleaning machines—is gaining traction due to heightened demand for maintenance efficiency, hygiene, and longevity of equipment. As automated and semi-automated solutions become more accessible, manufacturers are innovating to meet the needs of both professional and casual users. With the Asia-Pacific region emerging as a hotspot for production and consumption, and North America maintaining strong demand, the competitive landscape is evolving rapidly. This report highlights the top nine pool ball cleaning machine manufacturers leading the charge in technology, reliability, and market reach.

Top 9 Pool Ball Cleaning Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ABOUT

Domain Est. 2013

Website: 21stcpi.com

Key Highlights: 21st Century Products, Inc. is the largest manufacturer of Ball Pool Balls and Ball Washing machines in North America….

#2 Ball Cleaners

Domain Est. 1997

Website: billiards.com

Key Highlights: Free delivery · 30-day returnsBall Cleaners ; Ballstar Liquid Cleaner · $19.99. $19.99 ; Tiger Crystal Ball Cleaner · $22.00. $22.00 ; Ballstar Pro Automatic Ball Cleaner & Polish…

#3

Domain Est. 1999

Website: fairway.com.tw

Key Highlights: Fairway Making Cleaning Easy. We focus on developing power tools that are easy for people to use. We have 25 patents in four countries….

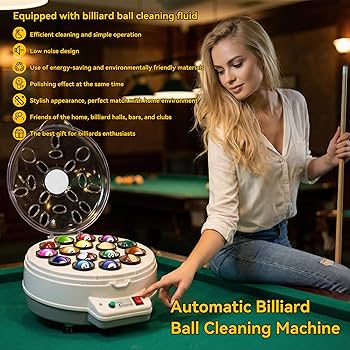

#4 Ballstar Pro Cleaning Machine (BSBC)

Domain Est. 2000

Website: cuesplus.com

Key Highlights: In stock Free deliveryBallstar Pro Cleaning Machine BSBC – cleans 8 balls at a time in under 2 minutes. Fast, durable, easy-to-use ball cleaner….

#5 Bludworth Ball Cleaner: Polish Your Pool

Domain Est. 2012

Website: bludworthballcleaner.com

Key Highlights: The Bludworth Ball Cleaner utilizes a tray with 16 holes for each individual ball. This facilitates faster cleaning, a nicer shine and ensures the balls aren’t ……

#6 Ghost Billiards Ball Polish & Cleaner

Domain Est. 2019

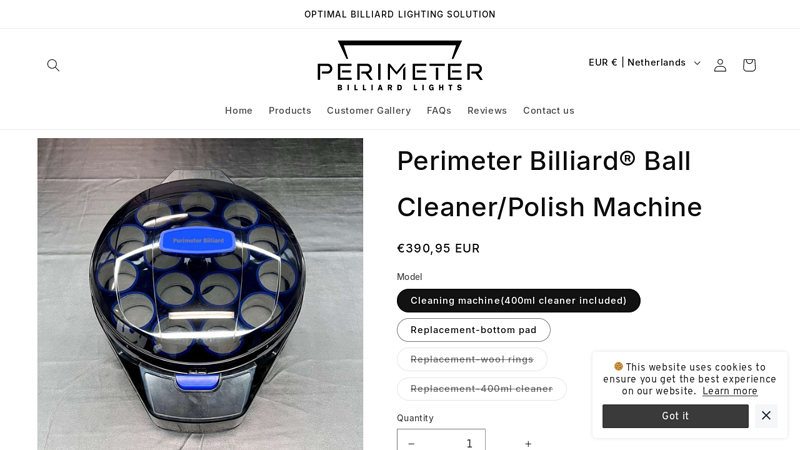

#7 Perimeter Billiard® Ball Cleaner/Polish Machine

Domain Est. 2021

Website: perimeterbilliardlights.com

Key Highlights: In stock Rating 4.8 (24) A fully automatic ball clean/polish machine with 16 independent ports. The quiet electric motor spins the balls at over 1000 RPM for the highest gloss …..

#8 Ball pit balls

Founded: 1994

Website: ball-pool.eu

Key Highlights: BallPool is an International brand in effective & labor cost Ball pit balls Cleaning system! THE ORIGINAL since 1994….

#9 Billiard Balls

Domain Est. 1998

Website: aramith.com

Key Highlights: Aramith ball sets are the benchmark, used in virtually all events and tournaments worldwide, whether in billiards, snooker, carom or other disciplines….

Expert Sourcing Insights for Pool Ball Cleaning Machine

H2: Projected 2026 Market Trends for Pool Ball Cleaning Machines

The global market for pool ball cleaning machines is expected to experience steady growth by 2026, driven by increasing demand from commercial and residential users, technological advancements, and the rising popularity of cue sports. Key trends shaping the market include:

-

Growing Adoption in Commercial Venues

Billiard halls, bars, sports clubs, and recreational centers are increasingly investing in automated pool ball cleaning machines to maintain equipment hygiene and enhance customer experience. As cleanliness standards rise post-pandemic, facility managers are prioritizing maintenance tools that reduce manual labor and ensure consistent ball quality. -

Technological Innovation and Automation

By 2026, manufacturers are expected to launch smarter, more efficient models featuring IoT integration, touch-screen controls, and energy-efficient motors. Some advanced machines may include self-diagnostic systems and compatibility with mobile apps for maintenance tracking, appealing to tech-savvy operators. -

Expansion in Emerging Markets

Regions such as Asia-Pacific and Latin America are witnessing a surge in recreational infrastructure development. Countries like India, China, and Brazil are seeing increased participation in cue sports, leading to higher demand for pool table accessories, including automated cleaning solutions. -

Rise in Home Use and Premiumization

The trend of luxury home entertainment spaces is fueling demand for residential-grade pool ball cleaners. Consumers are willing to invest in compact, aesthetically pleasing, and quiet machines that match high-end interior designs, driving product diversification. -

Sustainability and Eco-Friendly Designs

Environmental concerns are influencing product development. Companies are focusing on reducing water and energy consumption, using recyclable materials, and offering biodegradable cleaning solutions, aligning with global sustainability goals. -

Market Consolidation and Competitive Pricing

As more players enter the market, competition is intensifying. This is likely to result in product differentiation, improved customer support, and more competitive pricing, making pool ball cleaning machines more accessible to small businesses and individual users.

In conclusion, the 2026 market for pool ball cleaning machines is poised for moderate but meaningful growth, supported by innovation, expanding recreational infrastructure, and evolving consumer preferences. Manufacturers who focus on automation, sustainability, and user experience are likely to gain a competitive edge.

Common Pitfalls When Sourcing a Pool Ball Cleaning Machine (Quality & Intellectual Property)

Sourcing a pool ball cleaning machine, especially from international suppliers, involves navigating several potential risks related to quality assurance and intellectual property protection. Overlooking these pitfalls can lead to substandard equipment, production delays, legal disputes, and reputational damage. Below are key areas to be cautious of:

Quality-Related Pitfalls

1. Inconsistent Manufacturing Standards

Suppliers, particularly in low-cost regions, may lack strict adherence to international quality control standards. Machines might be built with inferior materials or inconsistent tolerances, leading to premature wear, malfunction, or failure during regular use. Always verify if the manufacturer follows recognized quality management systems (e.g., ISO 9001).

2. Misleading Product Specifications

Some suppliers exaggerate performance metrics such as cleaning speed, ball capacity, or durability. Without third-party testing or verifiable benchmarks, you may receive a machine that underperforms. Request detailed technical documentation and, if possible, performance testing data.

3. Poor After-Sales Support and Spare Parts Availability

Many budget suppliers offer limited technical support or fail to maintain an inventory of replacement parts. This can result in prolonged downtime when maintenance is needed. Ensure the supplier provides a warranty, support channels, and a clear parts supply agreement.

4. Lack of Safety and Compliance Certifications

Machines may not comply with electrical, mechanical, or safety standards required in your target market (e.g., CE, UL, RoHS). Non-compliant units can be rejected at customs or pose liability risks. Always confirm certification status before purchase.

Intellectual Property (IP)-Related Pitfalls

1. Risk of IP Infringement

Some manufacturers may copy patented designs or use proprietary technology without authorization. Sourcing such a machine could expose your business to legal action, especially if the original IP holder enforces their rights. Conduct due diligence on the design’s originality and request proof of IP ownership or licensing.

2. Absence of IP Protection in Contracts

General purchase agreements often fail to address IP ownership, especially for custom-designed machines. Without explicit clauses, the supplier may retain rights to design improvements or reuse your specifications for other clients. Ensure contracts include IP assignment and confidentiality provisions.

3. Reverse Engineering and Design Theft

Sharing detailed technical requirements with unvetted suppliers increases the risk of your design being replicated and sold to competitors. Use non-disclosure agreements (NDAs) and work only with reputable manufacturers when disclosing sensitive information.

4. Unclear Origin of Technology

Some machines may incorporate components or software protected by third-party IP. If the supplier hasn’t properly licensed these elements, you could inherit liability. Ask for a bill of materials and verify that all integrated technologies are legally sourced.

Conclusion

To mitigate these risks, conduct thorough supplier vetting, request prototypes or factory audits, and engage legal counsel to review contracts. Prioritizing quality and IP protection during sourcing ensures long-term reliability and safeguards your business interests.

Logistics & Compliance Guide for Pool Ball Cleaning Machine

This guide outlines the essential logistics and compliance considerations for the transportation, handling, import/export, and operation of a Pool Ball Cleaning Machine. Adhering to these guidelines ensures smooth operations, regulatory compliance, and product safety.

Product Classification and Documentation

Ensure accurate product classification for customs and shipping purposes. The Pool Ball Cleaning Machine typically falls under HS Code 8479.89 (Machines of a kind used in laboratories; other machines). Prepare comprehensive documentation, including commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. Include technical specifications (voltage, power consumption, dimensions, weight) to support classification and facilitate customs clearance.

Packaging and Handling Requirements

Package the machine securely to prevent damage during transit. Use sturdy, moisture-resistant corrugated boxes with internal foam or molded inserts to immobilize the unit. Clearly label packages with handling instructions such as “Fragile,” “This Side Up,” and “Do Not Stack.” Include internal padding to protect control panels, hoses, and rotating components. Ensure packaging complies with ISTA 3A or similar standards for transit durability.

Shipping and Transportation

Use reputable freight carriers experienced in handling industrial or consumer equipment. For international shipments, confirm compliance with IATA (air) or IMDG (sea) regulations if batteries or cleaning fluids are included. Clearly declare the contents and value on shipping documents. Opt for insured shipping to cover potential loss or damage. Track shipments in real time and maintain communication with logistics partners for timely delivery.

Import/Export Compliance

Verify import regulations in the destination country, including electrical safety standards (e.g., CE in Europe, UL in the U.S., CCC in China). Obtain necessary permits or certifications prior to shipment. Confirm voltage compatibility (e.g., 110V vs. 220V) and include appropriate power adapters or voltage converters if required. Comply with REACH, RoHS, and other environmental directives applicable to electronic components and materials.

Electrical and Safety Standards

The machine must meet regional safety certifications for electrical appliances. In the U.S., compliance with UL 197 or similar standards is recommended. In the EU, CE marking under the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive is mandatory. Ensure grounding, insulation, and overload protection are implemented per local regulations. Include multilingual safety labels and user instructions.

Environmental and Chemical Compliance

If the machine uses cleaning solutions, ensure they comply with EPA (U.S.), CLP (EU), or other local chemical regulations. Provide Safety Data Sheets (SDS) for any included or recommended cleaning agents. Confirm that waste water discharge (if applicable) adheres to local environmental codes. Design the machine to minimize chemical usage and support proper disposal or recycling.

Warranty and After-Sales Support Logistics

Establish a clear warranty policy and provide support channels for repairs or replacements. Maintain an inventory of spare parts in key regions to reduce downtime. Train local service providers or partner with certified technicians. Document return procedures for defective units, including reverse logistics and customs documentation for warranty claims.

Final Inspection and Quality Control

Conduct pre-shipment inspections to verify functionality, packaging integrity, and documentation accuracy. Perform final quality checks for leaks, electrical safety, and operational performance. Retain inspection records for compliance audits and traceability. Address any defects prior to dispatch to avoid delays or customer dissatisfaction.

Adhering to this guide ensures efficient logistics, regulatory alignment, and safe deployment of Pool Ball Cleaning Machines across domestic and international markets.

Conclusion: Sourcing a Pool Ball Cleaning Machine

After evaluating various options and considering key factors such as cleaning efficiency, durability, ease of use, maintenance requirements, and cost-effectiveness, sourcing a dedicated pool ball cleaning machine is a worthwhile investment for any billiards facility, tournament organizer, or high-traffic recreational venue. These machines not only extend the lifespan of pool balls by maintaining their finish and consistency but also enhance the overall playing experience for users.

Automated cleaning systems offer significant time and labor savings compared to manual cleaning methods, ensuring consistent results and reducing wear and tear on balls caused by improper handling. Additionally, modern models are designed with user-friendly features and environmentally friendly cleaning mechanisms, aligning with sustainability goals.

When sourcing, it’s essential to consider reputable manufacturers, warranty coverage, availability of replacement parts, and customer support. By selecting a reliable and efficient pool ball cleaning machine, operators can ensure optimal equipment performance, improve customer satisfaction, and reduce long-term maintenance costs. Ultimately, the integration of a cleaning machine supports both operational efficiency and the professional presentation of billiards equipment.